文章编号:1004-0609(2010)12-2283-08

不同温度退火处理后Al-Mg与Al-Mg-Sc合金板材的织构演变

姜 锋,黄宏锋,赵 娟,韦莉莉

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用X射线衍射反射法在角度(α)为0~75°时测量Al-Mg和Al-Mg-Sc合金板材经不同退火温度处理后的不完整极图,应用三维取向分布函数(ODF)以及晶粒取向汇集目标线(α、β取向线)研究合金冷轧板材中织构的形成及其在退火过程中的演变规律。结果表明:Al-Mg合金冷轧板材中主要存在Brass织构{011}á211?和Copper织构{112}á111?,退火温度升高到300 ℃时,Al-Mg合金板材的形变织构逐渐消失,Brass织构和Copper织构分别向立方织构{001}á100?以及旋转立方织构{001}á110?转变;添加Sc元素没有改变Al-Mg合金板材冷轧织构组分,但织构极密度和取向密度明显增强;退火温度升高到450 ℃时,Al-Mg-Sc合金板材的部分Brass织构和Copper织构才向立方织构和旋转立方织构转变,表明Sc的加入使Al-Mg-Sc合金在退火过程的再结晶温度显著提高。

关键词:Al-Mg-Sc合金;织构;退火;取向分布函数

中图分类号:TG146.2 文献标志码:A

Texture evolution of Al-Mg and Al-Mg-Sc alloy sheets after

annealing at different temperatures

JIANG Feng, HUANG Hong-feng, ZHAO Juan, WEI Li-li

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The uncompleted pole figures of Al-Mg and Al-Mg-Sc alloy sheets after annealing at different temperatures were measured by X-ray diffractometry at angle (α) from 0° to 75°. The texture compositions and their evolution law were analyzed by the orientation distribution functions(ODF) and the collection of grain orientation (α and β fibre). The results indicate that the brass {011}á211? and copper {112}á111? textures are primary in Al-Mg alloy cold-rolled sheets. When the annealing temperature increases to 300 ℃, the deformed textures disappear gradually, the brass and copper textures translate into cube and cube-rotation textures, respectively. Sc element addition can not change the texture compositions of Al-Mg alloy cold-rolled sheets, but it makes the pole and orientation densities increase significantly. For Al-Mg-Sc alloy sheet, the texture translations occur until the annealing temperature rises to 450 ℃, partial brass and copper textures change into the cube and cube-rotation textures, which indicates that Sc element addition would evidently enhance the recrystallization temperature of Al-Mg-Sc alloy in the annealing process.

Key words: Al-Mg-Sc alloy; texture; annealing; orientation distribution function

形变织构和再结晶织构是合金板材中最为常见的织构类型,对合金的综合性能影响最大。就铝合金而言,形变织构主要是由于金属多晶体中的晶粒取向在塑性变形过程中发生变化而引起的,晶粒的取向变化情况与晶粒受力状态关系密切,因此,合金成分和加工工艺对形变织构状态有重要影响,不同的织构组态则决定了不同的平面各向异性值[1]。经过塑性变形的金属存在以位错为主的晶体缺陷,储能较高,在加热条件下易发生再结晶使基体储能得以释放,快速生长的晶粒取向决定再结晶织构的类型,在此过程中,变织构沿晶粒易长大的晶体学方向向再结晶织构转变。根据再结晶形核理论[2]以及HUMPHERYS[3]的研究成果可知,温度和第二相粒子是影响再结晶的最主要因素。在此基础上,前人对各系铝合金的形变织构和再结晶织构都做了相关研究[4],SINGH等[5]揭示了 6×××铝合金板材在生产加工过程中织构的演变规律;MITSUTOSHI[6] 引入遗传算法优化设计织构分布来减少铝合金的各向异性;BENUM[7]重点研究了第二相粒子的析出状态对铝合金的再结晶织构组态的影响。

Al-Mg系合金具有良好的综合性能,越来越受到广大研究者的关注。研究发现[8-9],添加微量的Sc元素能显著改善传统的Al-Mg系合金强度不够高,不可热处理强化以及受热容易软化等不足,极大提高Al-Mg合金的综合性能。同样,不同的织构组态和晶粒取向对Al-Mg和Al-Mg-Sc合金的综合性能有显著影响。为了进一步改善结构材料Al-Mg以及Al-Mg-Sc合金的综合性能,对合金在不同加工条件下晶粒取向的分布进行研究,揭示在此过程中织构组态的演变规律和影响因素是一个重要的研究课题,但目前与此相关的研究鲜见报道。为此,本文作者针对Al-Mg和Al-Mg-Sc合金板材加工工艺特点,应用取向分布函数(ODF)重点研究在不同稳定化退火温度处理过程中Al-Mg以及Al-Mg-Sc合金板材织构的组分、演变规律及其影响因素,对比分析并讨论两种合金在退火过程中的再结晶机制,以期为控制再结晶织构组态从而提高板材成型性奠定基础。

1 实验

研究材料为在工厂条件下生产的Al-6Mg-0.4Mn (中国牌号5A06)及Al-6Mg-0.4Mn-0.2Sc -0.1Zr(俄罗斯牌号1570)合金。以工业纯铝、纯镁及Al-Mn、Al-Sc和Mg-Zr中间合金为原料采用水冷半连续铸造工艺制备铸锭,铸锭经多道次热轧得到6 mm热轧板,总变形量为85%;热轧板再经多道次冷轧得到2 mm冷轧板。从冷轧板上截取15 mm×10 mm×2 mm的样品,分别在130、250、300、350、450和550 ℃下进行稳定化退火处理1 h,出炉后空冷。

对经不同温度退火处理的样品进行表面抛光处理,经多道水磨砂纸粗磨后,依次采用400#、800#、1200#金相砂纸细磨,将细磨好的样品依次放入NaOH溶液和HCl溶液浸泡以除去样品表面的应力层。分别采用D8 Discover X射线衍射织构仪对样品进行织构测试。织构测量采用CuK辐射,测试中使样品作平动,管电压为40 kV,管电流为40 mA,扫测按同心圆步进方式进行,测量步长为5°,测量{111}、{200}、{220}这3个不完整极图(极图测绘范围α=0~75°,β=0~360°)。利用Bunge球谐函数与级数展开法计算ODF极图,结果用恒φ2的ODF截面图表示。

2 实验结果

2.1 Al-Mg合金的冷轧及退火织构

在Bunge系统中,用图解法分析ODF截面时通过(φ1,Φ,φ2)来确定各ODF截面所对应的织构类型,对立方晶系,相应的织构解析关系式为

H:K:L=sinΦsinφ2:sinΦcosφ2:cosΦ (1)

u:v:w=(cosφ1cosφ2-sinφ1sinφ2cosΦ):

(-cosφ1sinφ2-sinφ1cosφ2cosΦ):sinφ1sinΦ (2)

式中:H,K,L为晶面指数;u,v,w为晶向指数。

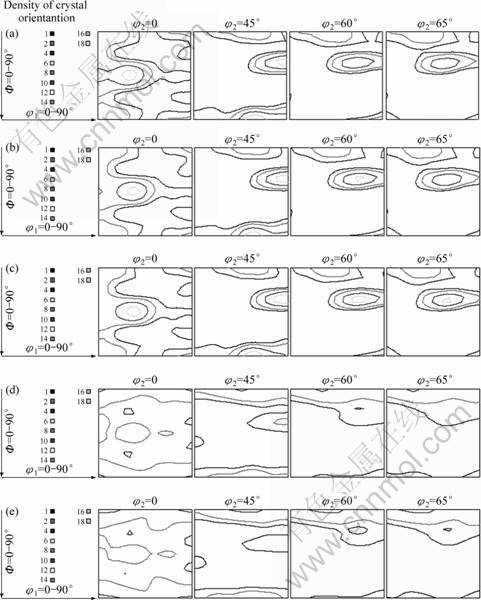

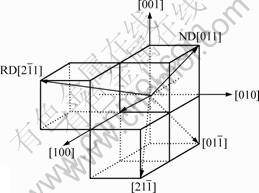

结合式(1)和(2)可计算各织构所对应的欧拉角,从而标出各织构组分在欧拉空间的位置,如图1所示。图2(a)所示为Al-Mg合金试样经多道次轧制变形后恒φ2为0°、45°、60°和65的ODF截面图。结合图1分析发现,Al-Mg合金冷轧板整体织构组态具有较强的面心立方金属形变织构特征,表现为典型的Brass织构取向{011}á112?和Copper复合织构{112}á111?,取向密度等级均超过6级,此外还有S织构取向{123}á634? (φ1=59°,Φ=37°,φ2=63°),这3种轧制织构均分布在

图1 欧拉空间织构分布示意图

Fig.1 Schematic diagram of texture distribution in Euler space

图2 Al-Mg合金在不同退火温度下的ODF图

Fig.2 ODFs maps of Al-Mg alloys at different annealing temperatures: (a) Cold-rolled; (b) 130 ℃, 1 h; (c) 250 ℃, 1 h; (d) 350 ℃, 1 h; (e) 450 ℃, 1 h

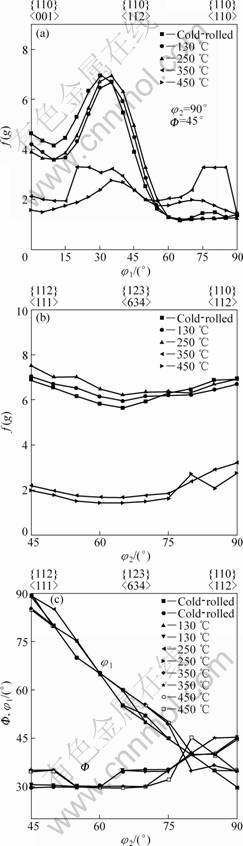

面心立方金属β取向线上,由Copper织构取向开始,经过S取向再转到Brass织构取向。各织构取向密度在β取向线上的分布见图3(b)。容易发现,Al-Mg合金冷轧板中Brass织构和Copper织构取向密度最强,等级接近于7级,S织构取向次之为5.5级。此外,结合图3(a)发现冷轧板中还有少量的Goss织构。

图2(b)和(c)所示为Al-Mg合金冷轧板分别经过(130 ℃, 1 h)和(250 ℃, 1 h)低温稳定化退火处理后的恒φ2的ODF截面图。由图3可知,低温稳定化退火并没有改变Al-Mg合金的织构组态。随着退火温度的升高,在α、β取向线上,部分Goss取向的晶粒向邻近的Brass取向偏转,使得Goss取向密度有所下降。Brass取向上的晶粒也向S取向和Copper织构偏转。使S织构和Copper织构有所增强,而Brass织构强度无明显变化。结合图5(a)发现,低温退火过程中Al-Mg合金总体仍然以形变织构组分为主。

随着稳定化退火温度的进一步升高,Al-Mg合金织构组分变化明显,形变织构组分降低,再结晶织构显著增强。图2(d)和(e)所示为Al-Mg合金冷轧板以及分别经过(350 ℃, 1 h)和(450 ℃, 1 h)退火处理后的ODF截面图。由图3和5(a)可知,退火温度达到350℃时,Al-Mg合金中Brass织构、Copper织构和S 织构

图3 Al-Mg合金冷轧板在退火过程中的取向密度变化

Fig.3 Changes of orientation densities of cold rolled Al-Mg sheet in annealing process: (a) α fibre; (b) β fibre; (c) Positions of β fibre

急剧下降,合金整体织构组态主要由立方织构{001} á100?和旋转立方织构{001}á110?组成,继续升高稳定化退火温度到450 ℃,Al-Mg合金板材织构无明显变化。

2.2 Al-Mg-Sc合金的冷轧及退火织构

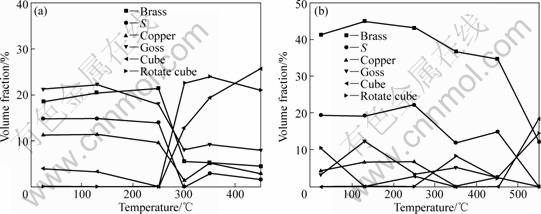

将Al-Mg-Sc合金冷轧后再进行不同温度稳定化退火处理,对其织构组分进行分析发现Al-Mg-Sc合金与Al-Mg合金有相同的织构组态(见图4(a)和(b))。冷轧态表现为Brass织构、Copper织构和S织构, 但Brass织构强度远远高于Copper织构和S织构。各织构组分相比Al-Mg合金都有明显增强。在稳定化退火过程中,Al-Mg-Sc合金晶粒取向转变与Al-Mg合金相似。低温稳定化退火阶段,在α、β取向线上,Al-Mg-Sc合金晶粒取向由S取向逐渐流向Brass取向,S织构强度稍有下降。与此同时,部分Brass织构向Goss取向的晶粒转变。随着稳定化退火温度的逐渐上升,Copper织构向旋转立方取向偏转,当温度达到550°时,在α、β取向线上的形变织构强度急剧下降,Al-Mg-Sc合金试样中立方织构和旋转立方织构显著增强,此外还保留有部分Brass织构,合金整体表现为强的再结晶织构组分(见图4(c)和5(b))。

3 分析与讨论

3.1 Al-Mg以及Al-Mg-Sc合金冷轧板形变织构的形成分析

Al-Mg合金和Al-Mg-Sc合金试样经过轧制变形,在冷轧板内均出现了面心立方金属中常出现的{011}á211?和{112}á111?等轧制织构(见图2(a)和4(a))。根据金属塑性加工原理,Al-Mg合金以及Al-Mg-Sc合金轧制织构的形成主要是在多道次轧制过程中,合金试样中的晶体受到轧制平面法线方向上的压缩力和轧制方向上的拉伸力共同作用,晶体沿着特定晶面和晶向发生滑移。晶粒在拉伸力的作用下会发生转动,使滑移方向和拉力方向差异趋于减小;压缩力的作用使得倾斜的滑移面的法线转向和压力方向一致。由于晶体塑性形变抗力的各向异性,根据临界分切应力定律:

(3)

(3)

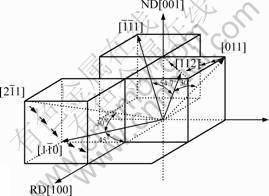

式中:μ为拉伸形变取向因子;τc为临界分切应力;σs为屈服应力。取向因子的大小取决于拉伸方向分别与滑移面法向及滑移方向的夹角余弦cosφ和cosλ。对于面心立方金属,滑移在分切应力最大(即取向因子μ最大)的滑移系统上进行。图6所示为面心立方结构的极

图4 Al-Mg-Sc合金在不同退火温度下的ODF图

Fig.4 ODF maps of Al-Mg-Sc alloys at different annealing temperatures: (a) Cold-rolled; (b) 450 ℃、1 h; (c) 550 ℃、1 h

图5 合金冷轧板退火过程各织构组分体积分数的变化

Fig.5 Volume fraction change of main texture components during annealing process: (a) Al-Mg alloy; (b) Al-Mg-Sc alloy

射赤面投影[10],根据面心立方结构的晶体学对称性,并结合面心立方金属{111}á110?滑移系取向因子μ值的反极图[11]分析可知,三角形[001]-[-111]-[011]中晶体拉力轴方向接近[ 23],[

23],[ 35]的H取向处在高取向因子区域,易发生滑移,此时主滑移系统为(

35]的H取向处在高取向因子区域,易发生滑移,此时主滑移系统为( 11)[101]。在轧向拉力作用下使晶体发生旋转,拉力轴线方向转向[101],当穿过[001]-[111]联线时次滑移系(1

11)[101]。在轧向拉力作用下使晶体发生旋转,拉力轴线方向转向[101],当穿过[001]-[111]联线时次滑移系(1 1)[011]开始取代原系统,拉力轴线往回转向新的滑移方向[011]。当超过[001]-[111]联线原先的滑移系统重新激活,故而拉力轴方向来回倒转最后转到[001]-[111]联线上的[112],因为该方向正好和[101]及[011]对称,此种状态两滑移系统的取向因子完全相同。与此同时,最初与H方向正交的压力轴线方向(图中的C点)也发生移动,在压缩力作用下,C应该转向[

1)[011]开始取代原系统,拉力轴线往回转向新的滑移方向[011]。当超过[001]-[111]联线原先的滑移系统重新激活,故而拉力轴方向来回倒转最后转到[001]-[111]联线上的[112],因为该方向正好和[101]及[011]对称,此种状态两滑移系统的取向因子完全相同。与此同时,最初与H方向正交的压力轴线方向(图中的C点)也发生移动,在压缩力作用下,C应该转向[ 11],但当H穿过[001]-[111]联线时,由于此滑移系统取代了原滑移系统,所以C又转向[1

11],但当H穿过[001]-[111]联线时,由于此滑移系统取代了原滑移系统,所以C又转向[1 1]。最后C的取向停在了[

1]。最后C的取向停在了[ 10]。因此,面心立方结构的Al-Mg合金以及Al-Mg-Sc合金在轧制过程中出现组分含量较高的Brass织构{011}á211?。

10]。因此,面心立方结构的Al-Mg合金以及Al-Mg-Sc合金在轧制过程中出现组分含量较高的Brass织构{011}á211?。

结合以上分析,面心立方金属仅以位错滑移方式

图6 面心立方晶体在轧制过程中的取向变化

Fig.6 Orientation changes of FCC crystal in rolling process

变形时取向{011}á211?和{112}á111?均为较稳定取向,在轧制过程中晶粒取向容易流向这两个取向,因此,在Al-Mg合金以及Al-Mg-Sc合金冷轧板中这两种织构组分强度比较高(见图2(a)和4(a))。由于Al-Mg及Al-Mg-Sc合金具有面心立方的晶体结构,具备有5个独立滑移系统以保证各晶粒形变的协调性,因而在轧制过程中晶体有多个滑移系统能同时启动,晶体塑性变形时处在更为复杂的应力应变状态,Brass织构会被较为复杂的织构代替,因此,冷轧板中还存在有Copper织构,Goss织构以及少量S织构等混合型织构组分(见图3和5)。

3.2 Sc对Al-Mg合金冷轧板形变织构形成的影响

在Al-Mg及Al-Mg-Sc合金冷轧板中,除了发现有较强的Brass织构等典型的轧制织构外,还发现Al-Mg-Sc合金冷轧板中的Brass织构显著强于Al-Mg合金冷轧板中的Brass织构(见图2(a)、4(a)和5)。根据晶体塑性变形理论以及大量研究表明,塑性变形金属中形变织构组分含量与金属位错滑移有很大关系,Brass织构的材料不易发生交滑移,如果提高轧制温度使得交滑移得以大量进行,则有助于使织构向Copper织构转变。当加工工艺相同时,Sc元素使Al-Mg-Sc合金的晶粒显著细化,组织形貌得以改善。研究发现[12],在塑性变形过程中,晶粒的尺寸对流变应力有显著影响。晶粒细化使得位错自由路程可以直达晶界,造成位错塞积,不利于交滑移的进行。此外,在Al-Mg-Sc合金中还存在与Al基体共格的Al3Sc粒子,根据Fleischer理论[12],在加工过程中Al3Sc粒子对位错的阻碍作用力F可以表示为

F=2Tsin(θ/2) (4)

式中:T为位错张力,近似取值为μb2,其中μ为弹性模量,b为位错的伯氏矢量。位错在切应力τ的作用下向前运动的过程中会被弥散分布于基体中的Al3Sc粒子钉扎而发生弯曲,随着τ的增大,θ达到一个临界值θc,F也增大到峰值Fm,所对应的切应力就是晶体的屈服应力:

(5)

(5)

图7所示为位错被点状障碍阻挡示意图。其中:λ为Al3Sc粒子的平均间距。根据以上可知,当Al3Sc粒子在基体中的分布越密集,则对位错的阻碍作用越明显,位错滑移越困难。另外,由于Al3Sc粒子与基体收缩系数的不同并存在共格关系,在粒子周围会产生应力应变场,进一步增大位错通过此区域的阻力,所以在轧制过程中更不易出现交滑移。因此,Al-Mg-Sc合金冷轧板中的Brass织构得以保存下来并显著增强。

图7 位错被点状障碍阻挡示意图

Fig.7 Schematic diagram of dislocation hindered by point defect

在多道次变形过程中Al3Sc粒子对位错滑移的显著阻碍作用,不但对Brass织构和Cupper织构的形成有重要影响,同时也增强Al-Mg-Sc合金的再结晶温度,使轧制过程中的动态回复和再结晶难以发生,因此,部分立方织构组态在Al-Mg合金冷轧板中得以保留,而在Al-Mg-Sc合金强度较弱。

3.3 冷轧织构在退火过程中的演变

由于Al-Mg和Al-Mg-Sc合金冷轧板经过大的形变,合金位错密集,形变储能较高。在退火过程中,这部分储能促进再结晶的进行,伴随着再结晶晶粒的形核长大和晶界迁移,变形合金的择优取向会沿着特定晶体学方向转变为再结晶织构。由试验可知,Al-Mg和Al-Mg-Sc合金冷轧板中含有典型的β纤维轧制织构,在稳定化退火过程中,合金轧制织构含量逐渐减少,再结晶织构组分逐渐增多(见图2(d)、图2(e)、图4(c)和图5),充分退火处理后合金织构组态为再结晶织构。

退火织构的形成是一个复杂的晶体位向转变过程,有诸多影响因素。在大量实验基础上,前人提出了许多织构转变机制和理论模型。COOK和RICHARDS[13]研究发现,形变织构类型对退火织构形成有很大关系,变形织构越清晰,稳定化退火生成的再结晶织构的轮廓也会越清楚。结合图6分析,面心立方金属{001}á100?取向处在高μ值区,在轧制过程中这些晶粒取向容易流向{011}á211?取向形成brass织构,RIDHA和RICHARDS[14]研究发现,轧制变形可以使得取向{001}á100?可以向(011)[100]和(01 )[100]两个子取向转动,使Goss取向{011}á100?可以向(011)[21

)[100]两个子取向转动,使Goss取向{011}á100?可以向(011)[21 ]和(011)[2

]和(011)[2 1]两个子取向转动,因此在稳定取向之间会留下转动痕迹,从而建立起相应的过渡带结构。同样,Al-Mg和Al-Mg-Sc合金冷轧板中强烈的Brass和Goss轧制织构是立方织构的晶体,它们也是在冷变形材料中以立方织构的痕迹所形成,均处在立方织构晶体滑移的过渡带中,取向接近于{112}á111?的大变形Cupper织构也与立方织构的痕迹相联系。因此,在退火过程中,合金中晶粒的主要再结晶方向与形变织构之间晶界发生移动,不断将形变织构并没而长大,从而导致相应的形变织构向立方织构转变。READ和SHOCKLEY[15]将此晶界的可动性表示为能量的函数:

1]两个子取向转动,因此在稳定取向之间会留下转动痕迹,从而建立起相应的过渡带结构。同样,Al-Mg和Al-Mg-Sc合金冷轧板中强烈的Brass和Goss轧制织构是立方织构的晶体,它们也是在冷变形材料中以立方织构的痕迹所形成,均处在立方织构晶体滑移的过渡带中,取向接近于{112}á111?的大变形Cupper织构也与立方织构的痕迹相联系。因此,在退火过程中,合金中晶粒的主要再结晶方向与形变织构之间晶界发生移动,不断将形变织构并没而长大,从而导致相应的形变织构向立方织构转变。READ和SHOCKLEY[15]将此晶界的可动性表示为能量的函数:

(6)

(6)

式中:E为晶界能;θ为位向差;E0和A为常数;在面心立方金属中可动性最大的晶界是绕á111?轴转动30°~50°,间或有绕á100?轴转动。图8和9为Al-Mg和Al-Mg-Sc合金冷轧板中的形变织构在退火过程中转变为退火织构的演变示意图,随着退火温度的进一步升高,再结晶驱动力的不断增大,{011}á2 1?取向的晶粒会绕á111?轴做30°的转动,使{011}á2

1?取向的晶粒会绕á111?轴做30°的转动,使{011}á2 1?不断向{112}á1

1?不断向{112}á1 0?取向区域聚集,Brass织构组分不断降低,{112}á1

0?取向区域聚集,Brass织构组分不断降低,{112}á1 0?取向为不稳定取向,该取向的晶粒在退火过程中会绕á100?轴转动形成Goss织构和稳定的立方织构,从而完成了由形变织构向稳定的退火织构的转变。{112}á111?取向在退火过程中会绕á110?轴做转动流向旋转立方织构。使得合金旋转立方织构组分上升(见图5)。因此,随着退火的进一步进行,合金形变织构组分不断下降,立方退火织构组分上升(见图5)。在退火过程中,Al-Mg和Al-Mg-Sc合金主要是立方过渡带形核机制。Sc元素没有改变Al-Mg合金形变织构转变机制,但是在退火过程中析出的A13(Sc, Zr)颗粒对晶界迁移具有很明显的阻碍作用,再结晶前沿向未再结晶基体中前进受阻碍,使再结晶晶核成长受阻,不利于再结晶的发生,稳定化退火温度高于450 ℃时,Al-Mg-Sc合金形变织构的取向密度仍然没有明显

0?取向为不稳定取向,该取向的晶粒在退火过程中会绕á100?轴转动形成Goss织构和稳定的立方织构,从而完成了由形变织构向稳定的退火织构的转变。{112}á111?取向在退火过程中会绕á110?轴做转动流向旋转立方织构。使得合金旋转立方织构组分上升(见图5)。因此,随着退火的进一步进行,合金形变织构组分不断下降,立方退火织构组分上升(见图5)。在退火过程中,Al-Mg和Al-Mg-Sc合金主要是立方过渡带形核机制。Sc元素没有改变Al-Mg合金形变织构转变机制,但是在退火过程中析出的A13(Sc, Zr)颗粒对晶界迁移具有很明显的阻碍作用,再结晶前沿向未再结晶基体中前进受阻碍,使再结晶晶核成长受阻,不利于再结晶的发生,稳定化退火温度高于450 ℃时,Al-Mg-Sc合金形变织构的取向密度仍然没有明显

图8 冷轧态织构形态示意图

Fig.8 Schematic diagram of texture morphology of cold- rollded alloy

图9 退火过程织构的演变

Fig.9 Texture evolvement in annealing process

下降(见图2和5(b)),当退火温度达到550 ℃时,合金发生再结晶,形变织构的强度才剧烈下降。因此,Al-Mg-Sc合金的再结晶温度有较大提高。

由于形变织构中S取向{123}á634?与再结晶织构R取向{124}á211?非常接近,Al-Mg合金在退火过程中发生原晶界形核,S取向不断流向R取向,使R织构的体积分数上升。但是在Al-Mg-Sc合金中由于存在阻碍晶界移动的析出相粒子,结晶初期R取向的晶粒常会遇到相似、互补的取向,此时很难继续长大,所以R织构被抑制。

4 结论

1) Al-Mg以及Al-Mg-Sc合金冷轧板的晶粒取向主要在β取向线上聚集,织构组分相似,主要是Brass织构{011}á211?,S织构{123}á634?以及Copper织构{112}á111? 3种形变织构。

2) 随着稳定化退火温度的升高,Al-Mg以及Al-Mg-Sc合金冷轧板中的形变织构都有减弱趋势,并逐渐向立方织构和旋转立方织构等再结晶织构转变。Sc对Al-Mg合金冷轧板织构类型以及在稳定化退火过程中织构转变机制影响不大。

3) Al-Mg合金在300 ℃稳定化退火时,发生再结晶,形变织构强度剧烈下降,立方织构和旋转立方织构强度迅速上升。Al-Mg-Sc冷轧板在退火温度达到550 ℃时,再结晶织构强度才迅速上升,Sc使Al-Mg合金的再结晶温度得到极大提高。

REFERENCES

[1] 五弓勇雄. 金属塑性加工技术[M]. 陈天忠, 张荣国, 译. 北京: 冶金工业出版社, 1987: 539-542.

[2] WUGONG Yong-xiong. Technology of metal plastic processing [M]. CHEN Tian-zhong, ZHANG Rong-guo, transl. Beijing: Metallurgical Industry Press, 1987: 539-542.

[3] 李松瑞, 周善初. 金属热处理[M]. 长沙: 中南大学出版社, 2005: 38-45.

[4] LI Song-rui, ZHOU Shan-chu. Heat treatment of metals[M]. Changsha: Central South University Press, 2005: 38-45.

[5] HANSEN N, JONES A R, LEFFERS T. Recrystallization and grain growth of multiphase and particle containing materials[M]. Roskide, Denmark: Riso National Laboratory, 1980: 35-44.

[6] Oscarsson A, Lindh E, Hutchionson W B. Evolution of microstructure and texture during hot and annealing of AA3004 can stock[C]//Thermo-Mechanical Processing in Theory. Stochkholm: Modeling & Practice, 1997: 290-306.

[7] Singh P K,Singh A K.Evolution of texture during thermo-mechanical processing of an Al-Mg-Si-Cu alloy[J]. Scripta Materialia, 1998, 38(8): 1299-1306.

[8] Mitsutoshi K.Effects of texture on mechanical properties of aluminum alloy sheets and texture optimization strategy[C]//AIP Conference Proceedings A, America Institute of Physics, 2005, 778(5): 445-450.

[9] Benum S, Nes E. Effect of precipitation on the evolution of cube recrystallization texture[J]. Acta Metallurgica, 1997, 45(11): 4593-4602.

[10] Fazeli F, Poole W J, SINCLAIR CW. Modeling the effect of Al3Sc precipitates on the yield stress and work hardening of an Al-Mg-Sc alloy[J]. Acta Metallurgica, 2008, 56(9): 1909-1918.

[11] Roumina R, Sinclair C. Recovery kinetics in the presence of precipitates: The softening response of an Al-Mg-Sc alloy[J]. Acta Metallurgica, 2009, 58(1): 111-121.

[12] 冯 端. 金属物理学[M]. 北京: 科学出版社, 1975: 658.

[13] FENG Duan. Metal physics[M]. Beijing: Science Press, 1975: 658.

[14] 马全仓, 毛卫民, 冯惠平. 工业铝板的低应变量拉伸变形行为[J]. 塑性工程学报, 2005, 12(6): 89-93.

[15] MA Quan-cang, MAO Wei-ming, FENG Hui-ping. Tensile behavior of commercial aluminum sheets at low deformation degree[J]. Journal of Plasticity engineering, 2005, 12(6): 89-93.

[16] JOHONSTOM T L, FELTNER C E. Grain size effects in the strain hardening of polycrystals[J]. Metallurgical and Materials Transactions B, 1970, 1(5): 1161-1167.

[17] COOK M, RICHARDS T L. Observations on the rate and mechanism of recrystallization in copper[J]. J Inst Metals, 1946/1947, 73: 1-31.

[18] Ridha A A, Hutchinson W B. Recrystallization mechanisms and the origin of cube texture in copper[J]. Acta Metallurgica, 1982, 30(10): 1929-1939.

[19] READ W T, SHOCKLEY W. Dislocation models of crystal grain boundaries[J]. Phys Rev, 1950, 78(3): 275-289.

(编辑 龙怀中)

基金项目:湖南省自然科学基金资助项目(10JJ2042)

收稿日期:2010-01-28;修订日期:2010-09-02

通信作者:姜 锋,教授,博士;电话:0731-88877682;E-mail:jfeng@mail.csu.edu.cn