Trans. Nonferrous Met. Soc. China 20(2010) s1042-s1047

Semi-solid moulding: Competition to cast and machine from forging in making automotive complex components

Q. ZHU1, S. P. MIDSON2

1. Cummins Turbo Technologies Limited, St. Andrew’s Road, Huddersfield, HD1 6RA, UK;

2. Aluminium Complex Components Inc, 2211 South Jason Street, Denver, Colorado 80223, USA

Received 13 May 2010; accepted 25 June 2010

Abstract:The very latest technique for impeller manufacture is called semi-solid moulding (SSM). Cummins Turbo Technologies Limited, together with Aluminum Complex Components Inc, developed SSM compressor wheels as a way of achieving cost and durability performance somewhere between that of cast and machined from solid (MFS) aluminium alloy wheels. Experimental results show SSM material has a superior microstructure and mechanical properties over cast and comparable to MFS materials. Component testing including durability testing, using accelerated speed cycle tests, proves SSM compressor wheels emerge as being significantly more durable than cast equivalents and approaching that of MFS impellers. Further challenges for semi-solid processing in manufacture of other complex components and other materials in automotive industry in terms of both cost and durability are also discussed.

Key words: aluminum alloys; semi-solid moulding; durability; automotive complex component; turbocharger compressor wheel

1 Introduction

Diesel and gasoline engines are one of the most important sources to cause emission and global warming. To increase fuel efficiency and to reduce emission, vehicle weight reduction is one of the effective ways. Semi-solid moulding (SSM) has successfully helped to reduce weight of automotive components due to the significant improvement of mechanical properties over cast, so, smaller or thinner wall parts can be used. Automotive components have been successfully manufactured by SSM. DASGUPTA[1] has summarized the most popular applications as: 1) fuel rail of A357-T5, 2) automatic transmission gear shift lever of A357-T5, 3) engine mount of A357-T5, 4) engine bracket 1 800 g of A357-T5, 5) upper control arm of A356-T6, 6) suspension of A357-T5, 7) engine bracket 720 g of A357-T5, 8) engine bracket 2 400 g of A357-T5, and 9) diesel engine pump body of A356-T5.

Engine technology development is another effective way increasing fuel efficiency and to reduce emission. Increasing the air pressure ratio to the engine is a way to achieve the objective of further improving fuel efficiency and reducing emission. One way to increase air pressure can be achieved by a compressor wheel in a turbocharger. The compressor wheel needs very complex blade geometry to achieve high pressure ratios. Compressor wheel withstands rotational speeds up to 200 000 r/min but must do so while coping with up to 250 ?C and a significant temperature gradient. In addition to the requirements of mechanical strength and temperature capability, fatigue is a typical failure mode of a compressor wheel in application due to changes in speed cycles and vibration of blades.

This combination of sophisticated geometry and tough operating conditions means that the modern compressor wheels demand the best material technology. Compressor wheels for decades have been cast from alloys containing aluminum, silicon and copper. To achieve the specified durability targets, however, it is necessary to restrict their release speed, i.e. to reduce efficiency of an engine during operation due to cast defects. Therefore, the machined from solid (MFS) or forging compressor wheels have been developed to overcome the casting defect problem. The improvement in durability also means MFS wheel can run reliably at the higher speeds, increasing fuel efficiency and reducing emission. The downside is that MFS is significantly more expensive than casting.

Therefore, semi-solid moulding (SSM) processing is applied to develop a manufacturing process that is a way of achieving cost and durability performance somewhere between that of cast and MFS aluminum alloy wheels. Due to the complex geometry, precision control requirement and severe operation condition of a compressor wheel, manufacturing compressor wheel may be one of the most difficult processes for SSM. In this work, development and results of SSM application in manufacturing compressor wheels are presented, as an example of SSM application in manufacture of complex geometric automotive components.

2 Turbocharging

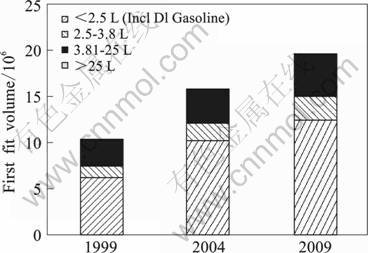

Turbocharging technology is widely used for diesel engine and recently also for gasoline engine together with direct injection technology development. The volume of turbocharger application for new vehicles (first fit) has steadily increased by about 10% between 1999 and 2004 and 5% between 2004 and 2009, leading to about 7% average annual increase rate in the past 10 years (Fig.1). The lower increase rate between 2004 and 2009 has been mainly caused by the economic recession since 2008 and it is expected that annual increase rate in the next 10 years will be about 8%. The total world wide volume of turbochargers in 2007 was about 20 million units for new vehicles, which was equivalent to 6.8 billion USD.

Fig.1 Global turbocharged engine market (first fit volume)

Turbocharger can effectively increase air pressure ratio through a compressor wheel, which is driven by turbine wheel through a shaft by exhaust gas. Fig.2 shows a typical wastegated turbocharger. The speed of rotation of the compressor wheel can reach as high as 200 000 r/min. Further increasing speed is desirable for improved efficiency and fuel economy. However, the rotation speed is limited by materials properties of the compressor and turbine wheels. Failure of a turbocharger is mainly caused by fatigue of the compressor or turbine wheel operated at high temperatures.

Fig.2 Overview of typical wastegated turbocharger

3 Challenges of manufacturing turbocharger compressor wheels by SSM

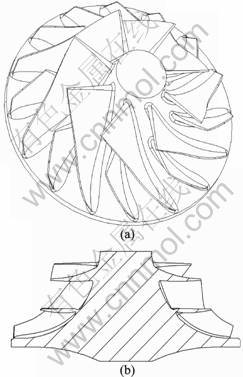

The geometry of a turbocharger compressor wheel is designed to be very complex in order to meet specific efficiency and durability requirement. Fig.3 presents a typical design of a compressor wheel. The ratio of blade length to blade thickness is about 25, which makes it difficult to fill the blade during SSM process, and the ratio of mass at central hub to blade can be about 80, which makes it difficult to get satisfied microstructure for both blade and hub simultaneously. In addition, the curvature of the blades makes it difficult to disassemble the SSM die after processing. Therefore, die design, runner system design and temperature control of the die and runner system are the key parameters to achieve a successful result[2]. In addition, materials must be also selected very carefully to meet the stringent requirements of durability of a compressor wheel under the severe operation conditions.

Fig.3 Overview (a) and section view (b) of typical compressor wheel

4 Materials selection

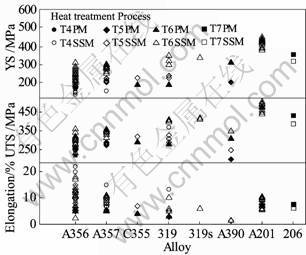

Materials selection was started from determining the physical properties such as thermal conductivity, thermal coefficient and alloy density to ensure the validity of current component design. It was recognized that all 3XX cast aluminum alloys can be applied for currently designed compressor wheels. After comparison of all available data[3-33] of mechanical properties for SSM and cast aluminum alloys, the 319s alloy was selected to manufacture compressor wheels. Fig.4 shows that SSM 319s alloy has reasonably the best and consistent tensile strength and elongation. From purely tensile property point of view, SSM A201 also shows promising results and therefore, trials were also conducted. Better strength and comparable ductility of SSM A201 than those in literature was achieved. However, SSM A201 was not commercially available so SSM 319s was still the alloy used to manufacture compressor wheels.

Fig.4 Tensile properties of SSM aluminum alloys compared with permanent mould (PM) cast ones

5 Results

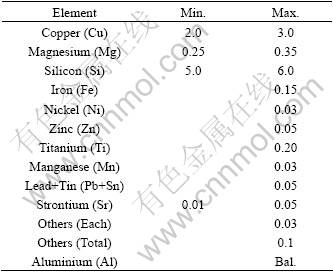

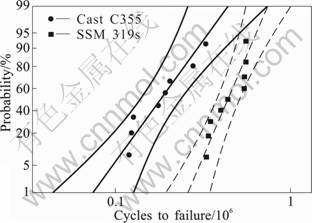

Chemical composition of the selected alloy 319s for SSM compressor wheel is given in Table 1. Fig.5 shows that the SSM 319s compressor wheel had superior tensile strength and ductility over cast C355 and 354.0 currently used on compressor wheels and approaching those of the forged 2618 under the condition of heat treatment T61. Uniaxial fatigue testing results showed that samples cut from forged 2618 alloy in a parallel direction to the metal flow had superior fatigue resistance whereas in the perpendicular direction it had similar fatigue resistance to cast 355 (Fig.6). This difference between orientations of sample to metal flow mainly arises from the alignment of coarse second phase particles. Improvement of fatigue property of SSM 319s over cast 355 can also be seen at small strains in Fig.6. This has been proven by component disk fatigue test, where uniaxial compressive stress with R>0 on the disk samples machined from back face of compressor wheel was performed, as shown in Fig.7. Component testing in a turbocharger was carried out on gas stand testing cells at Cummins Turbo Technologies Limited and the results are given in Fig.8.

Table 1 Chemical composition of 319s (mass fraction, %)

Fig.5 SSM 319s showing superior tensile properties over cast C355, 354.0 and 319 while comparable with forged 2618

Fig.6 SSM 319s showing superior fatigue resistance over cast C355 while comparable with forged 2618

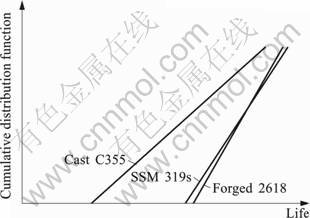

Life comparison between cast C355, forged 2618 and

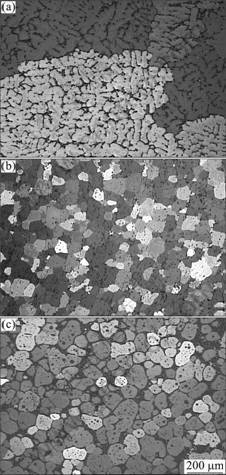

SSM 319s in Fig.8 shows a comparable durability between SSM 319s and forged 2618 compressor wheels, while they both have superior durability over cast C355. This significant improvement of SSM 319s and forged 2618 arises mainly from improvement of material integrity and the elimination of casting defect such as oxides. In addition to the material integrity and cleanliness improvement by forging and SSM, refinement of grain structure and thus microstructure of forged 2618 and SSM 319s compared with cast C355 and 354.0 is another contribution to the durability improvement of compressor wheels (Fig.9).

Fig.7 SSM 319s showing superior component uniaxial fatigue resistance over cast C355

Fig.8 SSM 319s compressor wheel showing superior durability over cast C355 compressor wheel while comparable with forged 2618

5 Executive summary

1) Turbocharging is one of the most successful technologies to achieve significant emission reduction and fuel economy. About 7% volume increase of turbocharged engines has been achieved in the past 10 years and 8% increase in the next 10 years is predicated.

2) SSM has been successfully applied to produce extremely complex geometric turbocharger compressor wheels.

Fig.9 Grains structure of cast C355 (a), forged 2618 (b) and SSM 319s (c), indicating comparable grain size between forged and SSM alloys, while both significant finer than cast alloy

3) SSM compressor wheel has achieved tensile and fatigue properties, and so component durability, approaching forged 2618 and superior over cast C355.

6 Future challenges

Although significant progress of manufacturing automotive components by SSM has been achieved and extensive efforts to develop new alloys and processes have been made by researchers, there are still needs for more efforts to satisfy requirements from the industry. These include:

1) More choices of alloys

There are different requirements for automotive industrial applications, some need high strength, while some may need high thermal capability, fatigue resistance, corrosion resistance and/or wearing resistance. These need different alloy systems to meet one or more requirements for industrial applications.

2) High melting point alloy systems

The greatest efforts of developing SSM processes historically are on alloys with relatively low melting points such as aluminum and magnesium alloys. Some efforts and success have been achieved on high melting point alloys such as steels[34], but further studies are desirable to develop material systems of cast iron, steels and nickel base alloys. These materials have significant higher density than aluminum and magnesium alloys, so there is greater potential to save more weight of automotive components, and thus more fuel economy, and to improve durability by quality and property improvement in terms of SSM processes than for light alloys.

3) Complex geometric components

Complex geometry of some automotive components, such as compressor wheels of a turbocharger and cylinder head in an engine, makes it difficult to achieve the stringent property requirements in cast and efficiency/cost in machining from forged billets. SSM has, therefore, great potential to manufacture complex geometric components. The very low shear strength of alloys at semi-solid status makes it achievable to manufacture complex geometric components when a proper design of runner system and die configuration can be achieved in accommodating the low shear strength but relatively high compressive strength.

4) Cost reduction of current SSM components

Cost reduction of manufacturing components has been achieved using SSM process over machining from forged billets. However, due to the high cost of manufacturing raw material bar stock, complexity of runner system and die configuration as well as relatively high process costs, the costs of SSM components are still significantly higher than those of casting. Therefore, efforts should be made to further achieve cost reduction of raw material bar stock, of design and manufacture of runner system and die configuration and of processes.

Acknowledgements The authors would express their acknowledgement to Dr. Michael VOONG of Cummins Turbo Technologies Limited for the critical reading and comments of this paper. Thanks also to Andrew P. JACKSON of Aluminum Complex Components Inc. for developing the tooling and general support for successfully manufacturing the SSM impellers.

References

[1] DASGUPTA R. [C]// Proc of 8th Inter Conf on Semi-Solid Processing of Alloys and Composites. Cyprus, 2004.

[2] ZHU Q, JACKSON A P. Method and apparatus of Manufacturing Turbine or Compressor Wheels[P]. WO2007/010181, 2007.

[3] LIU D. [D]. Sheffield: University of Sheffield, 2003.

[4] Metal Handbook. Properties and Selection: Nonferrous Alloys and Special Purpose Materials[M]. Vol.2, 10th Ed. Metal Park, OH: ASM, 1990.

[5] WABUSSEG H, KAUFMANN H, UGGOWITZER P J. [C]// CHIARMETTA G L, ROSSO M. Proc of 6th Inter Conf on Semi-Solid Processing of Alloys and Composites. Turin, Italy, 2000: 777-782.

[6] BERGSMA S C, TOLLE M C, EVANGELISTA E. [C]// BHASIN A K, MOORE J J, YOUNG K P, MIDSON S. Proc of 5th Inter Conf on Semi-Solid Processing of Alloys and Composites. Golden, Colorado, USA, 1998: 149-155.

[7] ROSSO M, GIORDANO P, CHIARMETTA G L. [C]// CHIARMETTA G L, ROSSO M. Proc of 6th Inter Conf on Semi-Solid Processing of Alloys and Composites. Turin, Italy, 2000: 325-330.

[8] GARAT M, BLAIS S, PLUCHON C. [C]// BHASIN A K, MOORE J J, YOUNG K P, MIDSON S P. Proc of 5th Inter Conf on Semi-Solid Processing of Alloys and Composites. Golden, Colorado, USA, 1998: xvii-xxxi.

[9] EISEN P. [C]// BHASIN A K, MOORE J J, YOUNG K P, MIDSON S P. Proc of 5th Inter Conf on Semi-Solid Processing of Alloys and Composites. Golden, Colorado, USA, 1998: ix-xvi.

[10] NIU X P, HU B H, HAO S W. [C]// BHASIN A K, MOORE J J, YOUNG K P, MIDSON S P. Proc of 5th Inter Conf on Semi-Solid Processing of Alloys and Composites. Golden, Colorado, USA, 1998: 141-148.

[11] CHIARMETTA G. [C]// KIRKWOOD D H, KAPRANOS P. Proc of 4th Inter Conf on Semi-Solid Processing of Alloys and Composites. Sheffield, UK, 1996: 204-207.

[12] WENDINGER D B. [C]// KIRKWOOD D H, KAPRANOS P. Proc of 4th Inter Conf on Semi-Solid Processing of Alloys and Composites. Sheffield, UK, 1996: 239-241.

[13] WITULSKI T, WINKELMANN A, HIRT G. [C]// KIRKWOOD D H, KAPRANOS P. Proc of 4th Inter Conf on Semi-Solid Processing of Alloys and Composites. Sheffield, UK, 1996: 242-247.

[14] SHIBATA R, KANEUCHI T, SODA T. [C]// KIRKWOOD D H, KAPRANOS P. Proc of 4th Inter Conf on Semi-Solid Processing of Alloys and Composites. Sheffield, UK, 1996: 296-300.

[15] GABATHULER J P, DITZLER C. [C]// KIRKWOOD D H, KAPRANOS P. Proc of 4th Inter conf on Semi-Solid Processing of Alloys and Composites. Sheffield, UK, 1996: 331-335.

[16] CHIARMETTA G. [C]// BHASIN A K, MOORE J J, YOUNG K P, MIDSON S. Proc of 5th Inter Conf on Semi-Solid Processing of Alloys and Composites. Golden, Colorado, USA, 1998: 87-95.

[17] FINK R, WITULSKI T. [C]// BHASIN A K, MOORE J J, YOUNG K P, MIDSON S. Proc of 5th Inter Conf on Semi-Solid Processing of Alloys and Composites. Golden, Colorado, USA, 1998: 557-564.

[18] BOERO F, CHIARMETTA G, GIORDANO P. [C]// CHIARMETTA G L, ROSSO M. Proc of 6th Inter Conf on Semi-Solid Processing of Alloys and Composites. Turin, Italy, 2000: 581-586.

[19] BERGSMA S C, KASSNER M E, EVANGELISTA E. [C]// CHIARMETTA G L, ROSSO M. Proc of 6th Inter Conf on Semi-Solid Processing of Alloys and Composites. Turin, Italy, 2000: 319-324.

[20] JUANG S H, WU S M, MA C Y. [C]// CHIARMETTA G L, ROSSO M. Proc of 6th Inter Conf on Semi-Solid Processing of Alloys and Composites. Turin, Italy, 2000: 705-710.

[21] GARAT M MAENNER L, SZTUR C. [C]// CHIARMETTA G L, ROSSO M. Proc of 6th Inter Conf on Semi-Solid Processing of Alloys and Composites. Turin, Italy, 2000:187-194.

[22] KOPP R P, WINNING G, KALLWEIT J. [C]// CHIARMETTA G L, ROSSO M. Proc of 6th Inter Conf on Semi-Solid Processing of Alloys and Composites. Turin, Italy, 2000: 687-691.

[23] LORSTAD J L. [C]// CHIARMETTA G L, ROSSO M. Proc of 6th Inter Conf on Semi-Solid Processing of Alloys and Composites. Turin, Italy, 2000: 227-233.

[24] ROSSO M ROMANO E, GIORDANO P. [C]// TSUTSUI Y, KIUCHI M, ICHIKAWA K. Proc of 7th Inter Conf on Semi-Solid Processing of Alloys and Composites. Tsukuba, Japan, 2002: 151-156.

[25] LOONG C A, ZHENG C Q, SCHEHATA M T. [C]// TSUTSUI Y, KIUCHI M ICHIKAWA K. Proc of 7th Inter Conf on Semi-Solid Processing of Alloys and Composites. Tsukuba, Japan, 2002: 213-220.

[26] de FREITAS E, FERRACINI E G, PIFFER V. [C]// TSUTSUI Y, KIUCHI M, ICHIKAWA K. Proc of 7th Inter Conf on Semi-Solid Processing of Alloys and Composites. Tsukuba, Japan, 2002: 233-238.

[27] KAUFMANN H, H?LZL A, UGGOWITZER P J. [C]// TSUTSUI Y, KIUCHI M, ICHIKAWA K. Proc of 7th Inter Conf on Semi-Solid Processing of Alloys and Composites. Tsukuba, Japan, 2002: 617-622.

[28] ADACHI M, SATO S, SASAKI H. [C]// TSUTSUI Y, KIUCHI M, ICHIKAWA K. Proc of 7th Inter Conf on Semi-Solid Processing of Alloys and Composites. Tsukuba, Japan, 2002: 629-634.

[29] OGRIS E, L?CHINGER H, UGGOWITZER P J. [C]// TSUTSUI Y, KIUCHI M, ICHIKAWA K. Proc of 7th Inter Conf on Semi-Solid Processing of Alloys and Composites. Tsukuba, Japan, 2002: 713-718.

[30] HAGA T, KAPRANOS P, KIRKWOOD D H. [C]// TSUTSUI Y, KIUCHI M ICHIKAWA K. Proc of 7th Inter Conf on Semi-Solid Processing of Alloys and Composites. Tsukuba, Japan, 2002: 801-806.

[31] PARK C, KIM S S, LEE, Y S. [C]// TSUTSUI Y, KIUCHI M, ICHIKAWA K. Proc of 7th Inter Conf on Semi-Solid Processing of Alloys and Composites. Tsukuba, Japan, 2002: 239-244.

[32] GIORDANO P, CHIARMETTA G L. [C]// TSUTSUI Y, KIUCHI M, ICHIKAWA K. Proc of 7th Inter Conf on Semi-Solid Processing of Alloys and Composites. Tsukuba, Japan, 2002: 665-670.

[33] LEE S Y, OH S I, SOHN K Y. [C]// TSUTSUI Y, KIUCHI M, ICHIKAWA K. Proc of 7th Inter Conf on Semi-Solid Processing of Alloys and Composites. Tsukuba, Japan, 2002: 725-730.

[34] CEZARD P, SOURMAIL T. [J]. Solid State Phenomena, 2008, 141/142/143: 25-35.

(Edited by YANG Bing)

Corresponding author: Q. ZHU; +44-1484-832567; E-mail: Qiang.zhu@Cummins.com; Qiang.zhu@ymail.com