宽幅无取向硅钢热轧板形控制技术

曹建国1,戴宝泉1,张 杰1,杨光辉1,宋 平2,苏 毅2,鄢檀力2

(1. 北京科技大学 机械工程学院,北京 100083;

2. 武汉钢铁(集团)公司 热轧带钢厂,湖北 武汉,430083)

摘 要:针对1700热连轧机下游机架工作辊磨损严重且不均匀导致宽幅无取向硅钢的板形控制等问题,采用ANSYS建立辊系弹性变形有限元模型并研制宽幅无取向硅钢生产的ASR-N非对称自补偿工作辊。研究结果表明:与长行程窜辊的常规凸度工作辊相比,ASR-N工作辊服役期内轧机辊缝横向刚度提高13.9%以上,凸度调节域扩大8.0%以上。该技术应用于1700热连轧机工业生产实践,不仅2.3 mm×1.28 m宽幅无取向硅钢轧制单位由试生产时的40卷扩大到正常轧制的70卷以上,且带钢出口凸度小于45 μm的比例由50.0%提高到94.9%,凸度大于60 μm的比例由20.2%下降到0.7%。

关键词:热连轧机;无取向硅钢;板形控制;边降控制;有限元分析

中图分类号:TG333.71 文献标识码:A 文章编号:1672-7207(2008)04-0771-05

Profile and flatness control technology of wide non-oriented

electrical steel in hot strip mills

CAO Jian-guo1, DAI Bao-quan1, ZHANG Jie1, YANG Guang-hui1, SONG Ping2, SU Yi2, YAN Tan-li2

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Hot Strip Mill Plant, Wuhan Iron and Steel Company, Wuhan 430083, China)

Abstract: In order to solve the problem of the wide non-oriented electrical steel profile and flatness control caused by the serious and uneven wear of work rolls in the downstream stands of 1700 hot strip mill, the elastic deformation finite element model of roll stacks was built by ANSYS software package and ASR-N (Asymmetry self-compensating work rolls) was developed for the wide non-oriented electrical steel production. The simulation analysis results show that, in comparison with the conventional work roll contour with long stroke shifting system, the ASR-N’s transverse stiffness of roll gap increases by above 13.9% and the contour-adjusting area expands by above 8.0%. When the technology is applied, the number of the wide non-oriented electrical steel (2.3 mm×1.28 m) in one rolling campaign rises from 40 coils of the trial production to 70 coils of the industrial production, the ratio of the measured strip crown less than 45 μm is increased from 50.0% to 94.9%, and the ratio of the measured strip crown more than 60 μm is decreased from 20.0% to 0.7%.

Key words: hot strip mill; non-oriented electrical steel; profile control; edge drop control; finite element analysis

冷轧硅钢片作为国家优先发展的高效、节能、用量大的优秀软磁功能材料,是我国钢铁工业品种结构调整的重点,硅钢片用量占全部磁性材料用量的95%以上。而低牌号无取向硅钢是目前国内产量最大、用途最广的冷轧硅钢材料。通过系统跟踪测试与理论研究发现,热轧是低牌号无取向硅钢板形控制的关键工序[1]。为了更好地满足工业用户要求,热连轧机增加冷轧硅钢片生产能力的有效手段是:一方面可扩大常规宽度无取向硅钢轧制单位的带钢卷数,如武汉钢铁(集团)公司1700热连轧机采用ASR技术后,2.3 mm×1.05 m常规宽度无取向硅钢工业应用轧制单位由60块稳定扩大到80块以上,试验轧制单位甚至可扩大到95块[2];另一方面,直接增加无取向硅钢轧制宽度。如武汉钢铁(集团)公司1700热连轧机开始生产2.3 mm×1.25 m,2.3 mm×1.28 m和2.3 mm×1.30 m等宽幅无取向硅钢,太原钢铁(集团)公司开始生产2.3 mm×1.25 m宽幅无取向硅钢。1.05 m常规宽度无取向硅钢板形控制已接近磨削、轧制与控制极限,而1.25,1.28和1.30 m等宽幅无取向硅钢宽度比原来的1.05 m的等宽幅无取向硅钢宽度分别增加200,230和250 mm,其板形更加难以控制。1700热连轧机最大窜辊量为-150~150 mm,实际使用范围通常为-120~120 mm,且其轧制单位由试生产的40块稳定增加到60块以上。这些变化都显著增加了宽幅无取向硅钢板形控制难度。因此,开展宽幅无取向硅钢热轧板形控制技术研究具有重要意义。

1 宽幅无取向硅钢凸度控制特性与磨损辊形变化

1.1 工艺特点

武汉钢铁(集团)公司1 700宽带钢热连轧机是我国从国外引进的第1套现代化热连轧机,采用常规四辊轧机机型。1978年建成投产,1992—1994年从国外引进高精度板形控制系统及其数学模型。改造后板形控制系统设备具有如下特点:F4~F7机架采用工作辊长行程窜辊(-150~150 mm)的WRS机型和强力液压弯辊(单侧最大弯辊力由原来的0.9 MN提高到2 MN)[3]。

硅钢轧制存在低温、同宽、快节奏等工艺特点,使其板形控制难度较普钢大很多[4-5]。对于宽带钢热连轧机,同等工艺条件下带钢宽度越大,板凸度也越大;且这个关系不是线性增加的。一般当带钢宽度为轧机支持辊宽度70%~85% 时,凸度达到最大[6-7]。对于1 700热连轧机,带宽宽度为1.20~1.30 m时处于凸度控制最艰难区域。图1所示为典型机架辊缝凸度与带钢宽度关系。

1—F3机架; 2—F5机架; 3—F7机架

图1 1700热连轧机辊缝凸度与带钢宽度关系

Fig.1 Relationship between exit contour and width of

strip in 1700 hot strip mill

1.2 工作辊磨损

在硅钢轧制过程中,突出的难点在于轧辊磨损量大,且磨损辊形是一个不断变化的过程[8-9]。目前,70块左右的轧制单位磨损辊形直径差达520 μm左右,是普通钢种轧制时的2~3倍。与2.3 mm×1.05 m常规宽度硅钢轧制工作辊磨损相比,宽幅硅钢整体磨损量相差不大,轧制单位内平均直径差为4 μm。宽幅硅钢轧制工作辊磨损辊形“箱形”宽度范围更大,这直接与带钢宽度相关。常规宽度工作辊“箱形”壁更加陡峭,宽幅硅钢工作辊“箱形”壁则略微平缓,如图2所示。这主要是因为前者已采用ASR-Y技术,但窜辊使用程度不高,而后者在未采用ASR技术之前使用长行程窜辊技术,窜辊使用程度高,磨损均匀化程度良好。因此,在设计宽幅无取向硅钢轧制的ASR-N工作辊时,一方面,要结合ASR-Y使用经验和效果,合理并巧妙地补偿轧辊磨损;另一方面,也要吸取长行程窜辊技术的优势,提高窜辊利用率,使均匀轧辊磨损最大化。

1—宽幅F5机架下;2—宽幅F5机架上;

3—常规格F5机架上

图2 硅钢轧制工作辊磨损辊形

Fig.2 Wear contour of work rolls during producing non-oriented electrical steel

2 有限元模型

采用APDL语言编程,在ANSYS环境下针对1700热连轧机建立辊系弹性变形有限元分析模型。可以分别进行不同工作辊和支持辊直径、辊形、摩擦因数、轧制力、窜辊量、弯辊力、带钢宽度等大量组合工况的数值模拟计算[10]。如图3所示,工作辊辊身直径×长为0.70 m×2.00 m,辊径尺寸直径×长为0.42 m×1.04 m,弯辊力间距为3.68 m;支持辊辊身尺寸直径×长为1.50 m×1.70 m,辊径尺寸直径×长为0.98 m×1.04 m,轴承座间距为3.68 m。

图3 1700热连轧机辊系三维有限元模型

Fig.3 3D finite element model of roll group

对于热连轧过程,工作辊工作环境恶劣,承受循环的高温载荷和严重的磨损。它们也成为导致工作辊辊形和板形控制性能变化的主要因素[11-12]。由于轧辊沿轴向温度不均引起的热凸度一旦建立,相对比较稳定,故以刚下机轧辊的热辊形作为轧制过程中的稳定热辊形值。本文作者将现场实测热辊形及磨损辊形进行叠加。轧辊服役初期综合辊形为原始设计辊形与热辊形的叠加,轧辊服役末期综合辊形为原始设计辊形、热辊形和下机后磨损辊形三者叠加。以此方法,分别对F5机架采用常规工作辊和ASR-N工作辊轧制2.3 mm×1.28 m规格宽幅无取向钢时轧辊服役周期内的板形控制特性进行仿真分析。

在2.3 mm×1.05 m常规宽度无取向硅钢ASR技术基础上,采用非对称自补偿控制原理,应用前述模型研究了宽幅无取向硅钢的ASR-N工作辊技术。

3 宽幅无取向硅钢ASR-N工作辊板形控制性能分析

板形控制的实质在于对承载辊缝形状的控制[13-15]。硅钢热轧板形控制性能评价指标主要包含如下方面:辊缝凸度调节域,反映轧机的承载辊缝调节柔性;辊缝横向刚度,衡量承载辊缝在轧制过程中轧制压力变动时的稳定性;板形控制效率曲线,反映板形控制手段单位作用引起辊缝形状的变化量,可用于描述板形控制手段及其变化对承载辊缝形状的控制能力。

3.1 凸度调节评价

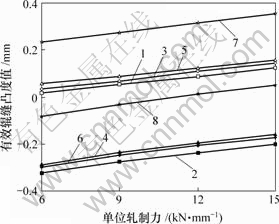

图4所示为1700热连轧机新旧工作辊的辊缝调节特性。其中:W代表轧辊磨损状态,W=0代表轧辊服役初期尚未发生磨损,W=1代表轧辊服役末期发生了最大的磨损;Fw为弯辊力。

1—ASR-N(W=0, Fw=0 MN); 2—ASR-N(W=0, Fw=2 MN);

3—常规(W=0, Fw=0 MN); 4—常规(W=0, Fw=2 MN);

5—ASR-N(W=1, Fw=0 MN); 6—ASR-N(W=1, Fw=2 MN);

7—常规(W=1, Fw=0 MN); 8—常规(W=1, Fw=2 MN)

图4 轧制周期内常规辊和ASR-N的凸度调节域

Fig.4 Contour-adjusting area of conventional work roll and ASR-N within rolling campaign

采用ASR-N工作辊以后,轧辊服役初期轧机的凸度调节域即弯辊力为0 MN和2 MN时,凸度域调节由302 μm扩大到330 μm,扩大幅度达8.8%;在轧辊服役末期,轧机的凸度调节域由303 μm扩大到327 μm,扩大8%。可见,ASR-N工作辊具有较宽的凸度调节域。且由图4可见,常规工作辊时,服役末期弯辊力为0 kN和2 MN时辊缝调节特性曲线所辖的凸度调节域相对服役初期平均上移幅度达0.220 mm。显然,为了保证良好板形,轧制末期要过度依靠较大弯辊力的使用。而对于ASR-N工作辊,在轧辊服役周期内,当弯辊力为0 kN和2 MN时,辊缝调节特性曲线所辖的凸度调节域相对服役初期平均上移幅度仅为0.035 mm,比较稳定。因此,不会存在轧制末期板形恶化和过度依靠弯辊力的问题。采用ASR-N工作辊以后,轧辊服役初期轧机辊缝横向刚度由98.48 kN/μm提高到112.07 kN/μm,提高幅度达13.8%;随着轧制的进行与磨损的发生,常规工作辊辊缝横向刚度略降低,为97.58 kN/μm,ASR-N工作辊辊缝横向刚度略升高,为116.07 kN/μm,后者比前者高18.9%。可见,在轧制周期内,随着磨损的发生,ASR-N工作辊有稳定且较高的辊缝横向刚度。

3.2 板形功效调控曲线评价

如图5和图6所示,轧辊初期服役初期与末 期,ASR-N相对于常规辊在弯辊力为0 kN和2 MN时辊缝曲线调节范围较大,即单位弯辊力调控功效较高。因此,ASR-N 可以提高弯辊调控功效,并降低弯辊力的使用。由图6可见,轧辊服役末期,由于磨损的产生使带钢边部出现大幅度减薄现象。当弯辊力在0~2 MN调整过程中,常规辊工作辊辊缝边降量(Ed= h100-h25)调控范围为26.7~88.2 μm,ASR-N工作辊边降量调控范围为-19.3~43.5 μm。显然,对于常规工作辊,即使加大弯辊力使用,边降量最小只可降到26.7 μm;而对于ASR-N工作辊,则可以在较小弯辊力使用的条件下实现边降量为零。

1—ASR-N辊(Fw=0 MN); 2—ASR-N辊(Fw=2 MN);

3—常规辊(Fw=0 MN); 4—常规辊(Fw=2 MN)

图5 轧制初期常规工作辊和ASR-N的弯辊调控曲线

Fig.5 Shape-adjusting curves of conventional work roll and ASR-N in the start of rolling campaign

1—常规辊(Fw=0 MN); 2—常规辊(Fw=2 MN);

3—ASR-N辊(Fw=0 MN); 4—ASR-N辊(Fw=2 MN)

图6 轧制末期常规工作辊和ASR-N的弯辊调控曲线

Fig.6 Shape-adjusting curves of conventional work roll and ASR-N in the end of rolling campaign

综上所述,采用ASR-N工作辊,轧制单位内轧机辊缝横向刚度提高13.9%~18.9%;凸度调节域扩大8.0%~8.8%,且辊缝刚度和调节域稳定性很强,远远优于常规工作辊。同时,ASR-N工作辊具有较强的边降控制能力。

4 工业轧制实验及应用

为了显著增加无取向硅钢产量,武钢1700热连轧机在扩大2.3 mm×1.05 m常规宽度无取向硅钢轧制单位基础上,开始试生产2.3 mm×1.28 m等宽幅无取向硅钢。试生产宽幅无取向硅钢轧制单位为40块时,25卷以后带钢板形难以稳定控制;通过合理调整宽幅无取向硅钢轧制的F1~F7机架常规工作辊工艺辊形,并增加硅钢轧制单位内普钢烫辊材和过渡材数量至10块以上,硅钢轧制可扩大到近60卷,但带钢出口凸度C40在45 μm以内的比例仅50.0%;为了更好地满足日趋严苛的板形质量要求,经过工业试验轧制完善1700热连轧机F5架投入宽幅无取向硅钢轧制的ASR-N工作辊,与常规宽度无取向硅钢轧制的ASR-Y工作辊一起投入工业应用。ASR-N工作辊投入工业实验应用后,宽幅无取向硅钢轧制单位普钢烫辊材和过渡材数量降至4~5块,而硅钢块数可扩大到70卷以上,且取得了明显的控制效果,为增强无取向硅钢质量和产量的双重市场竞争力做出了重要贡献。如表1所示,采用 ASR-N工作辊后,与常规工作辊热轧带钢相比,凸度C40小于45 μm的比例由50%提高到94.9%,大于60 μm的比例由20.2%降至0.7%。

表1 常规工作辊和ASR-N轧制宽幅硅钢的凸度分布

Table 1 Contour distribution of the wide non-oriented

electrical steel about conventional work roll and ASR-N

5 结 论

a. 对于1700热连轧机,1.20 m以上宽幅无取向硅钢时,磨损“箱形”明显,70块左右的轧制单位工作辊磨损直径差达520 μm,且带钢宽度处于轧机板 形控制最艰难区域。因此,结合厚度×宽度分别为 2.3 mm×1.28 m的等宽规格无取向硅钢轧制工艺特点,设计专用辊形ASR-N,形成宽幅无取向硅钢的轧制工艺。

b. 采用ASR-N工作辊之后,轧制单位内轧机辊缝横向刚度提高13.9%以上;凸度调节域扩大8%以上,且辊缝刚度和调节域稳定性良好,远远优于常规工作辊。同时,ASR-N工作辊具有较强的边降控制能力。

c. ASR-N工作辊形与常规工作辊相比热轧带钢凸度(C40)小于厂定考核指标45 μm的比例由50%提高至94.9%,大于60 μm的比例由20.2%降低至0.7%。

参考文献:

[1] 欧阳芸, 曹建国, 张 杰, 等. 无取向硅钢热轧板形控制特性与轧制特性关系[J]. 冶金设备, 2005(1): 6-9.

OUYANG Yun, CAO Jian-guo, ZHANG Jie, et al. The profile control characteristic and rolling characteristic of hot non-oriented silicon steel strip[J]. Metallurgical Equipment, 2005(1): 6-9.

[2] 曹建国, 张 杰, 宋 平, 等. 无取向硅钢热轧板形控制的ASR技术[J]. 钢铁, 2006, 41(6): 43-46.

CAO Jian-guo, ZHANG Jie, SONG Ping, et al. ASR technology for controlling profile and flatness of non-oriented electrical steel strip in hot rolling[J] . Iron and Steel, 2006, 41(6): 43-46.

[3] 曹建国, 张 杰, 陈先霖, 等. 宽带钢热连轧机选型配置与板形控制[J]. 钢铁, 2005, 40(6): 40-43.

CAO Jian-guo, ZHANG Jie, CHEN Xian-lin, et al. Selection of strip mill configuration and shape control[J]. Iron and Steel, 2005, 40(6): 40-43.

[4] 黄浩东, 徐世帅, 王小峰. 冷轧无取向硅钢热带钢生产工艺研究[J]. 鞍钢技术, 2003(5): 26-28.

HUANG Hao-dong, XU Shi-shuai, WANG Xiao-feng. Research on the hot strip production process of cold non-oriented silicon steel[J]. Angang Technology, 2003(5): 26-28.

[5] 刘广益. 森吉米尔轧机生产硅钢片横向厚差控制的分析[J]. 电工钢, 2003(1): 16-22.

LIU Guang-yi. Analysis of transverse thickness profile difference of silicon steel sheet in Sendzmir mills[J]. Electrical Steel, 2003(1): 16-22.

[6] V. B. 金兹伯格. 高精度板带材轧制理论与实践[M]. 姜明东, 王国栋, 译. 北京: 冶金工业出版社, 2000.

Ginzburg V B. High-practice quality steel rolling: Theory and practice[M]. JIANG Ming-dong, WANG Guo-dong, translate. Beijing: Metallurgical Industry Press, 2000.

[7] 张传银. 热轧宽带钢轧机[J]. 冶金设备, 1999(4): 22-26.

ZHANG Chuan-yin. Summarization of the hot rolling wide strip steel mill[J]. Metallurgical Equipment, 1999(4): 22-26.

[8] 张 杰, 陈先霖, 徐耀寰, 等. 轴向移位变凸度四辊轧机的辊型设计[J]. 北京科技大学学报, 1994, 16(S6): 98-101.

ZHANG Jie, CHEN Xian-lin, XU Yao-huan, et al. Roll contour design of 4-high mill with variable crown by axial shifting[J]. Journal of University of Science and Technology Beijing, 1994, 16(S6): 98-101.

[9] 曹建国, 张 杰, 甘建斌, 等. 无取向硅钢热轧工作辊磨损预报模型研究[J]. 北京科技大学学报, 2006, 28(3): 286-289.

CAO Jian-guo, ZHANG Jie, GAN Jian-bin, et al. Work roll wear prediction model of non-oriented silicon steel sheet in hot mills[J]. Journal of University of Science and Technology Beijing, 2006, 28(3): 286-289.

[10] 张 波, 胜和太, 范训益. ANSYS有限元数值分析原理与工程应用[M]. 北京: 清华大学出版社, 2005.

ZHANG Bo, SHENG He-tai, FAN Sun-yi. The principle and engineering application of ANSYS FEM simulation[M]. Beijing: Tsinghua University Press, 2005.

[11] 连家创, 黄传清, 陈连生. 2050CVC热连轧机精轧机组轧辊磨损的研究[J]. 钢铁, 2002, 37(3): 24-27.

LIAN Jia-chuang, HUANG Chuan-qing, CHEN Lian-sheng, Roll wear on finishing train of 2050 CVC hot strip mill[J]. Iron and Steel, 2002, 37(3): 24-27.

[12] 严洪凯, 杜素周, 张清东. CVC工作辊磨损和热凸度对轧机板形控制性能的影响[J] . 冶金设备, 2000(3): 1-4.

YAN Hong-kai, DU Su-zhou, ZHANG Qing-dong. Influence of wear and hot crown of CVC work roll on the behaviors of strip shape control[J]. Metallurgical Equipment, 2000(3): 1-4.

[13] 张秀芳, 白云阶, 张心白, 等. 热带钢边部减薄及凸度控制技术结合的探讨[J]. 轧钢, 1999, 16(1): 40-42.

ZHANG Xiu-fang, BAI Yun-jie, ZHANG Xin-bai, et al. Discussion on the edge drop and contour control technology about hot strip[J]. Steel Rolling, 1999, 16(1): 40-42.

[14] 岳晓丽, 连家创, 焦景民, 等. 热连轧机板凸度和板形控制技术工业试验的研究[J]. 钢铁, 2003, 38(3): 34-37.

YUE Xiao-li, LIAN Jiang-chuang, JIAO Jing-min, et al. Industrial trial of profile and shape control on hot strip mill[J]. Iron and Steel, 2003, 38(3): 34-37.

[15] 张清东, 黄纶伟, 周晓敏. 宽带钢轧机板形控制技术比较研究[J]. 北京科技大学学报, 2000, 22(2): 177-180.

ZHANG Qing-dong, HUANG Lun-wei, ZHOU Xiao-min. Comparative study on shape control technologies for wide strip mills[J]. Journal of University of Science and Technology Beijing, 2000, 22(2): 177-180.

收稿日期:2007-10-20;修回日期:2008-01-10

基金项目:国家自然科学基金重点资助项目(59835170);北京科技大学科技发展专项基金资助项目(20050311890)

通信作者:曹建国(1971-),男,湖南衡山人,博士,副教授,从事板形控制、板带轧制技术及自动化研究;电话:010-62332835;E-mail: geocao@me.ustb.edu.cn