铸态和热处理态Ti-6.55Al-3.41Mo-1.77Zr合金 微观组织和力学性能

来源期刊:中国有色金属学报(英文版)2013年第12期

论文作者:Khaled M. IBRAHIM Abdel Moty M. EL-HAKEEM Ramadan N. ELSHAER

文章页码:3517 - 3524

关键词:α+β钛合金;铸态;固溶处理;微观组织;力学性能

Key words:α+β Ti-alloy; casting; solution treatment; microstructure; mechanical properties

摘 要:采用真空感应熔炼炉将成分为Ti-6.55Al-3.41Mo-1.77Zr(质量分数)的α+β钛合金在石墨模具中浇铸成棒材。铸态棒材在700 °C下热锻后,通过两种不同的热处理后,分别得到细小和粗大的层片状结构。结果表明:铸态组织的晶粒尺寸约为660 μm,而锻造后样品具有细小的晶粒尺寸,约为50 μm。在1050 °C热处理后的α+β钛合金具有细小的层片状结构,得到最佳的硬度、拉伸性能和耐磨性。在800 °C热处理后的α+β钛合金具有粗大的层片状结构,具有最大的抗压强度。具有细小层片状结构的热处理态α+β钛合金的磨损率较小,而铸态α+β钛合金由于具有粗大和不均匀的微观组织,因此磨损率较大。

Abstract: α+β titanium alloy with a composition of Ti-6.55Al-3.41Mo-1.77Zr (mass fraction, %) was cast into bars in a graphite mould using vacuum induction skull melting furnace (ISM). The cast bars were hot swaged at 700 °C and then heat treated by two different regimes which resulted in fine and coarse lamella structures, respectively. The grain size of the as-cast structure was estimated to be 660 μm and the swaged samples obtained a very fine grain size in the range of 50 μm. The overall best combination of hardness, tensile properties, and wear resistance of the α+β titanium alloy was achieved by heat treating the samples at 1050 °C for getting fine lamellar structure. The maximum compression strength was reported for the heat treated samples at 800 °C with coarse lamella structure. The minimum wear rate was reported for the heat treated samples with fine lamellar structure and the maximum wear rate was obtained for as-cast samples due to its coarse and heterogeneity microstructure.

Trans. Nonferrous Met. Soc. China 23(2013) 3517-3524

Khaled M. IBRAHIM1, Abdel Moty M. EL-HAKEEM2, Ramadan N. ELSHAER1

1. Certral Metallurgical R&D Institute, Cairo, Egypt;

2. Benha University, Qalubia, Egypt

Received 21 March 2013; accepted 20 August 2013

Abstract: α+β titanium alloy with a composition of Ti-6.55Al-3.41Mo-1.77Zr (mass fraction, %) was cast into bars in a graphite mould using vacuum induction skull melting furnace (ISM). The cast bars were hot swaged at 700 °C and then heat treated by two different regimes which resulted in fine and coarse lamella structures, respectively. The grain size of the as-cast structure was estimated to be 660 μm and the swaged samples obtained a very fine grain size in the range of 50 μm. The overall best combination of hardness, tensile properties, and wear resistance of the α+β titanium alloy was achieved by heat treating the samples at 1050 °C for getting fine lamellar structure. The maximum compression strength was reported for the heat treated samples at 800 °C with coarse lamella structure. The minimum wear rate was reported for the heat treated samples with fine lamellar structure and the maximum wear rate was obtained for as-cast samples due to its coarse and heterogeneity microstructure.

Key words: α+β Ti-alloy; casting; solution treatment; microstructure; mechanical properties

1 Introduction

Titanium alloys, particularly two phases titanium alloys, have been widely used as advanced structural materials in aeronautic applications [1,2]. Especially titanium alloy with a nominal composition of Ti-6.5Al- 1.5Zr-3.5Mo-0.3Si (named TC11 alloy), developed on the basis of Russia alloy VT9, is a typical two-phase titanium alloy which is used in aerospace field to produce the compressor discs and blades [3]. The mechanical properties and processing ability of this alloy are dependent on the microstructure that can be tailored through hot deformation and thermal treatment [4,5]. The processing of such alloy generally involves hot working of ingots in the β-field to obtain a coarse transformed β microstructure and hot working in the α+β field to get a fine-grained equiaxed α+β structure [6]. During hot working in the α+β field, dynamic recrystallization of α phase leads to transformation of lamellar structures to equiaxed structures with fine grains, and though some deformation structures or substructures with a high density of dislocations are often retained [3]. Depending on the thermomechanical treatment or heat treatment of these α+β titanium alloys, the microstructure and mechanical properties can vary in a wide range [7,8]. Such influences have been documented in numerous studies for Ti-6Al-4V alloy in Refs. [9-11]. Therefore, it is of much interest to understand the effect of hot working and thermal treatment on the microstructure and mechanical properties of TC11 (or VT9) alloy.

The subsequent breakdown of the transformed microstructure during hot working at temperatures below β-transus plays a key role in development of an equiaxed α microstructure which is desirable for final shaping or service [12,13]. The final component microstructure is dependent on various structural features inherited from the primary stages (cogging or ingot breakdown) and the last forming and heat treatment processes [14]. Overall, these processing parameters define the chemistry, size, morphology and volume fraction of the α and β phases as well as the fines of both. Their effects have also a key role on the mechanical properties of such Ti-alloys. Most of these studies were mainly focused on the effect of hot deformation and thermal treatment on the microstructure and tensile properties of TC11 alloy. However, the detailed examination of the effect of various microstructures on wear property of TC11 alloy is not widely available yet. Therefore, in this work, the effects of applying different thermal treatment on microstructure and hence on mechanical properties as well as wear behavior of a Ti-alloy with a composition of Ti-6.55Al- 3.41Mo-1.77Zr (mass fraction, %) were studied.

2 Experimental

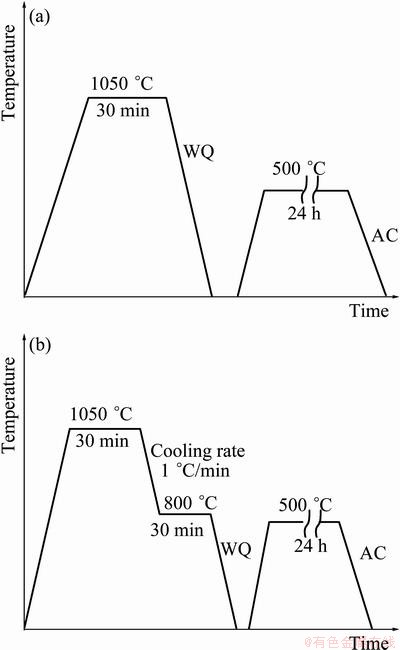

The material studied in this work was Ti-6.55Al- 3.41Mo-1.77Zr, which is closely near to the standard Russian VT9 alloy except for the Si-content. The nominal temperature for α+β to β transformation (i.e., the β-transus) of the studied Ti-alloy was determined using differential scanning calorimetry (DSC) test. The material was cast as ingots in a graphite mould using vacuum induction skull melting furnace. The ingots were cast as bars with diameter of 30 mm and length of 300 mm. The ingots were machined to a final size of diameter of 25 mm and length of 250 mm. The machined bars were then hot swaged (SW) at 700 °C to reduce the cast bar diameter from 25 mm to 8.5 mm. This process was performed with intermediate reheating of 2 min and a deformation degree φ of 2.16. Then the swaged samples were divided into two batches for applying two different thermal solution treatments, as shown in Fig. 1. The first treatment (FL) was carried out through holding at 1050 °C above β-transus for 30 min and then water quenching for getting fine lamella structure. In the second treatment (CL), a step treatment was used where the samples were quenched from 800 °C for getting coarse lamella structure. Both solution treatments were followed by ageing at 500 °C for 24 h.

The samples for optical metallographic examination were made by mechanical polishing and etching with a solution consisting of 3% HF, 30% HNO3 and 67% H2O. The Vickers hardness measurements were carried out using Vickers hardness tester with a load of 196 N for 15 s. Cylindrical samples with gage length and gage diameter of 25 and 5 mm, respectively, were prepared for the tensile testing according to DIN 50125 Standard. Cylindrical samples (d 8 mm×12 mm) were prepared for compression testing according to ASTM E9 Standard. Both tensile and compression tests were conducted at room temperature within a speed of 1 mm/min. Wear test was carried out using pin-on-ring wear testing machine. The wear samples with a cylindrical form (d 8 mm×12 mm) were fixed against a rotating stainless steel ring (outer diameter of 73 mm and surface hardness of 63 HRC). Various sliding speeds of 1, 1.25, 1.5, 1.75 and 2 m/s were used with an applied load of 55 N for 30 min. The wear test was performed in dry condition at room temperature. The wear mechanism was discussed based on the SEM observation.

Fig. 1 Solution treatment cycles of FL (a) and CL (b)

3 Results and discussion

3.1 DSC results

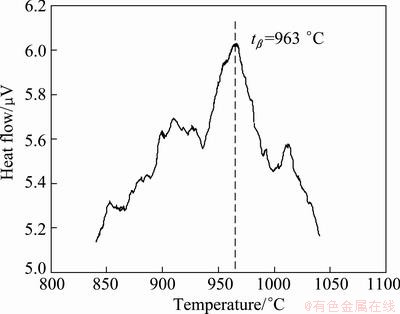

In this work, DSC was used to determine the β-transus of the investigated Ti-alloy with the composition of Ti-6.55Al-3.41Mo-1.77Zr. As shown in Fig. 2, the β-transus was evaluated to be about 963 °C which is relatively lower than that of the standard Russian VT9 alloy which has a β-transus of about 1020 °C. This shift in β-transus (between the studied alloy and the standard VT9 alloy) is due to the effect of Si-content existing in the standard VT9 alloy (0.3%, mass fraction).

Fig. 2 DSC curve of cast Ti-6.55Al-3.41Mo-1.77Zr alloy

This is because Si is considered as β-eutectoid forming element.

3.2 Microstructure

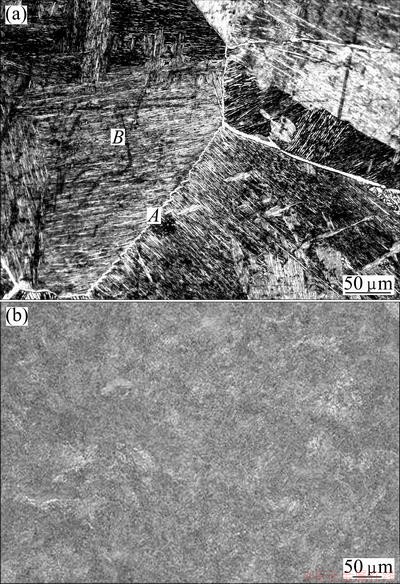

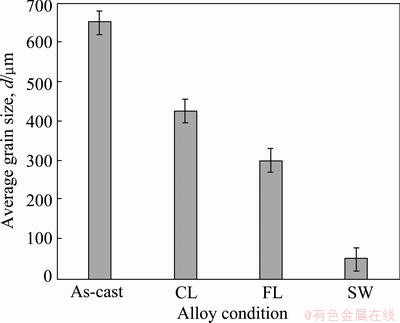

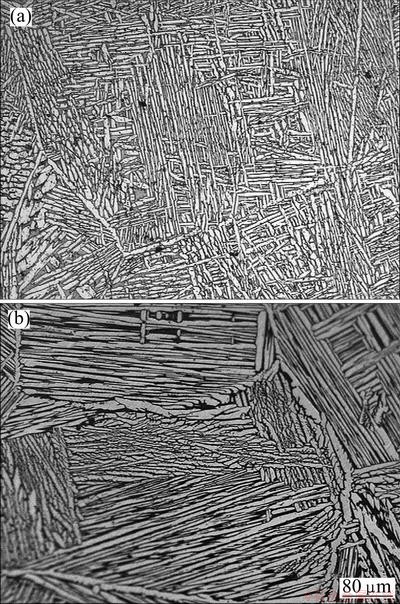

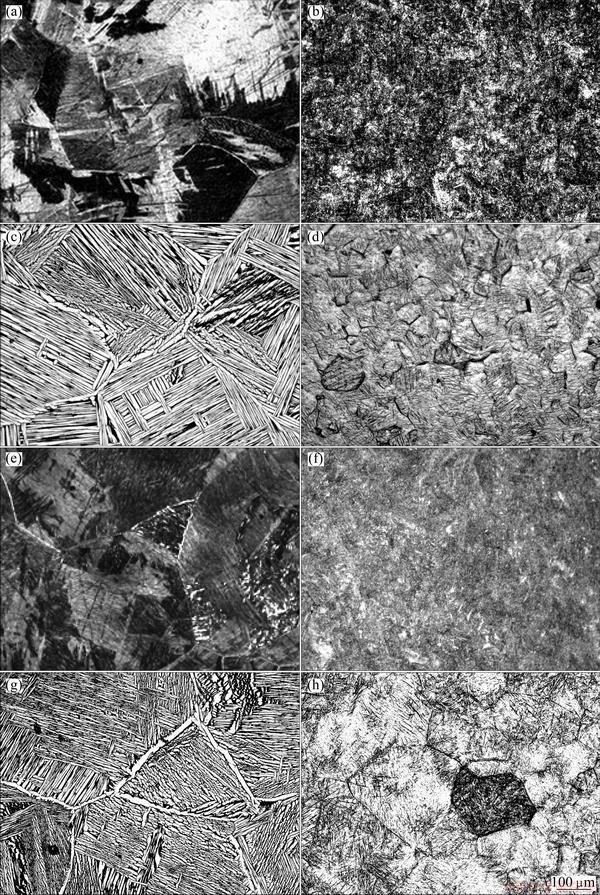

The as-cast samples showed a microstructure consisting of equiaxed β-grains and various morphologies of α-phase. The observed α-phase morphologies were as follows: at the grain boundary α and  α denoted as A and B, respectively, as shown in Fig. 3(a). On the other hand, the swaged alloy showed a microstructure consisting of very fine equiaxed α+β structure, as shown in Fig. 3(b). This is because these samples were exposed to hot swaging process at 700 °C (i.e., in α+β temperature range). It is clear that the coarse as-cast structure (Fig. 3(a)) is broken down into very fine equiaxed α+β structure (Fig. 3(b)) by applying the hot swaging process which normally occurred by applying severe plastic deformation well below the β-transus (963 °C). This finding was in agreement with the work done by TAMIRISAKANDALA et al [15]. Similar results have been achieved in Ref. [16] where it was suggested that much part of deformation was exerted on globularization of the phases and equiaxed fine grains were form. As shown in Fig. 4, the average grain size of the swaged samples was dramatically decreased to about 50 μm as compared to the as-cast condition of 660 μm.

α denoted as A and B, respectively, as shown in Fig. 3(a). On the other hand, the swaged alloy showed a microstructure consisting of very fine equiaxed α+β structure, as shown in Fig. 3(b). This is because these samples were exposed to hot swaging process at 700 °C (i.e., in α+β temperature range). It is clear that the coarse as-cast structure (Fig. 3(a)) is broken down into very fine equiaxed α+β structure (Fig. 3(b)) by applying the hot swaging process which normally occurred by applying severe plastic deformation well below the β-transus (963 °C). This finding was in agreement with the work done by TAMIRISAKANDALA et al [15]. Similar results have been achieved in Ref. [16] where it was suggested that much part of deformation was exerted on globularization of the phases and equiaxed fine grains were form. As shown in Fig. 4, the average grain size of the swaged samples was dramatically decreased to about 50 μm as compared to the as-cast condition of 660 μm.

Fig. 3 Microstructures of as-cast (a) and SW (b) Ti-6.55Al- 3.41Mo-1.77Zr alloy

Fig. 4 Average grain sizes of Ti-6.55Al-3.41Mo-1.77Zr alloy at various conditions

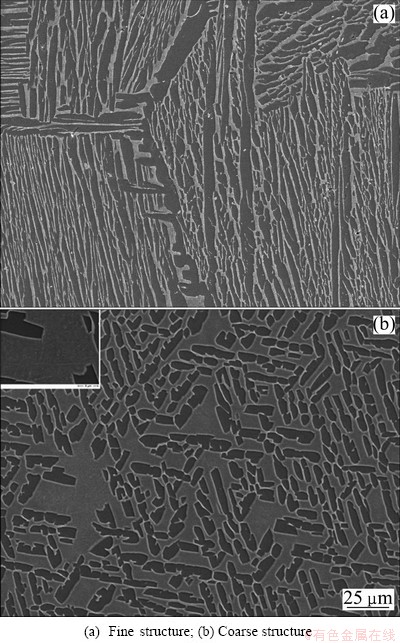

The heat treated samples showed another feature of microstructure compared to the as-cast and swaged conditions. The microstructure of the heat treated samples seemed to be dependent on the temperature of solution treatment. For example, the samples quenched from 1050 °C showed an equiaxed structure with fine lamella (FL) of α+β. The α-phase formed at the grain boundaries, as shown in Fig. 5(a). This is because the quenched temperature of 1050 °C is above the β-transus temperature (963 °C). However, by applying a two step solution treatment, a fine lamella structure was firstly formed at 1050 °C and then this lamella structure became coarser by quenching the samples from 800 °C, as shown in Fig. 5(b). When the samples were quenched from 800 °C, they also obtained an equiaxed coarse structure of α+β. In addition, α-phase was formed inside the grains and at the grain boundaries. For more details, SEM images of the heat treated α+β Ti samples were prepared and photographed, as shown in Fig. 6. In Fig. 6, α phase appears as grey and β phase appears as lighter gray or white. As shown in the backscattered SEM image of the fine lamella structure, there is no α phase precipitated along the prior β grain boundaries in Fig. 6(a). And only martensitic α′, a supersaturated HCP α phase, was formed in the β matrix. On the other side, SEM image of the coarse structure reveals only primary α' and α-grain boundary in Fig. 6(b).

Fig. 5 Microstructures of Ti-6.55Al-3.41Mo-1.77Zr alloy at FL (a) and CL (b) conditions

Fig. 6 SEM images of solution treated samples

3.3 Mechanical properties

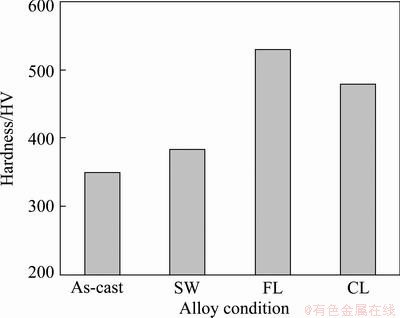

The Vickers hardness measurements were carried out to investigate the effects of applying hot swaging and solution treatment processes on the studied α+β Ti-alloy. The results of hardness for the as-cast, swaged condition (SW), fine lamella structure (FL), and coarse lamella structure (CL) are shown in Fig. 7. The as-cast sample obtained the lowest hardness (HV350) due to the presence of coarse β-grains and also existence of heterogeneity in the α+β structure. The SW sample revealed a higher hardness compared to the as-cast sample due to the refining effect caused by applying severe plastic deformation on the cast samples. The samples with FL showed the highest hardness value (HV529). However, the samples with CL showed lower hardness value of HV479 compared to the last one due to the existing higher amount of α-phase as well as the coarsening in the structure (Figs. 5(a) and (b)).

Fig. 7 Average hardness values of as-cast, SW, FL, and CL samples

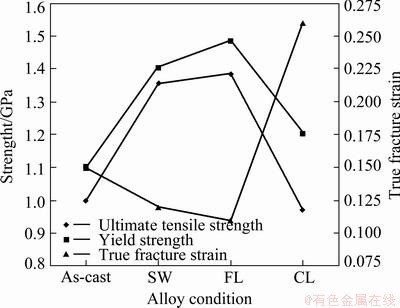

The tensile properties of as-cast, SW, FL, and CL samples are shown in Fig. 8. The as-cast sample obtained a tensile strength of 1100 MPa which is compatible for the α+β structure with a coarse grain size and a large degree of heterogeneity in the structure. By applying severe plastic deformation (swaging process), the tensile strength increased to 1405 MPa due to increasing the dislocation density as well as containing a very fine grain size structure. The FL samples showed the highest tensile strength (1485 MPa). This can be explained by the formation of α' martensitic plates existing inside the α+β structure. However, the CL samples obtained lower tensile strength (1205 MPa) compared to the last one. This finding was in agreement with the report by BERMINGHAM et al [17].

Fig. 8 Tensile properties of as-cast, SW, FL, and CL samples

As expected, the heat treated FL sample revealed the lowest true fracture strain (εf =0.11). Of course, the heat treated CL sample obtained the highest εf =0.26 compared to the FL sample because the CL sample was characterized by low strength and hardness compared to FL. The difference between ultimate tensile and yield strengths clearly increased amounting to 235 MPa for the CL sample (Fig. 8). However, the difference between ultimate tensile and yield strengths was estimated to be 100 MPa in the as-cast and FL samples.

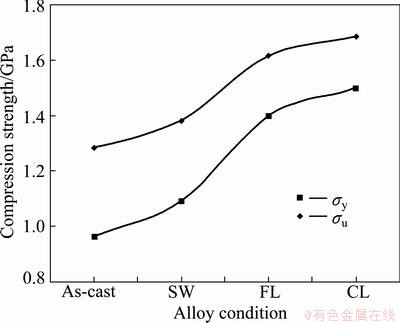

Figure 9 shows the compression properties of the investigated α+β alloy for the different studied conditions of as-cast, SW, FL, and CL. It is clear the compression properties have greater values than that of tensile properties for all conditions. This can be explained by the formation of α' martensitic plates and the increasing of dislocation density during the cold working. The lowest compression strength was obtained for the as-cast condition due to the existing of coarse equiaxed structure and large degree of heterogeneity in this structure. The highest compression strength was recorded for the samples with CL due to existing of high amount of α-phase (66.8%) that can sustain a high amount of compression strength. The effect of compression test on the microstructure changes was also studied, as shown in Fig. 10. Generally speaking, compression test changed the microstructure by decreasing relatively the fineness of the microstructure. In addition, some α' were formed in the structure. In the heat treated and as-cast samples, some high-angle α-boundaries were observed and the α-plates were also bent. This is due to the severe plastic deformation applied by compression test. The highly deformed α-boundaries were clearly shown in the FL sample (Fig. 10(h)). This observation was confirmed with the previous study by FURUHARA et al [18]. In another previous study on Ti-6Al-4V alloy by MATSUMOTO et al [19], it was mentioned that cold deformation can lead to lower ductility due to forming of a relative high amount of (α+α') equiaxed structure and fine-grained duplex structure. Thus, these findings were in agreement with this work.

Fig. 9 Compression properties of as-cast, SW, FL, and CL samples

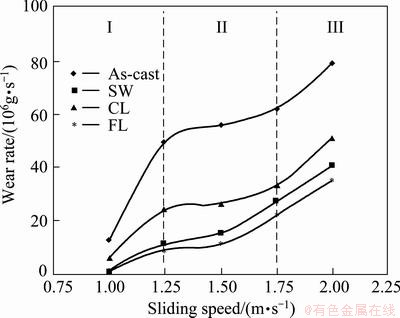

The effect of sliding speed on the wear rate of the studied Ti-alloy is shown in Fig. 11. The estimated wear rate in all conditions indicated that the wear rate increased with increasing sliding speed. The as-cast samples showed the highest wear rate compared to the other conditions. The wear rate of the as-cast samples is approximately two times higher than that of the samples with CL. This may be expected that the heat treated samples, irrespective of microstructure, exhibited higher hardness as compared to the as-cast condition. According to the Archard’s law, the wear rate of material is inversely proportional to hardness [20]. This implies that the higher the hardness of the material is, the smaller the wear rate is. The present conditions exhibited significant difference in hardness values, therefore the experimental sliding wear data correlated well with Archard’s law. The samples with FL might have enhanced wear resistance due to its high hardness as compared to the other conditions. Thus, the lowest wear rate is reported for the samples with FL due to its high hardness among all conditions. This means that the wear rate of studied samples could be controlled by their hardness, i.e. by microstructural effect.

The influence of sliding speed on the wear rate of the studied α+β alloy in different conditions was investigated. For example, the wear rate of the as-cast samples significantly changed with increasing sliding speed. Initially, the wear rate rapidly increased with increasing the sliding speed up to 1.25 m/s, then showed a steady state till 1.75 m/s and finally rapid increased with further increase of sliding speed up to 2 m/s. As shown in Fig. 11, this process can be divided into three stages. Stage Ι showed a high amount of wear rate due to occurring of the first contact between the sample and the rotating ring. In such case, the wear rate will be high till coinciding the sample surface with the rotating ring. Because the as-cast samples have a low hardness, they showed a high amount of wear rate in stage Ι. When the sample surface coincided with the ring, the wear rate will reach the steady state condition which is denoted as stage ΙΙ. With increasing the sliding speed up to 2 m/s, the temperature of the contact surface sample will be increased. In such case, a relative softening will be happened and then the wear rate will be increased. This phase is defined as stage ΙΙΙ.

The morphological analysis of wear tracks was confirmed well with the above results. The SEM micrographs in Fig. 12 showed the typical worn surface morphologies of the samples tested at low, medium and high sliding speeds of 1, 1.5 and 2 m/s, respectively. Some evidences of abrasion wear were detected in all tested samples. Continuous sliding marks with plastically deformed grooves were also seen on the wear tracks independently of the sliding speed. However, the extent of plastic deformation or ploughing was found to be higher in case of high sliding speed (2 m/s), as shown in Figs. 12(e, f). Only shallow grooves and scratches were observed in case of low sliding speed (1 m/s) (Figs. 12(a, b). The medium speed (1.5 m/s) showed moderate feature of worn surface that can be described as tire track wear mode (Figs. 12(c,d)).

Fig. 10 Microstructures of samples of as-cast (a), SW (b), CL (c), FL (d) before compression test and samples of as-cast (e), SW (f), CL (g), FL (h) after compression test

The SEM examination also showed that at least two types of wear mechanisms can be observed in this study. Lamination wear mechanism that can be seen at low sliding speed and it seemed to be more clear for the swaged condition because of its low hardness (Fig. 12(b)). While, delamination wear mechanism was more prominent at higher sliding speed and its feature was more visible in case of relative low hardness, as shown in Fig. 12(e), for the samples with CL. These characteristics of worn surfaces were in agreement with the study by MANIVASAGAM et al [21].

Fig. 11 Wear rate of studied α+β Ti-alloy as a function of sliding speed

4 Conclusions

The effect of severe plastic deformation and different solution treatments processes on microstructure and tribological behaviour of α+β Ti-alloy (Ti-6.55Al- 3.41Mo-1.77Zr) was investigated. The following conclusions were obtained.

1) The grain size of the as-cast structure was estimated as 660 μm and the swaged samples obtained a very fine grain size in the range of 50 μm.

2) Fine lamella structure was obtained by solution treatment at 1050 °C, and coarse lamella structure was obtained by applying a two step solution treatment and quenching from 800 °C.

3) A more suitable combination of hardness and tensile properties can be achieved by rapid quenching in water from 1050 °C.

4) Hardness was shown to be a key factor especially when wear was involved. Accordingly, the fine lamellar structure of the investigated α+β Ti-alloy was the most suitable microstructure for getting minimum wear rate.

5) Observation of the worn surfaces showed a lamination wear mechanism at low sliding speeds and a delamination wear mechanism at high sliding speeds.

Fig. 12 SEM images of worn surfaces of studied α+β Ti-alloy

References

[1] ZHU Y C, ZENG W D, LIU J L, ZHAO Y Q, ZHOU Y G, YU H Q. Effect of processing parameters on the hot deformation behavior of as-cast TC21 titanium alloy [J]. Materials and Design, 2012, 33: 264-272.

[2] IBRAHIM K M, MHAEDE M, WAGNER L. Microstructure evolution and mechanical properties of heat treated LCB titanium alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2609-2615.

[3] SONG H W, ZHANG S H, CHENG M. Subtransus deformation mechanisms of TC11 titanium alloy with lamellar structure [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 2168-2173.

[4] HUANG L J, GENG L, LI A B, WANG G S, CUI X P. Effects of hot compression and heat treatment on microstructure and tensile property of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy [J]. Materials Science and Engineering A, 2008, 489: 330-336.

[5] FILIP R, KUBIAK K, ZIAJA W, SIENIAWASKI J. The effect of microstructure on mechanical properties of two-phase titanium alloy [J]. Journal of Materials Processing and Technology, 2003, 133: 84-89.

[6] LI S, YANG L, LEI L, WEI C, ZHANG H. Development of microstructures and texture heterogeneities during static annealing of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy performed by hot working [J]. Journal of Materials Science and Technology, 2012, 28: 1015-1024.

[7] OBERWINKLER B, RIEDLER M, EICHLSEDER W. Importance of local microstructure for damage tolerant light weight of Ti-6Al-4V forgings [J]. International Journal of Fatigue, 2010, 32: 808-814.

[8] STOSCHKA M, TAN W, EICHLESEDER W, STOCKINGER M. Introduction to an approach based on the (α+β) microstructure of elements of alloy Ti-6Al-4V [J]. Procedia Engineering, 2009, 1: 31-34.

[9] OGUMA H, NAKAMURA T. The effect of microstructure on very high cycle fatigue properties in Ti-6Al-4V [J]. Scripta Materialia, 2010, 63: 32-34.

[10] ZOU J H, WANG Z G, HAN E H. Effect of microstructure on ultra-high cycle fatigue behavior of Ti-6Al-4V [J]. Materials Science and Engineering A, 2008, 473: 147-152.

[11] SZCZEPANSKI C J, JHA S K, LARSON J M, JONES J W. Microstructural influences on very-high-cycle fatigue crack initiation in Ti-6246 [J]. Metallurgical and Materials Transactions A, 2008, 39: 2841-2851.

[12] LI Z, FU L, FU B, HAN A. Yield point elongation in fine-grained titanium [J]. Materials Letters, 2013, 96: 1-4.

[13] SAUR C, LUETJERING G. Thermo-mechanical processing of high strength β-titanium alloys and effects on microstructure and properties [J]. Journal of Materials Processing and Technology, 2001, 117: 311-317.

[14] WANJARA P, JAHAZI M, MONAJATI H, YUE S. Influence of thermo-mechanical processing on microstructural evolution in near-α alloy IMI834 [J]. Materials Science and Engineering A, 2006, 416: 300-311.

[15] TAMIRISAKANDALA S, VEDAM B V, BHAT R B. Recent advances in the deformation processing of titanium alloys. ASM International [J]. Journal of Materials Engineering and Performance, 2003, 12: 661-673.

[16] SONG H W, ZHANG S H, CHENG M. Dynamic globularization kinetics during hot working of a two phase titanium alloy with a colony alpha microstructure [J]. Journal of Alloys and Compounds, 2009, 480: 922-927.

[17] BERMINGHAM M J, MCDONALD S D, DARGUSCH M S, JOHN D H. Microstructures of cast titanium alloys [J]. Materials Forum, 2007, 31: 84-89.

[18] FURUHARA T, ABE H, POORGANJI B, MAKI T. Dynamic recrystallization in titanium alloys during deformation [C]// Proceeding of the 11th World Conference on Titanium. Japan, 2007: 3-7.

[19] MATSUMOTO H, YONEDA H, SATO K, KURSON S, MAIRE E, CHIBA A. Room temperature ductility of Ti-6Al-4V alloy with α' martensite microstructure [J]. Materials Science and Engineering A, 2011, 528: 1512-1520.

[20] ARCHARD J F. Contact and rubbing of flat surfaces [J]. Journal of Applied Physics, 1953, 24: 981-988.

[21] MANIVASAGAM G, MUDALI U K, ASOKAMANI R, RAJ B. Corrosion and microstructural aspects of titanium and its alloys as orthopedic devices [J]. Corrosion Reviews, 2003, 21: 125-160.

Khaled M. IBRAHIM1, Abdel Moty M. EL-HAKEEM2, Ramadan N. ELSHAER1

1. Certral Metallurgical R&D Institute, Cairo, Egypt;

2. Benha University, Qalubia, Egypt

摘 要:采用真空感应熔炼炉将成分为Ti-6.55Al-3.41Mo-1.77Zr(质量分数)的α+β钛合金在石墨模具中浇铸成棒材。铸态棒材在700 °C下热锻后,通过两种不同的热处理后,分别得到细小和粗大的层片状结构。结果表明:铸态组织的晶粒尺寸约为660 μm,而锻造后样品具有细小的晶粒尺寸,约为50 μm。在1050 °C热处理后的α+β钛合金具有细小的层片状结构,得到最佳的硬度、拉伸性能和耐磨性。在800 °C热处理后的α+β钛合金具有粗大的层片状结构,具有最大的抗压强度。具有细小层片状结构的热处理态α+β钛合金的磨损率较小,而铸态α+β钛合金由于具有粗大和不均匀的微观组织,因此磨损率较大。

关键词:α+β钛合金;铸态;固溶处理;微观组织;力学性能

(Edited by Chao WANG)

Corresponding author: Khaled M. IBRAHIM; Tel: +20-1015036038; Fax: +20-225010639; E-mail: khaledabouelela@yahoo.com

DOI: 10.1016/S1003-6326(13)62896-4