DOI: 10.11817/j.issn.1672-7207.2020.11.017

银基纳米自润滑复合材料的润滑膜演变行为

张强1,张可墨1,周元子1,曲强1,康潇2

(1. 北京控制工程研究所,北京,100094;

2. 中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要:采用热压烧结法制备具有低摩擦因数和超低磨损率的银基纳米自润滑复合材料,并研究润滑膜的化学组成、微观结构和演变规律。研究结果表明:润滑膜由WS2和MoS2组成,降低滑动速度会增加润滑膜中WS2和MoS2的含量以及润滑膜的厚度。平稳的摩擦因数曲线归因于润滑膜形成和消耗之间的动态平衡,当润滑膜的厚度超过80 nm时,摩擦因数曲线会比较平稳。在真空摩擦磨损的初始阶段,MoS2颗粒比WS2更容易黏附在磨损表面形成润滑膜,使得该复合材料既可以在初始阶段迅速形成润滑膜,又可以在稳定阶段保持低摩擦因数。因此,银基纳米自润滑复合材料可以作为卫星用的滑动电接触材料。

关键词:润滑膜;金属基自润滑复合材料;摩擦学行为;复相固体润滑剂

中图分类号:TH117.1 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3144-08

Microstructural evolution of lubricating films of silver matrix self-lubricating nanocomposite

ZHANG Qiang1, ZHANG Kemo1, ZHOU Yuanzi1, QU Qiang1, KANG Xiao2

(1. Beijing Institute of Control Engineering, Beijing 100094, China;

2. State Key Laboratory for Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: A silver matrix self-lubricating nanocomposite with low friction coefficient and ultra-low wear rate was prepared by hot pressing sintering method, and the chemical composition, microstructure and microstructural evolution of the lubricating films were fully evaluated. The results show that the lubricating films are composed of WS2 and MoS2, and decreasing the sliding speed will increase the content of WS2 and MoS2 as well as the thickness of the lubricating films. The smooth friction coefficient curve is attributed to the dynamic balance between the formation and consumption of the lubricating films. When the thickness of the lubricating films exceeds 80 nm, the friction coefficient curve will be relatively smooth. In the initial stage of vacuum friction and wear, MoS2 particles are more likely to stick to the worn surface to form a lubrication film than WS2, which makes Ag-WS2-MoS2 composite not only form a lubrication film rapidly in the initial stage, but also maintain a low friction coefficient in the stable stage. Therefore, the silver matrix self-lubricating nanocomposite can be used as the sliding electrical contact materials for satellites.

Key words: lubricating films; metal matrix self-lubricating composite; tribological behavior; binary solid lubricants

过渡族金属二硫化物具有独特的层状晶体结构,金属元素和硫族元素间由结合力强的共价键连接,而相邻晶格层间由结合力弱的范德华力连接,其独特的层状晶体结构导致相邻晶格层间更容易滑动[1-3]。过渡族金属二硫化物被用于金属基自润滑复合材料中的固体润滑剂,而具有低摩擦因数的金属基自润滑复合材料被广泛用于电机和导电滑环系统[2-5]。添加润滑性能优异的固体润滑剂可以降低接触表面的剪切力,从而减少黏着磨损,与含有单一固体润滑剂的材料相比,含有复相固体润滑剂的材料具有更好的摩擦磨损性能[6-7]。通过添加复相固体润滑剂可以进一步降低材料的摩擦因数和磨损率,并制造出同时具有低摩擦因数和高耐磨性的金属基自润滑复合材料[8]。银具有良好的导电性、导热性、抗辐射性和耐腐蚀性,因此银基自润滑复合材料被广泛应用于航空航天设备中的精密电接触元器件[9-10]。最近,银基自润滑复合材料的摩擦磨损行为获得了广泛的关注,ZHANG等[11]研究了载荷对AgCu-8%MoS2(质量分数)复合材料大气摩擦磨损性能的影响,研究发现,随着载荷从1 N增加到4 N,银基自润滑复合材料的磨损率由9.72×10-5 mm3/(N·m)增加到21.26×10-5 mm3/(N·m)。CHEN等[12]研究发现,热挤压增强了AgCu-8%MoS2复合材料中润滑相与金属基体的界面结合,银基自润滑复合材料的磨损率由5.95×10-5 mm3/(N·m)降低到2.91×10-5 mm3/(N·m),摩擦因数由0.15降低到0.13。WU等[13]分析了AgCu-WS2复合材料真空摩擦磨损行为,研究结果表明:在真空摩擦磨损过程中,接触面上的WS2能发挥良好润滑作用,提高了摩擦的稳定性。CHEN等[14]研究了石墨和碳纳米管的添加对Ag-MoS2复合材料大气摩擦磨损性能的影响,结果表明石墨和碳纳米管的添加均可提高Ag-MoS2复合材料的硬度和强度,降低材料的摩擦因数和磨损率,石墨和MoS2具有协同润滑的作用,碳纳米管可以提高银基体的耐磨性。近年来,其他金属基自润滑复合材料的自润滑机理也引起了研究者们的广泛关注。XIAO等[6]采用热压烧结法制备了Cu-WS2自润滑复合材料并研究其摩擦磨损性能,当WS2的体积分数由0增加至40%时,复合材料的平均摩擦因数和磨损率分别下降了81.6%和96.0%。GRANDIN等[15]研究发现,当金属基自润滑复合材料中的固体润滑剂的质量分数高于5%时,金属基自润滑复合材料才会具有明显的自润滑功能。有研究表明,润滑膜的厚度随着滑动速度和接触压力的增加而减小,润滑膜厚度的逐渐减小导致接触面从完全润滑转变为边界润滑,润滑膜的润滑性能下降[16]。XIAO等[17]研究发现,Cu-MoS2复合材料的润滑膜是由大量MoS2纳米碎片形成,润滑膜的厚度在33~100 nm之间。大多数关于润滑膜的研究都集中在润滑剂含量、滑动速度和接触压力对润滑膜厚度和覆盖面积的影响[15-22],关于润滑膜演变的研究较少。本文作者以纳米银和复相固体润滑剂为原料,通过热压烧结法制备具有低摩擦因数和超低磨损率的银基纳米自润滑复合材料(Ag-WS2-MoS2)。主要研究复合材料润滑膜的演变行为和摩擦学性能,分析润滑膜的厚度、化学成分和微观结构的演变。

1 实验

1.1 材料制备

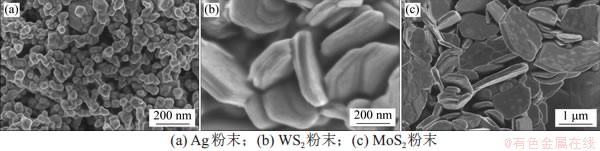

图1所示为原料的扫描电镜照片。由图1可知,原料纳米Ag粉末和纳米WS2粉末的平均粒度分别为53 nm和36 nm。以纳米Ag粉末(中值粒径D50=53 nm),纳米WS2粉末(D50=36 nm)和亚微米MoS2粉末(D50=350 nm)为原料,首先将原料固定比例倒入球磨罐中,在氮气保护下以120 r/min的速度混合24 h;然后将混合后的粉末装入石墨模具中,使用热压烧结炉在氮气保护下以750 °C和25 MPa压力进行热压烧结;最后将直径×高度为60 mm×3 mm的烧结样品制成长×宽×高为3 mm×3 mm×3 mm的立方体,用于真空摩擦磨损测试。

1.2 实验方法

采用VET-1销-盘式真空摩擦磨损试验机进行纳米复合材料的真空摩擦磨损性能测试,测试参数如表1所示。真空摩擦磨损测试前,分别使用13 μm和6.5 μm的金相砂纸对销和盘的接触表面进行抛光,抛光后的样品放入超声波清洗机并倒入无水乙醇清洗3 min。真空摩擦磨损测试前后样品均需要清洗并烘干,使用Sartorius TE214S数字天平(精度为0.1 mg)测量样品质量,材料的体积磨损率通过式(1)计算[23]:

图1 原料扫描电镜照片

Fig. 1 SEM images of raw materials

表1 真空摩擦磨损试验参数

Table 1 Conditions of friction and wear tests

(1)

(1)

式中:W为体积磨损率;m为质量损失;P为载荷;ρ为样品密度;s为距离。

1.3 表征手段

采用场发射扫描电子显微镜(SEM, FEI Nova Nano SEM 230)分析纳米复合材料的微观结构和断口形貌。通过X射线衍射(XRD, D/max 2550)分析纳米复合材料的物相组成,其扫描角度为10°~80°,扫描速率为5 (°)/min。润滑膜的成分可以通过X射线光电子能谱(XPS,K-Alpha 1063)分析,润滑膜的厚度通过离子蚀刻测量。

2 结果与讨论

2.1 微观结构

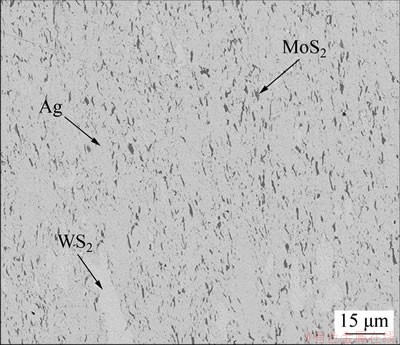

Ag-WS2-MoS2纳米复合材料的显微结构如图2所示,灰色、白色和黑色区域分别为Ag,WS2和MoS2,可以观察到WS2和MoS2较为均匀地分布在银基体中。纳米固体润滑剂颗粒容易发生团聚,因此纳米复合材料中的WS2颗粒会产生聚集的现象。采用热压制备工艺可以实现银基体与固体润滑相(WS2和MoS2)之间的良好结合,银基体与固体润滑相的界面上未观测到明显的孔隙,材料的相对密度高达98.9%。

图2 Ag-WS2-MoS2纳米复合材料的显微结构

Fig. 2 Microstructure of Ag-WS2-MoS2 nanocomposite

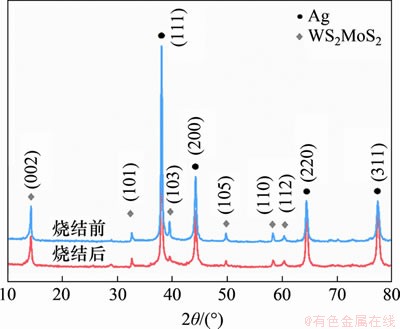

通过XRD分析生坯和烧结后样品的物相组成,如图3所示。从图3可知,纳米复合材料中固体润滑相的稳定性好,在热压烧结过程中没有其他物相生成。

图3 生坯和烧结后样品的X射线衍射图谱

Fig. 3 XRD patterns of green body and sintered sample

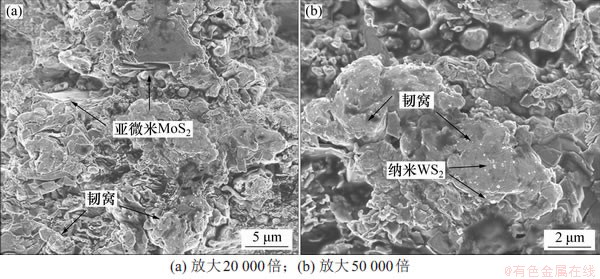

2.2 力学性能

Ag-WS2-MoS2纳米复合材料的硬度(HB)和抗弯强度分别为71.6和196.2 MPa,其硬度和抗弯强度明显比现有的银基自润滑复合材料的高。为进一步分析Ag-WS2-MoS2纳米复合材料的力学性能,研究纳米复合材料的断口形貌。抗弯强度测试后的Ag-WS2-MoS2纳米复合材料的断口形貌如图4所示。可见:纳米复合材料的断口形貌成45°,断裂方式为脆性断裂。断口面上的固体润滑剂较少、韧窝结构较多,表明Ag-WS2-MoS2纳米复合材料具有较好的抗弯强度。在球磨混合过程中添加分散剂(PEG),减少纳米WS2颗粒团聚,有利于形成更加均匀的结构,从而可以抑制微裂纹产生,显著提高纳米复合材料的力学性能。

图4 抗弯强度测试后的Ag-WS2-MoS2纳米复合材料的断口形貌

Fig. 4 Fracture surfaces of Ag-WS2-MoS2 nanocomposite after bending strength test

2.3 摩擦磨损性能

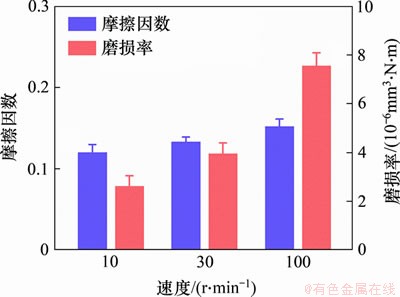

滑动速度对Ag-WS2-MoS2纳米复合材料平均摩擦因数和磨损率的影响如图5所示。从图5可见:当滑动速度为10 r/min时,纳米复合材料的平均摩擦因数最低,此时磨损率也最低(2.81×10-6 mm3/(N·m))。随着滑动速度的提高,纳米复合材料的磨损率比摩擦因数增大更明显。

图5 速度对Ag-WS2-MoS2纳米复合材料的摩擦因数和磨损率的影响

Fig. 5 Effect of speed on friction coefficients and wear rates of Ag-WS2-MoS2 nanocomposite

2.4 润滑膜演变行为

通过X射线光电子能谱(XPS)研究Ag-WS2-MoS2纳米复合材料磨损表面润滑膜的物相组成,并使用Ar+蚀刻分析润滑膜厚度。Ag-WS2-MoS2纳米复合材料磨损表面润滑膜的XPS光谱如图6所示。从图6(a)可见:在367.3 eV和373.4 eV结合能处的峰代表Ag3d,峰强随着蚀刻时间的增加而增强。从图6(b)~(d)可见:位于30.8,227.3,和162.2 eV结合能处的峰分别代表W4f,Mo3d和S2p。W4f,Mo3d和S2p的峰强随着刻蚀时间的增加而减弱,表明润滑膜的覆盖面积在深度方向上的减小。

图6 Ag-WS2-MoS2纳米复合材料磨损表面的元素变化

Fig. 6 Elemental evolution of worn surface of Ag-WS2-MoS2 nanocomposite

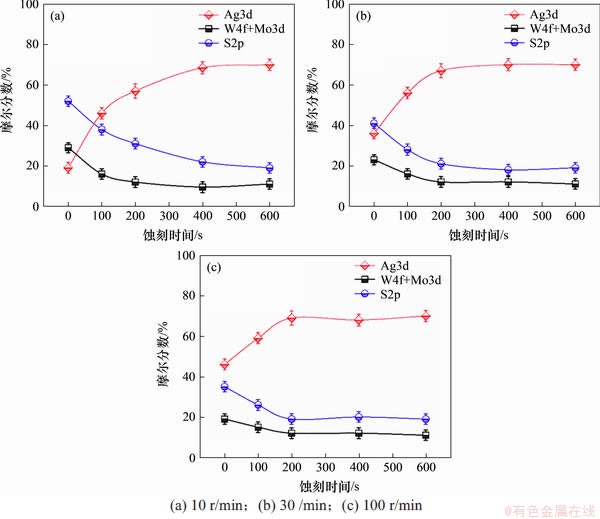

Ag-WS2-MoS2纳米复合材料磨损表面的润滑膜的元素含量演变如图7所示。从图7可见:随着蚀刻时间的增加,润滑膜中的Ag3d(图6(a)),W4f+Mo3d (图6(b)和6(c))和S2p(图6(d))的含量发生变化。当蚀刻时间达到400 s时,润滑膜中Ag,W,Mo和S的含量接近纳米复合材料中的含量。银基复合材料的蚀刻速度为0.35 nm/s,根据文献[17]中的模型计算可得:当速度为10 r/min时,润滑膜的厚度约为140 nm。由图7(b)和图7(c)的结果表明,当速度为30 r/min 和100 r/min时,润滑膜的厚度约为70 nm。在真空摩擦磨损过程中,WS2和MoS2颗粒被吸附在磨损表面形成润滑膜。润滑膜的形成增加了磨损表面W,Mo和S的含量,并降低了Ag的含量。

图7 Ag-WS2-MoS2纳米复合材料磨损表面的润滑膜的元素含量演变

Fig. 7 Elemental evolution of lubricating film on worn surface of Ag-WS2-MoS2 nanocomposite

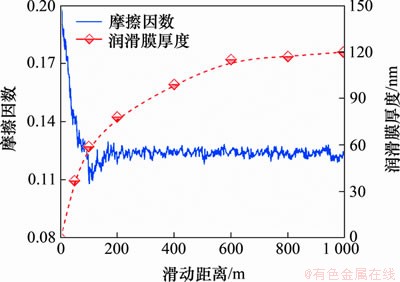

在摩擦磨损过程中,润滑膜的形成与接触面的塑性变形有关[24-25]。固体润滑相在剪切力的作用下分裂成很多纳米片,因此固体润滑相可以通过不断分裂而覆盖磨损表面的大部分面积。对金属基自润滑复合材料而言,磨损表面润滑膜厚度的变化会影响摩擦因数的变化,而润滑膜厚度的变化又会受到滑动距离、滑动速度、润滑剂含量等因素的影响[6, 26]。摩擦因数的演变可分为3个阶段:初始阶段、过渡阶段和稳定阶段。在初始阶段,摩擦因数随着润滑膜厚度的增加而迅速降低;在稳定阶段,摩擦因数保持恒定。图8所示为摩擦因数曲线和润滑膜厚度之间的动态关系。从图8可见:在初始阶段,摩擦因数显著降低,润滑膜厚度显著增加;在过渡阶段,摩擦因数曲线产生波动,润滑膜厚度随着滑动距离的增加而缓慢增加[20, 27]。当润滑膜的厚度超过80 nm,摩擦因数曲线会变得比较平稳。润滑膜厚度的逐渐增加导致接触面从边界润滑过渡到完全润滑,平稳的摩擦因数曲线归因于润滑膜形成和消耗之间的动态平衡[12, 28]。

图8 摩擦因数曲线和润滑膜厚度的演变关系

Fig. 8 Evolution of friction coefficient profiles and lubricating film thickness

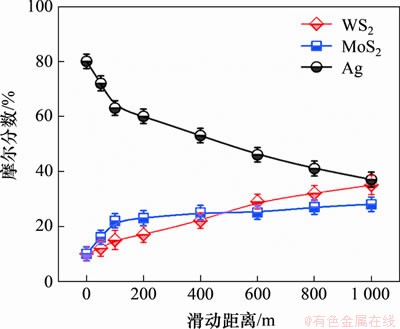

润滑膜中W,Mo和S元素的变化规律如图9所示。从图9可见:W元素的含量在初始阶段增长缓慢,而在过渡阶段增长迅速。然而,Mo元素的含量在初始阶段快速增长,但随着滑动距离的增加其增长也变得缓慢。在初始阶段和过渡阶段,Mo元素的含量高于W元素的含量,但在稳定阶段Mo和W元素的含量相近。在摩擦磨损的初始阶段,MoS2颗粒比WS2更容易黏附在磨损表面形成润滑膜。但与MoS2相比,WS2可以提供更好的润滑性能。因此,Ag-WS2-MoS2纳米复合材料既可以在初始阶段迅速形成润滑膜,又可以在稳定阶段保持低摩擦因数(0.12)和低磨损率(2.81×10-6 mm3/(N·m))。

图9 润滑膜中W,Mo和S元素的变化

Fig. 9 Evolution of atomic percentage of W, Mo and S in lubricating film

3 结论

1) 采用热压烧结法制备具有低摩擦因数和超低磨损率的银基纳米自润滑复合材料,Ag-WS2-MoS2纳米自润滑复合材料的力学性能较好,其相对密度为98.9%,布氏硬度(HB)为71.6,抗弯强度为196.2 MPa,同时具有低摩擦因数(0.12)和超低磨损率(2.81×10-6 mm3/(N·m))。

2) Ag-WS2-MoS2纳米自润滑复合材料磨损表面的润滑膜由WS2和MoS2组成,降低滑动速度会增加润滑膜中WS2和MoS2的含量以及润滑膜的厚度,在10 r/min速度时润滑膜的厚度约为121 nm。润滑膜厚度的逐渐增加导致接触面从边界润滑过渡到完全润滑,平稳的摩擦因数曲线归因于润滑膜形成和消耗之间的动态平衡。当润滑膜的厚度超过80 nm时,摩擦因数曲线会比较平稳。

3) 在真空摩擦磨损的初始阶段,MoS2颗粒比WS2更容易黏附在磨损表面形成润滑膜。Ag-WS2-MoS2纳米复合材料既可以在初始阶段迅速形成润滑膜,又可以在稳定阶段保持低摩擦因数,非常适合用作卫星用的滑动电接触材料。

参考文献:

[1] LI He, WANG Jinhuan, GAO Song, et al. Superlubricity between MoS2 monolayers[J]. Advanced Materials, 2017, 29(27): 1701474.

[2] UFLYAND I E, ZHINZHILO V A, BURLAKOVA V E. Metal-containing nanomaterials as lubricant additives: state-of-the-art and future development[J]. Friction, 2019, 7(2): 93-116.

[3] CHHOWALLA M, AMARATUNGA G A J. Thin films of fullerene-like MoS2 nanoparticles with ultra-low friction and wear[J]. Nature, 2000, 407(6801): 164-167.

[4] SCHARF T W, PRASAD S V. Solid lubricants: a review[J]. Journal of Materials Science, 2013, 48(2): 511-531.

[5] TUDELA I, COBLEY A J, ZHANG Y. Tribological performance of novel nickel-based composite coatings with lubricant particles[J]. Friction, 2019, 7(2): 169-180.

[6] XIAO Jinkun, WU Yuqing, ZHANG Wei, et al. Friction of metal-matrix self-lubricating composites: relationships among lubricant content, lubricating film coverage, and friction coefficient[J]. Friction, 2020, 8(3): 517-530.

[7] CHEN Beibei, YANG Jin, ZHANG Qing, et al. Tribological properties of copper-based composites with copper coated NbSe2 and CNT[J]. Materials & Design, 2015, 75: 24-31.

[8] LI Shu, FENG Yi, YANG Xiting. Influence of adding carbon nanotubes and graphite to Ag-MoS2 composites on the electrical sliding wear properties[J]. Acta Metallurgica Sinica, 2010, 23(1): 27-34.

[9] MOBERLY L E, JOHNSON J L. Electrical sliding contacts for application in space environments[J]. IEEE Transactions on Aerospace, 1965, AS-3(2): 252-257.

[10] WINGERT P C, ALLEN S E, BEVINGTON R C. The effects of graphite particle size and processing on the performance of silver-graphite contacts[J]. IEEE Transactions on Components, Hybrids, and Manufacturing Technology, 1992, 15(2): 154-159.

[11] ZHANG Lei, XIAO Jinkun, ZHOU Kechao. Sliding wear behavior of silver-molybdenum disulfide composite[J]. Tribology Transactions, 2012, 55(4): 473-480.

[12] CHEN Wu, WANG Yan, FENG Chunfang, et al. Effect of hot extrusion on electrical tribological behavior of Ag-Cu/MoS2 composite under air and vacuum conditions[J]. Tribology Transactions, 2017, 60(4): 653-662.

[13] WU Jisi, LI Jingfu, ZHANG Lei, et al. Effects of environment on dry sliding wear behavior of silver-copper based composites containing tungsten disulfide[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(10): 2202-2213.

[14] CHEN Fanyan, FENG Yi, SHAO Hao, et al. Friction and wear behaviors of Ag/MoS2/G composite in different atmospheres and at different temperatures[J]. Tribology Letters, 2012, 47(1): 139-148.

[15] GRANDIN M, WIKLUND U. Wear phenomena and tribofilm formation of copper/copper-graphite sliding electrical contact materials[J]. Wear, 2018, 398/399: 227-235.

[16] HU Y, WANG L, POLITIS D J, et al. Development of an interactive friction model for the prediction of lubricant breakdown behaviour during sliding wear[J]. Tribology International, 2017, 110: 370-377.

[17] XIAO Jinkun, ZHANG Wei, LIU Liming, et al. Tribological behavior of copper-molybdenum disulfide composites[J]. Wear, 2017, 384/385: 61-71.

[18] RAJKUMAR K, ARAVINDAN S. Tribological behavior of microwave processed copper-nanographite composites[J]. Tribology International, 2013, 57: 282-296.

[19] KRUPKA I, SPERKA P, HARTL M. Effect of surface roughness on lubricant film breakdown and transition from EHL to mixed lubrication[J]. Tribology International, 2016, 100: 116-125.

[20] CEN H, LUGT P M. Film thickness in a grease lubricated ball bearing[J]. Tribology International, 2019, 134: 26-35.

[21] WANG Yan, CHEN Wu, WANG Tuo, et al. Crystallization behavior of sub-surface in (Zr, Cu)95Al5 bulk metallic glass induced by different counter-face materials[J]. Materials & Design, 2016, 111: 213-221.

[22] 张雷, 周科朝, 刘文胜, 等. 梯度结构Ag-Cu-MoS2电刷材料的制备及性能[J]. 中国有色金属学报, 2005, 15(11): 1766-1769.

ZHANG Lei, ZHOU Kechao, LIU Wensheng, et al. Preparation and properties of Ag-Cu-MoS2 brush materials[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(11): 1766-1769.

[23] MANDRINO D, PODGORNIK B. XPS investigations of tribofilms formed on CrN coatings[J]. Applied Surface Science, 2017, 396: 554-559.

[24] CHENG Jun, LI Fei, ZHU Shengyu, et al. High temperature tribological properties of a nickel-alloy-based solid-lubricating composite: effect of surface tribo-chemistry, counterpart and mechanical properties[J]. Wear, 2017, 386/387: 39-48.

[25] MURATORE C, VOEVODIN A. Chameleon coatings: adaptive surfaces to reduce friction and wear in extreme environments[J]. Annual Review of Materials Research, 2009, 39(1): 297-324.

[26] HUANG Shiyin, FENG Yi, LIU Hongjuan, et al. Electrical sliding friction and wear properties of Cu-MoS2-graphite-WS2 nanotubes composites in air and vacuum conditions[J]. Materials Science and Engineering: A, 2013, 560: 685-692.

[27] MENG Yuan, SU Fenghua, CHEN Yangzhi. Effective lubricant additive of nano-Ag/MWCNTs nanocomposite produced by supercritical CO2 synthesis[J]. Tribology International, 2018, 118: 180-188.

[28] HWANG J, YOON T, JIN S H, et al. Enhanced mechanical properties of graphene/copper nanocomposites using a molecular-level mixing process[J]. Advanced Materials, 2013, 25(46): 6724-6729.

(编辑 赵俊)

收稿日期: 2020 -08 -17; 修回日期: 2020 -09 -27

基金项目(Foundation item):国家自然科学基金资助项目(11972078) (Project(11972078) supported by the National Natural Science Foundation of China)

通信作者:张可墨,工程师,从事空间指向机构技术和旋转电传输技术研究;E-mail:candyzkm@126.com