文章编号:1004-0609(2010)01-0137-06

Ni-Cr合金真空钎焊金刚石的碳化物生长及位向关系

卢金斌1, 2,席艳君1,王志新1

(1. 中原工学院 材料与化工学院,郑州 450007;

2. 南京航空航天大学 机电学院,南京 210016 )

摘 要:采用Ni-Cr合金在不同温度下进行钎焊单晶金刚石磨粒试验,使用SEM、EDS和XRD对Ni-Cr合金钎焊金刚石的碳化物生长及形貌进行分析。结果表明:真空钎焊过程中,在Ni-Cr合金完全熔化前,在合金前端有碳化物开始形核,并生成排列整齐的Cr3C2和无序的SiC,Cr3C2的生长方向与金刚石的外露晶面有一定的位向关系;合金完全熔化后,在金刚石表面生成两层碳化物,内层为排列整齐的Cr3C2,外层为无序的Cr7C3。

关键词:真空钎焊;金刚石;碳化物;位向关系;晶面

中图分类号:TG401 文献标识码:A

Carbide growth and orientation relationship of vacuum brazing diamond with Ni-Cr alloy

LU Jin-bin1, 2, XI Yan-jun1, WANG Zhi-xin1

(1. School of Materials and Chemical Engineering, Zhongyuan University of Technology, Zhengzhou 450007, China;

2. College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics,

Nanjing 210016, China)

Abstract: In the experiments on vacuum brazing diamond with Ni-Cr alloy at different temperatures, the morphology and growth of carbide that was formed on the diamond surface were observed with scanning electron microscope(SEM) and the components were analyzed with energy dispersion spectroscope(EDS). The results show that during vacuum brazing, before Ni-Cr alloy is not melted completely, some carbides begin to nucleate in the front of the filler, and then form good order Cr3C2 and disorder SiC until the filler melts. There is a certain orientation relationship between the growth of Cr3C2 and the diamond crystal plane. After the filler is melted, two layers of carbide are formed on the diamond surface, the inner layer is order Cr3C2, and the outer layer is disorder Cr7C3.

Key words: vacuum brazing; diamond; carbide; orientation relationship; crystal plane

钎焊金刚石工具因具有高的连接强度、高的出刃而引起业内专家极大的兴趣。钎焊法制作的单层金刚石工具能够通过钎料与金刚石化学冶金结合而获得很高的结合强度,避免出现传统砂轮在重负荷磨削加工中磨料极易从结合层整颗脱落的现象,使得这种钎焊金刚石单层工具更具竞争力[1?3]。

由于金刚石与一般金属有很高的界面能,因此钎焊中常采用活性钎料进行钎焊,其中包括含Cr、Ti等活性元素的Ag、Cu、Ni基等钎料。实际应用中由于石材、陶瓷等硬度很高,为提高连接层的耐磨性和连接强度,制作单层钎焊金刚石工具多采用Ni-Cr钎料,其活性元素为Cr,钎焊方法主要有真空钎焊、 保护气氛钎焊、感应钎焊、激光钎焊等方法。研究表明[3?6],Ni-Cr钎料真空钎焊金刚石的工艺、界面微结构、碳化物形貌、数量等研究已较多,而研究金刚石钎焊过程中碳化物如何长大,尤其是钎料前端碳化物的形成及碳化物与金刚石的晶面是否有位向关系未见提及[1?7]。KHALID等[8]采用Cu-Sn-Ti钎料对金刚石 进行钎焊,发现TiC与金刚石晶面有一定的关系。此外,NOMURA等[9?10]和林国标[11]等在研究Ag-Cu-Ti钎焊SiC、Si3N4时发现在钎料的前端有碳化物生成。本文作者在研究处于不同温度下Ni-Cr活性钎料与金刚石的界面反应行为时发现,钎料未完全熔化前,在钎料铺展前端就开始有Cr3C2生成,该碳化物在金刚石(100)和(111)晶面的生长方向有所不同,并形成了有序的碳化物形貌,这对研究活性钎料的润湿机理、提高连接强度等具有重要的意义,且对于制造金刚石工具有一定的现实意义。

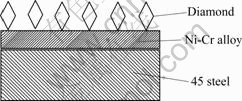

1 实验

试验选用GB/T6405?94标准300~420 μm金刚石,基体选45钢,钎料为Ni-Cr合金粉,真空度<0.01 Pa;在VOQ2?80型真空淬火炉中进行铺展和钎焊试验。工艺过程为:钎焊前对45钢基体、金刚石表面用丙酮清洗,然后再浸泡在丙酮中用超声波清洗5 min,吹干。将Ni-Cr合金置于钢基体表面,在Ni-Cr合金上布置金刚石磨粒(见图1),分别加热至900、920、 1 020、1 050 ℃,保温适宜时间,自然冷却至100 ℃,取出。

图1 Ni-Cr合金钎焊金刚石接头示意图

Fig.1 Schematic diagram for joint framework of brazing diamond with Ni-Cr alloy

腐蚀方法:对焊后的部分金刚石试样进行深腐蚀。由于金刚石、铬的碳化物、石墨都耐腐蚀,基体与钎料被腐蚀去除,仅剩下金刚石与表面生成的碳化物。该试样不仅可以用扫描电镜直接观察金刚石表面三维碳化物的形貌,而且进行X射线衍射分析可以准确确定金刚石表面生成碳化物的相组成。

测试方法:用日本电子公司(JEOL)JSM?6300型扫描电镜(SEM)及美国KEVEX公司的X射线能谱仪(EDS)对焊后金刚石表面形貌进行观察及成分分析。用日本Shimadzu公司的XD?3A型X射线衍射仪在Cu靶、电压40 kV,电流30 mA的条件下,作X射线衍射结构分析。

2 结果与分析

2.1 钎料前端碳化物分析及位向关系

金刚石是面心立方结构,常见的晶体多为生长形态,晶体显露的面多为(111)和(100)晶面,并组成立方?八面体。其中,(111)面上相邻原子间距为0.252 nm,(100)面上相邻原子间距为0.356 nm[12]。

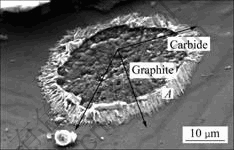

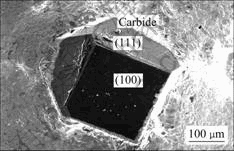

为了研究金刚石表面碳化物的生长,在钎料尚未完全熔化前(900 ℃)观察金刚石表面,结果如图2所示。从图2可以看出,金刚石的晶体形态为立方?八面体,其中四边形面为(100)面,六边形面为(111)面,钎料在900 ℃时未熔化形状为大小不一的球形,并且在金刚石的(111)和(100)晶面上由于钎料球脱落留下一个个圆的痕迹。图3所示为钎料与金刚石(111)晶面的放大图。从图3可以看出,在钎料与金刚石接触区的中心形成了石墨,这是由于Ni是石墨化元素,因此在接触区促使金刚石向石墨转化;而在钎料的前沿有

图2 钎料球与金刚石表面接触区

Fig.2 Contact zone between filler and diamond

图3 金刚石表面(111)晶面的碳化物形貌

Fig.3 Carbide morphology of (111) plane on diamond surface

大约4~5 μm的针状化合物,并且化合物沿3个方向生长,其正好与金刚石(111)面的六边形的边平行(如图3中的3个箭头所示),其在金刚石上的实际浸润角为0?。

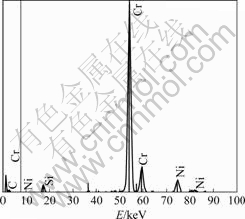

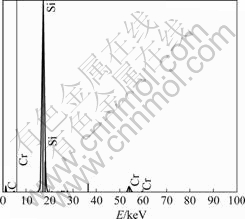

对钎料前端的针状化合物(见图3中A处)进行能谱测试,结果如图4所示。化合物的成分为(摩尔分数)C:45.10%;Cr:53.62%;Si:0.03%;Ni:1.24%,可以判断针状化合物为Cr的碳化物,根据摩尔比初步推断为Cr3C2。由于碳化物Cr3C2是斜方晶系,其晶胞形状为:a≠b≠c,α=β=γ=90?[13],故从晶体形态可进一步判断该碳化物为Cr3C2。进而可以推断在钎料尚未完全熔化前,金刚石与钎料中的液态部分就开始反应生成碳化物,其碳化物的C原子由金刚石表面的C及溶解在Ni中的活性C原子提供,活性Cr原子由钎料提供。通过化学反应:C+2/3Cr=1/2Cr3C2,其?Gm= ?10 500?0.3T[4],?Gm<0,说明该碳化物可以生成,并考虑到金刚石表面的C原子较多,而Cr原子是一定的,从热力学角度看生成的Cr3C2是稳定的。该碳化物晶体的生长是由于C原子吸引使得活性Cr原子远距离扩散,并与C原子结合形成。同时,在金刚石的局部区域发现如图5所示的絮状化合物(见图5中A处),对其进行能谱测试,结果如图6所示。化合物的成份(摩尔分数)为C:46.21%;Si:50.51%;Cr:3.28%,可以判断该化合物为SiC。Ni-Cr钎料中含有一定的Si元素,其化学反应方程式为C+Si=SiC,其?Gm=?26 700+2.0T[4],?Gm<0,因此在局部能够生成SiC,而SiC与金刚石的结构相似,可看成是将半数的C原子换成了Si原子,SiC的生成可以起到减小金刚石与碳化物之间晶格失配和应力的重要作用。

图4 Cr3C2的EDS能谱

Fig.4 EDS pattern of Cr3C2

图5 金刚石表面的SiC形貌

Fig.5 Morphology of SiC on diamond surface

图6 SiC的EDS能谱

Fig.6 EDS pattern of SiC

图7所示为金刚石在1 050 ℃钎焊后的形貌。 由图7可以看出,焊后金刚石形貌完好,在金刚石与钎料界面处,一些排列整齐的碳化物沿金刚石晶面生长。金刚石(111)晶面上的碳化物的形貌如图8所示。由图8可以看出,碳化物均沿着3个固定的方向生长,并且平行于(111)晶面六边形的边,但碳化物的尺寸明显增大。由于在真空炉中加热或冷却速度很慢,温度梯度很小,因此不是因温度梯度的原因导致其碳化物沿某些方向生长。分析认为这与单晶金刚石基体(111)晶面上的原子排列有关。(111)晶面上的原子排列如 图9所示。由图9可以看出,(111)晶面原子排列最紧密的方向正好是3个,Cr3C2的Cr、C原子间距为2.027~2.307 nm,与金刚石(111)晶面的原子间距较接近,从而可以判断Cr3C2在金刚石(111)面生长时,Cr3C2首先以现成的单晶金刚石基体为形核核心,从而以科塞尔?斯特兰斯基的生长模型进行生长,同时由于单晶的金刚石表面(111)原子排列有序,共有3个择优方向,最后长成如图8所示的碳化物分布形式。这与Ag-Cu-Ti钎焊金刚石表面生成的TiC类似,也是沿某个方向生长[14?15]。

图7 焊后金刚石的形貌

Fig.7 Morphology of diamond after being brazed

图8 金刚石表面分布规则的碳化物

Fig.8 Carbide of diamond surface

图9 金刚石(111)晶面的原子排列[12]

Fig.9 Atomic arrangement of diamond crystal plane (111)[12]

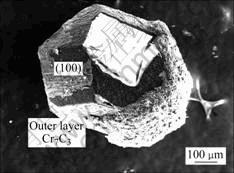

为了解金刚石(100)晶面的碳化物生长情况,观察如图10所示的深腐蚀后的金刚石,可以发现碳化物分为两层,内层为有序的Cr3C2,外层为针状的化合物。外露的呈四边形的面为(100)晶而,可以清晰发现其碳化物的生长主要沿四边形的边生长,少量沿对角线方向生长。分析认为,这与(100)晶面的原子排列有关,其(100)晶面的原子排列如图11所示。从图11可以看出,金刚石(100)原子排列的方向为<100>,因此碳化物沿<100>择优生长。

图10 金刚石(100)晶面的碳化物形貌

Fig.10 Morphology of carbide in diamond crystal plane (100)

图11 金刚石(100)晶面的原子排列[12]

Fig.11 Atomic arrangement of diamond crystal plane (100)[12]

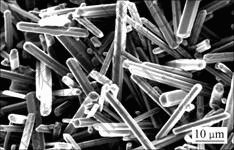

为了进一步研究碳化物的生长方向及焊后碳化物的形貌,对焊后的金刚石进行深腐蚀并进行适当处理,使里层的碳化物显露出来,其SEM像如图12所示。由图12可以看出,尽管部分碳化物脱落,金刚石(111)面的碳化物Cr3C2沿金刚石(111)面的六边形的边在生长,这与前面的分析基本符合。从图10可以看出,金刚石表面的碳化物实际分为两层,对外层的针状化合物进行能谱测试,各元素的摩尔分数为Cr61.24%,C33.53%,Ni5.23%。Cr与C的摩尔比大约为7?3。由此判断外层的碳化物为Cr7C3,而Cr7C3是六方晶系,a=b≠c,α=β=90?,γ=120?,其分布与形状如图13所示。从图13可以看出,碳化物呈六边形的棱柱,这与其晶体形态相符合,但分布却明显无序,这主要是因为Cr7C3的C原子主要来源于金刚石溶于钎料的C与Cr反应,生成的Cr7C3紧紧围绕在Cr3C2的外面。关于Cr7C3的确证及形成参见文献[4]。

图12 焊后金刚石的形貌

Fig.12 Morphology of diamond after being brazed

图13 焊后金刚石表面碳化物的形貌

Fig.13 Morphology of carbide on surface of brazed diamond

2.2 XRD分析

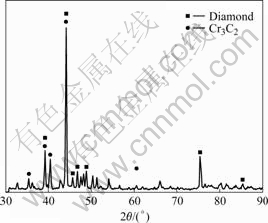

为了确证金刚石表面生成Cr3C2,采用微粉金刚石在920 ℃与钎料进行混合,促使表面生成更多的碳化物,对焊后的微粉金刚石深腐蚀后进行X射线衍射,其XRD谱如图14所示。因为经过深腐蚀后金刚石表面仅有金刚石与碳化物,有助于判断表面的碳化物类型,通过PDF卡片对比分析表明金刚石表面确实有Cr3C2衍射峰存在,从而确证生成了Cr3C2。

图14 金刚石及碳化物的XRD谱

Fig.14 XRD pattern of diamond and carbide

3 结论

1) Ni-Cr合金钎焊金刚石在合金熔化前,碳化物Cr3C2就开始在合金前端开始形成,这有助于提高镍基钎料的润湿性。

2) Ni-Cr合金钎焊金刚石生成的碳化物Cr3C2不仅排列有序,而且其生长方向与所在晶面有关,其中(111)晶面的Cr3C2生长方向共有3个,分别平行于所在晶面六边形的边,而(100)晶面的碳化物生长方向 主要平行于所在晶面四边形的边,显示出一定的各向异性。

3) Ni-Cr合金钎焊金刚石生成的碳化物主要分为两层,即最底层的Cr3C2,外层的Cr7C3,其中Cr3C2与金刚石的晶面有位向关系,而Cr7C3的生长方向是无序的。

REFERENCES

[1] CHATTOPADHYAY A K, CHOLLET L, HINTERMANN H E. On performance of brazed bonded mono layer diamond grinding wheel[J]. Annals of the CIRP, 1991, 40(1): 347?350.

[2] SUNG C M. Brazed diamond grid: a revolutionary design for diamond saws[J]. Diamond and Related Materials, 1999, 8: 1540?1543.

[3] 武志斌, 徐鸿钧, 姚正军, 肖 冰. 钎焊单层金刚石砂轮的现存问题及其对策[J]. 焊接学报, 2001, 22(3): 38?40.

WU Zhi-bin, XU Hong-jun, YAO Zheng-jun, XIAO Bing. Difficult problems and its countermeasures of brazed bonded monolayer diamond grinding wheel[J]. Transactions of the China Welding Institution, 2001, 22(3): 38?40.

[4] 卢金斌, 徐九华, 徐鸿钧, 傅玉灿, 姜澄宇. Ni-Cr合金真空钎焊金刚石界面反应的热力学与动力学分析[J]. 焊接学报, 2004, 25(1): 21?24.

LU Jin-bin, XU Jiu-hua, XU Hong-jun, FU Yu-can, JIANG Cheng-yu. Thermodynamic studies on interfacial reactions between diamond and Ni-Cr filler metal in vacuum brazing[J]. Transactions of the China Welding Institution, 2004, 25(1): 21?24.

[5] 陈建毅, 黄 辉, 徐西鹏. 钎焊超硬磨料工具的研究进展[J]. 工具技术, 2007, 41(2): 9?14.

CHEN Jian-yi, HUANG Hui, XU Xi-pen. Progress of study on brazed superabrasive tools[J]. Tool Engineering, 2007, 41(2): 9?14.

[6] 卢金斌, 穆云超. Ni-Cr合金钎焊镀钛金刚石的研究[J]. 金刚石与磨料磨具工程, 2006(6): 19?21.

LU Jin-bin, MU Yun-chao. Study on brazing of Ti-coated diamond with Ni-Cr filler[J]. Diamond & Abrasives Engineering, 2006(6): 19?21.

[7] KLOTZ U E, KHALID F A, ELSENER H R. Nanocrystalline phases and epitaxial interface reactions during brazing of diamond grits with silver based Incusil-ABA alloy[J]. Diamond and Related Materials, 2006, 15: 1520?1524.

[8] KHALID F A, KLOTZ U E, ELSENER H R, ZIGERLIG B, GASSER P. On the interfacial nanostructure of brazed diamond grits[J]. Scripta Materialia, 2004, 50: 1139?1143.

[9] NOMURA M, ICHIMORI T, IWAMOTO C. Structure of wetting front in the Ag-Cu-Ti/SiC reactive system[J]. Journal of Materials Science, 2000, 35: 3953?3958.

[10] NOMURA M, IWAMOTO C, TANAKA S I. Nanostructure of wetting triple line in a Ag-Cu-Ti/Si3N4 reactive system[J]. Acta Materialia, 1999, 47: 407?413.

[11] 林国标, 黄继华, 张建纲, 刘慧渊, 毛建英, 李海刚. Ag-Cu-Ti-(Ti+C)反应-复合钎焊SiC陶瓷和Ti合金的接头组织[J]. 中国有色金属学报, 2005, 15(9): 1326?1331.

LIN Guo-biao, HUANG Ji-hua, ZHANG Jian-gang, LIU Hui-yuan, MAO Jian-ying, LI Hai-gang. Microstructure of reactive composite brazing joints of SiC ceramics and Ti alloy by using Ag-Cu-Ti-(Ti+C) as bonding material[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(9): 1326?1331.

[12] 王秦生. 超硬材料及制品[M]. 郑州: 郑州大学出版社, 2006: 24?38.

WANG Qin-sheng. Superhard materials and tools[M]. Zhengzhou: Zhengzhou University Press, 2006: 24?38.

[13] 虞觉奇, 易文质, 陈邦迪, 陈宏鉴. 二元合金状态图集[M]. 上海: 上海科学技术出版社, 1984: 574.

YU Jue-qi, YI Wen-zhi, CHEN Bang-di, CHEN Hong-jian. Handbooks of binary alloy phase diagrams[M]. Shanghai: Shanghai Scientific Press, 1984: 574.

[14] 卢金斌, 徐九华. Ag-Cu-Ti钎料钎焊金刚石的界面微观组织分析[J]. 焊接学报, 2007, 28(8): 29?33.

LU Jin-bin, XU Jiu-hua. Microstructure of interface between Ag-Cu-Ti brazing filler metal and diamond[J]. Transactions of the China Welding Institution, 2007, 28: 29?33.

[15] 卢金斌, 徐九华. 真空钎焊金刚石界面碳化物的形貌[J]. 中国有色金属学报, 2007, 17(7): 1143?1148.

LU Jin-bin, XU Jiu-hua. Morphology of carbide on diamond interface by vacuum brazing[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1143?1148.

基金项目:国家自然科学基金资助项目(50175052),江苏省自然科学基金资助项目(BK20001049)

收稿日期:2009-04-13;修订日期:2009-06-11

通信作者:卢金斌,副教授,博士;电话:13938483493;E-mail:ljbjohn@163.com

(编辑 李向群)