DOI: 10.11817/j.issn.1672-7207.2017.10.011

微透镜阵列注射压缩成型的残余应力

孙磊磊,蒋炳炎,陈磊,蒋丰泽

(中南大学 机电工程学院,高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:利用Autodesk Moldflow Insight软件,通过正交实验仿真分析熔体温度、模具温度、压缩速度、压缩距离、压缩压力和压缩延迟时间这6个因素的工艺特性,并进行极差分析。按照压缩框主轴压缩的方式制作注射压缩模具,采用单因素实验设计研究熔体温度、模具温度、压缩速度这3个主要因素的工艺特性,运用应力-光学定律,根据测量所得光程差间接得到平均残余应力。研究结果表明:模具温度对残余应力的影响最大,其次是压缩延迟时间和熔体温度;残余应力随模具温度的升高而降低,随熔体温度的升高先减小后增大,随压缩延迟时间的增加而上升。

关键词:微透镜阵列;注射压缩成型;残余应力

中图分类号:TQ320.63 文献标志码:A 文章编号:1672-7207(2017)10-2635-06

Residual force of microlens array by injection compression molding

SUN Leilei, JIANG Bingyan, CHEN Lei, JIANG Fengze

(State Key Laboratory of High Performance Complex Manufacturing,School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: Melt temperature, mold temperature, compression speed, compression distance, compression pressure and compression delay time were studied to simulate the process properties by the orthogonal experimental design using the Autodesk Moldflow Insight software. Range analysis was conducted, and the injection compression mold was designed using the compression frame driven by spindle to experimentally study the effect of the melt temperature, mold temperature and compression speed on the residual force of microlens array (MLA).Injection compression experiments were made with single factor experiment method. Stress-optic law was used to switch the optical path difference on residual stress. The results show that mold temperature is more significant than any other parameters, followed by compression delay time and melt temperature. With the increase of mold temperature, the residual stress of the microlens array tends to decrease. The residual stress decreases at first and increases later with the increase of melt temperature. The residual stress increases with the increase of compression delay time.

Key words: microlens array; injection compression molding; residual force

微透镜阵列是微光学系统中重要的光学元件之一,在光学领域中的应用日益广泛[1-5]。微透镜阵列的成型材料有石英和聚合物,传统石英材料多采用热压成型,成型精度高,制件质量好,但生产效率低;当前聚合物微透镜阵列多采用注射成型时,生产效率高,但制件几何尺寸和光学性能较差[6-7]。注射压缩成型是传统注射成型的一种高级形式,是综合注射成型和热压成型形成的新工艺,兼有热压成型几何精度高、内应力小和注射成型生产周期短、成本低等的优势,可以实现廉价、高效、批量生产,是成型高质量微透镜阵列最有前景的方法[8-10]。残余应力是聚合物光学元件的关键指标,直接影响着微透镜阵列的成像质量和光学性能[11-12]。MICHAELI[13]通过研究发现注射压缩成型高分子透镜在尺寸精度和光学质量上相比注射成型得到的透镜质量更好。KIM等[14]通过仿真研究注压成型光盘基板,结果表明注射压缩成型得到的基板双折射比注射成型的双折射小,增大保压压力会使双折射增大,增大熔体温度可以降低双折射。李沙[15]通过观察干涉条纹,研究了在注射压缩成型和注射成型制品上的双折射现象,发现注射压缩成型制品的双折射较注射成型更小且分布更均匀。现有研究只是对残余应力进行定性分析,本文作者通过正交实验仿真得出注射压缩成型中的关键工艺参数,再通过单因素方法研究这些关键参数对制件残余应力的定量影响。

1 注射压缩成型数值仿真

注射压缩成型与注射成型相比,具有注射压力低、分子取向小的优点,因此,可以不考虑制件的流动残余应力,制件的残余应力由热残余应力决定。采用Moldflow Insight/Injection Compression 软件计算残余应力时,使用基于热应力和压缩压力诱导的残余应力分布的数学模型:

(1)

(1)

式中:σij为应力张量;Cijkl为材料机械性能张量;Bij为材料热性能张量;t为时间;T为热力学温度; εkl为热膨胀系数张量;ξ(t)为材料温度随时间的变化函数,

εkl为热膨胀系数张量;ξ(t)为材料温度随时间的变化函数,

(2)

(2)

aT为温度与时间的转化因子。

1.1 有限元模型及正交实验设计

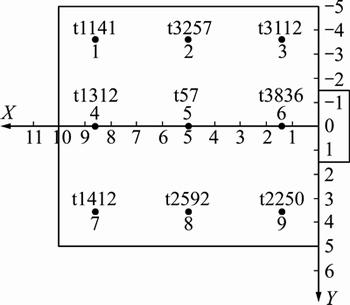

采用模流分析软件Moldflow进行注射压缩成型工艺仿真及产品残余应力研究。利用Pro/E软件建立平凸型微透镜阵列的基板物理模型,其长×宽×高为10.0 mm×10.0 mm×0.8 mm。导入Autodesk Moldflow Insight 2010软件,对微透镜阵列进行注射压缩分析。型腔布局方式为1模2腔,选用圆形浇口,采用中性面(Midplane)进行网格划分,三角形单元的边长为0.2 mm,共8 950个单元,单元平均纵横比为1.44。微透镜阵列基板的Moldflow网格模型如图1所示。

图1 微透镜阵列Moldflow网格模型

Fig. 1 Moldflow grid models of microlens array

采用正交实验设计,使用L18(37)正交表,研究不同工艺参数组合对制件残余应力的影响,工艺参数水平如表1所示。

注射压缩成型制品的残余应力会随位置的变化而变化。为了全面分析注射压缩制品的残余应力变化情况,每个制件选9个点,各取值点对应的单元编号为t1141,t325,t311,t1312,t57, t3836,t141,t2592和t2250,其坐标位置如图2所示。图3所示为微透镜阵列结构尺寸。

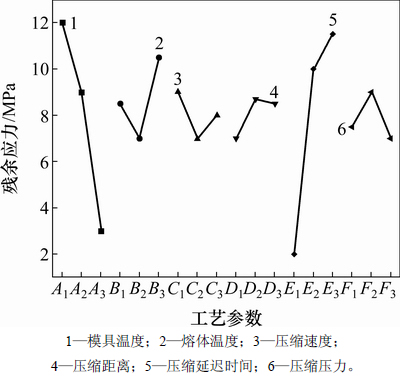

1.2 仿真结果分析

常用极差分析法对正交试验结果进行分析,比较不同因素对实验指标的影响力,计算结果如表2所示。注射压缩成型参数对残余应力的影响如图4所示。上述6个因素中,模具温度A对微透镜阵列表面残余应力的影响最大,其极差为8.665;压缩延迟时间E的影响次之,熔体温度B排的影响最小;其余3个因数D,C和F对残余应力的影响较小,影响由大至小依次为A,E,B,D,C和F。制件残余应力随着模具温度的增大而减小,随压缩延迟时间的增加而迅速增大;随着熔体温度、压缩速度的增大先减小后增大,存在1个极小值;随压缩压力、压缩距离的增大先增大后减小,存在1个极大值。

表1 注射压缩成型工艺参数水平

Table 1 Levels of process parameters of ICM

表2 注射压缩成型6因素极差

Table 2 Range value of six factors in ICM

图2 残余应力测试取点位置图

Fig. 2 Location of residual force test

图3 微透镜阵列结构尺寸

Fig. 3 Structure and dimensions of microlens array

图4 注射压缩成型参数对残余应力的影响

Fig. 4 Influence of parameters on residual stress in ICM

2 微透镜阵列注射压缩成型实验研究

2.1 实验材料与设备

选用聚甲基丙烯酸甲酯(PMMA)为微透镜阵列材料,牌号为EVONIK PLEXIGLAS 8N,与仿真所用材料相同,主要性能参数如表3所示。采用配备注射压缩功能模块的德国雅宝公司注塑成型机,型号为ARBURG 370S。

自行设计制作注射压缩成型实验模具,选用压缩框形式、二级顶杆顶出、主轴压缩等功能,有效解决了压缩及顶出的协调性问题,其关键结构如图5所示。初次合模后,动模板7与定模板8之间有一微小间隙,动模镶块5与定模镶块6在矩形弹簧4的作用下紧密贴合在一起,贴合面为模具的分型面;然后,进行塑料熔体注射,矩形弹簧提供足够锁模力;注射完毕后,动模部分在主轴的推力下整体向前移动1 mm的压缩距离,顶杆2也相应前移,完成2次合模;最后,制件被顶出,在顶杆1,2和3作用下将制件顶出。二级顶杆的设计有效避免了流道内的聚合物被压缩,保证了充填计量的准确性。

表3 PMMA材料基本参数

Table 3 Basic properties of PMMA

图5 模具压缩顶出结构

Fig. 5 Compression and ejection structure of mold

2.2 单因素实验方案

参考微透镜阵列注射压缩成型仿真结果和前人研究结果,选定模具温度、熔体温度和压缩延迟时间等6个工艺参数作为研究对象,采用单因素实验方法研究各工艺参数对微透镜阵列残余应力的影响规律,根据注塑机压缩模块参数范围和初期工艺调试情况,设定各工艺参数的水平,如表4所示。

2.3 残余应力检测仪器与原理

为实现微透镜阵列残余应力检测,采用MoticBA300Pol型偏光显微镜检测仪器。其主要性能参数如下:放大倍数为600倍;检偏镜旋转角度精度为0.2°;载物台旋转角度精度为0.1°;单色光波长为589 nm;光程差测量精度为0.65 nm。

表4 因素试验水平

Table 4 Experiment levels of factors

运用应力光学定律,根据制件某点2个主应力方向上折射率的差值,由式(3)计算光程差,再由式(4)间接得到制件的残余应力:

(3)

(3)

(4)

(4)

式中:△n为折射率差;δ为光程差;h为投影件厚度;σR为残余应力;k为材料系数。

3 实验结果分析

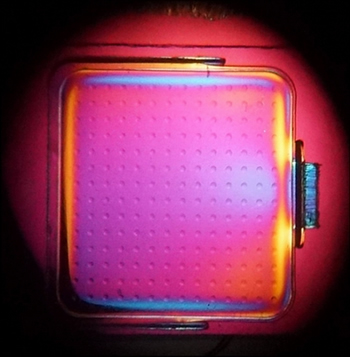

将工艺参数设为基准水平,即模具温度为80 ℃,熔体温度为240 ℃,压缩延迟时间为1 s。其他参数恒定,如压缩压力为350 kN,压缩速度为6 mm/s,压缩距离为0.6 mm,在该基准参数下得到样件光弹图如图6所示。

3.1 模具温度

模具温度对带微结构零件的成型质量有较大影响,其他参数不变,模具温度从60,70,90和100 ℃依次变化进行实验,得到模具温度对残余应力的影响如图7所示。

图6 基准参数下的光弹图

Fig. 6 Photoelastic picture under criterion parameters

从图7可见:随着模具温度上升,微透镜阵列残余应力呈现降低趋势,在60~70 ℃时尤为显著,由60 ℃时的14.5 MPa下降为100 ℃时的11.8 MPa。模具温度升高,利于聚合物熔体充填,分子取向减小;较高模具温度使型腔表面的冷凝层变薄,熔体冷却凝固时间加长,更加充分地释放制件表面的内应力,这些都使微透镜阵列制件残余应力降低。

图7 模具温度对残余应力的影响

Fig. 7 Effect of mold temperature on residual force

3.2 熔体温度

熔体温度将直接影响PMMA熔体的流动性能和冷却凝固时间。其他参数不变,熔体温度从220,230,250和260 ℃依次变化进行实验,得到不同熔体温度下的光弹图如图8所示。

从图8可见:当熔体温度为220 ℃时,熔体黏度过高,无法成型制件,故无法检测其光弹图;随着熔体温度升高,微透镜阵列的残余应力先减小后增大,由230 ℃时的13.1 MPa下降到250 ℃的10.8 MPa,再增加至260 ℃时的17.8 MPa; 当熔体温度升高后,聚合物熔体的流动性加强,制件更易充填,流动残余应力较小;随着熔体温度进一步升高,超过250 ℃后,熔体的高温导致浇口不能冷凝完全,在压缩过程中产生熔体从浇口回流的现象,造成制件内部密度分布不均匀,微透镜阵列残余应力增加。因此,在微透镜阵列注射压缩过程中,不宜采用过高的熔体温度。

图8 熔体温度对残余应力的影响

Fig. 8 Effect of melt temperature on residual force

3.3 压缩延迟时间

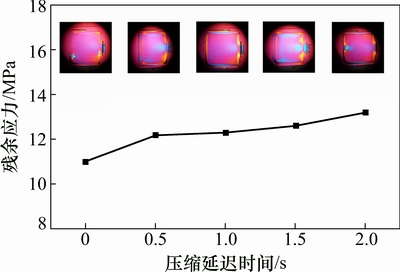

压缩延迟时间直接影响PMMA熔体的冷凝层厚度。其他参数不变,压缩延迟时间从0,0.5,1.5和2.0 s依次变化进行实验,得到不同压缩延迟时间与残余应力的关系,如图9所示。

从图9可见:随着压缩延迟时间增加,微透镜阵列的残余应力呈逐渐上升的趋势,由0 s时的11 MPa增加至2 s时的13.6 MPa; 压缩延迟时间增加,型腔界面的冷凝层厚度也随之增加,因此,在二次压缩过程中,型腔内压缩机构对接近冷凝熔体的挤压影响了应力的平衡分布,残余应力也相应增大。

图9 压缩延迟时间对残余应力的影响

Fig. 9 Effect of compression delay time on residual force

4 结论

1) 仿真得到各工艺参数对微透镜阵列残余应力的影响力,其中模具温度、压缩延迟时间、熔体温度对制件残余应力的变化起主要作用。

2) 采用单因素实验研究了3个主要参数对微透镜阵列残余应力的影响规律,与仿真所得规律相符,即残余应力随模具温度的升高而降低,随熔体温度升高先减小后增大,随压缩延迟时间的增长而变大。

参考文献:

[1] NAGATO K, HAMAGUCHI T, NAKAO M. Injection compression molding of high-aspect-ratio nanostructures[J]. Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures, 2011, 29(6): 6F-10F.

[2] LEE B K, KIM D S, KWON T H. Replication of microlens arrays by injection molding[J]. Microsystem Technologies, 2004, 10(6/7): 531-535.

[3] 齐斌, 朱建毅, 尹清珍. 光盘注射压缩模设计[J]. 模具工业, 2010, 36(7): 46-48.

QI Bin, ZHU Jianyi, YIN Qingzhen. Design of CD injection compression mold[J]. Die & Mold Industry, 2010, 36(7): 46-48.

[4] 费春红, 张长春, 李达, 等. 塑料光学制件精密成型技术的现状[J]. 橡塑技术与装备, 2004, 30(11): 11-16.

FEI Chunhong, ZHANG Changchun, LI Da, et al. Current situation of plastic optical component precision molding technology[J]. China Rubber/Plastics Technology & Equipment, 2004, 30(11): 11-16.

[5] 蒋丰泽, 刘义伦, 陈磊, 等. 工艺参数对注射压缩成型微透镜阵列基板双折射率的影响[J]. 中南大学学报(自然科学版), 2014, 45(8): 2610-2616.

JIANG Fengze, LIU Yilun, CHEN Lei, et al. Effects of compression parameters on birefringence of injection compression molded microlens array substrate[J]. Journal of Central South University (Science and Technology), 2014, 45(8): 2610-2616.

[6] SHEN Y K. A novel fabrication method for mold insert of injection molded microlens array[C]//Materials Science Forum. Switzerland: Trans Tech Publication Ltd, 2006: 665-668.

[7] CHEN L, KIRCHBERG S, JIANG B Y, et al. Fabrication of long-focal-length plano-convex microlens array by combining the micro-milling and injection molding processes[J]. Appl Opt, 2014,53(31): 7369-7380.

[8] 李沙, 黄汉雄. 注射-压缩精密成型制品收缩率均匀度的研究[J]. 塑料, 2007, 36(5): 54-58.

LI Sha, HUANG Hanxiong. Shrinkage uniformity of injection-compression molded part[J]. Plastics, 2007, 36(5): 54-58.

[9] 陈燕春, 何文翰, 区仲荣. 注射压缩成型技术在塑料光学透镜生产中的应用[J]. 模具技术, 2010(2): 159-161.

CHEN Yanchun, HE Wenhan, QU Zhongrong. The application of injection compression shaping technology in the production of plastic opticas lens[J]. Moulds & Dies, 2010(2): 159-161.

[10] 戴亚春, 董芳. 注射压缩成型新方法[J]. 模具工业, 2006, 32(3): 53-56.

DAI Yachun, DONG Fang. New method of injection and compression molding[J]. Die & Mold Industry, 2006, 32(3): 53-56.

[11] 邱庆军, 蒋炳炎, 陈磊, 等. 薄壁塑件注射压缩成型热残余应力仿真研究[J]. 塑料工业, 2012, 40(7): 35-39.

QIU Qingjun, JIANG Bingyan, CHEN Lei, et al. Study on thermal residual stress of injection compression molded thin-walled plastic part by simulation[J]. China Plastics Industry, 2012, 40(7): 35-39.

[12] 蒋丰泽. 微透镜阵列注射压缩工艺与模具技术研究[D]. 长沙: 中南大学机电工程学院, 2014: 42-60.

JIANG Fengze. Research on parameters and mold technology of microlens array by injection compression molding[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2014: 42-60.

[13] MICHAELI W. Injection-compression moulding of high precision optical lenses[C]//4M/ICOMM 2009. Kahsruhe, Germany: the Global Conference on Micro Manufacture, 2009: 407-410.

[14] KIM I H, PARK S J, CHUNG S T, et al. Numerical modeling of injection/compression molding for center-gated disk: Part II.Effect of compression stage[J]. Polym Eng Sci, 1999, 39(10): 1943-1951.

[15] 李沙. 注射-压缩成型的制品收缩率均匀度以及双折射与可视化研究[D]. 广州: 华南理工大学机电工程学院, 2007: 53-59.

LI Sha. The study of shrinkage rate uniformity and birefringence and visualization in injection compression molding[D]. Guangzhou: South China University of Technology. School of Mechanical and Electrical Engineering, 2007: 53-59.

(编辑 陈灿华)

收稿日期:2016-10-07;修回日期:2016-12-08

基金项目(Foundation item):国家重点基础研究发展计划(973计划)项目(2012CB025905)(Project(2012CB025905) supported by the National Basic Research Development Program (973 Program) of China)

通信作者:蒋炳炎,博士,教授,从事高分子材料精密成型技术研究;E-mail:jby@csu.edu.cn