SiC颗粒表面处理对6066Al基

复合材料力学性能的影响

王日初1, 毕 豫2, 黄伯云1, 张传福3

(1. 中南大学 材料科学与工程学院, 湖南 长沙, 410083;

2. 河南工业大学 材料科学与工程学院, 河南 郑州, 450007;

3. 中南大学 冶金科学与工程学院, 湖南 长沙, 410083)

摘要: 分别对SiC颗粒进行高温氧化、酸洗和高温氧化后再酸洗等表面处理,采用粉末冶金工艺制备了SiC颗粒增强的6066Al基复合材料。金相显微照片、扫描电镜照片和室温拉伸性能分析结果表明:采用氧化和酸洗表面处理工艺能使SiC颗粒产生明显钝化,且随着氧化时间的延长,钝化效果提高,SiC颗粒分布更均匀;随着氧化时间的延长,复合材料的抗拉强度σb和断裂韧性KIC提高,且酸洗态的性能优于相应氧化态的性能;6066Al基复合材料的力学性能除与SiC颗粒分布的均匀程度有关外,还与颗粒的形状以及复合材料的界面状况有关。

关键词: 6066Al基复合材料; SiC颗粒; 表面处理; 力学性能

中图分类号:TG146.2+1 文献标识码:A 文章编号: 1672-7207(2005)03-0369-06

Effect of surface treatment of SiC particle on

mechanical properties of SiCp/6066Al composites

WANG Ri-chu1, BI Yu2, HUANG Bai-yun1, ZHANG Chuan-fu3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Henan University of Technology, Zhengzhou 450007, China;

3. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The surface treatment of oxidation, acid-washing and acid-washing after oxidation were carried out on SiC particles, then 6066 aluminum alloy reinforced by SiC particles was fabricated by powder metallurgy route. The analytical results of metallography, scanning electron microscopy and tensile test show that SiC particles are apparently passivated by oxidation and acid-washing; with the increase of oxidation time the passivated effect is enhanced, and the distribution of SiC particles is more homogeneous. At the same time the tensile strength(σb) and fracture toughness(KIC) of the composites are improved, and tensile strength and fracture toughness of acid-washing after oxidation are greater than those of oxidation, which are concerned with the distribution of SiC particles, and are also related to the interfacial nature and interfacial bonding of the composites. Such surface treatment as high temperature oxidation and acid-washing can be used to improve the distribution of SiC particles and enhance the strength of composites.

Key words: 6066aluminum matrix alloy; SiC particles; surface treatment; mechanical properties

近年来,SiC增强Al基复合材料由于具有较高的比强度和比刚度,作为结构材料越来越受重视, 这些性能对质量要求高的部件,如航空、汽车及航海等方面的应用来说尤为重要。然而,所加入的增强相在提高复合材料强度和刚度的同时将显著降低材料的塑性和断裂韧性。颗粒增强金属基复合材料的断裂韧性KIC一般只有15~27 MPa·m1/2,均低于相应基体合金的断裂韧性,这在一定程度上限制了复合材料的推广应用。

为了提高SiC颗粒增强铝基复合材料的强度和塑性,出现了多种对SiC颗粒进行表面预处理的方法,最常用的表面处理方法有高温氧化[1-3]、酸洗[4]、表面涂层[5]等方法。在此,作者利用高温氧化和高温氧化后再酸洗2种方法对SiC颗粒进行表面处理,研究不同表面处理方法对复合材料力学性能的影响。

1 实验过程

用N2雾化获得粒径为147μm以下的6066铝合金粉末,通过化学分析,所得合金的实际成分为:Al-1.32%Mg-1.62%Si-1.21%Cu-0.82%Mn(其中数据为质量分数)。所用增强相是平均颗粒尺寸为5μm的绿色SiC。

对SiC颗粒分别进行低温加热、高温氧化和高温氧化后酸洗处理,即进行:原始态处理(置于箱式电阻炉中于200 ℃加热以除去结晶水和吸附物)、氧化态处理(置于刚玉坩埚中于1100 ℃分别氧化6,10 h)、酸洗态处理(原始态和氧化态样品在5%的氢氟酸中浸泡3 h后烘干)。

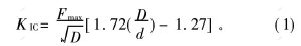

在不同状态下,体积分数为13%的SiC与6066铝合金粉末球磨混料后冷等静压成锭坯,然后于410 ℃以16∶1的挤压比挤压成棒材。挤压棒材于520 ℃固溶1 h后水淬,再于170 ℃时效8 h。性能测试采用直径为6 mm的圆柱状标准试样。断裂韧性用“V”形环缺口试样圆棒拉伸法测定,试样加工形状与尺寸参见文献[6],最后,采用如下公式计算其断裂韧性:

其中:Fmax为最大拉断力;D为试样的外径;d为“V”形环的内径。拉伸试样在CSS-44100电子万能试样机上以1 mm/min的夹头位移速度进行。采用Polyvar-MET金相显微镜和JSM-5600LV型扫描电子显微镜分别观察试样变形前、后以及断口的显微组织。

2 实验结果与分析

2.1 SiC颗粒形貌

图1所示为SiC颗粒原始态和于1100 ℃空气环境中氧化10 h以及氧化10 h后再酸洗的SEM照片。可见:氧化处理后的颗粒几乎完全除去了很尖锐的角,说明氧化处理具有一定的钝化作用;尖角处的能量比平滑处的能量高,所以,在氧化腐蚀时尖角处的反应更剧烈,随着反应程度的增加,尖角处的钝化效果逐渐提高。图1(b)中颗粒表面的小粒状凸起比图1(a)中的更多、更大和更明显。由文献[2,7]可知,这些白色的凸起为氧化层SiO2,说明随着氧化时间的延长,SiC颗粒表面沉积的SiO2增厚,这与文献[2,8]中的结果相符合。比较图1(c)和1(d)可知,图1(d)中颗粒表面较干净,没有白色的小斑点,说明酸洗能消除SiC表面的凸起,净化颗粒表面,而且对钝化颗粒尖角具有一定作用。

2.2 复合材料显微组织

图2所示为挤压后SiCp/6066铝基复合材料的显微组织照片。可见,经挤压变形后,SiC颗粒沿挤压方向呈流线分布,存在SiC颗粒团聚及分布不均匀现象,这与混料工艺有关。经高温氧化(图2(b))和氧化后再酸洗(图2(c))的SiCp/6066铝基复合材料中SiC颗粒的分布比图2(a)中原始态SiCp/6066铝基复合材料中SiC颗粒的分布更加均匀,团聚现象有所减弱。在相同混料工艺下,经高温氧化和高温氧化后再酸洗的样品中增强颗粒的分布均匀性提高,这可能与SiC颗粒高温氧化后尖角钝化以及表面状态的不同有关。此外,在图2(a)中SiC颗粒团聚处还出现不少空洞。图2(b)和2(c)中经过表面处理的SiCp/6066Al虽然存在团聚现象,但团聚处基本上没有出现孔洞。这些孔洞是在样品制备过程中留下的孔隙或制备金相样品过程中SiC颗粒脱落留下的痕迹,说明在经过表面处理的SiC粒径增强的复合材料中,增强相的分布和界面结合状况优于原始态SiC颗粒增强的复合材料中增强相的分布和界面结合状况。这些原始的微裂纹、弱的界面结合以及不均匀分布的SiC颗粒将显著降低复合材料的力学性能,这是由于它们削弱了在变形过程中载荷从基体向增强相的传递作用。因此,提高增强相在基体中分布的均匀性和改善SiC/Al界面的结合状况非常重要。

![]()

(a) 原始态; (b) 1100 ℃氧化10 h,低倍; (c) 1100 ℃氧化10 h,高倍; (d) 1100 ℃氧化10 h+酸洗

图 1 表面处理前、后SiC颗粒的SEM照片

Fig. 1 SEM images of SiC particles before and after surface treatment

![]()

(a) 原始态; (b) 1100 ℃氧化10 h; (c) 1100 ℃氧化10 h+酸洗

图 2 原始态、氧化态和氧化后酸洗SiCp/6066复合材料的金相照片

Fig. 2 Optical morphologies of SiCp/6066 aluminum matrix composites reinforced

by SiC particles of originality, oxidation and acid-washing after oxidation

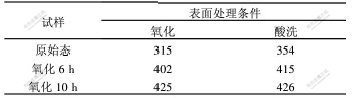

2.3 SiC颗粒表面处理对复合材料抗拉强度的影响

经过不同表面处理后SiC增强复合材料的抗拉强度见表1。可见,原始态SiC增强复合材料的抗拉强度只有315 MPa,而1100 ℃氧化6 h和10 h后样品的抗拉强度分别为402 MPa和425 MPa,比原始态+酸洗复合材料的抗拉强度分别提高了27.6%和34.9%;高温氧化后再酸洗的SiC颗粒增强复合材料的抗拉强度与氧化态样品的抗拉强度类似,原始态+酸洗样品的抗拉强度为354 MPa,氧化6 h后酸洗和氧化10 h后酸洗样品的抗拉强度分别为415 MPa和426 MPa,比原始态复合材料的抗拉强度分别提高了17.2%和20.3%。在相同的氧化时间下,高温氧化后再酸洗的SiC颗粒增强复合材料的抗拉强度高于高温氧化的SiC颗粒增强的复合材料的抗拉强度;而且随着氧化时间的增加,高温氧化后再酸洗颗粒增强复合材料的抗拉强度与高温氧化颗粒增强的复合材料的抗拉强度越来越接近。制备工艺完全相同,而SiC性能却有差别,这与对SiC的表面处理方法有很大关系。由图1和图2可知,经表面处理后的SiC颗粒,其形状和表面状况以及由此引起的颗粒分布均发生了改变,也就是说,SiC性能差异与此有关。

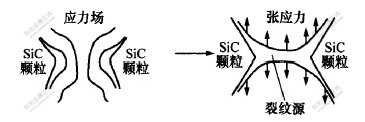

颗粒的形状对复合材料的性能如拉伸性能和断裂性能以及延伸率有很大影响。SiC与Al的热膨胀系数相差较大,约为6∶1。当复合材料从加工温度或固溶温度冷却至室温时,SiC/Al界面处将产生很大的热残余应力,界面附近的基体受张应力作用而SiC颗粒受压应力作用,离颗粒越近,基体所受张应力作用也越大。QIN Shi-yi等[8]利用有限元模拟了不同颗粒形状SiC尖角处的应力场,结果表明:当颗粒为球形时,基体中应力分布均匀,没有出现应力集中现象;当颗粒存在棱角时,在尖角处出现应力集中现象,而且角越尖(角度越小),应力集中越严重,在基体中离颗粒一样远的地方,尖角处的应力远远高于平滑处的应力。由热错配应力造成的基体微区应力场很强,对于Al-SiC体系,增强体颗粒引起基体周围的塑性变形硬化区半径与颗粒的半径相近。在实际复合材料中,增强相并不是均匀分布,往往出现几个SiC颗粒团聚在一起的现象,这时几个带有棱角的SiC颗粒周围的张应力场相互叠加(见图3),轴向张应力互相叠加后形成张应力区,导致微裂纹产生,成为复合材料裂纹形成源,这也是复合材料往往从颗粒聚集处断裂的原因。由图2可看出,经表面处理后的SiC颗粒增强的复合材料中增强相的分布比原始态的SiC增强的复合材料中的增强相的分布更加均匀,因而其性能较优。

表 1 SiC表面处理对复合材料抗拉强度σb的影响

Table 1 Effects of surface treatment of SiC

particle on tensile strength MPa

图 3 SiC颗粒周围应力场叠加使基体中

出现张应力区而产生裂纹源

Fig. 3 Sketch map of overlap of stress field

around SiC particle causing crack source in matrix

SiC颗粒在高温氧化时,尖角处的活性高于平滑处的活性,氧化时尖角处的氧化程度比平面处的氧化程度严重,使原先的尖角被钝化。由图1可见,图1(b)中SiC颗粒明显与图1(a)中的SiC颗粒的形状不同,虽然其中也存在长条形的SiC,但其头部比较光滑,在复合材料中此处的应力集中现象也大大减弱。虽然复合材料中也存在增强相的聚集现象,但几个应力场相互叠加后出现微裂纹的概率已经减少。这是氧化后SiC颗粒增强复合材料的力学性能较好的另一个原因。

SiC颗粒经高温氧化后再酸洗,其形状比原始态SiC颗粒的形状光滑;与氧化10 h后的表面相比,其表面的SiO2层反应完毕,表面光滑,在复合材料中表现为界面光滑、平直及无界面反应产物的干净界面[4],这种界面减少了裂纹生成的概率,所以,比有一层MgAl2O4界面反应产物的界面光滑,性能也优于相应的氧化颗粒增强的复合材料。

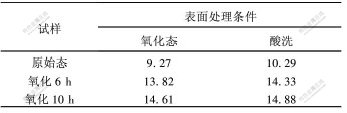

2.4 SiC颗粒表面处理对断裂韧性的影响

经过不同表面处理后的SiC颗粒增强复合材料的断裂韧性如表2所示。可以看出,复合材料的断裂韧性与表1中的抗拉强度存在类似规律,即随着增强颗粒高温氧化时间的增长,其断裂韧性提高。原始态SiC颗粒增强复合材料的断裂韧度为9.27 MPa·m1/2,而1100 ℃氧化6 h和10 h后样品的断裂韧性分别为13.82 MPa·m1/2和14.61 MPa·m1/2,比原始态复合材料分别提高49.1%和57.6%;高温氧化后再酸洗的SiC颗粒增强复合材料的断裂韧性与氧化态样品的断裂韧性存在类似规律,原始态+酸洗样品的断裂韧性为10.29 MPa·m1/2,氧化6 h+酸洗和氧化10 h+酸洗样品的断裂韧性分别为14.33 MPa·m1/2和14.88 MPa·m1/2,比原始态复合材料分别提高39.3%和44.6%。此外,高温氧化后再酸洗颗粒增强复合材料的断裂韧性高于经相同氧化时间氧化后颗粒增强复合材料的断裂韧性。

表 2 SiC表面处理对断裂韧性KIC的影响

Table 2 Effects of surface treatment of SiC

particle on fracture toughness MPa·m1/2

经高温氧化后,SiC颗粒形状发生了改变,基本上没有很尖锐的角,大大减小了棱角处热残余应力和应变的集中现象,提高了裂纹生成能,延缓了裂纹的生成。此外,氧化时间不同,表面覆盖SiO2层的厚度也不相同,在随后的一系列工艺中,于界面处生成一层厚度不同的MgAl2O4。研究结果表明:Al4C3与铝的相对结合强度和SiO2与铝的相对结合强度相当,而MgAl2O4与铝的相对结合强度是前两者的2.5倍,在原始态SiC颗粒增强的复合材料中的界面处也会生成MgAl2O4[3,6];界面生成的脆性尖晶石结构MgAl2O4很少,不连续地分布在界面上,成为裂纹源,导致其断裂韧性比氧化SiC颗粒增强复合材料的低[4]。从图4所示的扫描断口照片可以看到,复合材料的断裂主要沿着界面断开,而氧化后SiC颗粒增强的复合材料的界面结合强度高于原始态SiC颗粒增强的复合材料的界面强度,提高了裂纹生成能和扩展能。综合以上2个方面可知:氧化后SiC颗粒增强复合材料的断裂韧性高于原始态SiC颗粒增强复合材料的断裂韧性,且氧化时间越长,其断裂韧性越强。由图1可见,经氧化和氧化后再酸洗处理,SiC颗粒形状发生了改变,减小了热残余应力和应变的集中现象,延缓了裂纹的生成;同时,酸洗后其表面光滑,使SiC/Al直接结合生成界面裂纹的概率大大减小,而且能有效地阻止裂纹的扩展,宏观表现为经氧化后再酸洗处理的复合材料的断裂韧性高于氧化态的复合材料的断裂韧性。

2.5 SiC颗粒表面处理对断口形貌的影响

复合材料的断裂方式主要有以下4种[9-13]:

a. 空洞在基体中形核和长大而引起基体的延性断裂;

b. 在增强相与基体界面形成的空洞造成界面脱粘,出现增强相从基体中拔出的现象;

c. 在增强相附近基体的延性断裂,表现为增强相从基体中拔出并且外面覆盖一层基体合金;

d. 颗粒的断裂。

当增强相尺寸较小(只有几μm)时,复合材料的断裂方式以c.为主;当颗粒尺寸大于20μm时,断裂以颗粒断裂为主,同时伴随部分SiC颗粒被拔出的界面脱粘现象;当颗粒尺寸介于二者之间且颗粒体积分数较低时,主要表现为基体延性断裂和颗粒被拔出;当SiC体积分数较高时则表现为基体的延性断裂和颗粒的断裂共存。

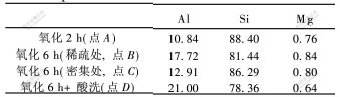

图4所示为复合材料断口的SEM照片。其中,图4(a)为SiC颗粒断裂的照片,图4(b)为SiC颗粒被拔出后韧窝内的基体裂开照片,这2种断裂方式是热残余应力作用的结果。SiC颗粒与基体的热膨胀系数差别较大,在高温冷却时将产生很大热残余应力,SiC颗粒受到压应力的作用,出现图4(a)中的断裂方式;而基体受到张应力的作用,因而出现图4(b)所示的断裂方式。图4(c)所示为SiC颗粒间的基体合金发生塑性变形后留下的细小韧窝,其尺寸明显比SiC颗粒的尺寸小。从图4(d),4(e)和4(f)可以看出:SiC颗粒存在微观分布不均匀现象,随着氧化时间的增长,SiC颗粒分布均匀程度大大提高,这与SiC颗粒在高温氧化时棱角的钝化和表面状态不同有关。同时,复合材料的主要断裂方式为增强体从基体中被拔出和基体合金的延性断裂,而图4(a)和4(b)所示的断裂方式很少。对被拔出的SiC颗粒进行能谱分析,结果见表3。可见,被拔出的SiC颗粒表面含有基体合金元素,说明其表面覆盖一层基体合金,且所覆盖的基体合金厚度随表面处理方法不同而不同。由表3和图4可以看出,经过高温氧化的SiC颗粒增强复合材料的断口中,SiC颗粒表面覆盖的基体合金厚度大于原始态的样品中SiC颗粒表面覆盖的基体合金厚度,但小于高温氧化后再酸洗的样品中SiC颗粒表面覆盖的基体合金厚度。在没有酸洗的情况下,由于氧化时间越长,表面覆盖的SiO2越多,反应2SiO2+2Al+Mg=MgAl2O4+2Si使合金元素向界面偏聚的程度也越大。从表3也可以看出:氧化态样品中的SiC颗粒表面元素偏聚最严重;在所有表面处理的样品中,酸洗态样品中SiC颗粒表面覆盖的基体合金层厚度最大,这可能是由于洁净的SiC/Al界面的结合强度比较高,结合较为牢固;稀疏处的SiC颗粒表面覆盖的基体合金层厚度比密集处的SiC颗粒表面覆盖的基体合金层厚度小。由上可知,复合材料的断裂主要表现为增强相从基体中被拔出,且外面覆盖一层基体合金的基体延性断裂,而颗粒的断裂和基体的热应力断裂方式较少。

![]()

(a) 颗粒断裂; (b) 韧窝内的基体断裂; (c) 基体的韧性断裂; (d) 原始态; (e) 1100 ℃氧化6 h; (f) 1100 ℃氧化6 h+酸洗

图 4 SiCp/6066Al基复合材料断口的SEM照片

Fig. 4 SEM images of tensile fracture face of SiCp/6066Al composites

表 3 SiC颗粒表面能谱分析结果

Table 3 Results of energy spectrum of SiC

particles of tensile fracture face %

3 结 论

a. SiC颗粒于1100 ℃高温氧化后除去了尖锐的角部,存在明显的钝化现象;随着氧化时间的延长钝化效果提高,1100 ℃氧化10 h的钝化效果优于1100 ℃氧化6 h。

b. 高温氧化后再用5%HF酸洗3 h的SiC颗粒表面无白色的粒状凸起物,表面光滑,且尖角处明显钝化。

c. 随着SiC颗粒氧化时间的延长,SiCp/6066Al复合材料的抗拉强度σb和断裂韧度KIC增大。原始态SiC颗粒增强复合材料的σb和KIC分别为315 MPa和9.27 MPa·m1/2,1100 ℃氧化10 h后颗粒增强复合材料的σb和KIC分别为425 MPa和14.61 MPa·m1/2;原始态+酸洗后颗粒增强复合材料的σb和KIC分别为354 MPa和10.29 MPa·m1/2;1100 ℃氧化10 h+酸洗后颗粒增强复合材料的σb和KIC分别为426 MPa和14.88 MPa·m1/2;当氧化时间相同时,酸洗态复合材料的σb和KIC值均高于相应氧化态的值。

d. 复合材料的断裂方式主要是增强相从基体中被拔出,且外面覆盖一层基体合金的基体的延性断裂。

参考文献:

[1]李建平, 郭永春, 董晟全.氧化SiCp增强ZL101铝基复合材料的显微结构[J].西安工业学院学报, 1999,19(4): 316-320.

LI Jian-ping, GUO Yong-chun, DONG Sheng-quan. Microstructural characterization of oxidized SiCp reinforced Al-based composite[J]. Journal of Xi′an Institute of Technology, 1999, 19(4): 316-320.

[2]GU Ming-yuan, JIN Yan-ping, MEI Zhi. Effects of reinforcement oxidation on the mechanical properties of SiC particulate reinforced aluminum composites[J]. Mater Sci and Eng, 1998, A252(9): 188-198.

[3]Lee J C, Byun J Y, Park S B. Prediction of Si contents to suppress the formation of Al4C3 in the composite[J]. Acta Materialia, 1998, 46(5): 1771-1780.

[4]崔岩, 耿林, 姚忠凯. SiCp/6061Al复合材料的界面优化与控制[J].中国有色金属学报, 1997, 7(4): 159-162.

CHUI Yan, GENG Lin, YAO Zhong-kai. Interface optimization and control in SiCp/6061 Al composites[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(4): 159-162.

[5]Nyberg E. Coating particulate SiC in aluminum metal matrix[J]. Key Engineering Materials, 1993, 77-78: 349-356.

[6]库徳良绍夫, 斯莫连采夫.铝合金断裂韧性[M].高云震,译.北京:冶金工业出版社,1980.

KyДΡЯЩОв В Г,СМолеНЦев В И. Fracture toughness of aluminum alloy[M]. GAO Yun-zheng, translates. Beijing: Metallurgical Industry Press,1980.

[7]Lee J C, Ahn J P, Shi Z L. Modification of the interface in SiC/Al composites[J]. Metallurgical and Materials Transactions A, 2000, 31(9): 2361-2368.

[8]QIN Shu-yi, CHEN Chang-rong, ZHANG Guo-ding, et al. The effect of particle shape on ductility of SiCp reinforced 6061 Al matrix composites[J]. Mater Sci Eng A, 1999, A272(2): 363-370.

[9]Clyne T W, Withers P J.金属基复合材料导论[M].北京:冶金工业出版社,1996.

Clyne T W, Withers P J. An introduction to metal matrix composites[M]. Beijing: Metallurgical Industry Press,1996.

[10]傅敏士, 肖亚航. SiCp/Al复合材料的断裂行为[J].机械工程材料, 2001, 25(11): 17-18.

FU Min-shi, XIAO Ya-hang. Fracture behavior of SiCp/Al matrix composites[J]. Materials for Mechanical Engineering, 2001, 25(11): 17-18.

[11]耿林, 姚忠凯, 李义春. SiCp/6061Al复合材料的微观结构与界面[J].高技术通讯, 1994(4): 17-20.

GENG Lin, YAO Zhong-kai, LI Yi-chun. Microsrtucture and interface of SiCp/Al composites[J]. High-tech Communication, 1994(4): 17-20.

[12]郦定强,洪淳亨.增强体颗粒尺寸对SiCp/2124Al复合材料变形行为的影响[J].上海交通大学学报, 2000, 34(3): 342-346.

LI Ding-qiang, HONG chun-heng. Effects of particle reinforcement size on deformation behavior of SiCp/2121Al composites[J]. Journal of Shanghai Jiaotong University, 2000, 34(3): 342-346.

[13]CHEN C R, QIN S Y. Finite element analysis about effects of particle morphology on mechanical response of composites[J]. Mater Sci and Eng, 2000, A278(1-2): 96-105.

收稿日期: 2004-08-19

基金项目:国家“十五”科技攻关项目(MKPT02-0182)

作者简介:王日初(1965-), 男, 广东和平人, 教授, 从事快速凝固铝合金制备技术研究

论文联系人: 王日初,男,教授; 电话:0731-8876264(O); E-mail: wrc@mail.csu.edu.cn