La0.6Sr0.4Co0.2Fe0.8O3-α超细粉体的喷雾热分解法合成与电性能

孟秀霞1, 庞兆宝1, 谭小耀1, 孟 波1, 杨乃涛2

(1. 山东理工大学 化学工程学院, 淄博 255049;

2. 上海交通大学 化学化工学院, 上海 200240)

摘 要: 用喷雾热分解法制备La0.6Sr0.4Co0.2Fe0.8O3-α (LSCF)超细粉体材料, 用扫描电镜和透射电镜研究粉体的形貌与粒度, 用X射线衍射仪研究粉体材料的晶相结构, 通过能谱仪研究其元素组成和掺杂性能, 用激光粒度分析仪分析粒度分布, 并测试其电性能。 结果表明: 喷雾热分解法合成的LSCF粉体材料粒子呈球形, 平均粒度3.13μm, 超声喷雾在900℃热分解的产物能直接形成钙钛矿型晶相, 且经过1100℃处理后结晶度更完整; 能谱仪分析显示喷雾热分解法直接制成的LSCF粉体掺杂均匀; 粉体的粒度符合液滴粒子转变机理, 即1个产物粒子由1个液滴形成; 当加入乙醇时, 粉体的粒度将减小, 但加入尿素、 硝酸铵和柠檬酸时其粒度增加。 粉体的电导率峰值出现的位置为650℃。

关键词: 钙钛矿型复合氧化物; 混合导体; 喷雾热分解 中图分类号: O611.4; O614.81

文献标识码: A

Preparation of La0.6Sr0.4Co0.2Fe0.8O3-α ultra fine powder by spray pyrolysis method and its electrical property

MENG Xiu-xia1, PANG Zhao-bao1, TAN Xiao-yao1,MENG Bo1, YANG Nai-tao2

(1. School of Chemical Engineering,Shandong University of Technology, Zibo 255049, China;

2. School of Chemistry and Chemical Technology,Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: La0.6Sr0.4Co0.2Fe0.8O3-α (LSCF) ultrafine powders were synthesized through an ultrasonic spray pyrolysis process. The products were characterized by scanning electron microscopy and transmitted electron microscopy to observe the morphology, by X-ray diffractrometry to display the crystalline phase and by energy dispersive spectrometry to determine the elemental compositions and doping performance, and by laser particle size analyzer to analyze the particle size. Lastly, the conductivity of LSCF was tested. The results indicate that the prepared powders consist mainly of spherical particles with diameters of 3.13μm. At the operating temperature of 900℃, a single perovskite crystalline phase may be formed, although the higher temperature favors the formation of perovskite structure. The energy dispersive spectrometer spectra show that the spray pyrolysis allows for the perfectly even-doping. The particle size can be adjusted by the parameters such as the concentration of precursor solution and additives. The particle size increases with increasing concentration of precursor solution and conforms to One-Droplet-One-Particle mechanism (ODOP). The particle size is decreased by addition of ethanol but increased when carbamide, ammonium nitrate or citric acid is used as the additive. Experimental result indicates that maximum conductivity occurs at 650℃, which is the expectation temperature for SOFC.

Key words: perovskite composite oxide; mixed conductor; spray pyrolysis

随着超导材料、 磁性材料、 陶瓷材料、 荧光材料、 催化剂和传感器等领域的迅猛发展, 稀土超细粉体的合成和应用日益受到重视, 成为稀土材料的研究热点。 LaxSr1-xCoyFe1-yO3-α(0〈x〈1, 0〈y〈1, 简称LSCF)是一种ABO3型钙钛矿结构的复合氧化物, 具有良好的氧离子-电子混合导电性[1]和优良的催化活性, 可应用于中低温固体氧化物燃料电池(SOFC)的电极材料[2], 气体传感器, 氧分离膜, 甲烷偶联催化剂等[3]。

合成ABO3型复合氧化物的方法目前主要有: 固相反应法[4-6], 共沉淀法[7-8], 前驱体法[9-10], 溶胶-凝胶法[11-12]以及燃烧合成[13-14]等。 喷雾热分解法是近年来新兴的一种超细粉体制备技术, 它将金属盐溶液雾化喷入低压高温分解炉中, 使无数微小的液滴受热蒸发、 分解, 从而直接生成所要求的固相微粒粉料。 该法适用于连续操作, 可制备出成分均匀, 粒度在亚微米级和纯度较高的粉料。 本文作者用喷雾热分解法制备了La0.6Sr0.4Co0.2Fe0.8O3-α(LSCF)钙钛矿型粉体材料, 研究了粉体的形貌、 晶相结构、 元素组成及掺杂性能、 粒度分布和电性能, 以期为喷雾热分解技术应用于其它稀土氧化物的制备奠定基础。

1 实验

1.1 粉体的制备与表征

采用La, Sr, Co, Fe的硝酸盐或水合硝酸盐作为原料, 按照目标材料La0.6Sr0.4Co0.2Fe0.8O3-α中金属元素的摩尔比分别配制成一定浓度的混合硝酸盐水溶液各100mL。 将该混合溶液分别注入超声波雾化器中, 直接雾化成为直径2~5μm的溶液雾, 此溶液雾在气流的推动下, 快速穿过高温电炉中的石英管, 石英管的加热温度是900℃, 雾滴的停留时间小于2s, 石英管的出口用高压电场收集微细粉尘。

粉体的微观形貌用FEI Sirion200扫描电子显微镜和JEM-2010的透射电子显微镜观察; 用Oxford Instruments Inca X-sight能谱仪(EDS)研究粉体微球的元素组成; 用Winner 2000激光粒度分析仪分析粉体的粒度; 晶相结构通过Rigaku D/max2200 X射线衍射仪确定, 以 Cu Kα作射线源, 波长λ=0.15404nm, 通过连续扫描方式测取2θ为5°~70°, 扫描速率为2.0 (°)/min, 记录步长为0.02°。 X射线管的电压和电流分别为 40kV 和30mA。

1.2 电导率测试

将制备的粉体用压片机压制成直径25mm, 厚约1.0mm的圆片, 置于高温电炉中以1250℃焙烧4h, 取出称量, 测量其尺寸。 将烧好的阴极薄片两面涂上银浆, 粘上银丝, 安放在不锈钢夹具上, 一边升温一边用Hewlett Packard 4284A阻抗分析仪测量其电阻值。 电导率σ可计算为

式中 σ为电导率, S/cm; L为电极厚度, cm; R为电阻, Ω; d为电极片直径, cm。

2 结果与分析

2.1 粒子的粒度与形貌

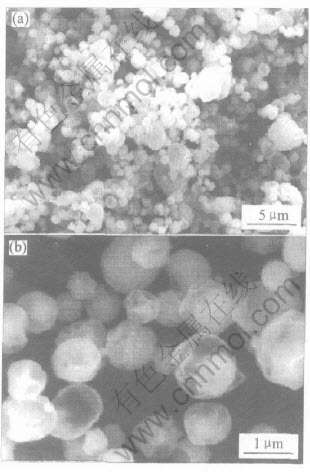

由SEM像分析可见(图1), 喷雾热解所得粉

图1 喷雾热解法制备LSCF粉体的SEM像

Fig.1 SEM micrographs of LSCF powders by spray pyrolysis

体的形貌大体呈球形, 粒度约0.5~1μm。 这些微球经高倍放大后可观察到部分碎片、 空心和表面褶皱。 造成这种现象的原因与雾滴表面硬壳的形成以及雾滴热分解的传热传质有关[15]。 喷雾使原料液雾化呈球形液珠, 在经过高温区时, 雾滴受热蒸发和分解, 蒸发和分解作用首先从液珠表面开始, 形成固体氧化物硬壳。 随着进一步受热, 微球内部的气体通过硬壳释放出来, 从而导致热分解生成的微球形成空心或海绵心。 内部气体的快速喷出可能导致部分微球破裂成碎片; 而分解蒸汽缓慢释出, 则可能使微球的硬壳逐渐萎缩塌陷生成表面褶皱(图2)。 研究发现, 料液浓度较高时, 单位体积内的溶液粒子数目增多, 形成的硬壳厚度增加, 强度较大不易破裂, 粒子的圆度较好; 浓度较小时, 表层硬壳较薄, 强度小, 更容易生成碎片。

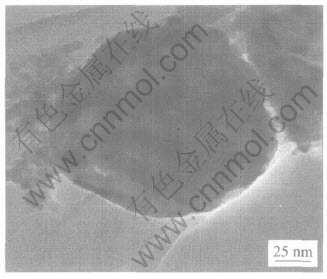

图2 单个粒子的TEM像

Fig.2 TEM micrograph of single LSCF particle

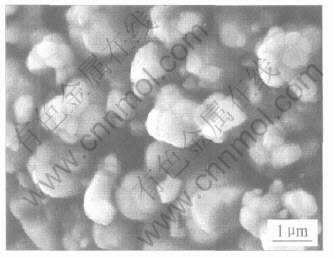

粉体在1100℃焙烧2h后, 扫描电子显微镜像如图3所示。 可以看出, 粉体从球形变为团聚晶粒, 这显示了高温处理对粉体的烧结和晶化[16]。 此外, 经1100℃焙烧后, 粒度长大, 原来分散的小球发生团聚。

2.2 粉体晶体结构

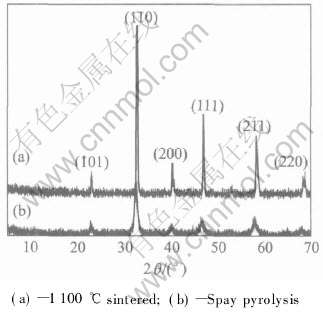

以0.2mol/L前躯体溶液制得的粉体进行X射线衍射分析, 结果如图4所示。 可见, 喷雾热解法直接制备的粉体已经呈钙钛矿结构的晶相, 虽然基线不很清晰, 峰强度较小, 但各主要衍射峰与钙钛矿型结构的晶相均重合。 经过高温处理后(图4(a)), 相对于直接喷雾热解制备的粉体(图4(b)),其谱基线平整, 峰型尖锐, 强度增强。 这表明高温

图3 1100℃时烧结后LSCF粉体的SEM像

Fig.3 SEM micrograph of LSCF powders sintered at 1100℃

图4 LSCF经过1100℃处理前后的X射线衍射谱

Fig.4 XRD patterns of LSCF powders before and after 1100℃ sintering

焙烧有助于粉体的晶化。 晶体的成长也可以对比图2和图3的电镜照片。 图2显示喷雾热解制备微球, TEM呈半透明, 且附近发现部分纳米尺度的碎屑。 可见该微球应该是由更细小的纳米微晶构成, 这些微晶的尺寸可以通过XRD谱的数值, 结合Sherrer方程可得(110)面的晶粒尺寸为11.25nm。 因此可以说, 喷雾热解得到的微球, 是由11nm左右的超细晶粒构成的, 这些超细晶粒晶化不够完整, 所以才形成图4(a)所示的X射线衍射谱。 而经过1100℃焙烧后, 晶粒长大完整, 从图3可以看到这些大而完整的晶粒, 而其衍射谱则显示为图4(b)所示的窄锐峰型。

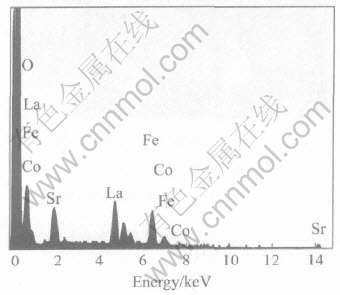

2.3 粉体的元素组成

粉体微球的EDS谱如图5所示。 可见在粉体微球上同时存在4种金属元素以及氧元素, 而其余的元素如碳、 氢、 氮等均已被烧除。 因此, 所采用的热解温度(900℃)和停留时间(2s)已足以实现完全热解。

图5 喷雾热解法制备的微球EDS谱

Fig.5 EDS spectrum of micro sphere

用喷雾热分解法制备的这种粉体, 4种金属元素在各个微粒中之所以能够掺杂均匀, 经过简单热处理后, 即形成晶相单一, 晶型完整地钙钛矿型晶粒, 是由于使用水溶性硝酸盐作为前体, 可以使金属离子实现绝对地均匀混合。 超声喷雾是一种低温下的机械雾化, 雾珠中仍然能保持所配溶液的成分和浓度。 雾珠经过分解炉管的速率很快, 每个雾珠在1~2s内完全分解, 雾珠内的溶液体系在这么短的时间里未来得及生成沉淀而迅速分解完毕, 因此形成的粉体微粒中, 各金属元素能够掺杂均匀, 并且晶相单一。

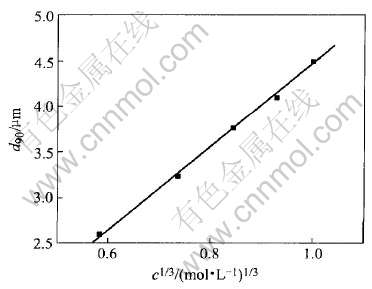

2.4 溶液浓度和添加剂与粉体粒度的关系

图6所示为制备的粉体所用的前驱体的浓度与粒度的关系。 由图可知, 粉体的粒径与浓度的1/3次方成正比, 这说明此工艺制备的粉体符合液滴粒子转变机理(ODOP), 即一个产物粒子由一个液滴形成[17]。

图6 粒度与溶液浓度的关系

Fig.6 Relation between particle size and solution concentration

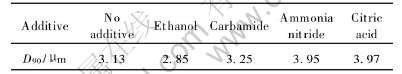

相同质量比的添加剂对浓度为0.4mol/L前驱体所制备的粉体粒径的影响列于表1。 由表可知, 前驱体溶液中若加入乙醇, 粉体的粒度将变小, 其主要原因是乙醇的沸点较低, 在热解初期就能迅速蒸发掉, 使颗粒迅速收缩。 故利用乙醇的良好分散性可提高雾滴的蒸发分解效率, 得到粒径更细、 更均匀的粉体。 而以尿素、 硝酸铵和柠檬酸作为添加剂, 在受热分解时, 会在颗粒中生成大量的气体, 这些气体导致粒子发泡膨胀, 从而使得粒子内部更加疏松, 而粒径随之增大。 尤其是柠檬酸分子, 能与金属离子络合形成溶胶, 在分解过程中会与硝酸根发生氧化燃烧, 在粒子内部发泡膨胀生成的气体较多, 因此形成的粒径最大。

表1 粉体粒度与添加剂的关系

Table 1 Relationship between particle size and additive

2.5 材料的导电性能

图7所示为在不同操作温度下LSCF的电导率。 随着温度从100℃升高到650℃, LSCF的电导率逐渐增加, 但是当温度升高到650℃时, 达到最大值, 随后又逐渐降低。 LSCF为氧离子-电子混合导电导体, 当温度升高的时候, Co3+的3d轨道电子能量升高, 更容易挣脱束缚, 转移到Co4+, 同时O2-也更容易在晶格之间扩散, 表现出电导率随着温度的升高而增大。 但随着温度的升高对晶格的震动能也增大, 阻碍了导电载流子的迁移, 当载流子的数量不能够增加的时候, 温度的升高反而会对电导率起到阻碍的作用, 因此LSCF的电导率随着温度的升高有一个最大值, 最大值出现的位置650℃正是中温固体氧化物燃料电池所期望的位置。

图7 LSCF在不同温度下的电导率

Fig.7 Conductivity of LSCF at different temperatures

3 结论

1) 用喷雾热解法可以制备出呈球形的LSCF粉体, 其元素掺杂均匀, 晶相单一, 呈钙钛矿型结构, 高温焙烧有助于晶体的成长和结晶度完整。

2) 所制备的LSCF粉体粒度符合ODOP机理, 即1个产物粒子由1个液滴形成。 当在前驱体溶液中加入乙醇时, 粉体的粒度将减小, 但加入尿素、 硝酸铵和柠檬酸时其粒度增加。

3) 所制备的LSCF粉体具有较好的电性能, 电导率的最大值出现的位置约为650℃。

REFERENCES

[1]Kharton V V, Naumovich E N, Kovalevsky A V, et al. Mixed electronic and ionic conductivity of LaCo(M)O3(M=Ga, Cr, Fe or Ni)Ⅳ: Effect of preparation method on oxygen transport in LaCoO3-δ[J]. Solid State Ionics, 2000, 138: 135-148.

[2]黄文华, 杨建华, 聂怀文, 等. 中温固体氧化物燃料电池阴极材料Ln0.6Sr0.4Fe1-xCoxO3-δ的合成和性能表征[J]. 无机材料学报, 2002, 17(4): 679-684.

HUANG Wen-hua, YANG Jian-hua, NIE Huai-wen, et al. Synthesis and characterization of Ln0.6Sr0.4Fe1-x-CoxO3-δ for ITSOFC[J]. Journal of Inorganic Materials, 2002, 17(4): 679-684.

[3]Zeng Y, Lin Y S, Swartz S L. Perovskite-type ceramic membrane: synthesis, oxygen permeation and membrane reactor performance for oxidative coupling of methane[J]. J Membr Sci, 1998, 150: 87-98.

[4]Song K S, Cui H X, Kim S D. Catalytic combustion of CH4 and CO on La1-xMxMnO3 perovskites[J]. Catalysis Today, 1999, 47(1-4): 155-160.

[5]LI Shi-guang, JIN Wan-qin, XU Nan-ping, et al. Synthesis and oxygen permeation properties ofLa0.2Sr0.8Co0.2Fe0.8O3-δ membranes[J]. Solid State Ionics, 1999, 124: 161-170.

[6]罗广圣, 李小怡, 吴小山. 稀土空位锰氧化物(La(1-x-y)Yy)2/3Ca1/3MnO3的结构和输运性质[J]. 中国有色金属学报, 2005, 15(12): 1968-1973.

LUO Guang-sheng, LI Xiao-yi, WU Xiao-shan. Structural and transport properties of manganese oxides (La(1-x-y)Yy)2/3Ca1/3MnO3 with rare earth vacanties[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 1968-1973.

[7]Bell R J, Millar G J, Drennan J. Influence of synthesis route on the catalytic properties of La1-xSrxMnO3[J]. Solid State Ionics, 2000, 131: 211-220.

[8]Ishihara T, Matsuda H, Takita Y. Doped LaGaO3 perovskite type oxide as a new oxide ionic conductor[J]. J Am Chem Soc, 1994, 116: 3801-3803.

[9]杨彧, 贾殿赠, 葛炜炜, 等. 低热固相反应制备无机纳米材料的方法[J]. 无机化学学报, 2004, 20(8): 881-888.

YANG Yu, JIA Dian-zeng, GE Wei-wei, et al. Synthesis of inorganic nano-materials by solid state reaction at low-heating temperature[J]. Chinese J Inorg Chem, 2004, 20(8): 881-888.

[10]Xu S J, Thomson W J. Oxygen permeation rates through ion-conducting perovskite membranes[J]. Chemical Engineering Science, 1999, 54: 3839-3850.

[11]Chen C H, Bouwmeester H J M, van Doorn R H E, et al. Oxygen permeation of La0.3Sr0.7CoO3-δ[J]. Solid State Ionics, 1997, 98: 7-13.

[12]尹荔松, 樊志良, 王达, 等. 纳米晶La1-xSrxMnO3的溶胶凝胶法合成及表征[J]. 中国有色金属学报, 2005, 15(8): 1267-1271.

YIN Li-song, FAN Zhi-liang, WANG Da, et al. Preparation and characteristics of nanocrystalline La1-xSrxMnO3 derived by sol-gel process[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1267-1271.

[13]杨乃涛, 冯柳, 谭小耀, 等. 凝胶自燃法合成LaxSr1-xCoyFe1-yO3-α纳米粉体[J]. 无机化学学报, 2005, 21(11): 1623-1626.

YANG Nai-tao, FENG Liu, TAN Xiao-yao, et al. Synthesis of LaxSr1-xCoyFe1-yO3-α nanopower by the gel-selfcombustion process[J]. Chinese J Inorg Chem, 2005, 21(11): 1623-1626.

[14]庞兆宝, 孟波, 谭小耀. 高温质子导体Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ的合成与性能[J]. 中国有色金属学报, 2006, 16(5): 858-861.

PANG Zhao-bao, MENG Bo, TAN Xiao-yao. Synthesis and characteristics of Ba(Ce0.8Zr0.2)0.9Y0.1-O3-δ high temperature proton conductor[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(5): 858-861.

[15]Okuyama K, Lenggoro I W. Preparation of nanoparticles via spray route[J]. Chemical Engineering Science, 2003, 58: 537-547.

[16]Inagaki T, Miura K, Yoshida H, et al. High-performance electrodes for reduced temperature solid oxide fuel cells with doped lanthanum gallate electrolyte(Ⅱ): La(Sr )CoO3 cathode[J]. Journal of Power Sources, 2000, 86: 347-351.

[17]赵新宇, 张煜, 古宏晨, 等. 喷雾热解制备稀土超细粉末(Ⅰ): 氧化钇粒子形态与形成机理[J]. 高等学校化学学报, 1998, 19(4): 507-510.

ZHAO Xin-yu, ZHANG Yu, GU Hong-chen, et al. Synthesis of rare earth ultrafine powders by spray pyrolysis(Ⅰ)[J]. Chemical Journal of Chinese Universities, 1998, 19(4): 507-510.

(编辑陈爱华)

基金项目: 国家自然科学基金资助项目(20676073); 山东省自然科学基金资助项目(2003ZX09); 山东理工大学科技基金资助项目(2005KJM34)

收稿日期: 2006-02-28; 修订日期: 2006-10-12

通讯作者: 孟秀霞, 讲师; 电话: 0533-2786292; E-mail: mengxiux@126.com