文章编号:1004-0609(2010)11-2112-06

混合稀土含量对A356铝合金组织结构的影响

唐小龙1, 彭继华1, 2, 黄芳亮1, 许德英2, 杜日升1

(1. 华南理工大学 材料科学与工程学院,广州 510640;

2. 广州钢铁企业集团有限公司 有色金属研究所,广州 510340)

摘 要: 采用金相显微镜、SEM、EDS和差示扫描量热法(DSC)等手段研究混合稀土(RE)合金添加量对Ti-B-Sr联合细化变质的A356 铝合金显微组织结构的影响。结果表明:当稀土添加量为0.1%~0.3%(质量分数)时,随着稀土含量的增加,初晶晶胞尺寸、硅相尺寸、二次枝晶臂间距减小,硅相圆整度提高(长径比降低);当稀土添加量为0.3%时,初始α(Al)相的平均枝晶胞尺寸为76 mm,二次枝晶间距为11.3 mm,Si相长径比为2.13;加入0.1%~0.3%的稀土降低了合金的共晶点温度和初晶a(Al)的形核温度,并减小组织熔化过程中共晶反应的放热量。

关键词:A356铝合金;稀土; 混合稀土;晶粒细化;变质处理; 微观组织

中图分类号:TG146.2 文献标志码:A

Effect of mass fraction of mischmetal addition on microstructures of A356 alloy

TANG Xiao-long1, PENG Ji-hua1, 2, HUANG Fang-liang1, XU De-ying2, DU Ri-sheng1

(1. School of Materials Science and Engineering, South China University of Technology, Guangzhou 510640, China;

2. Non-ferrous Metal Research Institute,Guangzhou Iron and Steel Enterprises Holding Co. Ltd., Guangzhou 510340, China)

Abstract:The effect of RE addition on the microstructures of A356 alloys refined and modified with Ti-B-Sr was investigated by optical microscopy, scanning electron microscopy, energy dispersive spectrometry and differential scanning calorimetry. With the increase of the RE mass fraction in the range of 0.1%-0.3%, the size of primary α(Al) cell, the size of silicon phase and the secondary dendrite arm spacing decrease, and the aspect ratio of silicon phase increases. When the mass fraction RE added is 0.3%, the average size of primary α(Al) cell, the secondary dendrite arm spacing and the aspect ratio of silicon phase are 76 μm, 11.3 μm and 2.13, respectively. 0.1%-0.3% RE addition makes eutectic temperature and nucleation temperature of primary α(Al) fall down, and lowers the eutectic reaction releasing heat.

Key words:A356 Al alloy; rare earth; mischmetal; grain refining; modification; microstructure

为了改善铸态亚共晶Al-Si合金的组织结构,已经研究开发了多种晶粒细化剂,如Al-Ti-B系[1-5]、Al-Ti-C系[6-7] 中间合金等。随着高温保温时间的延长,AlTiB中间合金对高Si铝合金的细化效果存在明显的 “衰退”现象。Al-Si合金中添加适量稀土(RE),不仅具有细化和变质的综合效果,而且能够有效减缓变质剂的“衰退”现象[1-5];同时,可以强化Sr对硅相的变质效果,减少合金针孔的数量, 改善合金的冶金质量[8]。但是,添加过量的稀土则可能形成RE-Sr金属间化合物相,弱化Sr对硅相的变质效果[9]。同时添加Sr与Al-Ti-B中间合金期望能够获得理想的变质、细化效果。但采用含超量B的中间合金,在亚共晶Al-Si合金中可能形成SrB6相而弱化硅相的变质 [10];采用超量Ti的中间合金,在近共晶的Al-Si合金中可能形成TiSrSiAl化合物相,弱化细化变质效果[11-12]。目前,尚缺乏稀土添加量对Ti-B-Sr综合细化变质A356合金的组织结构、凝固过程影响的规律性认识。为此,本文作者研究不同混合稀土添加量对Al-5Ti-B+Al-10Sr联合细化变质A356合金的组织结构的影响,确定稀土的最佳添加量;并结合组织分析及差示扫描量热法(DSC)等探讨添加稀土的影响机理。

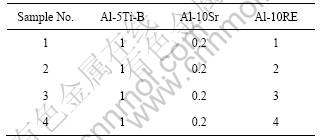

1 实验

采用广州金邦有色合金有限公司提供的含钛量为0.10%的A356合金为初始原料(合金成分见表1)。采用功率为7.5 kW的石墨坩埚电阻炉熔炼合金。将A356合金加热至熔化,覆盖熔剂后升温到760 ℃并保温10 min,扒渣,加入六氯乙烷精炼除气,静置10 min。加入适量Al-5Ti-1B和Al-10RE中间合金后均匀搅拌,静置10 min,再次加入六氯乙烷精炼除气,静置10 min。待熔体温度降低到720~730 ℃时,加入适量的Al-10Sr中间合金并搅拌熔体,静置并保持熔体温度在720 ℃左右15 min,将熔体浇注入预热到200 ℃的金属模中。4组试样的中间合金加入量见表2,将 Al-5Ti-1B的加入量固定为1%,Al-10Sr的加入量固定为0.2%, Al-10RE的加入量为1%~4%。凝固后从距试样底部4 cm处取样,研磨抛光后用1%HF水溶液腐蚀制得金相试样。采用Leica-430金相显微镜和S-3700N扫描电子显微观察合金的微观组织,用Image-pro Plus 6.0金相测量软件对光学金相图片进行分析测量,每组试样至少选取3张不同区域的显微组织图片统计分析其中初始α(Al)的面积(体积)。采用STA409-PC型热分析仪对A356铝合金试样进行差示扫描量热(DSC)测试,扫描温度范围为500~800 ℃,

表1 A356铝合金的成分

Table 1 Chemical composition of A356 alloy (mass fraction, %)

表2 不同中间合金的加入量

Table 2 Addition amount of master alloy (mass fraction, %)

升温速率为10 ℃/min,试样在氩气气氛保护下进行,氩气的流量为25 mL/min。

2 结果与分析

2.1 稀土含量对A356合金显微组织的影响

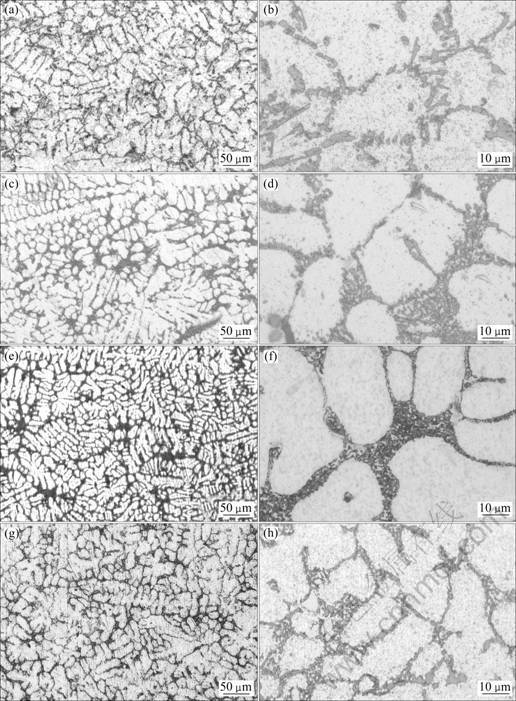

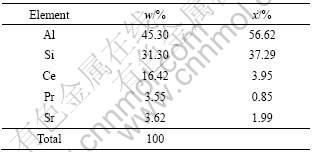

图1所示为A356铝合金铸态试样的微观组织形貌。4组试样的初始α(Al)相呈等轴、柱状枝晶的混合形式。随着Al-10RE中间合金加入量的增加,Si相明显细化,从针状、板条转变为短棒或圆球状。当加入的稀土质量分数为3%时,Si相尺寸最小,且圆整度最好。但当添加的稀土质量分数为4%时,Si相变质效果弱化。采用Image-Pro Plus 6.0金相测量软件统计分析这些试样的微观组织特征参数(见表3),其中包括初始α(Al)的晶胞尺寸(DCS)、α(Al)相的面积分数(Va)、柱状枝晶的二次臂间距(dSDAS) 、Si相的平均长度(LSi)及其平均宽度(WSi)、Si相长径比(ASi=LSi/WSi)。表3表明:随着RE含量的增加(1%到3%),Va逐渐增加;DCS、dSDAS、LSi×WSi、ASi单调下降;当稀土的加入量为3%时,这些微观组织特征参数达到极值:其中α(Al)晶胞尺寸降低幅度达到50%,二次枝晶臂间距也降低约33%,Si相长径比均值从3.44降低到2.13。继续增加稀土含量,无论初始α(Al)相的细化效果及共晶硅相的变质效果均明显弱化。其中,在高稀土添加量的试样4中,在共晶区域有一些富含稀土的化合物相存在(见图2和表4)。

表3 A356铝合金的微观组织分析结果

Table 3 Microstructures analysis results of A356 allays

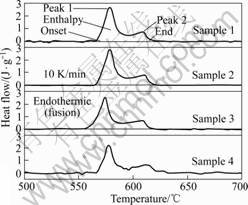

2.2 稀土含量对A356合金熔化行为的影响

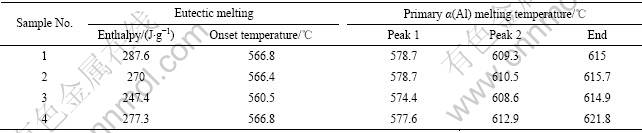

图3和表5所示为4组试样在升温速率为10 K/min时的DSC曲线及曲线分析结果。由图3和表5可看出,在添加稀土合金的A356合金中,DSC曲线特征参数(共晶熔化焓、共晶熔化温度、初晶α (Al)的熔化温度)随着稀土合金添加量的变化趋势同微观组织特征参数变化一致。当稀土合金添加量为3%时,共晶凝固过程的放热最少,共晶点温度最低,初晶凝

图1 A356铝合金铸态试样的光学金相组织

Fig.1 Optical images of microstructures of as-cast A356 aluminum alloys: (a), (b) Sample 1; (c), (d): Sample 2; (e), (f): Sample 3; (g), (h): Sample 4

固温度也最低。即在联合细化变质的A356合金中,加入一定量(1%~3%)的稀土合金能降低共晶点温度、初晶α(Al)的形核温度,并减少共晶生长过程中的共晶反应的放热;加入过量稀土则会明显提高初始α(Al)的形核温度,导致合金固、液相线间温度间距增大,从而延缓A356铝合金的固化过程。

2.3 分析与讨论

将Al-5Ti-B中间合金加入到A356合金熔体中,大部分的TiAl3相将会溶入熔体中,高温稳定的TiB2相不能直接成为α(Al)初晶的有效形核点,需要在其表面覆盖一层TiAl3/Ti(Al1-xSix)3膜后才与α(Al)有良好的晶格匹配,从而成为初晶有效形核位置[13]。溶入熔体

图2 试样4富含稀土相的SEM像

Fig.2 SEM image of RE-enriched phase in sample 4

表4 试样富含稀土相的能谱分析

Table 4 EDS results of RE-enriched phase in sample 4

图3 A356 铝合金试样的DSC曲线

Fig.3 DSC curves of A356 aluminum alloy samples

中的溶质Ti具有很高的生长限制因子(Growth restriction factor, Q),促进了熔体中成分过冷,因此,容易达到初晶形核所需过冷度要求,从而降低初晶晶胞尺寸[14]。最近研究[15]指出,Al-7Si合金中添加Al-Ti-B细化剂大大降低了初晶形核所需的过冷度,从而导致柱状枝晶向等轴晶的转变。TiB2相密度较高,在熔体静置时可能团聚、下沉,降低其对Al-Si合金的细化效果。因此,促进Al-Ti-B中间合金细化效果的途径可以从以下方面考虑:1) 有效形成Ti(Al1-xSix)3膜层覆盖的TiB2相;2) 增强TiB2相与熔体的相容性,降低它们的团聚、下沉速度;3) 有效降低形核过冷度。

含稀土的联合细化变质A356合金的DSC曲线分析结果(表5)同文献[15]比较,初晶形核温度几乎相同,可以推断适量添加RE和Sr只要不形成富含Ti/B的化合物相,则几乎不会影响初晶形核过冷度。添加稀土对A356合金初晶形貌、尺寸的影响主要通过影响细化相(TiAl3、TiB2)在熔体中分布及其同熔体的相容性。在Al-5Ti-4RE-1B中间合金中发现面心立方的Ti2Al20RE相,该相的溶解温度高于TiAl3相,且具有更多的晶面同Al晶体匹配[1]。另外,稀土元素同细化相表面“活性触点”结合后形成一层富含稀土的膜层,可以增强细化相与熔体的润湿性,降低细化相团聚倾向,增加细化相在熔体中的悬浮时间[2]。随着稀土添加量的增加,初始Al晶胞尺寸变细,但当加入量超过4%以后,细化效果并非呈一种“饱和”状态,而是明显弱化,一方面是形成如图2所示的富含稀土相,另一方面由于Sr联合变质,可能形成如文献[9]所分析的RE-Sr金属间化合物相。

Sr和RE均对硅相具有变质效果[8, 16-17],但Sr变质效果更佳,添加1%La对硅相的变质效果相当于添加0.01%Sr的[18]。与稀土元素一样,亚共晶Al-Si合金中添加微量Sr吸附在硅相表面,阻止硅相的定向生长,从而改变硅相形貌;同时,Sr元素在固液界面溶液一侧富集导致共晶温度降低,过量Sr添加则会毒化共晶形核点,导致共晶尺寸长大[19]。

表5 添加稀土的A356铝合金试样的DSC曲线分析结果

Table 5 Results of DSC analysis on A356 Al alloys with RE addition

已有研究[18-19]报道证实共晶形核过冷度与硅相形貌的改变并无直接关系。在本研究中,Sr的添加量仅为0.02%,考虑到氧化和烧损等因素,合金中的Sr含量可能低于0.02%。因此,图1(a)和(b)所示的硅相变质不彻底。随着合金中RE含量的增加,Si相变质效果趋于理想(见图1(c)),表明在一定范围内,Sr/RE对硅相变质具有协同效应;但当添加稀土合金达到4%时,不仅变质效果不理想,同时,初晶α(Al)的细化效果也弱化。所用细化剂为富钛Al-5Ti-B中间合金,可能的原因是超量添加RE后,导致形成TiSrSiAl化合物相[11-12],从而降低熔体中Ti和Sr的含量。

向近共晶Al-Si合金中单独添加Sr变质剂,由于共晶点温度下降,导致共晶点成分往高Si方向偏移,因此Al-11.6%Si合金中初晶Al的体积分数随着Sr含量的增加而单调增加[11]。当只加入Al-5Ti-B中间合金时,细化后Al-12Si合金中α(Al)初晶体积分数增加;同时,当加入Al-5Ti-B、Al-10Sr中间合金时,α(Al)初晶体积分数介于单独加Al-5Ti-B或添加Al-10Sr的体积分数之间,没有出现高于二者中最大体积分数的情况[12]。Ti/ B/Sr/RE在Al中的溶解度均很低,它们在固、液界面的富集是导致共晶点温度降低的主要原因,这些溶质元素间如果存在相互作用,必然影响熔体中的有效浓度,因此,α(Al)初晶体积分数不会产生简单的迭加效果。另外,从添加4%稀土中间合金的DSC分析结果来看,Ti/ B/Sr/RE间的交互作用还会影响初晶形核温度及凝固过程的放热,即影响液相线斜率和凝固动力学过程,导致合金微观组织发生变化。这些元素间的交互作用及微观组织演变规律需要深入探讨。

3 结论

1) 在AlTiB、Sr联合细化变质的A356合金中添加适量混合稀土RE对于进一步改善合金的细化变质效果具有积极的意义。当Al-10RE中间合金加入量为1%~3%时,随着稀土含量的增加,初晶晶胞尺寸、硅相尺寸、二次枝晶臂间距减小,硅相圆整度提高(长径比降低)。

2) 对于含有Ti/B、Sr的A356合金加入1%~3%的稀土合金能降低共晶点温度、初晶α(Al)的形核温度,并减少共晶生长过程中的共晶反应的放热。

3) 当Al-5Ti-B、Al-10Sr中间合金加入质量分数分别固定为1%,0.2%时,最佳的Al-10中间合金加入量为3%,α(Al)初始晶胞平均尺寸可以细化到约 76 mm,硅相最大平均尺寸约为2.2 mm,硅相平均长径比为2.13。超量稀土添加将导致细化变质效果的弱化。

REFERENCES

[1] 陈亚军, 许庆彦, 黄天佑. 稀土铝钛硼中间合金的细化能力与长效性[J].中国有色金属学报, 2007, 17(8): 1232-1239.

CHEN Ya-jun, XU Qing-yan, HUANG Tian-you. Refining performance and long time efficiency of Al-Ti-B-RE master alloy[J]. The Chinese Journal Nonferrous Metals, 2007, 17(8): 1232-1239.

[2] 兰晔峰, 郭 朋, 张继军. 稀土对Al TiBRE 中间合金细化性能的影响[J]. 铸造技术, 2005, 26(9): 774-778.

LAN Ye-feng, GUO Peng, ZHANG Ji-jun. The effect of rare earth on the refining property of the Al-Ti-B-RE intermediate alloy[J]. Foundry Technology, 2005, 26(9): 774-778.

[3] 张作贵, 刘相法, 边秀房. TiB2分布形态对AlTi5B合金细化特性的影响[J]. 特种铸造及有色合金, 1999(5): 12-13.

ZHANG Zuo-gui, LIU Xiang-fa, BIAN Xiu-fang. Influence of the TiB2 distribution morphologies on the refining characteristics of AlTi5B master alloys[J]. Special Cast Nonferrous Alloys, 1999(5): 12-13.

[4] 倪红军, 孙宝德, 蒋海燕, 丁文江. 稀土熔剂对A356铝合金的作用[J]. 中国有色金属学报, 2001, 11(4): 547-552.

NI Hong-jun, SUN Bao-de, JIANG Hai-yan, DING Wen-jiang. Effect of new flux including rare earth on A356 alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 547-552.

[5] FU G S, CHEN W Z, QIAN K W. Refining effect of a new Al3Ti1B1RE master alloy on Al sheet used for can and behavior of rare earths in the master alloy[J]. Journal of Rare Earths, 2003, 21(5): 572-577.

[6] 张柏清, 马洪涛, 李建国, 方鸿生. Al-Ti-C中间合金细化剂的组织及其细化性能[J]. 金属学报, 2000, 36(4): 341-346.

ZHANG Bai-qing, MA Hong-tao, LI Jian-guo, FANG Hong-sheng. Study on the microstructures and grain refining performance of Al-Ti-C grain refining alloys[J]. Acta Metallurgic Sinica, 2000, 36(4): 341-346.

[7] 胡宪正, 梁 超, 于 金, 谈荣生, 曾宇乔, 蒋建清. 稀土对AlTiC细化剂组织及细化剂效果的影响[J]. 中国稀土学报, 2004, 22(2): 247-250.

HU Xian-zheng, LIANG Chao, YU Jin, TAN Rong-sheng, ZENG Yu-qiao, JIANG Jian-qing. Effect of rare earths on structure and refining efficiency of AlTiC refiner[J]. Journal of Chinese Rare Earth Society 2004, 22(2): 247-250.

[8] 孙洪强, 赵玉涛, 陈 刚, 张松利. 添加微量稀土对锶变质铝轮毂材料组织和性能的影响[J]. 热加工工艺, 2007,36(13): 5-8.

SUN Hong-qiang, ZHAO Yu-tao, CHEN Gang, ZHANG Song-li. Influence of adding little RE on microstructure & mechanical properties of aluminum hub material modified with Sr[J]. Hot Working Technology, 2007,36(13): 5-8.

[9] SEBAIE O E, SAMUEL A M, SAMUEL F H, DOTY H W. The effects of mischmetal, cooling rate and heat treatment on the eutectic Si particle characteristics of A319.1, A356.2 and A413.1 Al-Si casting alloys[J]. Materials Science and Engineering A, 2008, 480(1/2): 342-355.

[10] ASENSIO-LOZANO J, SUAREZ-PENA B. Effect of the addition of refiners and/or modifiers on the microstructure of die cast Al-12Si alloys[J]. Scripta Mater, 2006, 54(1): 943-947.

[11] LIAO Heng-cheng, SUN Yu, SUN Guo-xiong. Correlation between mechanical properties and amount of dendritic a(Al) phase in as-cast near-eutectic Al-11.6% Si alloys modified with strontium[J]. Materials Science and Engineering A, 2002, 335(1/2): 62-66.

[12] LU L, DAHLE A K. Effects of combined additions of Sr and AlTiB grain refiners in hypoeutectic Al-Si foundry alloys[J]. Materials Science and Engineering A, 2006, 435/436: 288-296.

[13] MOHNANTY P S, GRUZL ESKI J E. Grain refinement mechanisms of hypoeutectic Al-Si alloys[J]. Acta Mater, 1996, 44(9): 3749-3760.

[14] EASTON M A, STJOHN D H. A Model of grain refinement incorporation alloy constitution and potency of heterogeneous nucleant particles[J]. Acta Mater, 2001, 49(10): 1867-1878.

[15] JUNG H, MANGELINCK-NOEL N, BERGMAN C, BILLIA B. Determination of the average nucleation undercooling of primary Al-phase on refining particles from Al-5.0 wt% Ti-1.0 wt% B in Al-based alloys using DSC[J]. J Alloys Compound, 2009, 477(1/2): 622-627.

[16] PENG J H, LI W F, HUANG F L, TIAN J, LIU G J, DU J. Study on the microstructure evolution of rare earth Pr modified alumina-silicate short fiber-reinforced Al-Si metal matrix composites[J]. Rare Metals, 2009, 28(2): 1-5.

[17] PENG Ji-hua, LI Wang-fang, HUANG Fang-liang, DU Jun. Effect of rare earth Pr on microstructure and mechanical properties of Al2O3-SiO2(sf)/Al-Si composites[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 1081-1086.

[18] TSAI Y, CHOU C, LEE S, LIN C, LIN J, LIM S. Effect of trace La addition on the microstructure and mechanical properties of A356 (Al-7Si-0.35Mg) aluminum alloys[J/OL]. [2009-07-01]. J Alloys Compound, doi: 10.1016/j.jallcom.

[19] MACDONALD S D, NOGITA K, DAHLE A K. Eutectic nucleation in Al-Si alloys[J]. Acta Materialia, 2004, 52(14): 4273-4280.

(编辑 杨 华)

基金项目:广东省科技计划资助项目(2008B080703001);广州市科技计划资助项目(2009Z2-D221);广州增城市科技计划资助项目(ZC2009015)

收稿日期:2009-12-17;修订日期:2010-05-12

通信作者:彭继华, 副教授, 博士;电话:020-87113747; 传真:020-87113747; E-mail: jhpeng@scut.edu.cn