基于数值模拟的液压路径对汽车覆盖件成形的影响

刘晓晶1,闫 巍1,代洪庆2

(1. 哈尔滨理工大学 材料科学与工程学院,黑龙江 哈尔滨,150040;

2. 黑龙江八一农垦大学 工程学院,黑龙江 大庆,163319)

摘 要:针对汽车覆盖件在冲压过程中出现的破裂和变形不足问题,应用数值模拟方法,采用大型非线性动力显式分析软件ETA/Dynaform5.5,对大圆弧曲面、深拉深的汽车排气管零件充液拉深成形过程进行研究,分析液室压力变化对覆盖件成形性的影响规律。以覆盖件成形壁厚分布为评定标准,研究不同液压加载路径对成形质量的影响,获得合理的液压加载曲线,提高覆盖件的贴模性和刚度。模拟结果表明,汽车排气管充液拉深的最佳液压加载路径是:拉深初始液压力由0增加到1 MPa,缓慢增加压力并稳定在5 MPa,拉深后期压力快速增至35 MPa后进行保压到拉深结束。获得的成形覆盖件质量较高,最小壁厚为0.868 mm,壁厚分布较均匀。

关键词:汽车覆盖件;充液拉深;数值模拟;液压加载路径

中图分类号:TG394 文献标识码:A 文章编号:1672-7207(2008)03-0543-06

Effect of hydraulic pressure loading paths on forming of

automobile panels based on numerical simulation

LIU Xiao-jing1, YAN Wei1, DAI Hong-qing2

(1. College of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150040, China;

2. College of Engineering, Heilongjiang August First Land Reclamation University, Daqing 163319, China)

Abstract: Aiming at the appearance of crack and deforming deficiency in the stamping process of the large curved surface automobile panels, the numerical simulations of hydromechanical deep drawing process were carried out by employing the large non-linear dynamic explicit analytical software ETA/Dynaform5.5. The effects of chamber pressure variations on the formability were analyzed. The influence of different loading paths on the forming quality was investigated with the wall-thickness distribution used as standard. The reasonable loading curve of chamber pressure was obtained. The attaching capability and rigidity can be increased. The results show that the optimum chamber pressure loading path of exhaust’s hydromechanical deep drawing is as follows. At the initial stage, the chamber pressure increases from 0 to 1 MPa. Then, the pressure is raised and stabilized at 5 MPa. At the final stage, the chamber pressure increases to 35 MPa quickly and is kept it to the end. The higher quality with the well-proportioned wall-thickness distribution for the formed automobile panel is obtained and the minimum wall-thickness is 0.868 mm.

Key words: automobile panel; hydromechanical deep drawing; numerical simulation; hydraulic pressure loading path

汽车覆盖件大都具有形状复杂,结构尺寸大,材料厚度较小,变形过程复杂的特点

[1-2]。对质量标准要求十分严格,因1%的车身制造缺陷都能给产品最终用户带来恶劣的影响,乃至降低整个企业的市场竞争力。因此,世界各大汽车公司都加快了覆盖件成形的研究和应用。近年来,随着成形设备和相关控制技术的发展,以流体为传力介质的板材液压成形技术在国外迅速发展起来

[3],广泛应用于汽车、飞机和航空航天制造业,如制造汽车反光镜、翼子板等覆盖件及航天领域中复杂难成形零件

[4-5],并且开始应用于许多其他工业领域,其应用前景十分广阔。

板材充液拉深(hydromechanical deep drawing,HDD)是在拉深模的凹模中以一定压力液体作为传力介质代替刚性凹模传递载荷,使坯料在液体压力作用下贴靠凸模以实现金属板材零件的成形[6]。充液拉深与普通的冲压拉深相比,能有效抑制破裂、克服拉延不足、改善贴模性、提高成形极限,使一次拉深成为可能。此外,模具结构简化,使模具成本降低30%以上,缩短了生产准备周期[7-8]。

目前,国内外学者对回转体、方盒形、筒形、锥形、抛物线形等规则零件的充液拉深进行研究,内容涉及流体压力分布、液室压力与板料厚度、凹模圆角、压边力、拉深比之间的关系、缺陷分类及缺陷形成机理、成形精度、残余应力、加载路径优化、变形过程应力分析及其数值模拟技术的应用等。在汽车覆盖件充液拉深研究中,B. Larsen[9]针对马达罩的液压拉深成形过程,就板料初始反胀效果对零件成形性的影响进行研究,提出初始反胀有助于零件的成形。初始反胀可产生软拉延筋的效果,增加板料变形,提高贴模程度。覆盖件具有空间曲面结构尺寸大、形状复杂的特点,某些覆盖件在成形部位还有沟槽,从而决定了覆盖件在普通冲压成形中一般都不可能在一道冲压工序中直接获得,有的需要十几道工序才能完成,并可能产生拉裂、拉延不足、尺寸和形状精度低,刚度不够等缺陷[2]。因此,采用充液拉深技术是控制拉裂和拉延不足、提高贴模性、克服成形缺陷的最有效手段。其中,液室压力变化可对零件成形产生较大影响,包括板料的减薄量,成形件的刚度等,而液压加载路径的选取又是充液拉深技术的关键之一。基于以上原因,本文作者采用以LS-DYNA3D为内核的动态显式分析软件ETA/Dynaform5.5,通过数值模拟的方法研究液压加载路径变化对汽车排气管这种大圆弧曲面、深拉深零件成形的影响。

1 有限元算法及材料屈服准则

1.1 动态显式算法

根据积分方法不同,可将板料成形有限元方法分为静态隐式(static implicit),静态显式(static explicit)和动态显式(dynamic explicit)。前二者是一个准静态的变形过程,是比较精确的方法。但该算法的计算量与求解问题大小的平方成正比,内存消耗量大,计算效率低。并且对于动态接触问题由于接触力与边界条件的不断变动,而存在比较严重的收敛问题,不能得到问题的解,不利于大规模工程问题的分析。而动态显式算法的计算时间与求解问题的大小成正比变化。在发生起皱、失稳时不会引起数值计算困难,特别适合于求解大型复杂成形问题。因此,目前汽车覆盖件冲压分析多采用动态显式算法,在显式求解中,用中心差分法进行动态问题的时域积分。采用该算法不存在收敛性问题,也不需要求解联立方程组,但其时间步长受到数值积分稳定性的限制,不能超过系统的临界时间步长。

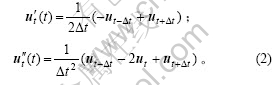

动力显式有限元基本方程为[10-12]:

采用显式中心差分法进行求解。把全程时间T分成n等份,即?t=T/n。则t时刻近似解为:

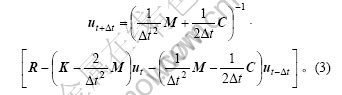

将式(2)代入式(1),可得位移递推公式为:

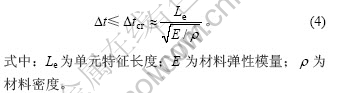

由于中心差分算法是条件稳定的积分算法,所以,为保证式(3)得到稳定的解,计算时间步长?t必须小于由计算的问题的性质所决定的某个临界值?tcr ,否则,采用该算法所得结果不准确。

?t≤

1.2 Hill屈服准则

由于生产中用到的板料轧制时出现纤维组织等因素,绝大部分都存在厚向各向异性,且厚向各向异性对板料冲压成形中的起皱和破裂现象影响较大,所以,采用各向同性的材料屈服模型所得的结果与实际结果相差较大[13]。Hill假设屈服函数在材料的每一质点上存在互相垂直的3个各向异性平面,其交线构成3个各向异性主轴1,2和3,相应的屈服函数为[14-15]:

在ETA/Dynaform5.5中,材料模型37号即为考虑了厚向各向异性的Hill屈服模型。

2 汽车排气管充液拉深数值模拟

2.1 模型的建立

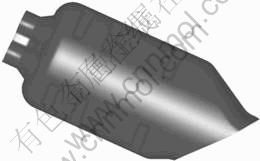

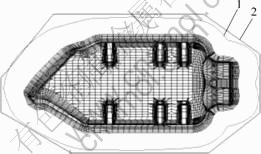

采用仿真模拟软件Dynaform对汽车排气管充液拉深过程进行有限元模拟。图1所示为汽车排气管的三维模型。

图1 排气管三维模型

Fig.1 Three-dimensional model of exhaust

该三维模型在UG中建立,然后,由标准数据格式IGS导入到Dynaform中划分网格。之后设计压料面类型和尺寸,调整压料面位置,划分压料面网格,并依据排气管模型和压料面位置,生成工艺补充面。得到压料面和工艺补充面以后就可以通过Dynaform中的BSE模块估算出板料的尺寸,如图2所示。图2中,线条1为估算出的板料轮廓线。但在实际生产中,为使落料工序简单,通常采用较规则的外轮廓设计,线条2为考虑落料工序后得到的轮廓线。

1—估算出的板料轮廓线;2—考虑落料工序后得到的轮廓线

图2 板料尺寸估计

Fig.2 Estimation of blank dimension

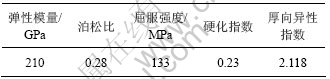

板料选取st16冷冲压钢板,厚度为1.2 mm,其他参数如表1所示。材料模型为37号厚向各向异性材料模型。板料单元采用成形数值模拟中应用非常广泛的Belytschko-Tsay(BT)壳单元。接触类型为单向面—面接触。

表1 材料性能参数

Table 1 Mechanical properties of material

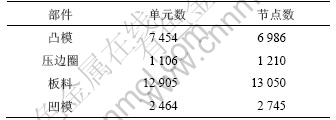

经过以上设计后,得到充液拉深模具和板料模型如图3所示,并在压边圈上设置等效拉延筋,压边力为392 kN,凸模模拟冲压速度设定为1 m/s。

图3 充液拉深模型

Fig.3 FEM model of hydromechanical deep drawing

模拟模型全部建立后,经统计得到凸模、压边圈、板料和凹模单元数和节点数如表2所示。

表2 单元和节点数

Table 2 Numbers of elements and nodes

2.2 液室加载曲线设计

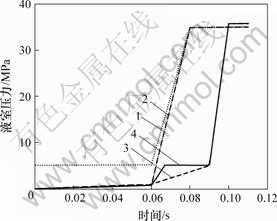

采用有限元模拟软件为动态显式算法的LS- DY NA3D,前后处理程序为ETA/ Dynaform5.5。目前,板材成形的通用有限元软件还不能根据变形情况通过前处理模块实现液室液压自动加载到单元。LS-DYNA具有开放性的特点,可通过关键字文件的二次开发来实现充液拉深的数值模拟。本文液室压力的加载就利用LS-DYNA中提供的关键字LOAD_MASK来实现,通过定义区域来限定施加的对象,进入区域的单元被施加液压,这使得充液拉深过程的模拟更准确。液室压力加载曲线如图4所示,采用4条加载路径进行模拟。

1—1号液室;2—2号液室;3—3号液室;4—4号液室

图4 液室压力加载曲线

Fig.4 Loading paths of chamber pressure

当采用图4中1号液室压力加载曲线时,由于凸模模面为大圆弧形,凸模与板料接触面积太小,加之液室压力加载过早,使板料发生严重的反向变形,其中大部分板料高度大大超过凹模高度,从而产生一个很大的与冲压方向相反的拉应力。该反向拉应力严重阻碍板料的拉入,板料迅速变薄,造成破裂。

由于液室内初始压力不能过大,因此,采用2号加载曲线,即在0~0.06 s时间段内加载压力由0上升到1 MPa,之后压力上升至35 MPa。在成形初始阶段,由于液室压力小,板料在初期拉深时没有产生类似于采用1号加载曲线时产生的巨大反向拉应力,故没有发生板料破裂现象。但当液室压力迅速增加至35 MPa时,形成的反向拉应力再次将凹模口处板料顶起,增大了拉深阻力,导致凸模行进77.8 mm时板料在凹模口处破裂,如图5所示。

图5 2号液室压力下破裂的FLD图

Fig.5 Fracture FLD for loading path 2

考虑到1号和2号加载曲线存在的问题,既不能使初始液室压力过大,又要让板料拉深到所需零件尺寸要求。经过反复模拟确定了3号和4号2条液室压力加载曲线。

第一阶段:在0~0.06 s时压力缓慢上升至1 MPa。这一方面克服因摩擦保持效应造成的成形零件拉延不足问题,另一方面也避免因较大的反向拉应力造成板料破裂问题。

第二阶段:3号曲线在0.06~0.09 s压力由1 MPa增至5 MPa,4号曲线在由1 MPa增至5 MPa后进行了一段时间的保压。其原因是:大部分板料包覆住凸模,但排气管口部深度较浅,且刚与该处板料相接触。如果仍然施加1 MPa的液室压力,会导致因第三阶段压力迅速增加造成该处的破裂。因此,在该阶段,适当增加液室压力以使该位置有良好的贴模性,避免因下一阶段的板料减薄而产生破裂。

第三阶段:在0.09~0.11 s液室压力迅速增加到35 MPa后稳定。这一阶段主要是考虑到零件要达到最终尺寸,使曲面的沟槽部位与凸模更好地贴合而设计的。

2.3 模拟结果分析

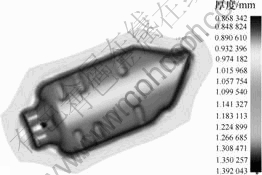

采用3号和4号2条液室压力加载曲线进行模拟均可成形,但成形效果有所不同。3号曲线成形后最小壁厚为0.817 mm,其发生在排气管口处;4号曲线的最小壁厚为0.868 mm,也发生在该处,其最终的成形壁厚分布如图6所示。

图6 4号液室压力的成形零件厚度分布

Fig.6 Wall-thickness distribution of part for loading path 4

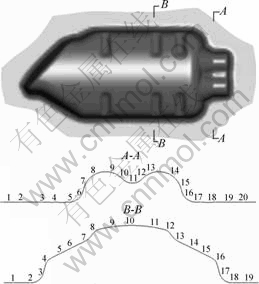

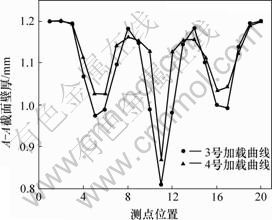

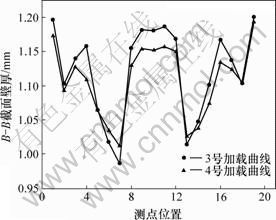

为进一步讨论3号和4号加载曲线对成形性的影响,选取壁厚变化较大截面A-A 和成形不足截面B-B进行分析,截面位置如图7所示。图8和图9所示分别为采用3号和4号2条液室加载曲线时A-A和B-B截面的壁厚曲线对比图。可见,A-A截面在排气管口附近壁厚减薄量很大,4号曲线成形危险部位的壁厚减薄较3号曲线有所改善。在B-B截面上,4号曲线使曲面中间部位变形增加,材料得到进一步强化,提高了汽车在发生碰撞时的抗冲击、抗变形能力。

图7 排气管A-A 和B-B截面

Fig.7 Cross sections of A-A and B-B

图8 A-A截面壁厚分布曲线

Fig.8 Wall-thickness distribution curves of cross section A-A

图9 B-B截面壁厚分布曲线

Fig.9 Wall-thickness distribution curves of cross section B-B

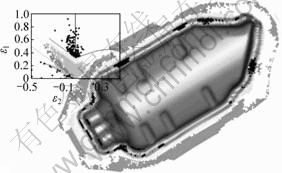

从对比结果可知,采用4号液室压力加载曲线成形后的覆盖件性能较好。图10所示为其成形极限图。可见,在排气管后部有破裂倾向,压边处板料有起皱现象,但由于这些地方都不属于成形零件的部分,在之后的裁剪工序中会被裁掉,因此,不会对覆盖件质量产生任何影响。处于所需要的部分板料都处在安全范围之内,无成形缺陷。

图10 4号液室压力下的成形极限图

Fig.10 FLD for loading path 4

3 结 论

a. 对于形状复杂、成形部位有沟槽等普通冲压难以一次成形的覆盖件,选择充液拉深加工可实现该覆盖件的成形,并且能有效控制拉裂和拉延不足,提高贴模性。

b. 液室加载路径对汽车排气管零件成形有较大影响。初期的液室压力增长不能过快,即由0增加到1 MPa,以避免破裂。而后缓慢增加压力至5 MPa并保持稳定,提高排气管口部的贴模性;后期液室压力迅速增加至35MPa进行保压,以满足最终的尺寸精度要求。获得的排气管零件最小壁厚为0.868 mm。

c. 采用有限元数值模拟分析软件Dynaform可以检验在设计汽车覆盖件的成形工艺过程中方法的可行性和可靠性,为改进模具设计和修正工艺参数提供有用信息。此外,可提高模具制造质量,缩短模具的开发周期,降低成本。

参考文献:

[1] 刘 炜, 李 赞. 充液拉深对覆盖件成形性能影响的数值模拟[J]. 锻压技术, 2003, 28(5): 23-26.

LIU Wei, LI Zan. Numerical simulation of influence of hydro-mechanical drawing on autobody panel formability[J]. Forging & Stamping Technology, 2003, 28(5): 23-26.

[2] 崔令江. 汽车覆盖件冲压成形技术[M]. 北京: 机械工业出版社, 2003.

CUI Ling-jiang. Technique of auto panels stamping[M]. Beijing: China Machine Press, 2003.

[3] 徐永超. 板材液压成形工艺及其数值模拟研究[D]. 哈尔滨: 哈尔滨工业大学材料科学与工程学院, 2003.

XU Yong-chao. Sheet-metal hydroforming and the numerical simulation of the forming process[D]. Harbin: School of Materials Science and Engineering, Harbin Institute of Technology, 2003.

[4] 郭烈恩, 涂文斌. 金属管、板材液压成形工艺[J]. 新技术新工艺, 2004(11): 52-53.

GUO Lie-en, TU Wen-bin. Brief introduction to hydro- mechanical forming of metal sheets and tubes[J]. New Technology & New Process, 2004(11): 52-53.

[5] KANG Da-chang, CHEN Yu, XU Yong-chao. Hydromechanical deep drawing of superalloy cup[J]. Journal of Materials Processing Technology, 2005, 166: 243-246.

[6] 康达昌, 郎利辉, 张士宏, 等. 液压拉深工艺的研究[J]. 哈尔滨工业大学学报, 2000, 32(5): 42-44.

KANG Da-chang, LANG Li-hui, ZHANG Shi-hong, et al. Hydrodynamic deep drawing process[J]. Journal of Harbin Institute of Technology, 2000, 32(5): 42-44.

[7] Nakamura K, Nakagawa T, Amino H. Various application of hydraulic counter pressure deep drawing[J]. J Mater Process Technol, 1997, 71(1): 160-167.

[8] 唐井林, 聂绍珉. 充液成形装置及锥形件充液拉深成形研究[J]. 塑性工程学报, 2001, 8(3): 32-34.

TANG Jing-lin, NIE Shao-min. A equipment for hydroforming and research on hydroforming technology on conical parts[J]. Journal of Plasticity Engineering, 2001, 8(3): 32-34.

[9] Larsen B. Hydromechanic forming of sheet metal[J]. Sheet Metal Industries, 1997, 54(2): 162-168.

[10] 赵 侠, 傅 建, 万长东. 汽车覆盖件成形过程的数值模拟[J]. 锻压装备与制造技术, 2005, 40(4): 67-69.

ZHAO Xia, FU Jian, WAN Chang-dong. Numerical simulation in automobile panel parts forming process[J]. China Metalforming Equipment & Manufacturing Technology, 2005, 40(4): 67-69.

[11] 王 强, 张进国. 汽车覆盖件冲压成形有限元数值仿真研究[J]. 机械设计与制造, 2006(11): 140-142.

WANG Qiang, ZHANG Jin-guo. The finite element analysis research in auto panel stamping forming numerical simulation[J]. Machinery Design & Manufacture, 2006(11): 140-142.

[12] 彭必友, 殷国富, 赵 侠, 等. 板料形状、压料筋的设置对汽车覆盖件成形中起皱和未充分拉深的影响[J]. 塑性工程学报, 2006, 13(6): 39-43.

PENG Bi-you, YIN Guo-fu, ZHAO Xia, et al. The influence of blank shape and setting of drawbead on wrinkling and inadequate stretch areas in automobile covering parts forming process[J]. Journal of Plasticity Engineering, 2006, 13(6): 39-43.

[13] 陈文亮. 板料成形CAE分析教程[M]. 北京: 机械工业出版社, 2005.

CHEN Wen-liang. CAE analysis tutorial of sheets’ forming[M]. Beijing: China Machine Press, 2005.

[14] 林忠钦. 车身覆盖件冲压成形仿真[M]. 北京: 机械工业出版社, 2005.

LIN Zhong-qin. Simulation of stamping of auto body panel[M]. Beijing: China Machine Press, 2005.

[15] 李建华, 胡道钟, 李志刚, 等. 汽车覆盖件板成形数值模拟和工程应用关键技术研究[J]. 汽车科技, 2002(1): 36-39.

LI Jian-hua, HU Dao-zhong, LI Zhi-gang, et al. The research and application on sheet metal forming simulation of automobile panel[J]. Automobile Science and Technology, 2002(1): 36-39.

收稿日期:2007-08-03;修回日期:2007-10-06

基金项目:哈尔滨市培养学科后备带头人项目(2004AFXXJ035)

通信作者:刘晓晶(1966-),女,黑龙江哈尔滨人,博士,副教授,从事模具CAD/CAPP/CAE及集成技术,板料液压成形技术及数值模拟研究;电话:0451-86393466;E-mail: lxj812@126.com