DOI: 10.11817/j.issn.1672-7207.2015.08.006

NaOH-NaNO3-Air体系低温碱性熔炼处理废弃电路板多金属粉末

刘旸,刘静欣,秦红,江晓健,郭学益

(中南大学 冶金与环境学院,湖南 长沙,410083)

摘要:研究NaOH-NaNO3-Air体系低温碱性熔炼处理废弃电路板多金属粉末的工艺流程,在熔炼过程中对各因素对两性金属的影响进行系统研究,优化得到较为适宜的熔体组成与工艺条件:NaNO3,NaOH和多金属粉末质量比为0.6:2.5:1.0,温度为350 ℃,空气流量为1.5 L/min,熔炼时间为30 min。研究结果表明:在此条件下Sn,Pb,Al和Sn的转化率分别为100%,83.99%,93.26%和91.97%。针对含两性金属的碱性浸出液,设计Ca(OH)2沉锡和Na2S·9H2O沉铅锌的分离工艺,得到纯度(质量分数)98%以上的SnO2及PbS-ZnO混合物。

关键词:NaOH-NaNO3-Air体系;低温碱性熔炼;废弃电路板;分离

中图分类号:X758 文献标志码:A 文章编号:1672-7207(2015)08-2804-08

Treatment of crushed metal enrichment of waste printed circuit board by low-temperature alkaline smelting in NaOH-NaNO3-air system

LIU Yang, LIU Jingxin, QIN Hong, JIANG Xiaojian, GUO Xueyi

(School of Metallurgy & Environment, Central South University, Changsha 410083, China)

Abstract: The process of disposing crushed metal enrichment of waste printed circuit boards by low-temperature alkaline smelting in NaOH-NaNO3-Air system was studied. The effects of factors about conversion of amphoteric metal during smelting process were studied systematically. The composition of melt and optimum conditions of NaOH-NaNO3-Air system were obtained under such conditions as mass ratio among NaNO3, NaOH and crushed metal enrichment (CME) being 0.6:2.5:1.0, the temperature being 350 ℃, smelting time being 30 min at 1.5 L/min of air flow. The results show that under the condition, the conversion percentages of each metal are as follows: Sn 100%, Pb 83.99%, Al 93.26% and Zn 91.97%. A precipitation process is proposed to separate Sn by Ca(OH)2 and Pb, Zn by Na2S from the alkaline leaching solution, which contains amphoteric metals. SnO2 with purity (mass fraction) of over 98% and mixture of PbS-ZnO are produced as the final product of this process.

Key words: NaOH-NaNO3-Air system; low-temperature alkaline smelting; waste printed circuit board; separation

随着电子科技的高速发展及人们收入水平的不断提高,电子产品更新换代速度越来越快[1-4],电子废弃物成为了增长最快的垃圾之一[5-7]。联合国环境计划称全球每年产生的电子废弃物量高达4 000~5 000万t,并预计仍以5%~10%的年增长率增加[8-10]。电子废弃物中含有大量有毒有害的物质,如果不合理地处理这些垃圾,将对环境产生巨大的危害。废弃电路板作为电子废弃物的重要组成部分,其质量占电子废弃物总质量的3%左右[11],里面含有铅等易挥发的重金属及溴化物等在燃烧中会产生二噁英等物质。同时,废弃电路板中蕴藏着铜锡及贵金属等极具经济价值的金属,是一座潜力巨大的“城市矿山”[12]。如何合理地处理废弃电路板,对于实现环境保护与资源综合回收利用具有重要的意义。低温碱性熔炼是在碱性介质中在相对低的温度下进行熔炼的新方法。通过低温碱性熔炼处理,废弃电路板多金属粉末中的低熔点两性金属Sn,Zn和Pb等在氧化性气氛下与熔融态的碱反应生成可溶性钠盐,而铜及贵金属不与碱反应以固态形式存在于渣相,再通过水浸的方式溶解钠盐,从而实现两性金属与铜及贵金属的高效分离[13]。本文对NaOH-NaNO3体系中废弃电路板多金属粉末低温碱性熔炼[14]进行研究,以便提高两性金属Sn,Zn,Pb和Al等的转化率。本文探索NaOH-NaNO3-Air体系低温碱性熔炼处理废弃电路板多金属粉末的工艺,同时,开发碱性浸出液处理工艺,得到二氧化锡和铅锌混合物2种产品。

1 实验原料及方法

1.1 原料

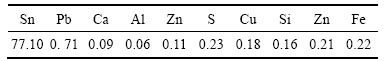

研究所用原料为电路板经过破碎、分选得到的多金属粉末。粉末经过球磨充分粉碎后,粒径在74 μm左右,成分(质量分数)如表1所示。从表1可以看出:本电路板中质量分数最高的是铜,达54.86%,其次依次是锡、 铅、锌和铝,这些元素都是以单质或合金的形态存在。

1.2 实验原理

实验工艺流程如图1所示。电路板多金属粉末中的两性金属Sn,Pb,Zn和Al等在氧化性气氛的低温碱性熔炼条件下先被氧化为金属氧化物,生成的金属氧化物再与熔融的碱反应,形成低熔点的钠盐,主要反应如下:

Sn+2[O]+4NaOH=Na2SnO3+2H2O (1)

Pb+[O]+2NaOH= Na2PbO2+H2O (2)

Zn+[O]+2NaOH=Na2ZnO2+H2O (3)

2Al+3[O]+2NaOH=2NaAlO2 +H2O (4)

铜在熔炼过程中可被氧化为CuO,但不与碱反应,且铜及其氧化物熔点高,在低温碱性熔炼体系下不熔化,以固态形式存在于渣中。熔炼产物通过水浸,两性金属形成的钠盐溶于水,过滤后可得碱性浸出液,固态渣中则富集了铜。

图1 实验流程图

Fig. 1 Flow chart of the process

表1 电路板多金属粉末的化学组成(质量分数)

Table 1 Chemical composition of CME %

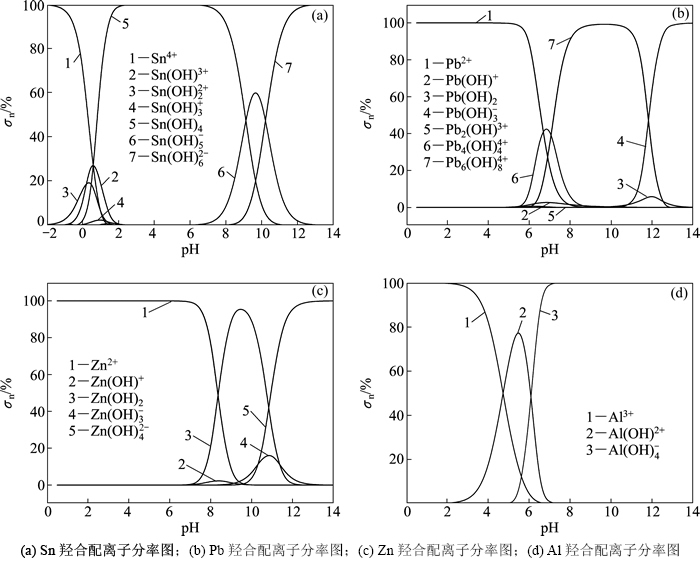

碱性浸出液中主要涉及Sn,Pb,Zn和Al共4种金属。通过查阅相关的热力学数据,计算推导并绘制了这4种金属在水溶液中的羟合配离子分布图,如图2所示。

由图2可以看出:在pH>14的碱性溶液中Sn,Pb,Zn和Al分别以Sn(OH)62-,Pb(OH)3-,Zn(OH)42-和Al(OH)4-形式存在。Ca(OH)2可与溶液中Sn(OH)62-反应生成锡酸钙沉淀,而不与其他3种金属的羟和配离子反应[15];Na2S·9H2O可与溶液中的Pb(OH)3-和Zn(OH)42-反应生成硫化物沉淀而与Al分离,生成产物NaOH不会破坏原有体系,并且实现了NaOH的再生,主要的化学反应如下[16]:

Na2SnO3+Ca(OH)2=CaSnO3↓+2NaOH (5)

xNa2Zn(OH)4(aq)+yNa2S(s)→nZnS(s)+ bNa2Zn(OH)mS(4-m)/2(s)+kZn(OH)2(s)+pNaOH(aq) (6)

xNaPb(OH)3(aq)+yNa2S(s)→nPbS(s)+ bNaPb(OH)mS(3-m)/2(s)+kPb(OH)2(s)+pNaOH(aq) (7)

1.3 实验方法

将50 g废弃电路板多金属粉末与一定质量的NaNO3和NaOH充分混合后,装入特制坩埚,同时向坩埚中通入空气,置于坩埚电阻炉中恒温熔炼。熔炼结束后,熔炼产物速冷,磨碎后加水恒温搅拌冷却,加蒸馏水至液固质量比为7左右,于40 ℃浸出40 min。

浸出结束后抽滤,取滤液进行检测。通过测定滤液中金属离子质量浓度判断各金属的转化率(R)。

图2 水溶液中羟合配离子分率αn-pH图

Fig. 2 Hydroxyl and ion distribution of αn-pH

2 结果与讨论

2.1 NaOH-NaNO3-Air体系低温碱性熔炼

2.1.1 NaNO3和电路板多金属粉末(CME)质量比对两性金属转化率的影响

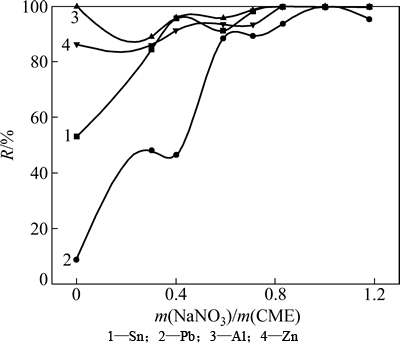

研究结果表明,NaNO3在NaOH-NaNO3-Air体系中作为主要氧化剂,其用量对两性金属转化率影响较大,故实验首先对NaNO3和CME质量比对金属转化率的影响进行考察。将NaOH与CME以质量比3.0:1.0混合,改变NaNO3和CME质量比,450 ℃,空气流量0.9 L/min条件下熔炼60 min,实验结果如图3所示。

从图3可知:随着NaNO3和CME质量比的增加,Sn,Pb和Zn这3种金属的转化率呈上升趋势,而当NaNO3与CME质量比大于0.6后,NaNO3的加入量进一步增加对各金属转化率影响不大,Sn,Pb和Zn的转化率分别维持在91.07%,88.30%和93.43%,而Al的转化率始终高于90.00%。增加NaNO3加入量增强了体系的氧化性气氛[17],使得金属更易被氧化,进而提高了金属的转化率,其中NaNO3加入量对于Pb的转化率影响最明显。而Al与碱的反应对氧化性气氛的要求不高,故其转化率始终维持在较高值。综合考虑转化率及物料消耗等因素,选择NaNO3与废弃电路板粉末质量比为0.6比较合适。

2.1.2 NaOH和CME质量比对两性金属转化率的影响

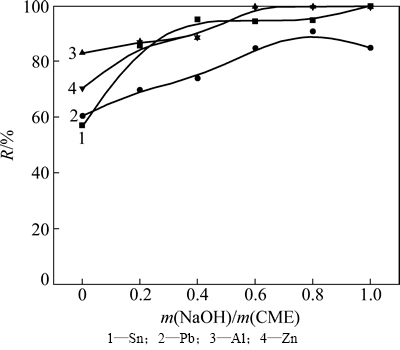

将NaNO3与CME以0.6:1.0的质量比混合,改变NaOH和CME质量比,于450 ℃、空气流量为0.9 L/min条件下熔炼60 min,实验结果如图4所示。

图3 NaNO3和CME质量比对两性金属转化率R的影响

Fig. 3 Effect of mass ratio of NaNO3 to CME on conversion of amphoteric metals

图4 NaOH和CME质量比对两性金属转化率R的影响

Fig. 4 Effect of mass ratio of NaOH to CME on conversion of amphoteric metals

从图4可知:随着NaOH和CME质量比的增加,各金属的转化率都呈上升趋势,而当NaOH与CME质量比大于2.5时,金属Sn,Pb,Al和Zn的转化率基本保持不变,分别可达94.36%,84.77%,100%和100%。NaOH在NaOH-NaNO3-Air体系中主要起反应介质与提供碱性条件的作用,足够的NaOH能够保证液相层的厚度较大,通入空气的熔体搅动更加充分,从而增加了反应物之间的接触面积,强化了反应,提高了各金属的转化率。综合考虑转化率及物料消耗,选择NaOH与CME质量比为2.5适宜。

2.1.3 空气流量对两性金属转化率的影响

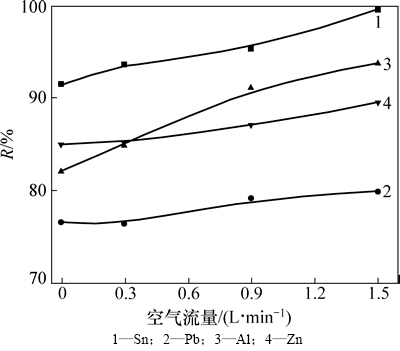

按NaNO3,NaOH与CME质量比为0.6:2.5:1.0,改变空气流量,于450 ℃条件下熔炼60 min,实验结果如图5所示。

图5 空气流量对两性金属转化率R的影响

Fig. 5 Effect of air flow on conversion of amphoteric metals

从图5可以看出:随着空气流量的增加,各金属的转化率均增加,但各金属增加的幅度不同。空气流量增加对Sn和Al的影响较其他2种金属的影响更为明显。空气流量的增加能够增强熔体搅动,使碱和游离的氧充分与两性金属反应,强化了冶炼过程。当空气流量1.5 L/min时熔体在坩埚中搅动十分剧烈,为防止空气流量进一步增加可能造成的熔体喷溅,选择空气流量为1.5 L/min比较合适。

2.1.4 熔炼时间对两性金属转化率的影响

按NaNO3,NaOH与CME质量比为0.6:2.5:1.0,改变熔炼时间,在450 ℃,空气流量为1.5 L/min条件下熔炼,实验结果如图6(a)所示。同时,从图5可知:空气流量为0 L/min时两性金属的转化率已维持在比较高的水平。为了探究鼓气对熔炼时间的影响,在相同的配料及温度,空气流量为0 L/min的条件下,改变熔炼时间进行对比实验,实验结果如图6(b)所示。

从图6(a)和6(b)可知:增加熔炼时间能够使熔炼反应更充分,各金属的转化率均有所提高。对比图6(a)和6(b)可知,图6(a)中各金属的转化率均高于图6(b)中各金属的转化率。从图6(a)可见:当熔炼时间为30 min时,金属的转化率分别为100%, 72.24%,100%和97.97%;而从图6(b)可见:当熔炼时间为30 min时,各金属的转化率都低于图6(a)中各金属的转化率。这说明鼓入空气可增加熔体的搅动,强化熔炼反应的传质过程,进而缩短反应达到平衡所需时间,即缩短了熔炼时间。同时,由于氧气的协同氧化作用,鼓入空气能够提高熔炼的氧化性气氛,使各金属的转化率有所提高。综合考虑能耗及各金属转化率,选择反应时间为30 min。

图6 熔炼时间对两性金属转化率R的影响

Fig. 6 Effect of smelting time on conversion of amphoteric metals

2.1.5 熔炼温度对两性金属转化率的影响

按NaNO3,NaOH与CME质量比为0.6:2.5:1.0,在改变熔炼温度,空气流量1.5 L/min条件下熔炼30 min。NaNO3与NaOH在上述配比恰好是Na3(OH)2 NO3与NaOH 的共晶点,熔点仅为258 ℃,一般熔炼温度高于熔体温度50 ℃左右,熔体即能保持较好的流动性与传质速率,故选择实验的熔炼温度为300~450 ℃,实验结果如图7所示。

图7 熔炼温度对两性金属转化率R的影响

Fig. 7 Effect of smelting temperature on conversion of amphoteric metals

从图7可知:当温度低于350 ℃时,随着熔炼温度的增加,各金属的转化率均有所提高;当温度高于350 ℃时,温度继续升高,Sn和Al的转化率基本不变,而Pb和Zn的转化率反而有所下降。这可能由于Pb和Zn的钠盐产物在熔体中不稳定,温度升高其有所分解所致[18]。NaOH-NaNO3-Air体系下熔炼,350 ℃各金属即能达到高的转化率,分别为Sn 100%,Pb 83.99%,Al 93.26%和Zn 91.97%,故选择此温度为较优反应温度,NaNO3,NaOH和CME质量比为0.6:2.5:1.0,温度为350 ℃,空气流量为1.5 L/min条件下熔炼30 min即为NaOH-NaNO3-Air体系的优化工艺条件。

2.1.6 氧气体积分数对两性金属转化率的影响

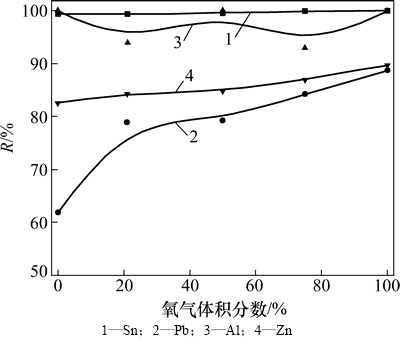

为了验证在NaNO3作为主要氧化剂的熔炼体系中,鼓入的空气起协同氧化作用,实验研究氧气体积分数对两性金属转化率的影响。按NaNO3,NaOH与CME质量比为0.6:2.5:1.9,改变气体中的氧气体积分数,温度为350 ℃,气体流量为1.5 L/min条件下熔炼30 min,实验结果如图8所示。其中,氧气体积分数为0时,本实验向熔炼体系鼓入惰性气体Ar。

图8 氧气体积分数对两性金属转化率R的影响

Fig. 8 Effect of oxygen volume fraction on conversion of amphoteric metals

由图8可以看出:随着氧气体积分数的升高,Zn和Pb的转化率呈上升趋势,其中Pb的转化率提升尤为明显,从氧气体积分数0至21%,转化率上升了17%;Sn的转化率由于一直接近100%,变化并不明显;而Al的转化率在一定范围内波动。这说明在NaNO3作为主要氧化剂的体系,氧气作为鼓入空气的一部分对熔炼体系有着协同氧化的作用,氧气在碱性体系中的反应过程为[19]

0.5O2+O2-→O22- (8)

鼓入的氧气在气液界面扩散后,溶解于熔体界面而与金属粉末发生氧化反应。在氧气的协同氧化作用下,转化需较高氧化性气氛的Pb和Zn转化率提高明显。Sn在NaNO3的氧化作用下即能达到理想转化率,故其转化率基本不变。Al的转化对氧化性要求不高,亦不随氧气体积分数的增加而变化。综合考虑成本及各金属转化率,选择氧气体积分数为21%的空气作为鼓入气体较为适宜。

2.2 碱性浸出液分步分离及产品表征

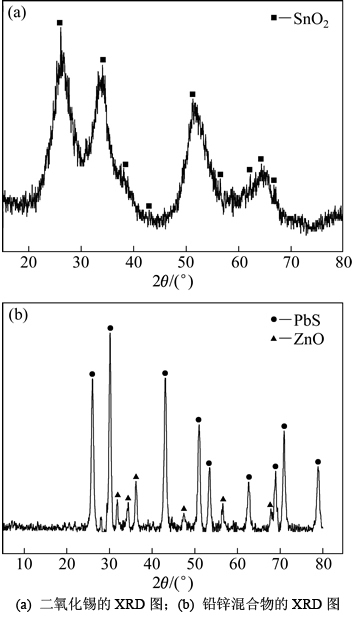

表2所示为废弃电路板NaOH-NaNO3-Air体系低温碱性熔炼碱性浸出液中各物质质量浓度。取NaOH-NaNO3-Air体系熔炼最佳条件的碱性浸出液(见表2),在一定温度及搅拌条件下向浸出液中加入沉淀剂反应,从而分离浸出液中的金属[20]。通过大量实验,得到沉锡的较佳条件如下:反应温度为80 ℃,Ca(OH)2加入量为理论量的3.0倍,反应时间为60 min。对酸处理烘干后的产品进行物相分析,可得产品为二氧化锡,如图9(a)所示。通过电感耦合等离子体-原子发射光谱仪(ICP-AES)所得检测结果如表3所示。从表3可知:产品的纯度达到98%以上。二氧化锡可作为透明导电材料,也可用于制造乳白玻璃、锡盐、瓷着色剂、织物媒染剂和增重剂、钢和玻璃的磨光剂等。

表2 废弃电路板NaOH-NaNO3-Air体系低温碱性熔炼碱性浸出液中各物质质量浓度

Table 2 Substance mass concentration of leaching liquid from low-temperature alkaline smelting of waste printed circuit board g/L

图9 产品XRD图

Fig. 9 XRD patterns of products

沉锡后液中Sn,Pb,Zn和Al各离子质量浓度分别为0.50,3.20,3.00和2.30 g/L,碱质量浓度约80 g/L。该溶液作为Na2S·9H2O沉铅锌实验研究的原料。通过研究,得到Na2S·9H2O沉铅锌实验的较佳条件为:反应温度20 ℃,Na2S·9H2O加入量为理论量,反应时间为15 min。表4所示为铅锌混合物的X荧光检测结果。从表4可以看出:混合物中的主要含有Pb,Zn和S 3种元素,铅锌总含量(质量分数)达到55.74%。由图9(b)所示铅锌混合物的XRD物相可知:水洗烘干后的铅锌混合物中,主要由PbS和ZnO构成。ZnO的生成主要是由于反应过程温度较低,使得ZnS结晶不够完全,在烘干时通过加Na2S沉锌所得ZnS很容易被氧化为ZnO[21]。铅锌混合物可作为铅锌冶炼企业的冶炼原料。

表3 二氧化锡的 ICP-AES检测结果(质量分数)

Table 3 Inductively coupled plasma atomic emission spectrometry results of stannic oxide %

表4 铅锌混合物的X荧光检测结果(质量分数)

Table 4 X fluorescence detection results of lead and zinc concentrates %

在沉铅锌后液中,Sn,Pb,Zn和Al离子质量浓度分别为0.30,0.05,0.03和2.00 g/L,碱质量浓度约为80 g/L,该溶液将蒸发浓缩并返回至低温碱性熔炼步骤。溶液中Al在熔炼体系中进一步循环,待富集成高质量浓度的铝酸钠溶液后,通过拜耳法晶种分解,以氢氧化铝的形式回收。

3 结论

1) 通过考察NaOH-NaNO3-Air体系低温碱性熔炼中各因素对熔炼过程的影响,确定了处理废弃电路板多金属粉末的最佳工艺条件是:NaNO3,NaOH和多金属粉末混合体系质量比为0.6:2.5:10,温度为350 ℃,空气流量为1.5 L/min,熔炼时间为30 min,在此条件下金属Sn,Pb,Al和Zn的转化率分别为100%,83.99%,93.26%和91.97%。

2) 在NaNO3和空气组成的协同氧化体系下,氧化性气氛的低温碱性熔炼体系使得两性金属得以高效转化。同时,鼓入的空气起到搅拌熔体的作用,强化熔炼反应的传质过程,缩短了熔炼时间。

3) 针对含两性金属的碱性浸出液,利用 Ca(OH)2可以与碱性浸出液中的Sn反应生成锡酸钙沉淀的特性,与溶液中的Pb,Zn和Al等选择性分离,所得锡酸钙酸处理后制得纯度(质量分数)高于98%的二氧化锡;利用Na2S·9H2O沉淀沉锡后液中铅锌得到铅锌混合物,可作为工业生产的原料;溶液中的铝也可在体系中循环富集后回收利用。

参考文献:

[1] Yazici E Y, Deveci H. Extraction of metals from waste printed circuit boards(WPCBs) in H2SO4-CuSO4-NaCl solutions[J]. Hydrometallgy, 2013, 139: 30-38.

[2] ZHOU Yihui, QIU Keqiang. A new technology for recycling materials from waste printed circuit boards[J]. Journal of Hazardous Materials, 2010, 175(1): 823-828.

[3] Bizzo W A, Figueiredo R A, de Andrade V F. Characterization of printed circuit boards for metal and energy recovery after milling and mechanical separation[J]. Materials, 2014, 7(6): 4555-4566.

[4] HE Yunxia, XU Zhenming. The status and development of treatment techniques of typical waste electrical and electronic equipment in China: A review[J]. Waste Management & Research, 2014, 32(4): 254-269.

[5] LUO Pei, BAO Lianjun, WU Fengchang, et al. Health risk characterization for resident inhalation exposure to particle-bound halogenated flame retardants in a typical e-waste recycling zone[J]. Environmental Science & Technology, 2014, 48 (15): 8815-8822.

[6] Rajarao R, Sahajwalla V, Cayumil R, et al. Novel approach for processing hazardous electronic waste[J]. Procedia Environmental Sciences, 2014, 21: 33-41.

[7] ZHU P, CHEN Y., WANG L Y, et al. A new technology for separation and recovery of materials from waste printed circuit boards by dissolving bromine epoxy resins using ionic liquid[J]. Journal of Hazardous Materials, 2012, 239: 270-278.

[8] ZENG Xianlai, ZHENG Lixia, XIE Henghua, et al. Current status and future perspective of waste printed circuit boards recycling[J]. Procedia Environmental Sciences, 2012, 16: 590-597.

[9] GUO Jiuyong, GUO Jie, XU Zhenming Guo. Recycling of non-metallic fractions from waste printed circuit boards: A review[J]. Journal of Hazardous Materials, 2009, 168(2): 567-590.

[10] WANG Ruixue, XU Zhenming. Recycling of non-metallic fractions from waste electrical and electronic equipment (WEEE): A review[J]. Waste Management, 2014, 34(8): 1455-1469.

[11] Nasdere B, Seliger G. Disassembly factories for electrical and electronic products to recover resources in product and material cycles[J]. Environmental Science & Technology, 2003, 37(23): 5354-5362.

[12] Veit H M, Diehl T R, Salami A P, et al. Utilization of magnetic and electrostatic separation in the recycling of printed circuit board scrap[J]. Waste Management & Research, 2005, 25(1): 67-74.

[13] 刘静欣, 田庆华, 程利振, 等. 低温碱性熔炼在有色冶金中的应用[J]. 金属材料与冶金工程, 2011, 39(6): 26-30.

LIU Jingxin, TIAN Qinghua, CHENG Lizhen,et al. Application of low temperature alkaline smelting in non-ferrous metallurgy[J]. Metal Materials and Metallurgy Engineering, 2011, 39(6): 26-30.

[14] 郭学益, 刘静欣, 田庆华. 废弃电路板多金属粉末低温碱性熔炼过程的元素行为[J]. 中国有色金属学报, 2013, 23(6): 1757-1763.

GUO Xueyi, LIU Jingxin, TIAN Qinghua. Elemental behavior of multi-component metal powders from waste printed circuit board during low-temperature alkaline smelting[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1757-1763.

[15] 程利振. 铜阳极泥分银渣综合回收新工艺研究[D]. 长沙: 中南大学冶金与环境学院, 2013: 50-51.

CHEN Lizhen. The novel process study on comprehensive recovery of silver separated residue from copper anode mud[D]. Changsha: Central South University. School of Metallurgy & Environment, 2013: 50-51.

[16] 刘清, 赵有才, 招国栋. 氢氧化钠浸出-两步沉淀法制备铅锌精矿新工艺[J]. 湿法冶金, 2010, 29(1): 32-36.

LIU Qing, ZHAO Youcai, ZHAO Guodong. A novel process for preparation of zinc and lead concentrates by alkaline leaching and precipitation[J]. Hydrometallurgy of Chinese, 2010, 29(1): 32-36.

[17] 谭宪章. 冶金废旧杂料回收金属实用技术[M]. 北京: 冶金工业出版社, 2010: 117-120.

TAN Xianzhang. Practical techniques on conversion of metals from metallurgical waste[M]. Beijing: Metallurgical Industry Press, 2010: 117-120.

[18] 谢兆凤. 火法-湿法联合工艺综合回收脆硫铅锑矿中有价金属的研究[D]. 长沙: 中南大学冶金与环境学院, 2011: 44-48.

XIE Zhaofeng. Recovery of valuable metals from jamesonite with united pyrometallurgical and hydrometallurgical process[D]. Changsha: Central South University. School of Metallurgy & Environment, 2011: 44-48.

[19] SUN Zhi, ZHANG Yi, ZHENG Shili, et al. A new method of potassium chromate production from chromite and KOH-KNO3-H2O binary submolten salt system[J]. AIChE Journal, 2009, 55(10): 2646-2656.

[20] WANG Shaona, ZHENG Shili, ZHANG Yi. Stability of 3CaO·Al2O3·6H2O in KOH+K2CO3+H2O system for chromate production[J]. Hydrometallurgy, 2008, 90(2): 201-206.

[21] 贾希俊. 氧化锌矿物碱法提取新工艺[D]. 长沙: 中南大学冶金与环境学院, 2009: 38-41.

JIA Xijun. The recovery of zinc oxide ore by the new process of alkaline leaching[D]. Changsha: Central South University. School of Metallurgy & Environment, 2009: 38-41.

(编辑 罗金花)

收稿日期:2014-09-24;修回日期:2014-11-26

基金项目(Foundation item):国家自然科学基金重点资助项目(51234009);广东省产学研项目(2013A100003);科技部国际合作项目(2014DFA90520)(Project (51234009) supported by the Key Program of the National Natural Science Foundation of China; Project (2013A100003) supported by the Production, Teaching and Research Program of Guangdong Province; Project (2014DFA90520) supported by the International Cooperation Projects of the Ministry of Science and Technology)

通信作者:郭学益,博士,教授,从事难冶有色金属提取、资源循环利用及环境材料制备研究;E-mail:xyguo@csu.edu.cn