Characteristics of electrodeposited RE-Ni-W-B-B4C-MoS2 composite coating

来源期刊:中国有色金属学报(英文版)2003年第5期

论文作者:马克毅 郭忠诚 朱晓云 徐瑞东

文章页码:1220 - 1225

Key words:electrodeposition; RE-Ni-W-B-B4C-MoS2 composite coating; characteristics

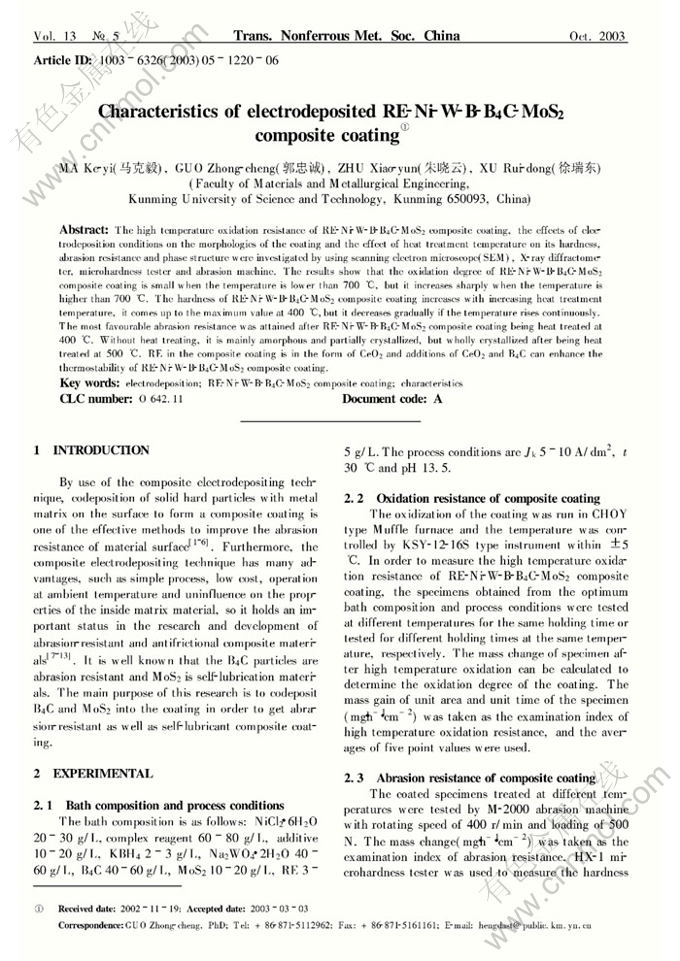

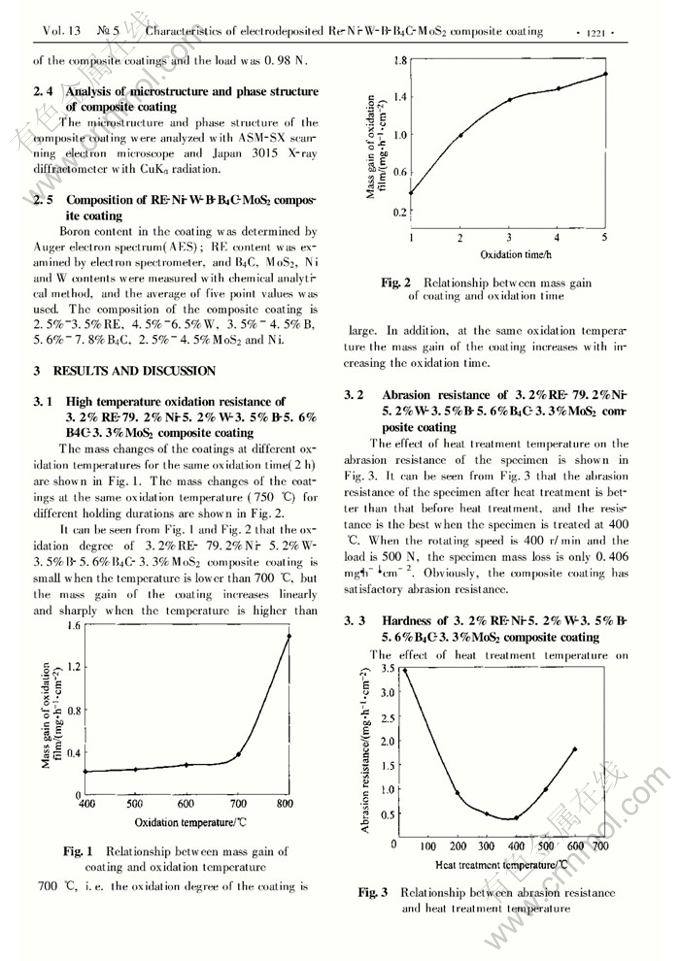

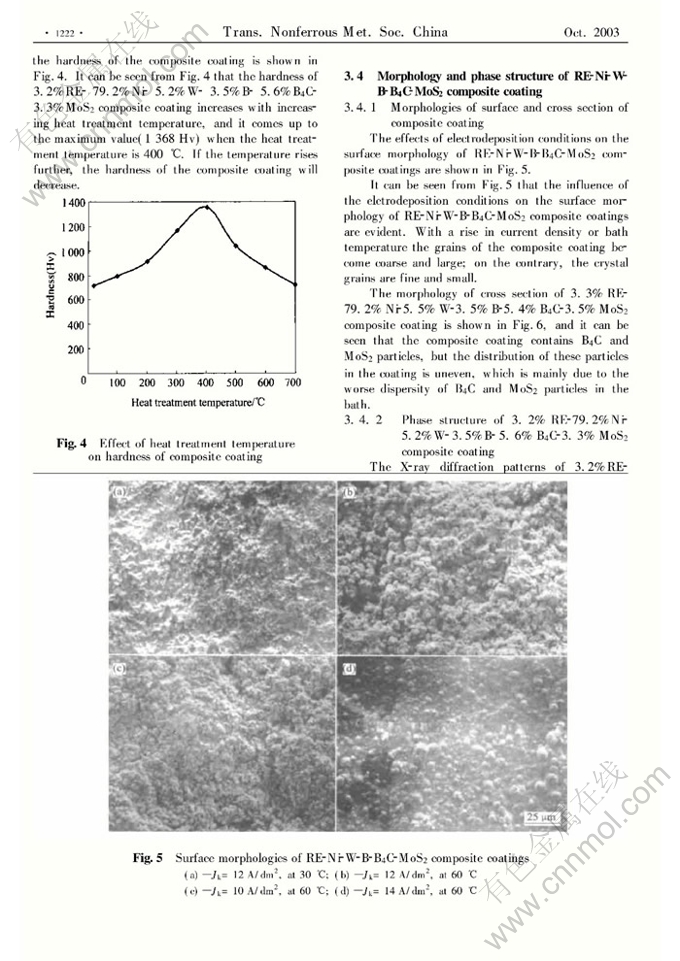

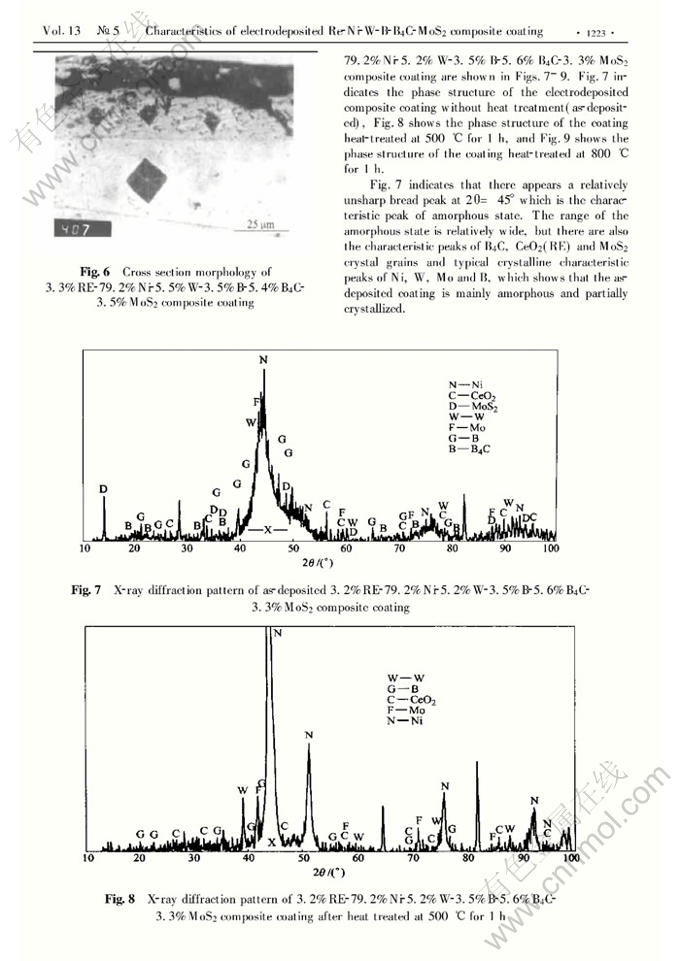

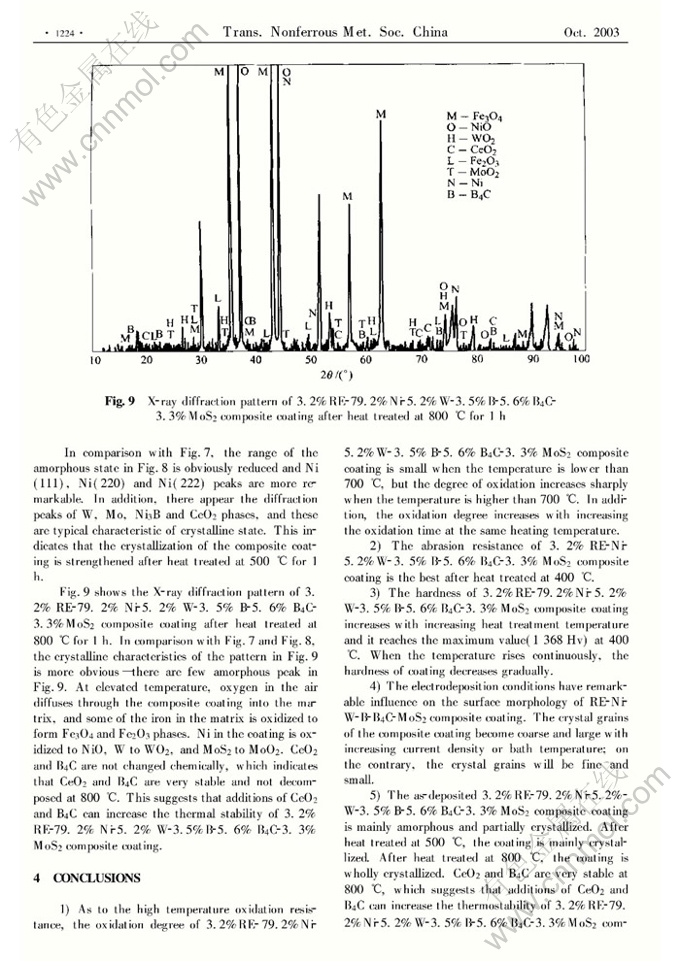

Abstract: The high temperature oxidation resistance of RE-Ni-W-B-B4C-MoS2 composite coating, the effects of electrodeposition conditions on the morphologies of the coating and the effect of heat treatment temperature on its hardness, abrasion resistance and phase structure were investigated by using scanning electron microscope(SEM), X-ray diffractometer, microhardness tester and abrasion machine. The results show that the oxidation degree of RE-Ni-W-B-B4C-MoS2 composite coating is small when the temperature is lower than 700℃, but it increases sharply when the temperature is higher than 700℃. The hardness of RE-Ni-W-B-B4C-MoS2 composite coating increases with increasing heat treatment temperature, it comes up to the maximum value at 400℃, but it decreases gradually if the temperature rises continuously. The most favourable abrasion resistance was attained after RE-Ni-W-B-B4C-MoS2 composite coating being heat treated at 400℃. Without heat treating, it is mainly amorphous and partially crystallized, but wholly crystallized after being heat treated at 500℃. RE in the composite coating is in the form of CeO2 and additions of CeO2 and B4C can enhance the thermostability of RE-Ni-W-B-B4C-MoS2 composite coating.