文章编号: 1004-0609(2005)04-0531-05

粉末冶金盘式汽车摩擦片热压成形的数值模拟与实验研究

欧阳鸿武, 张 新, 陈 欣, 余文焘

(中南大学 粉末冶金国家重点实验室, 长沙 410083)

摘 要: 为了探明汽车盘式摩擦片剪切强度不稳定的原因, 用数值方法模拟摩擦片热压成形过程中温度分布和模具局部失效对粉末流动和固结的影响, 并进行了相应的实验分析和验证。 结果表明: 模具局部失效及温度梯度分布造成基体材料溢出, 基体材料的流动导致在剪切面上纤维集合定向排列, 从而大幅度降低试样的剪切强度; 当基体出现剪切层, 导致纤维成定向分布时, 剪切强度明显下降, 低于要求的0.4MPa(最高值仅为0.356MPa), 而在无溢出情况下, 剪切强度都高于0.4MPa。

关键词: 盘式摩擦片; 粉末冶金; 热压成形; 数值模拟 中图分类号: TF124.3

文献标识码: A

Numerical and experimental study on hot press of

powder metallurgical disk brake pad

OUYANG Hong-wu, ZHANG Xin, CHEN Xin, YU Wen-tao

(State Key Laboratory of Powder Metallurgy,Central South University, Changsha 410083, China)

Abstract: To find out the causes about unstable shear strength of PM disk break pad, the hot press process of PM disk brake pad was numerically simulated by using finite element method. The influence of temperature distribution and mould failure on powder flow and consolidation was analyzed, and the corresponding experiments were conducted. The effect of powder flow on fiber orientation and shear strength was unveiled. The results show that mould failure and temperature gradient can lead to obvious flow of matrix in the shear direction. The flowing of matrix can result in oriented arrangement of fiber in shear direction and greatly reduce the shear strength of samples. In the situation of fiber orientation caused by shear layer, the pads shear strength can only reach 0.356MPa; while in normal condition it can attain to 0.4MPa or higher.

Key words: disk brake pad; powder metallurgy; hot press; numerical simulation

汽车的制动性是关系到交通安全的一个十分重要的性能。 汽车制动, 尤其是急制动时, 摩擦片在摩擦方向上要承受很高的剪切力, 而且动能转化会使摩擦片温度急剧上升, 从而使其强度显著降低。 沿摩擦方向的剪切强度是汽车摩擦片一个至关重要的性能指标[1] 。 摩擦片剪切强度是否足够高, 直接关系到汽车制动系统的可靠性和安全性[2]。 为了确保汽车的安全性, 一般要求盘式摩擦片与钢背间的剪切强度大于某一指标, 如0.4MPa以上。 这就对摩擦片的生产工艺提出了较高的要求。

热固性树脂基汽车盘式摩擦片的生产基本上采用加热模压工艺。 这个热压成形过程很复杂, 既是摩擦材料的成形过程, 又是树脂受热液化胶联的固化过程[3, 4]。 影响热固化树脂基汽车摩擦片剪切强度的主要因素有摩擦片的结构、 摩擦材料成分、 粘结剂、 加工工艺、 模具和设备。 如果由于模具局部失效等原因, 在成形过程中材料产生不合理流动, 形成剪切层, 将导致摩擦片与钢背的结合强度降低, 形成安全隐患; 另外, 由于存在温度梯度树脂分层液化造成压坯在垂直方向上分层开裂, 导致产生大量废品。

大量研究表明, 增强纤维在基体中的分布状况对摩擦材料的剪切强度有至关重要的影响。 在材料的热压成形过程中, 粉末的不合理流动可能导致纤维的定向分布, 从而使剪切强度不稳定, 不能达到标准要求 (0.4MPa以上)。 在实际的生产过程中, 往往出现产品的剪切强度不够或是在很大范围内波动的情况, 成为汽车摩擦片生产中急需解决的质量隐患。

基于有限元方法的数值模拟技术近年来成为研究粉末压制成形过程的有效手段 [5-10]。 通过数值模拟可以掌握摩擦片压制成形过程中的粉末流动规律, 获得各种场量分布状态, 进而优化工艺。 本文作者采用非线性有限元软件Marc.Mentat[11]模拟分析了摩擦片压制成形过程中温度分布和模具结构对粉末流动的影响, 确定影响摩擦片剪切强度的关键因素。 在此基础上, 通过实验研究了粉末流动对纤维取向及纤维取向对剪切强度的影响, 并提出了行之有效的方法和措施, 以改善剪切强度, 提高汽车摩擦片的产品质量。

1 热压成形过程模拟

摩擦材料热压成形过程的计算简化模型如图1所示。 取压模的径向截面作为研究对象, 将问题简化为平面应力问题。 数值模拟的参数选取如下: 模腔直径45mm, 填粉高度18mm, 填粉的初始相对密度0.60, 摩擦因子0.2, 压制终了高度10mm。 材料模型为与温度相关的Mooney[11, 12]。

图1 温度场的简化计算模型

Fig.1 Computation model

1.1 温度场的模拟

为了探明温度分布对热压成形过程中摩擦片的影响和特征, 设计了一个温度场的简化模型。 在上模冲与下模冲温度为170℃的恒温下进行压制并保压保温20s后, 其温度场的分布如图2所示。

图2 压制过程中的温度梯度分布

Fig.2 Gradient temperature distribution in pressing process

很明显, 温度场在材料内的分布在y方向有明显的分层现象, 靠近模壁位置的材料温度比内部要高很多, 所以这些位置的材料流动性比内部要高很多。 易于形成平行于剪切面的温度梯度分布。

1.2 压制过程的模拟

根据模具结构和成形工艺的实际情况, 设定如下两个算例, 其几何模型和网格划分如图3所示, 装粉高度均为18.00mm。 图3(a)所示为钢背与模具密合的情形; 图3(b)为钢背与模具的结合面间由于钢背的不平整或模具局部破损产生间隙的情形。 钢背的不平整, 或模具密封边缘的破损在生产中经常发生, 这是导致膜腔不密闭的主要原因; 另外, 由于模具密封面不够清洁, 夹杂物或颗粒的存在, 也可以导致膜腔不密合。

图3 计算模型和网格划分

Fig.3 Two computation models

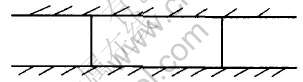

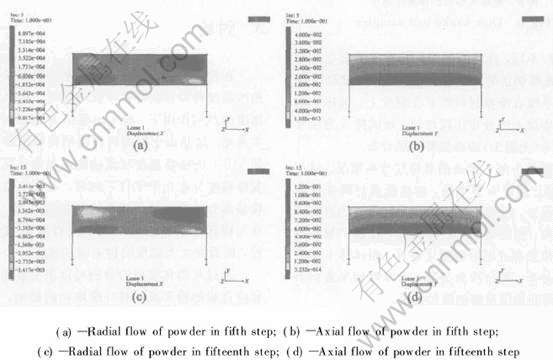

设置计算参量时, 以阳模轴向位移为输入, 将模拟设计为可以压制到接近全致密, 以观察摩擦材料由松装粉末到全致密的过程。 图4所示为密合情况下粉末的流动状况, 图5所示为存在间隙情况下的粉末流动状况。

图4 密合模型粉末轴向流动和径向流动状况

Fig.4 Powder flowing state simulated by sealed model

图5 有间隙模型粉末轴向流动和径向流动状况

Fig.5 Powder flowing state simulated by unsealed model

分析压制过程的模拟结果可以发现, 在压制过程中一旦有溢出, 粉末在剪切面上将发生大幅度的横向流动, 尤其是当剪切面靠近并平行钢背时, 这种现象尤为明显, 将导致产品剪切强度的降低。

2 实验验证

为了探明摩擦片热压成形过程中粉末流动状况, 进行了相应的实验对比分析。

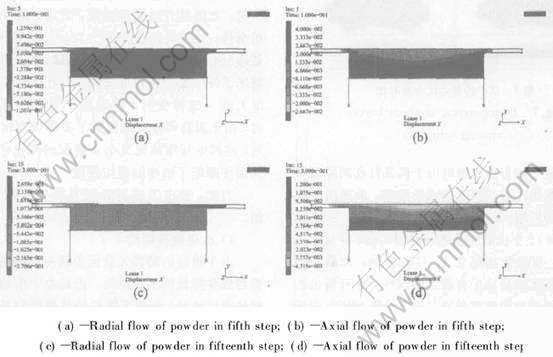

图6所示为一组摩擦片在剪切实验后摩擦材料在钢背上的粘附情况及剪切层分布。 由于模具条件(间隙)不同, 压坯在压制后的溢出情况也各有不同, 导致剪切层的分布有很大的差别。 试样1在剪切后几乎没有摩擦材料附着在钢背上, 试样3的纤维在剪切层上的分布比较均匀, 而试样5为正常压制情况下(无溢出)的典型剪切层分布。

图6 剪切实验后的摩擦片试样

Fig.6 Disk brake pad samples

图7所示为两个样品的剪切层分布情况。 试样a的剪切层比试样b要平整, 而且摩擦材料在钢背上附着的很少, 这是由于纤维在剪切层处的取向不是随机分布, 而是呈一定的方向性, 导致了剪切层处与其它位置存在明显的强度差异。 而试样b中的纤维随机分布, 取向较为分散, 所以剪切层表面很粗糙, 因而能提供足够的剪切强度。

图7 试样的剪切层分布对比

Fig.7 Comparison of shear layers among samples

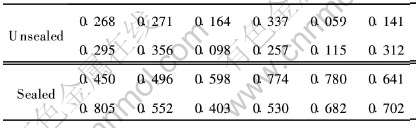

为了进一步分析压制时由于模具存在间隙使粉末溢出对摩擦片剪切强度造成的影响, 取两组模具进行试样的压制。 一组在压制时存在溢出, 一组无溢出。 各取12个压制样品进行剪切实验, 并对比其剪切强度。 实验数据见表1。 可以看到, 无溢出的试样剪切强度明显高于有溢出的试样。 在有溢出的情况下试样的剪切强度最高只有0.356MPa, 而无溢出时的剪切强度有大幅度提高, 可以达到0.7~0.8MPa, 最低的也高于0.4MPa。 结果表明: 纤维的分布情况直接影响剪切强度, 纤维在剪切面的定向分布显著降低了摩擦片的剪切强度。

表1 无溢出与有溢出两种情况下剪切强度的对比

Table 1 Contrast between shear strength of two group of samples (MPa)

3 讨论

在没有溢出的情况下, 粉末的流动状况与理想的压制过程符合较好; 存在间隙时, 在外力与温度梯度的共同作用下, 粉末沿溢出方向有大幅度的粉末流动。 这是由于摩擦材料内的树脂基体在温度达到110℃的临界温度时流动性有很大提高[12], 并且温度梯度分布几乎平行于钢背, 在受热过程中靠近模壁部分的摩擦材料首先达到临界温度, 而此处钢背与模具之间密合不均匀, 没有能形成封闭的模腔, 因而发生大幅度的粉末流动现象。

通过对简化模型的分析可以很明显的看到温度梯度造成的粉末流动对纤维取向的影响。 纤维在摩擦材料中的作用是提高强度, 增强承载能力。 在工作过程中, 作用于基体材料上的压力和剪切力, 通过基体转嫁到纤维上。 而基体的作用是传递应力, 保护纤维表面不受损伤, 维持纤维原来的尺寸, 稳定纤维的集合排列。 基体和纤维必须很好地结合在一起, 才能具有足够的强度, 否则, 基体与纤维互相滑移, 材料就会被破坏[12, 13]。 在成形中, 纤维与基体没有很好地结合在一起, 它们之间的相互滑移破坏了纤维集合排列与取向。 当纤维与基体的滑移增大到一定程度时, 就形成了定向的剪切面。 同时, 由于滑移致使纤维形成了沿剪切方向的定向排列, 这样的纤维排列完全不能起到强化作用, 反而大幅度降低了试样的剪切强度[14, 15]。

为此, 提出了提高摩擦片剪切强度的改进措施。

1) 改进模具结构

由于模具的局部失效而导致材料的溢出是试样剪切强度降低的主要原因。 正是由于压制时基体材料的剪切流动, 形成了明显的剪切层和基体材料中纤维的定向排列, 造成试样剪切强度的大幅降低。 通过改进模具结构设计, 或加强对模具的维护保养, 防止溢出的产生, 避免基体材料中纤维的定向排列, 可以有效提高试样的剪切强度。

2) 改善温度场的分布状况

压制时的热传导造成基体材料内部产生的温度梯度分布是导致材料流动和基体材料内部纤维定向分布的重要原因。 通过调整模具压力、 放气次数和时间, 以及加热时间、 保温时间来降低温度梯度, 使摩擦材料在压制过程中内外温度基本一致, 可以有效地避免出现剪切流, 从而提高试样的剪切强度。

4 结论

通过对汽车制动材料压制成形过程的数值模拟与剪切实验研究, 探讨了模具局部失效和温度场的梯度分布对摩擦片产品质量(剪切强度)的影响。 结果表明, 模具局部失效及温度梯度分布会造成基体材料在剪切方向上的大幅度流动而形成剪切层, 导致纤维局部沿平行于剪切面定向排列, 从而使剪切强度由正常状况下的0.4~0.8MPa下降到0.356MPa以下。 降低温度梯度和避免模具失效, 是提高汽车盘式摩擦片剪切强度, 从而预防产品失效的有效措施。

REFERENCES

[1] 郑怡地, 苏天祝. 粉末冶金汽车刹车片抗剪强度试验[J]. 粉末冶金技术, 1991(2): 43-45.

ZHENG Yi-di, SU Tian-zhu. Experiment on shear strength of powder metallurgical disk brake pad[J]. Powder Metallurgy Technology, 1991(2): 43-45.

[2] 李 欣, 刘晓辉. 影响汽车刹车片粘接质量的因素分析[J]. 粘接, 1999(6): 35-37.

LI Xin, LIU Xiao-hui. Analysis of the factors of adhesion quality of disk break pad[J]. Adhesion in China, 1999(6): 35-37.

[3] 张广平, 戴干策. GMT流动成形纤维取向研究[J]. 高分子材料科学与工程, 2003(1): 140-143.

ZHANG Guang-ping, DAI Gan-ce. Research of orientation GMT flow forming fiber[J]. Polymeric Materials Science and Engineering, 2003(1): 140-143.

[4] 康忠武. 汽车刹车片新型热压模[J]. 模具工业, 1993(10): 42-44.

KANG Zhong-wu. New style of disk break pad hot-pressing mold[J]. Die and Mould Industry, 1993(10): 42-44.

[5] 黄培云. 粉末冶金原理[M]. 第二版. 北京: 冶金工业出版社, 1997.

HUANG Pei-yun. Fundamentals of Powder Metallurgy[M]. 2nd ed. Beijing: Metallurgical Industry Press, 1997.

[6] 王盘鑫. 粉末冶金学[M]. 北京: 冶金工业出版社, 1997.

WANG Pan-xin. P/M Metallurgy[M]. Beijing: Metallurgical Industry Press, 1997.

[7] Krezalek I C, Sivakumar K. Computational simulation of powder movement during uni-axial die compaction of metal powders[J]. Journal of Materials Processing Technology, 1995, 48: 421-427.

[8] PM Modnet Research Group. Numerical simulation of powder compaction for two multilevel ferrous parts, including powder characterisation and experimental validation[J]. Powder Metallurgy, 2002, 45: 335-344.

[9] 陈火红. Marc有限元实例分析教程[M]. 北京: 机械工业出版社, 2002.

CHEN Huo-hong. Instance Analysis Course of Marc[M]. Beijing: China Machine Press, 2002.

[10] 董林峰. 粉末金属成形中的缺陷预测与成形过程的计算机仿真[D]. 上海: 上海交通大学, 2000.

DONG Lin-feng. Defect Forecast and Computer Emulation of Progress in Metal Powder Formation[D]. Shanghai: Shanghai Jiaotong University, 2000.

[11] 汪 俊. 粉末金属成形过程建模与成形工艺计算机仿真[D]. 上海: 上海交通大学, 1999.

WANG Jun. Progress Modeling and Computer Emulation in Metal Powder Formation[D]. Shanghai: Shanghai Jiaotong University, 1999.

[12] 任学平. 粉末金属屈服准则和流动应力的研究[D]. 哈尔滨: 哈尔滨工业大学, 1989.

REN Xue-ping. Research of Yield Criterion and Flow Stress of Metal Powder[D]. Harbin: Harbin Institute of Technology, 1989.

[13] 史铁钧, 何 涛, 吴德峰. 改性滑石粉填充聚丙烯/高密度聚乙烯复合体系的流变性能[J]. 高分子材料科学与工程, 2004(1): 125-128.

SHI Tie-jun, HE Tao, WU De-feng. Rheological property of complexus of polyethylene filling with denatured talcum powder and high density polyethylene[J]. Polymeric Materials Science and Engineering, 2004(1): 125-128.

[14] 苏 堤, 李度成. 汽车半金属刹车材料的磨损问题[J]. 汽车工艺与材料, 1997(5): 33-34.

SU Di, LI Du-cheng. Defacement of semimetallic break material[J]. Automobile Technology & Material, 1997(5): 33-34.

[15] 马保吉, 朱 均. 芳纶纤维增强酚醛树脂摩擦材料的磨损机理研究[J]. 摩擦学学报, 2001, 21: 205-209.

MA Bao-ji, ZHU Jun. Research of defacement of kevlar enhanced bakelite friction material[J]. Tribology, 2001, 21: 205-209.

基金项目: 国家自然科学基金资助项目(10476034)

收稿日期: 2004-09-21; 修订日期: 2005-01-04

作者简介: 欧阳鸿武(1964-), 男, 教授, 博士.

通讯作者: 欧阳鸿武, 教授; 电话: 0731-8836264; E-mail: oyxy163@163.com

(编辑 袁赛前)