原位生长纳米炭纤维增强C/C复合材料的弯曲破坏过程

来源期刊:中国有色金属学报(英文版)2014年第10期

论文作者:卢雪峰 肖 鹏 徐先锋 陈 洁

文章页码:3134 - 3141

Key words:carbon nanofiber; C/C composites; flexural destruction; crack propagation

摘 要:采用催化化学气相沉积法制备原位生长纳米炭纤维(CNFs)改性单向C/C复合材料。通过分析弯曲破坏过程,研究原位生长CNFs对C/C复合材料弯曲性能的影响。结果表明,CNFs的存在明显改变了载荷-位移曲线的线形,在开始的弹性变形阶段出现一个台阶,随后出现类似塑性材料的锯齿状屈服特性曲线。CNF-C/C复合材料的破坏模式由单根纤维的拔出转变为纤维束的断裂。由中织构热解炭(PyC)、CNFs和高织构PyC形成的复杂界面阻碍了裂纹的扩展,改变了裂纹的扩展方向从而导致C/C复合材料具有较高的弯曲强度和模量。

Abstract: Unidirectional carbon/carbon (C/C) composites modified with in situ grown carbon nanofibers (CNFs) were prepared by catalysis chemical vapor deposition. The effect of in situ grown CNFs on the flexural properties of the C/C composites was investigated by detailed analyses of destructive process. The results show that there is a sharp increase in the flexural load-displacement curve in the axial direction of the CNF-C/C composites, followed by a serrated yielding phenomenon similar to the plastic materials. The failure mode of the C/C composites modified with in situ grown CNFs is changed from the pull-out of single fiber to the breaking of fiber bundles. The existence of interfacial layer composed by middle-textured pyrocarbon, CNFs and high-textured pyrocarbon can block the crack propagation and change the propagation direction of the main crack, which leads to the higher flexural strength and modulus of C/C composites.

Trans. Nonferrous Met. Soc. China 24(2014) 3134-3141

Xue-feng LU1, Peng XIAO2, Xian-feng XU3, Jie CHEN2

1. Key Laboratory of Eco-textiles, Ministry of Education, Jiangnan University, Wuxi 214122, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

3. Key Laboratory of Ministry of Education for Conveyance and Equipment, College of Mechanical and Electrical Engineering, East China Jiaotong University, Nanchang 330013, China

Received 21 October 2013; accepted 30 March 2014

Abstract: Unidirectional carbon/carbon (C/C) composites modified with in situ grown carbon nanofibers (CNFs) were prepared by catalysis chemical vapor deposition. The effect of in situ grown CNFs on the flexural properties of the C/C composites was investigated by detailed analyses of destructive process. The results show that there is a sharp increase in the flexural load-displacement curve in the axial direction of the CNF-C/C composites, followed by a serrated yielding phenomenon similar to the plastic materials. The failure mode of the C/C composites modified with in situ grown CNFs is changed from the pull-out of single fiber to the breaking of fiber bundles. The existence of interfacial layer composed by middle-textured pyrocarbon, CNFs and high-textured pyrocarbon can block the crack propagation and change the propagation direction of the main crack, which leads to the higher flexural strength and modulus of C/C composites.

Key words: carbon nanofiber; C/C composites; flexural destruction; crack propagation

1 Introduction

The carbon fiber/pyrocarbon (PyC) interface is the bridge between carbon fiber and PyC, transferring stress and heat, which has a direct influence on the physical, chemical and mechanical properties of C/C composites [1,2]. There are more and more researches focusing on the modification of the fiber/matrix interface in order to improve the performance of C/C composites [3,4]. Carbon nanofibers (CNFs) with high strength and modulus can be used as a modifier. Typically, CNFs have 60-200 nm in diameter and 100 μm in length. The elastic modulus is about 600 GPa and the tensile strength is between 2.5 and 3.5 GPa [5-7]. In addition, CNFs with the same element and the similar structure as C/C composites can be used as the secondary reinforcement of C/C composites [8,9].

To date, many studies have been conducted on adding CNFs to C/C composites [10-18]. LI et al [12,13] obtained the CNF-modified C/C composites (CNF-C/C) by spreading layers of carbon cloth and found that when the CNF content was 5% (mass fraction), CNF-C/C composites had the best mechanical properties.  et al [14] synthesized the CNF-C/C composites by catalytically growing a layer of CNFs on carbon felt and found that the flexural strength of the preform with in situ grown CNFs was improved from approximately 0 to 4 MPa, which results in the higher flexural strength of the CNF-C/C composites. However, the above addition method can only be used to modify the structure of carbon matrix, and few influences the fiber/matrix interface. LI et al

et al [14] synthesized the CNF-C/C composites by catalytically growing a layer of CNFs on carbon felt and found that the flexural strength of the preform with in situ grown CNFs was improved from approximately 0 to 4 MPa, which results in the higher flexural strength of the CNF-C/C composites. However, the above addition method can only be used to modify the structure of carbon matrix, and few influences the fiber/matrix interface. LI et al

2 Experimental

2.1 Materials

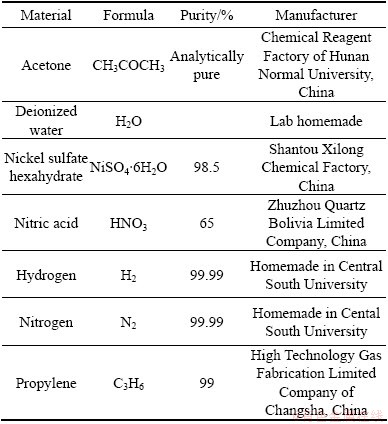

The preform materials were unidirectional carbon fiber cloth of polyacrylonitrile (PAN) based carbon fiber (T700, 12K) manufactured by Toray Industries, Inc., Japan. Details of the manufacturer and the physical properties of other materials are shown in Table 1.

Table 1 Manufacturer and physical or chemical properties of other materials

2.2 Preparation of samples

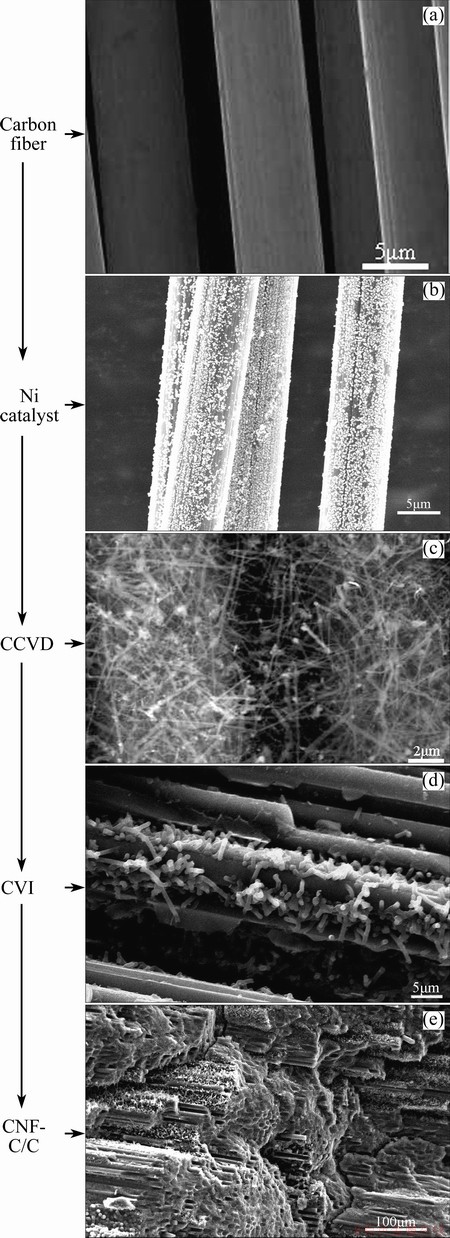

In order to remove the organic glue and impurities on the carbon fiber surface, the unidirectional carbon cloths were soaked in acetone for 24 h, followed by repeated washing in deionized water. The preparation process of CNF-C/C composites had three steps and the process diagram is shown in Fig. 1.

Fig. 1 Schematic diagram of preparation process (left) and corresponding structural image (right) of CNF-C/C composites

2.2.1 Preparation of catalyst Ni

Ni particles used as the catalyst were deposited on the fiber surface by electroplating, using the unidirectional carbon cloths as the cathode and electroplating bath as the anode. The electrolyte was 10% nickel sulfate solution and the current was 10 A. The small uniform Ni particles were obtained by controlling electroplating time.

2.2.2 In situ growth of CNF

After the preparation of Ni particles in the unidirectional carbon cloths, the unidirectional carbon preforms (0.65 g/m3) were obtained by stacking the carbon cloths in the same direction. CNFs were prepared on the fiber surface of the preforms by catalysis chemical vapor deposition (CCVD). The CCVD was performed at the temperature of 900 °C under the pressure of 500 Pa. Propylene, hydrogen and nitrogen were used as the source of carbon, reducing gas and dilute gas, respectively. The preforms with CNFs were obtained by controlling the deposition time during CCVD. In order to get rid of the Ni particles, the preforms modified by CNFs were soaked in the nitric acid solution at 60 °C for 20 min and then washed repeatedly with deionized water. Then the preforms were dried in the air. Finally, the CNF contents of C/C composite were 3%, 5% and 7%, respectively.

2.2.3 Densification of preforms

The preforms with CNFs were densified by CVI to obtain CNF-C/C composites. The CVI was performed at the temperature of 1000 °C under the pressure of 1 kPa. Propylene was used as the source of carbon and nitrogen was used as dilute gas.

For comparison, a blank sample without the modification of CNFs (C/C composites) was also prepared with the same carbon fiber content in the same CVI.

2.3 Flexural test and structural characterization

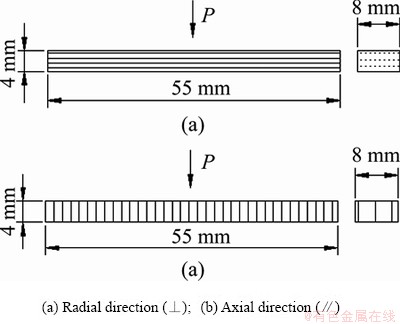

The flexural strength was measured using three-point bending test. Specimens were prepared from four various composites. The testing directions were divided into the carbon fiber axial direction and the carbon fiber radial direction, as shown in Fig. 2. Seven test specimens were prepared for each testing group. The bending test was performed on an electronic universal testing machine (CSS-44100). The span was 50 mm and the loading rate was 0.2 mm/min. The final data were the averages of five valid test data of each testing group. The structure and fracture morphology of the samples were examined by scanning electron microscopy (SEM, Jeol-6360LV).

Fig. 2 Sketch of flexing intension test

3 Results and discussion

3.1 Effect of CNFs on flexural properties of C/C composites

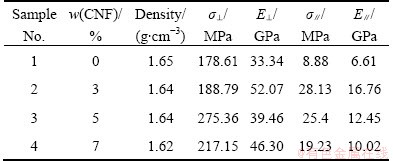

The flexural properties of the C/C composites with and without CNFs are shown in Table 2. Compared with the C/C composites, the flexural strength and modulus of the CNF-C/C composites in the axial and radial directions are both improved, especially in the axial direction. The flexural strength and modulus of the C/C composites with 3% CNFs have the maximum increment in the axial direction, with the increments of 217 and 154%, respectively, while in the radial direction, the increments of the flexural strength and modulus reach the maximum when the content of CNF is 5%. The strength in radial direction of the composites is dependent on the strength of carbon fibers and the state of the fiber/matrix interface, while the strength in axial direction of the composites is related to the strength of matrix and the interfacial bonding between fibers and matrix. The existence of CNFs contributes mainly to the structural change of the matrix and the fiber/matrix interface [16], which results in the more influence of CNFs on the properties of C/C composites in the axial than that in the radial direction. Meanwhile, from the Table 2, it can also be found that the flexural properties of C/C composites firstly increase and then decrease with the CNF content increasing. The flexural property change of C/C composites is not only dependent on the structural change resulting from CNFs, but also related to the porosity of composites. The pore structure of the preforms with CNFs is changed according to the increase of the CNF content [18], which results in the change of the aperture and the distribution of the pores inside of the composites. Therefore, when the CNF content reaches a certain degree, the flexural properties of CNF-C/C will decrease, but the reasons need more researches.

Table 2 Flexural properties of composites

Fig. 3 Load-displacement curves of C/C composites with different CNF contents

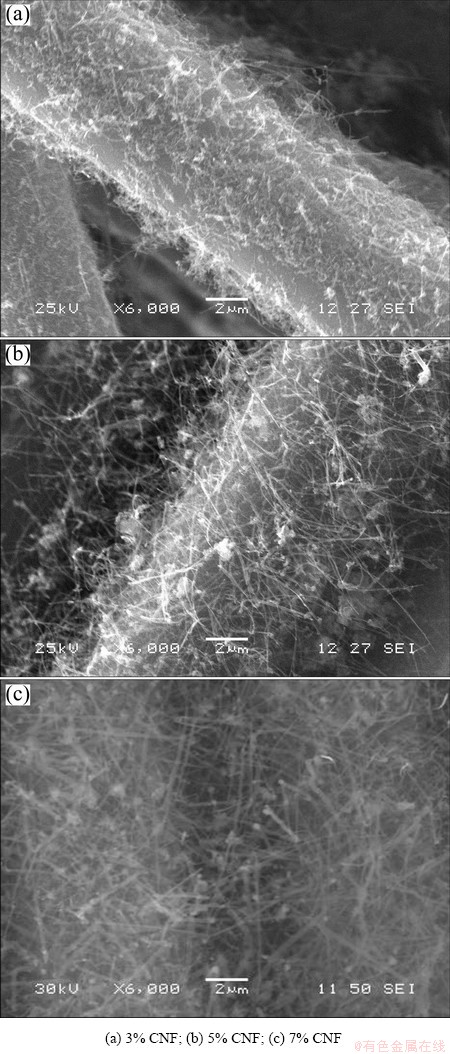

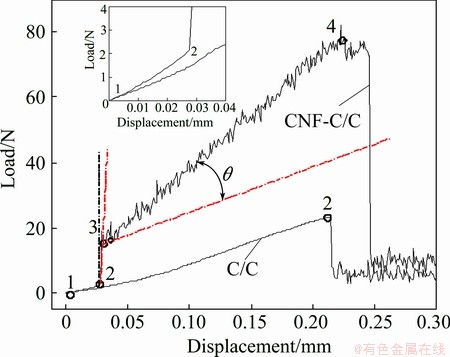

The load-displacement curves of C/C composites with different CNF contents by three-point bending test are shown in Fig. 3. It is obvious that the curve slop and the maximal load taken by the CNF-C/C composites are both higher than those of the C/C composites. The curves of the CNF-C/C composites with different CNF content are similar in shape, but all the curves of the CNF-C/C composites are different from those of the C/C composites without CNFs. It can also be seen that the load-displacement curves in the radial direction of the two kinds of composites are in the same shape as in Fig. 3(a), while the shapes of load-displacement curves in the axial direction of the CNF-C/C composites are different from those of the C/C composites as shown in Fig. 3(b). In the axial direction, there is a sharp increase at the beginning in the curves of the CNF-C/C composites, which is the elastic deformation stage, followed by a serrated yielding phenomenon similar to the plastic materials. The structure of the matrix and the fiber/matrix interface which carry the main load in the axial direction are both changed under the influence of CNFs, which lead to the shape change of the curves. Although the fiber/matrix interface is amended by CNFs, carbon fibers mainly take the load in the radial direction. So the shapes of the curves are not changed. In addition, it can also be found from Table 2 and Fig. 3 that the increase of the slop is not in accordance with the increase of CNF content. In our work, the diameter of CNFs is shown in Fig. 4. However, the change of the length and distribution density of CNFs causes the different structures of the matrix and fiber/matrix interface (the detail seen in Ref. [16]). But the relationship between the length and distribution density of CNFs and the fiber/matrix interfacial bonding needs more research, which is also included in our next work.

Fig. 4 SEM images of in situ grown CNFs on surface of carbon fibers

Based on the similar load-displacement curves of the C/C composites with the different CNF contents, the detailed analysis of destructive process can be made by choosing one of the curves. Considering the different influence of CNFs on the flexural properties in the different directions, in order to give prominence to the effect of CNFs, the microstructure and the flexural properties of the CNF-C/C composites with the CNF content of 3% were studied in this research.

3.2 Effect of CNFs on fracture surface of C/C composites

The photographs of fracture surfaces of the two composites in the radial direction are shown in Fig. 5 and Fig. 6. It can be observed that the main failure mode of the C/C composites is the pull-out of single fiber, whereas that of the CNF-C/C composites is the breaking of fiber bundles. For the C/C composites, single carbon fiber is pulled out from pyrocarbon (PyC) and the conspicuous stratification of PyC around carbon fibers can be seen clearly in Fig. 5(a). Those structural characteristics indicate that the cracks formed by the load contribute to the matrix damage preferentially. Owing to the interface cracks and the weak bonding between carbon fibers and matrix, matrix cracks propagate to the fiber/matrix interface and then change the propagation direction, which results in the pull-out of carbon fiber. However, for the CNF-C/C composites, the fracture surface is rough and stepwise as shown in Fig. 5(b). The interface between carbon fiber and PyC is fuzzy and there is no stratification in PyC. The existence of CNFs not only leads to the structural change of PyC from low textured (LT) to high textured (HT) and middle textured (MT) structure (shown in Fig. 6), but also amends the fiber/matrix interface, forming multi-structural interface.

Fig. 5 SEM images of fracture surface in radial direction of C/C composites (a) and CNF-C/C composites (b)

Fig. 6 TEM image of C/C composites (a) and CNF-C/C composites (b)

In addition, deposition of PyC occurs preferentially on the CNF surface, which results in the change of direction between PyC layer and carbon fiber. The details of the structural changes could be seen in the previous report

In the axial direction, the bending loads are carried mainly by the matrix and the flexural strength is strongly influenced by the fiber/matrix interface. Figure 7 shows the photographs of the fracture surfaces of the two composites in the axial direction. For the C/C composites, the fracture surface is smooth and PyC of adjacent fibers is torn. While for the CNF-C/C composites, there is stepwise fracture surface and many cracks occur in the different direction, which indicates that the flexural failure mechanism of C/C composites with CNF modification is converted in the axial direction.

Fig. 7 SEM images of fracture surfaces in axial direction of C/C composites (a) and CNF-C/C composites (b)

Fig. 8 Load-displacement curves of C/C composite and CNF- C/C composites in axial direction

Fig. 9 Schematic of fracture process of C/C composite

3.3 Enhancement mechanism of CNFs on flexural properties of C/C composites

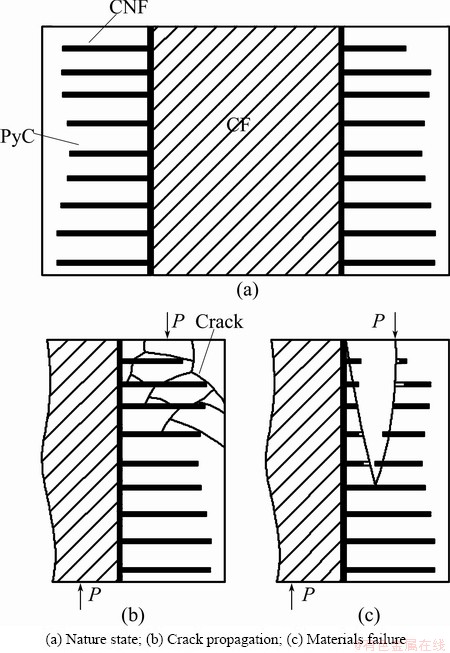

In order to further investigate the influence of CNFs on the flexural properties of C/C composites, the detailed analysis of Fig. 3(b) is shown in Fig. 8. For the C/C composites, there are two stages in the load- displacement curve. One is the stage of matrix elastic deformation, and the other is the stage of brittle fracture of the whole composites. The schematic of the fracture process of C/C composites is shown in Fig. 9. When the external load is beyond the elastic limit of the matrix, the matrix cracks are initiating, growing and propagating to the fiber/matrix interface, and then the C/C composites are torn along the fiber/matrix interface. Many fiber/matrix interfaces apart and consequently brittle fracture occurs. Therefore, the facture surface of C/C composites is smooth and torn, just like shown in Fig. 7(a).

Compared with the two stages of the C/C composites, the load-displacement curve of the CNF- C/C composites in the axial direction can be divided into four stages, as shown in Fig. 8. The first one is the stage of elastic deformation of matrix (from point 1 to point 2). The second one is the stage of elastic deformation of the interface reinforced by CNFs (from point 2 to point 3). The third one is the stage of visco-elastic deformation of the PyC matrix reinforced by CNFs (from point 3 to point 4). The last one is the stage of brittle fracture of the whole composites. To better explain the fracture process, the schematic of the fracture process of CNF-C/C composites is shown in Fig. 10. In this schematic, the CNFs are assumed to grow along the radial direction in order to simplify the schematic.

In the first stage, the external load is low and the curve slop of the CNF-C/C composites is slightly larger than that of the C/C composites. In this stage, the elastic deformation of the composites is mainly dependent on the elastic deformation of the matrix. Modified by in-situ grown CNFs, the matrix is composed by CNFs and granular PyC, which result in the higher strength and modulus of the matrix in the axial direction. Therefore, the curve slop of the CNF-C/C composites increases.

In the second stage, the external load is beyond the elastic limit of the matrix (point 2 in Fig. 8). At this stage, the matrix cracks are quickly initiative, growing and propagating. When the cracks propagate to the fiber/matrix interface, the complex interface which consists of the in-situ grown CNFs, HT-PyC and MT-PyC can block the crack propagation and change the propagating direction of the main crack, resulting in lower propagation rate of the cracks, and consequently the internal stress is released (Fig. 10(b)). In addition, CNFs with exceedingly high strength and modulus are grown randomly along the radial direction, which can effectively transfer and bear loads. Therefore, the deformation of the composites is more difficult. The curve slop increases suddenly, and a sharp increase appears in the load-displacement curve.

Fig. 10 Schematic of fracture process of CNF-C/C composites

In the third stage, with the continuous increase of the external load, the slope of the load-displacement curve is less than that of the second stage, and the CNF-C/C composites show the serrated yielding phenomenon similar to the plastic materials. Nevertheless, the curve slope of the CNF-C/C composites is still much higher than that of the C/C composites. In this stage, the external load is larger than the elasticity limit of the PyC-covered CNF. Owing to the existence of micro-interfaces between CNF and HT-PyC, the crack propagation can be blocked and the propagating direction of the main cracks is varied, by means of the mechanisms such as micro-interfacial debonding, pull-out of CNF and the bridge between CNFs. Consequently, the purpose of reinforcement reaches, and the load-displacement curve in this stage rises along with fluctuations (Fig. 10(c)).

In the last stage, the external load increases to over the elasticity limit of carbon fiber bundle (point 4 in Fig. 8). Cracks quickly grow and propagate along the boundary of carbon fiber bundle, which results in the breakage of carbon fiber bundles. Then the brittle fracture failure of the whole composites occurs.

4 Conclusions

1) The flexural curve of the CNF-C/C composites shows a sharp increase followed by the serrated yielding phenomenon similar to the plastic materials. The failure mode of the C/C composites modified by in situ grown CNFs is changed from the pull-out of single fiber to the breakage of fiber bundles.

2) These flexural property changes are attributed to the microstructural change. Modified by in situ grown CNF, the interfacial layer which consists of CNF and PyC is formed, which conduces the lower crack propagation rate.

3) The CNFs with high strength and modulus can effectively transfer and bear loads, which leads to more difficult deformation of the composites. The existence of CNFs can also amend the microstructure of PyC and change the direction between carbon fiber and graphite layers in PyC, which is the other reason that the flexural properties of composites are significantly increased.

4) Although the reasons of the improvement of the properties of the C/C composites with CNFs have been given in this work, it is not yet clear to the relationship between the CNF content and the strength of the carbon fiber, matrix and interface, which needs more research.

References

[1] ROLLIN M, JOUANNIGOT S, LAMON J, PAILLER R. Characterization of fiber /matrix interfaces in carbon/carbon composites [J]. Composites Science and Technology 2009, 69(9): 1442-1446

[2] CHEN Jie, XIONG Xiang, XIAO peng. Effect of boric acid on carbon fiber and thermal conductivity of C/C composites [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(5): 783-788. (in Chinese)

[3] LU Jin-hua, LI He-jun, LIU Hao, HU Zhi-biao, CHEN Qiang. Effect of surface treatment on flexural property of 2D C/C composites conductive oxide thin films [J]. Journal of Materials Engineering 2005, 9: 3-6.

[4] CHEN Jie, YU Shu, XIONG Xiang. Effect of nitric acid oxidation on carbon fibers and microstructure of pyrocarbon during CVD [J]. Journal of Central South University: Science and Technology, 2012, 43(2): 460-465. (in Chinese)

[5] MAPKAR J A, BELASHI A, BERHAN L M, COLEMAN R M. Formation of high loading flexible carbon nanofiber network composites [J]. Composites Science and Technology 2013, 75: 1-6.

[6] AL-SALEH M H, SUNDARARAJ U. A review of vapor grown carbon nanofiber/polymer conductive composites [J]. Carbon, 2009, 47(1): 2-22.

[7] LAKSHMINARAYANAN V P, TOGHIANI H, PITTMAN C U Jr. Nitric acid oxidation of vapor grown carbon nanofibers [J]. Carbon, 2004, 42(12-13): 2433-2442.

[8] WANG Sha-sha. Preparation and characterization of blocky cabon nanofibers and carbon/carbon composites [D]. Shanghai: East China University of Science and Technology, 2011: 1-13. (in Chinese)

[9] MATSUI K, LANTICSE LJ, TANABE Y, YASUDA E, ENDO M. Stress graphitization of C/C composite reinforced by carbon nanofiber [J]. Carbon, 2005, 43(7): 1577-1579.

[10] GONG Qian-ming, LI Zhi, ZHOU Xiang-wen, WU Jian-jun, WANG Ye, LIANG Ji. Synthesis and characterization of in situ grown carbon nanofiber/nanotube reinforced carbon/carbon composites [J]. Carbon, 2005, 43(11): 2426-2429.

[11] LI Xin-tao, LI Ke-zhi, LI He-jun, WEI Jian, WANG Chuang. Microstructures and mechanical properties of carbon/carbon composites reinforced with carbon nanofibers/nanotubes produced in situ [J]. Carbon, 2007, 45(8): 1662-1668.

[12] LI Jin-song, LUO Rui-ying. Study of the mechanical properties of carbon nanofiber reinforced carbon/carbon composites [J]. Composites A, 2008, 39(11): 1700-1704.

[13] LI Jin-song, LUO Rui-ying, YAN Ying. Effect of carbon nanofibers on the infiltration and thermal conductivity of carbon/carbon composites [J]. Material Research Bulletin, 2011, 46(9): 1437-1442.

[14]  M, DENEUVE A, AMADOU J, BEGIN D, PHAM-HUU C. Mechanical enhancement of C/C composites via the formation of a machinable carbon nanofiber interphase [J]. Carbon, 2008, 46(1): 76-83.

M, DENEUVE A, AMADOU J, BEGIN D, PHAM-HUU C. Mechanical enhancement of C/C composites via the formation of a machinable carbon nanofiber interphase [J]. Carbon, 2008, 46(1): 76-83.

[15] LI Hai-liang, LI He-jun, LU Jin-hua, LI Ke-zhi, CAN Sun, ZHANG Dong-sheng. Mechanical properties enhancement of carbon/carbon composites by in situ grown carbon nanofibers [J]. Material Science and Engineering A, 2012, 547: 138-141.

[16] LIU Ye-qun, HE Lian-long, LU Xue-feng, XIAO Peng. Transmission electron microscopy study of the microstructure of carbon/carbon composites reinforced with in situ grown carbon nanofibers [J]. Carbon, 2012, 50(7): 2424-2430.

[17] XIAO Peng, LU Xue-feng, LIU Ye-qun, HE Lian-long. Effect of in situ grown carbon nanotubes on the structure and mechanical properties of unidirectional carbon/carbon composites [J]. Material Science and Engineering A, 2011, 528(7-8): 3056-3061.

[18] LI Jin-song, LUO Rui-ying, YAN Yu. Densification kinetics and matrix microstructure of carbon/carbon nanofiber/pyrocarbon composites prepared by electrophoresis and thermal gradient chemical vapor infiltration [J]. Carbon, 2011, 49(1): 242-248.

卢雪峰1,肖 鹏2,徐先锋3,陈 洁2

1. 江南大学 纺织服装学院,生态纺织教育部重点实验室,无锡 214122;

2. 中南大学 粉末冶金国家重点实验室,长沙 410083;

3. 华东交通大学 机电工程学院,载运工具与装备重点实验室,南昌 330013

摘 要:采用催化化学气相沉积法制备原位生长纳米炭纤维(CNFs)改性单向C/C复合材料。通过分析弯曲破坏过程,研究原位生长CNFs对C/C复合材料弯曲性能的影响。结果表明,CNFs的存在明显改变了载荷-位移曲线的线形,在开始的弹性变形阶段出现一个台阶,随后出现类似塑性材料的锯齿状屈服特性曲线。CNF-C/C复合材料的破坏模式由单根纤维的拔出转变为纤维束的断裂。由中织构热解炭(PyC)、CNFs和高织构PyC形成的复杂界面阻碍了裂纹的扩展,改变了裂纹的扩展方向从而导致C/C复合材料具有较高的弯曲强度和模量。

关键词:纳米炭纤维;C/C复合材料;弯曲破坏;裂纹扩展

(Edited by Hua YANG)

Foundation item: Project (2011CB605804) supported by the National Basic Research Program of China; Project (51165006) supported by the National Natural Science Foundation of China; Project (BY2013015-32) supported by Cooperative Innovation Fund-Prospective Project of Jiangsu Province, China; Project (JUSRP1045) supported by the Fundamental Research Funds for the Central Universities, China

Corresponding author: Peng XIAO; Tel: +86-731-88830131; E-mail: xiaopeng@mail.csu.edu.cn

DOI: 10.1016/S1003-6326(14)63452-X