工艺参数对触变模锻6061 Al合金微观组织与力学性能的影响

来源期刊:中国有色金属学报(英文版)2015年第3期

论文作者:陈玉狮 陈体军 张素卿 李普博

文章页码:699 - 712

关键词:6061铝合金;半固态粉末触变模锻;力学性能;拉伸性能;硬度;微观组织

Key words:6061 aluminum alloy; semisolid powder thixoforging; mechanical properties; tensile properties; hardness; microstructure

摘 要:提出一种制备颗粒增强金属基复合材料的新技术—粉末触变成形, 并利用该技术对基体6061铝合金进行触变模锻。首先,将雾化的6061合金粉末冷压成块,压出的块体作为初始锭料,经部分重熔后再进行触变模锻。研究重熔时间、模具温度和重熔温度对触变模锻6061合金微观组织与力学性能的影响。结果表明,这3个加工工艺参数对微观组织与力学性能均有较大影响;合金的断裂机理是由不同加工工艺参数下的微观组织决定的;此外,裂纹往往起源于缩松和夹杂处,沿着二次凝固组织或者初生相颗粒扩展;经触变模锻得到的合金的抗拉强度、伸长率和硬度分别可达196 MPa、11.0% 和HV 55.7。

Abstract: A new processing technology, powder thixoforming, for preparation of particle reinforced metal matrix composites was proposed and 6061 aluminum alloy was prepared by powder thixoforging. 6061 ingots were first prepared by cold-pressing the atomized 6061 alloy powders, and then the ingots were partially remelted followed by thixoforging. The effects of reheating time, mould temperature and reheating temperature on microstructure and mechanical properties of the thixoforged alloys were investigated. The results indicate that all of the three parameters have large effects on the microstructure and mechanical properties. Owing to the microstructure changes, the fracture regime varies with the processing parameters. Furthermore, cracks always initiate from shrinkage porosities and inclusions, and then propagate either along the secondarily solidified structures or primary particles. The ultimate tensile strength, elongation and hardness of the resulting alloy are up to 196 MPa, 11.0% and HV 55.7 respectively.

Trans. Nonferrous Met. Soc. China 25(2015) 699-712

Yu-shi CHEN, Ti-jun CHEN, Su-qing ZHANG, Pu-bo LI

Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China

Received 11 April 2014; accepted 5 August 2014

Abstract: A new processing technology, powder thixoforming, for preparation of particle reinforced metal matrix composites was proposed and 6061 aluminum alloy was prepared by powder thixoforging. 6061 ingots were first prepared by cold-pressing the atomized 6061 alloy powders, and then the ingots were partially remelted followed by thixoforging. The effects of reheating time, mould temperature and reheating temperature on microstructure and mechanical properties of the thixoforged alloys were investigated. The results indicate that all of the three parameters have large effects on the microstructure and mechanical properties. Owing to the microstructure changes, the fracture regime varies with the processing parameters. Furthermore, cracks always initiate from shrinkage porosities and inclusions, and then propagate either along the secondarily solidified structures or primary particles. The ultimate tensile strength, elongation and hardness of the resulting alloy are up to 196 MPa, 11.0% and HV 55.7 respectively.

Key words: 6061 aluminum alloy; semisolid powder thixoforging; mechanical properties; tensile properties; hardness; microstructure

1 Introduction

Particle-reinforced aluminum matrix composites (AMCs) have been widely used in aerospace and automotive fields because of their attractive properties, such as low cost, low density, high stiffness and high strength [1-4]. Many methods have been developed to fabricate AMCs, such as pressureless infiltration [5], squeeze-cast [6] and powder metallurgy (PM) [7,8]. It is known that PM process is popularly used because of the uniform distribution of reinforcements and the flexible design of constituents [1]. But the resultant composites generally have many voids besides high cost [8]. In addition, it is difficult to obtain large-sized components with complex shape [9]. However, thixoforming is not only a simple process, but also can significantly decrease or eliminate voids. In addition, this technology is also suitable to fabricating large-sized parts with complex shape [10,11]. For PM technology, atomization technology has been widely used for preparing small and spheroidal alloy powders. The bulk alloy prepared by pressing the atomized powders can be used as the feedstock of thixoforming [11]. Therefore, a novel technology named powder thixoforming which combines the advantages of powder metallurgy and thixoforming has been proposed, the blending and pressing steps of PM are applied to preparing the ingots with uniform distribution of reinforcing particles in the matrix, and then the ingots are partially remelted and thixoformed. It can be expected that composite components with uniform distribution of reinforcing particles and low or without voids can be obtained by using this technology. Simultaneously, the process is simplified and thus the cost is lower compared with the PM technology.

The heat-treatable 6061 alloy has taken as the most commonly used matrix alloy of the AMCs [12-16]. In addition, CHEN et al [17] indicated that an ideal semisolid microstructure with small and spheroidal primary particles could be obtained after the 6061 bulk alloy prepared by cold-pressing the atomized alloy powders was partially remelted. Namely, the 6061 bulk alloy prepared by cold-pressing the atomized alloy powders can be taken as the start ingots of thixoforming.

In order to obtain high performance AMCs components, it is necessary to optimize the processing parameters [6]. And the effects of processing parameters on the matrix alloy should be first clarified, so as to further study the effects on its based composite. However, most of the existing investigations focused on the effects of reinforcement size, morphology, distribution and volume fraction [16,18,19]. Study on the detailed effects of processing parameters on microstructure and mechanical properties of the matrix alloy is scarce.

Three processing parameters of reheating time, mould temperature and reheating temperature have large effects on the microstructure and tensile properties of thixoforged alloys [20,21]. Therefore, the effects of the three processing parameters on microstructure and mechanical properties of powder-thixoforged 6061 alloys were investigated in this work.

2 Experimental

The used material was 6061 aluminum alloy powder prepared by atomization, and had an average particle size of 18.376 μm. The nominal composition was 0.8%-1.2% Mg, 0.4%-0.8% Si, 0.7% Fe, 0.15%-0.40% Cu, 0.04%- 0.35% Cr, 0.15% Mn, 0.25% Zn, 0.15% Ti, with a balance of Al. The solidus and liquidus temperatures of this alloy measured by a Pyris Diamond TG/DTA differential thermal analyzer (DTA) were 610.2 and 674.6 °C, respectively.

Specimens with sizes of d45 mm×30 mm as the starting ingots of thixoforging were obtained using cold pressing under a pressure of 145 MPa. One specimen was heated in a resistance furnace for a time at a semisolid temperature, and then was quickly handled into a forging mould with a cavity of 60 mm×60 mm×30 mm and forged under a pressure of 105 MPa. The detailed parameters employed in this work are shown in Table 1. By repeating the above forming procedures according to the parameters shown in Table 1, the thixoforging products with different processing parameters were then obtained. To examine the temperature change of the specimen during partial remelting, a thermocouple was mounted in the center of a specimen. Subsequently, the specimen was heated at a semisolid temperature of 660 °C.

Table 1 Processing parameters used in this work

At least three tensile specimens were machined from the central region of each thixoforged product perpendicular to the forging pressure. The dimensions of the tensile specimen are shown in Fig. 1. The tensile tests were carried out on a universal material testing machine at a nominal tensile rate of 1 mm/min. The average of at least three test values was taken as the tensile properties of a thixoforged alloy. Some specimens were also cut from the central regions of the products and were used for microstructure observation with a MeF3 optical microscope and micro-hardness examination with an HBRVU-187.5 optical Brinell-Rockwell-Vichers hardness tester. The obtained optical images were analyzed by Image-Pro Plus 6.0 software and the area ratio of the primary particles to the whole ones was taken as the primary particle fraction. On each specimen, three typical images were examined (the microstructure is nonuniform because of the plastic deformation process, and so three different parts of a specimen were examined). An average of five tests examined in different locations of each specimen was taken as the hardness of a thixoforged alloy. Some typical fracture surfaces and their side views were observed by a QUANTA FEG 450 scanning electron microscope (SEM).

Fig. 1 Dimensions of tensile testing specimen (unit: mm)

3 Results and discussion

3.1 Semisolid microstructure prior to thixoforging

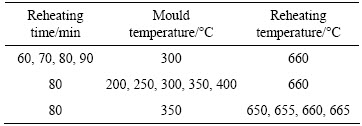

It is well known that a semisolid microstructure with small and spheroidal primary particles surrounded by liquid phase is the origin of semisolid forming [10]. Therefore, it is necessary to verify that if the 6061 alloy used in the present work can obtain such a semisolid microstructure after being partially remelted. As shown in Fig. 2(a), the as-cold-pressed microstructure of the 6061 bulk alloy is composed of mechanically bonded powders with inhomogeneous size. After a bulk alloy with a diameter of 22 mm was heated at 660 °C for 30 min, a semisolid microstructure with small and spheroidal primary particles is obtained (Fig. 2(b)). The particle size slightly decreases compared with the powders in the as-cold-pressed microstructure due to partial remelting. In addition, some black voids exist within the primary particles (Fig. 2(b)). It can be expected that some liquid pools can form within the primary particles during partial remelting, the solidified structures from the liquid pools are etched by the etching solution during the preparation of metallographic specimens, resulting in the formation of the voids. When the bulk alloy with a diameter of 45 mm is heated at 660 °C for 80 min, the primary particles, secondarily primary α(Al) grains (solidified from the liquid phase) and the voids within the primary particles are larger than those of the small specimen with a diameter of 22 mm (comparing Figs. 2(b) and (c)). Furthermore, the large-sized particles become more irregular (comparing Figs. 2(b) and (c)).

Fig. 2 Microstructures of as-cold-pressed (a), semisolid (heated at 660°C for 30 min) 6061 bulk alloy with diameter of 22 mm (b), and semisolid (heated at 660 °C for 80 min) 6061 bulk alloy with diameter of 45 mm (c)

The formation of the large-sized irregular primary particles in the larger specimen should be attributed to two reasons. The first one is that the solidification rate during water quenching is slower than that of the smaller one. Hence, more secondarily primary α(Al) phase should directly grow up on the primary particle surface without nucleation. The second one is that the reheating of the larger ingot needs longer time. Figure 3 gives the temperature variation in a large-sized specimen with the heating time during partial remelting at 660 °C. It indicates that the temperature in the central region of the specimen is not up to the given temperature of 660 °C until it is heated for 69 min. But the heating time for the smaller ingot only needs 20 min [17]. It is known that the primary particles may coarsen during partial remelting, and the longer the reheating time is, the larger the primary particle size is. Even so, the irregular primary particle size is still smaller than 50 μm.

Fig. 3 Temperature variation of specimen (with diameter of 45 mm) with heating time

Therefore, it can be suggested that the semisolid microstructure of the 6061 bulk alloy with a diameter of 45 mm is adequate for thixoforming in view of its primary particle size and morphology. It should be pointed out that the attached growth of the secondarily primary α(Al) particles solidified during water- quenching, a small amount of eutectic phases and the inhomogeneous primary particles make it difficult to distinguish the solid phase and liquid phase in the water-quenched microstructures. However, the following experimental results demonstrate that the liquid fraction is also appropriate for thixoforming.

3.2 Effects of reheating time on microstructure and mechanical properties

Table 2 presents the tensile properties and hardness of the powder-thixoforged 6061 alloys. For the convenience of analysis, the primary particle fractions are also included in Table 2. It can be found that the UTS, elongation and hardness can be up to 196 MPa, 11.0% and HV 55.7, respectively. According to the ASTM, the T4-treated 6061 alloy has the UTS of 180 MPa and the elongation of 14%. The specimens are not heat-treated in the present work, but the higher UTS than that of the T4-treated alloy is achieved by the powder-thixoforged process. So it can be expected that higher performance can be obtained after the thixoforged alloy is properly heat-treated.

Table 2 Ultimate tensile strength (UTS), elongation, hardness and primary particle fraction (PF) of powder-thixoforged 6061 alloys

From Table 2, it can also be found that the processing parameters have little influence on the elongation, but have great effect on the UTS and hardness. For the effect of reheating time, both the UTS and hardness increase during the period of 60-80 min and then decrease. The alloy formed under reheating for 80 min has the highest UTS and hardness of 188 MPa and HV 48.3, respectively. Taking the UTS and hardness as the criterion for evaluating the mechanical properties of the alloy, it can be seen that the reheating time of 80 min is the most appropriate.

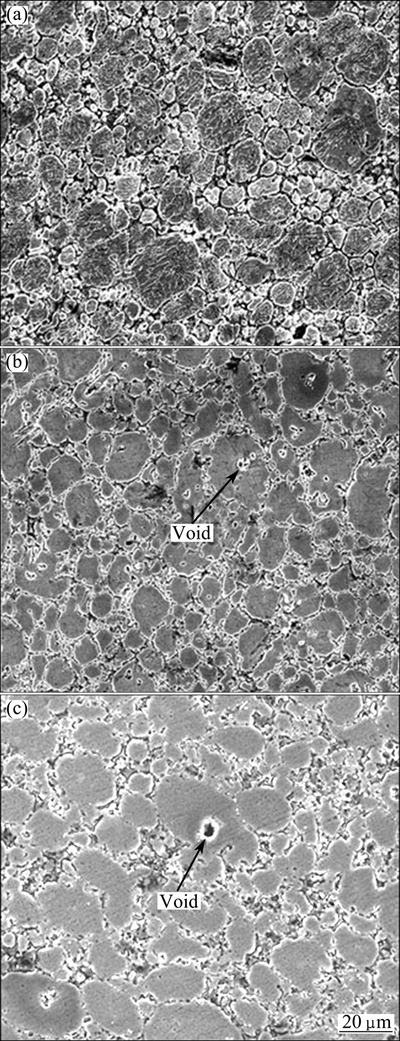

When the alloy is heated for 60 min, the temperature in the central region of the specimen is not up to the given temperature of 660 °C (Fig. 3), which indicates that the semisolid system does not reach its final equilibrium solid-liquid state. Namely, the liquid fraction is still lower than its equilibrium value, and it will increase as time further extends. So, it can be expected that the primary particles have not been completely separated by liquid phase. It is known that the deformation process of a semisolid non-dendritic ingot under pressure includes four regimes, liquid flow (LF), flow of liquid incorporating solid particles (FLS), sliding between solid particles (SS) and plastic deformation of solid particles (PDS) [22,23]. The former two regimes are dominant when the solid particles are surrounded by liquid phase while the latter two operate when the solid particles are in contact with each other. During the initial stage of thixoforging, the LF and FLS should operate in succession because the primary particles are always surrounded by liquid phase at this stage. The LF regime can generate constituent segregation, the liquid phase flows towards the edge of the ingot and the primary particles approach to each other along the direction parallel to the pressure. Simultaneously, solidification of the liquid phase occurs. Due to these two reasons, the liquid phase between the primary particles is decreased. So, the neighboring primary particles connect with each other to form larger ones during the LF and FLS regimes. Since 60 min is the shortest reheating time in this work, the primary particle fraction is the largest (Table 2), namely, the liquid phase is the least. Therefore, the deformation mechanisms should quickly turn into the SS and PDS regimes. These two regimes further accelerate the formation of large-sized interconnected particles (Fig. 4(a)).

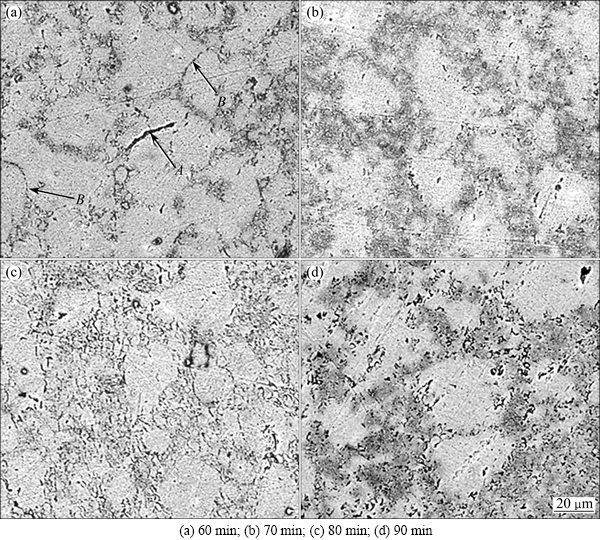

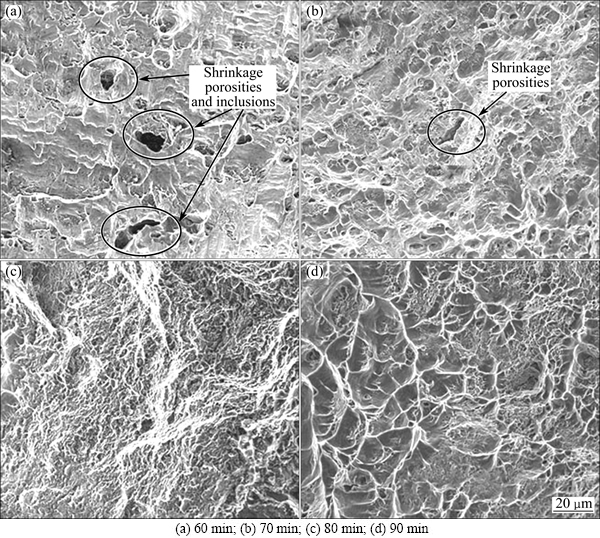

It is just due to the least liquid fraction at the reheating time of 60 min that the flowability, mould filling ability and the feeding ability to solidification shrinkage are the worst. Thus, porosities can easily form in the secondarily solidified structures. Namely, the secondarily solidified structures between the primary particles, especially those among the interconnected particles, are the weak points of this alloy. Therefore, cracks preferentially developed along these microstructures during tensile testing (marked by arrow A in Fig. 5(a)). This phenomenon is quite common and can be found in other thixoformed alloys [24,25]. In addition, it can be expected that the liquid pools within the primary particles are also the weak points because there is no extra liquid to feed the solidification microshrinkage during thixoforging and porosities are easily formed in these structures solidified from the liquid pools. The cracks initiate and develop at these sites, leading to the fracture of the particles (marked by arrow B in Fig. 5(a)). Therefore, it can be found that the cracks are always propagated along the secondarily solidified structures and across the primary particles (marked by arrow A in Fig. 6(a)). In the SS and PDS regimes, the amount of the liquid phase is not plentiful to fill the regions between the interconnected particles which are composed of many primary particles. Their protruding parts may easily collide or contact each other during thixoforging, causing these parts to plastically deform, which may generate local stress concentration [25,26]. Therefore, crevices can form between the solid particles, resulting in the formation of cracks during tensile testing (marked by arrow B in Fig. 6(a)).

Fig. 4 Microstructures of 6061 alloys thixoformed for different reheating time

Fig. 5 Side views of fracture surfaces of 6061 alloys thixoformed for different reheating time

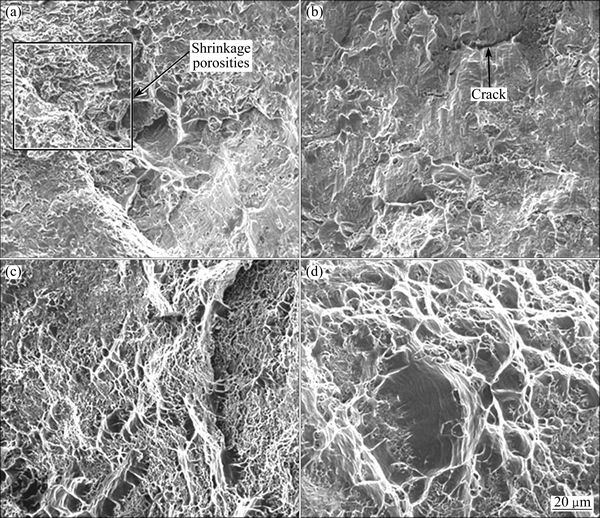

According to the discussion above, it can be concluded that the secondarily solidified structures (including those within the primary particles) and the boundaries of interconnected particles are the weak points of this alloy. In contrast, the former point has larger effect when the alloy thixoformed for 60 min. This can be demonstrated by the microstructures of the side view of the fracture surface and close to the fracture surface. The cracks formed in the former site are larger than those formed in the latter site (Figs. 5(a) and 6(a)). Furthermore, the fractograph (Fig. 7(a)) also indicates that there are many shrinkage porosities and inclusions in the secondarily solidified structures. Owing to these defects and stress concentration, it is reasonable to expect that the alloy thixoformed for 60 min has the lowest tensile properties (Table 2).

Fig. 6 Microstructures close to fracture surfaces of 6061 alloys thixoformed for different reheating time

Fig. 7 Fractographs of 6061 alloys thixoformed for different reheating time

As the heating time is prolonged to 70 min, the temperature in the central region of the specimen reaches the given temperature of 660 °C (Fig. 3). But the speed of the microstructural evolution during partial remelting is always slower than that of the temperature rise [26,27]. Namely, the semisolid system does not reach the equilibrium solid-liquid state and the liquid fraction is still smaller than what the temperature corresponds to. Therefore, the particles are still connected together (Fig. 4(b)). But the particle fraction is decreased (Table 2) and more particles are separated compared with those at heating time of 60 min (comparing Figs. 4(a) and (b)). Moreover, the flowability and mould filling ability, especially the feeding ability to solidification shrinkage during thixoforging are improved at this time. Therefore, the compactness of the secondarily solidified microstructures is enhanced. Simultaneously, the size of the interconnected particles is decreased and the residual deformation stress is also reduced. In addition, cracks cannot be found (Fig. 6(b)), although the fracture of this alloy still basically obeys the transgranular mode (Fig. 5(b)). Furthermore, the porosity amount in the fractograph is decreased (comparing Figs. 7(a) and (b)). So, it can be expected that the properties should be enhanced. However, the increase range of the liquid phase fraction is small, and the microstructure is still inhomogeneous (Fig. 6(b)). Therefore, the increase range of the properties is also small (Table 2).

When the heating time is extended to 80 min, the semisolid system reaches its final equilibrium solid-liquid state. The structures of the alloy have completely separated and the primary particles uniformly distribute in the secondarily solidified microstructures (Fig. 4(c)). It can be expected that the deformation during thixoforging should become homogenous. Simultaneously, the flowability and feeding ability to solidification shrinkage during thixoforging are further improved. Thus, the microstructure compactness of the alloy is enhanced. The dominative fracture regime maintains transgranular mode (Fig. 5(c)). Moreover, the porosities of the alloy are significantly decreased (comparing Figs. 6(b) and (c), Figs. 7(b) and (c)), and the fracture surface is characterized by many small dimples (Fig. 7(c)). Owing to the improvement of microstructure compactness and uniformity, the UTS and hardness of the alloy get a sharp rise (Table 2).

As the heating time is prolonged to 90 min, the primary particles coarsen into larger ones and the neighboring particles agglomerate and contact together (Fig. 4(d)). Due to the segregation of the liquid phase generated by the LF regime, porosities are easily formed in the secondarily solidified microstructures (Fig. 6(d)). The cracks always propagate along the interconnected particles, and the fracture mainly obeys the transgranular regimes, although intergranular fracture in some local zones can be occasionally found (Fig. 5(d)). And the fracture mode has a change tendency from transgranular regime to a mixture of transgranular and intergranular regimes (comparing Figs. 5(c) and (d)). The large dimples in the fractograph should be generated from the fracture of particles and the small dimples may be formed from the fracture of the secondarily solidified structures (Fig. 7(d)). Therefore, it can be concluded that the coarsening of the primary particles, the constituent segregation and the incompact microstructure lead to the decrease of the UTS and hardness.

Based on the above discussion, it can be concluded that the reheating time has large effects on the microstructure and mechanical properties of the powder-thixoforged 6061 alloy. When the semisolid system does not reach its final equilibrium solid-liquid state, the longer the reheating time is, the larger the liquid fraction is, and the more compact and homogeneous the microstructure is. Therefore, the UTS and hardness become higher and higher, and the peak values can be achieved when the semisolid system reaches the final equilibrium solid-liquid state. However, once the reheating time is further prolonged, the microstructure becomes inhomogeneous and incompact again due to liquid segregation. Thus, the UTS and hardness are decreased. Because of these microstructure changes, the fracture mode has a change tendency from transgranular regime to a mixture of transgranular and intergranular regimes. But it should be noted that the dominative fracture regime always maintains transgranular mode because the cracks preferentially propagate along the primary particles, regardless of the reheating time.

3.3 Effects of mould temperature on microstructure and mechanical properties

The UTS slightly increases when the mould temperature rises from 200 to 350 °C, and then decreases as the temperature is elevated to 400 °C (Table 2). The alloy formed at the mould temperature of 350 °C has the best comprehensive mechanical properties.

Figure 8 shows the microstructures of the 6061 alloys thixoforged at different mould temperatures. It indicates that at the microstructures are composed of primary particles and intergranular secondarily solidified microstructures. As the temperature rises to 250 and 300 °C, the primary particles gradually coarsen to larger ones (comparing Figs. 8(a, b) and 4(c)). When the temperature rises to 350 °C, the neighboring primary particles connect each other (Fig. 8(c)). As the temperature is elevated to 400 °C, the connection becomes more serious and lots of large-sized interconnected particles form (Fig. 8(d)). Simultaneously, the amount of the secondarily solidified structures decreases (comparing Figs. 8(b), (c) and (d)). Therefore, it suggests that the mould temperature also has large effects on the microstructure of the thixoforged 6061 alloy.

Fig. 8 Microstructures of 6061 alloys thixoformed at mould temperatures of 200 °C (a), 250 °C (b), 350 °C (c) and 400 °C (d)

It is known that the mould temperature mainly affects the liquid solidification rate. The higher the temperature is, the slower the solidification rate is. In this alloy, the content of each solute is originally small. All of the solute will almost completely dissolve into the secondarily primary phase when the solidification rate is slow, and thus the amount of the resulting eutectic phases is relatively small. The decrease of the eutectic amount implies the increase of the secondarily primary α(Al) phase. The secondarily primary α(Al) phase always attaches on the surfaces of the primary particles and it is difficult to distinguish these two kinds of α(Al) phase [17]. So, the amount of the secondarily solidified structures decreases as the mould temperature rises. Furthermore, the attached growth of the secondarily primary α(Al) particles also results in the increase of the particle size. In addition, it can be proposed that the solidification rate can also affect the deformation process during thixoforming besides the primary particle size. When the mould is at a low temperature, the liquid solidification is rapid. So, the time for the operation of the LF and FLS regimes is very short. Thus, the solid/liquid segregation produced by LF regime is reduced, and the distribution of the primary particles in the secondarily solidified microstructures is uniform. As the temperature rises, the effect of the LF and FLS regimes becomes larger and larger, so the liquid fraction is decreased in the central region of the deformed ingot, and the primary particles gradually coarsen to larger ones and contact to each other in the thixoformed products (Fig. 8).

Fig. 9 Side views of fracture surfaces of 6061 alloys thixoformed at mould temperatures of 200 °C (a), 250 °C (b), 350 °C (c) and 400 °C (d)

Fig. 10 Microstructures close to fracture surfaces of 6061 alloys thixoformed at mould temperatures of 200 °C (a), 250 °C (b), 350 °C (c) and 400 °C (d)

When the mould temperature is 200 °C, the feeding ability to solidification shrinkage is the worst due to the rapidest solidification rate. So, porosities can easily form in the secondarily solidified structures and these sites are the weak points of the alloy. Cracks generally develop along the secondarily solidified structures during the tensile test (marked by the arrow in Fig. 9(a)) where porosities and inclusions exist (Fig. 10(a) and Fig. 11(a)). Therefore, the alloy has low UTS (Table 2). In addition, the fracture belongs to the mixture of transgranular and intergranular regimes at this temperature. As the temperature rises to 250 °C, the solidification process slows down and the feeding ability to porosities is improved. Therefore, the tensile properties are increased due to the improved microstructure compactness although the secondarily solidified microstructures are still the weak points of this alloy (Fig. 9(b) and Fig. 10(b)). In some locations of the alloy, the primary particles are connected together (Fig. 8(b)), which should result in the inhomogeneous deformation during thixoforging. So, the residual stress in these sites is very high and the cracks preferentially develop along these microstructures (Fig. 10(b) and Fig. 11(b)). Because of the stress concentration, the increase range of the tensile properties is small and the hardness is decreased (Table 2). When the temperature is elevated to 300 and 350 °C, more compact and homogeneous microstructures are obtained (Fig. 6(c) and Fig. 10(c)). The deformation during thixoforging becomes more uniform. Hence, the bonding strength between the primary particles should be stronger. The dominative fracture regime then transforms from a mixture of transgranular and intergranular regimes (Fig. 9(b)) to transgranular regime (Figs. 5(c) and 9(c)) and the fracture surface is composed of many small dimples (Fig. 11(c)). The UTS and hardness of the alloy reach the highest values as the mould temperature is elevated to 350 °C. When the temperature rises to 400 °C, there are many liquid pools within the interconnected particles (Fig. 8(d)). It can be expected that the solidification shrinkage cannot be fully fed and porosities are easily formed during solidification. So, cracks always develop across these secondarily solidified particles (Fig. 9(d)). Namely, the fracture remains the transgranular regime. Furthermore, the primary particles coarsen into larger ones because of the longer solidification time (comparing Figs. 10(c) and (d)). The dimples also become larger on the fracture surface (comparing Figs. 11(c) and (d)). Because of the formation of the interconnected particles and coarsening of the primary particles, the properties of the alloy are decreased (Table 2).

In summary, the mould temperature also has obvious effects on the microstructure and mechanical properties of the powder-thixoforged 6061 alloy. The primary particles in the microstructure gradually coarsen and connect with each other due to the decreased solidification rate resulting from the mould temperature rising. Simultaneously, the primary particle fraction is also increased and the microstructure becomes more compact. Therefore, the UTS and hardness of the alloy increase and reach the maximum when the mould temperature is elevated to 350 °C. However, as the temperature is further elevated, the properties are decreased because of porosities and larger primary particle size. In addition, it is also due to the microstructure changes that the fracture regime changes from a mixture of transgranular and intergranular regimes to transgranular regime.

3.4 Effects of reheating temperature on microstructure and mechanical properties

Both the UTS and hardness continuously increase when the reheating temperature rises from 650 to 660 °C, and then decrease as the temperature rises from 660 to 665 °C (Table 2). Therefore, the temperature of 660 °C is the most appropriate reheating temperature.

Fig. 11 Fractographs of 6061 alloys thixoforged at mould temperatures of 200 °C (a), 250 °C (b), 350 °C (c) and 400 °C (d)

Figure 12 gives the microstructures of the 6061 alloys thixoforged at different reheating temperatures. When the temperature is 650 °C, the amount of liquid phase is relatively small and the neighboring primary particles are still interconnected after partial remelting [17]. Therefore, most of the primary particles connect together after deformation occurs during forming (Fig. 12(a)). As the temperature rises to 655 °C, more liquid phase forms and more primary particles are separated during partial remelting. So, the primary particles are separated by the secondarily solidified structures after thixoforging (Fig. 12(b)). When the temperature is elevated to 660 °C, the primary particles coarsen into larger ones, but are uniformly distributed in the secondarily solidified structures (Fig. 8(c)). Then, too much liquid phase is formed and the primary particles size is decreased as the temperature rises to 665 °C (Fig. 12(c)).

Fig. 12 Microstructures of thixoforged 6061 alloys at different reheating temperatures of 650 °C (a), 655 °C (b) and 665 °C (c)

Fig. 13 Side views of fracture surfaces of thixoforged 6061 alloys at different reheating temperatures of 650 °C (a), 655 °C (b) and 665 °C (c)

Fig. 14 Microstructures close to fracture surfaces of thixoforged 6061 alloys at different reheating temperatures of 650 °C (a), 655 °C (b) and 665 °C (c)

When the reheating temperature is at a lower temperature of 650 °C, the liquid fraction is small. As discussed in the Section 3.2, the secondarily solidified structures should be the weak points of the alloy due to the large number of shrinkage porosities. Cracks propagate along the secondarily solidified structures (marked by arrow A in Fig. 13(a)) and primary particles and the fracture obeys the mixture of transgranular and intergranular regimes (Fig. 13(a)). It can be expected that the boundaries of the interconnected particles should also be the weak points of the alloy. Therefore, cracks can easily form in these sites during tensile test (Fig. 14(a)). Figure 15(a) shows that there are many shrinkage porosities and inclusions on the fracture surface. Due to the incompact microstructure and the local stress concentration, cracks easily initiate and then propagate either along the secondarily solidified structures or between the primary particles. So, the properties of the alloy are relatively low (Table 2). As the temperature rises to 655 °C, the amount of liquid phase increases, and thus feeding ability to solidification shrinkage during thixoforging is improved. However, similar to those of heating at 650 °C, cracks generally develop along the boundaries of the interconnected particles (Fig. 14(b)), which can also be found on the fracture surface (Fig. 15(b)). Therefore, although the microstructure becomes denser because of the improvement of feeding ability, the increase range of the properties is relatively small. When the temperature rises to 660 °C, the amount of liquid phase is further increased, and the microstructure is more homogeneous (Fig. 8(c)). The properties of the resulting alloy reach the highest properties due to the resulted compact and uniform microstructure. In addition, the fracture mode changes from a mixture of transgranular and intergranular regimes (Fig. 13(b)) to transgranular regime (Fig. 9(c)). When the temperature is elevated to 665 °C, too much liquid phase forms, and cracks completely develop along the secondarily solidified structures (Fig. 13(c)) because of porosities (Fig. 14(c) and Fig. 15(c)). Furthermore, the amount of oxide inclusions should be increased because of the higher reheating temperature. Hence, the properties are decreased compared with those of the thixoforged alloy at reheating temperature 660 °C (Table 2). The fracture mode changes from transgranular regime to intergranular regime (comparing Figs. 13(b) and (c)).

Fig. 15 Fractographs of thixoforged 6061 alloys at different reheating temperatures of 650 °C (a), 655 °C (b) and 665 °C (c)

Therefore, it can be proposed that the reheating temperature also has significant effects on the microstructure and mechanical properties of the powder- thixoforged 6061 alloy. The microstructure evolution is attributed to the reasons similar to those from the reheating time. The changes of the mechanical properties are mainly ascribed to the shrinkage porosities, inclusions and stress concentration. Furthermore, due to the microstructure evolution, the fracture mode changes from a mixture of transgranular and intergranular regimes to transgranular regime and finally to intergranular regime with the rise of the reheating temperature.

4 Conclusions

1) The reheating time, mould temperature and reheating temperature all have large effects on the microstructure and mechanical properties of the powder-thixoforged 6061 aluminum alloy. Both microstructure changes with reheating time or reheating temperature and plastic deformation are mainly attributed to the variations of the liquid amount during thixoforging, while the microstructure evolution with mould temperature is ascribed to the changes of solidification rate and plastic deformation. The mechanical properties are mainly related to the shrinkage porosities, inclusions, microstructure uniformity and stress concentration.

2) Cracks always initiate from the shrinkage porosities and inclusions, and then propagate along either secondarily solidified structures or the primary particles. Due to the microstructure changes, the fracture regime varies as the mould temperature or reheating temperature rises, while the regime mainly maintains transgranular mode with the reheating time.

3) In contrast, the effects of the reheating time and reheating temperature on the microstructure are compactness and uniformity, and thus their effects on the mechanical properties are better than those of the mould temperature.

4) In order to obtain a high performance powder-thixoforged component, a compact and uniform microstructure should be obtained as far as possible through adjusting the processing parameters such as reheating time, mould temperature and reheating temperature.

5) The UTS, elongation and hardness of alloy are up to 196 MPa, 11.0% and HV 55.7 respectively when it is thixoformed at reheating temperature of 660 °C for 80 min and mould temperature of 350 °C.

References

[1] LLOYD D J. Particle reinforced aluminium and magnesium matrix composites [J]. International Materials Reviews, 1994, 39(1): 1-23.

[2] CHAWLA N, CHAWLA K K. Metal-matrix composites in ground transportation [J]. JOM, 2006, 58(11): 67-70.

[3] PRASAD S V, ASTHANA R. Aluminum metal-matrix composites for automotive applications: Tribological considerations [J]. Tribology Letters, 2004, 17(3): 445-453.

[4] RAWAL S P. Metal-matrix composites for space applications [J]. JOM, 2001, 53(4): 14-17.

[5] ZHANG L, QU X H, HE X B, DUAN B H, REN S B, QIN M L. Thermo-physical and mechanical properties of high volume fraction SiCp/Cu composites prepared by pressureless infiltration [J]. Materials Science and Engineering A, 2008, 489(1-2): 285-293.

[6] HWU B K, LIN S J, JAHN M T. Effects of process parameters on the properties of squeeze-cast SiCp-6061 Al metal-matrix composite [J]. Materials Science and Engineering A, 1996, 207: 135-141.

[7] CHENG N P, ZENG S M, LIU Z Y. Preparation, microstructures and deformation behavior of SiCp/6066-Al composites produced by PM route [J]. Journal of Materials Processing Technology, 2008, 202 (1-3): 27-40.

[8] BISHOP D P, CALEY W F, KIPOUROS G J, HEXEMER R L, DONALDSON I W. Powder metallurgy processing of 2xxx and 7xxx series aluminium alloys [J]. Canadian Metallurgical Quarterly, 2011, 50(3): 246-252.

[9] TZAMTZIS S, BAREKAR N S, HARI BABU N, PATEL J, DHINDAW B K, FAN Z. Processing of advanced Al/SiC particulate metal matrix composites under intensive shearing—A novel rheo-process [J]. Composites Part A: Applied Science and Manufacturing, 2009, 40(2): 144-151.

[10] FLEMINGS M C. Behavior of metal alloys in the semisolid state [J]. Metallurgical Transactions B, 1991, 22(3): 269-293.

[11] FAN Z. Semisolid metal processing [J]. International Materials Reviews, 2002, 47(2): 49-85.

[12] GANESAN G, RAGHUKANDAN K, KARTHIKEYAN R, PAI B C. Development of processing maps for 6061 Al/15% SiCp composite material [J]. Materials Science and Engineering A, 2004, 369(1): 230-235.

[13] HOSSEINI N, KARIMZADEH F, ABBASI M H, ENAYATI M H. Tribological properties of Al6061-Al2O3 nanocomposite prepared by milling and hot pressing [J]. Materials & Design, 2010, 31(10): 4777-4785.

[14] QIAN L, KOBAYASHI T, TODA H, WANG Z G. Dynamic fracture toughness of 6061Al composites reinforced with SiC particulates [J]. Materials Science and Engineering A, 2001, 318(1): 189-196.

[15] SON H T, KIM T S, SURYANARAYANA C, CHUN B S. Homogeneous dispersion of graphite in a 6061 aluminum alloy by ball milling [J]. Materials Science and Engineering A, 2003, 348(1): 163-169.

[16] WU Y, KIM G Y, ANDERSON I E, LOGRASSO T A. Fabrication of Al6061 composite with high SiC particle loading by semi-solid powder processing [J]. Acta Materialia, 2010, 58(13): 4398-4405.

[17] CHEN Y S, CHEN T J, FU W, LI P B. Microstructural evolution during partial remelting of 6061 aluminum bulk alloy prepared by cold-pressing of alloy powder [J]. Advanced Materials Research, 2013, 820: 20-24.

[18] SAHIN Y. Preparation and some properties of SiC particle reinforced aluminium alloy composites [J]. Materials & Design, 2003, 24(8): 671-679.

[19] TANM J, ZHANG X. Powder metal matrix composites: Selection and processing [J]. Materials Science and Engineering A, 1998, 244(1): 80-85.

[20] CHEN T J, HUANG L K, HUANG X F, MA Y, HAO Y. Effects of reheating temperature and time on microstructure and tensile properties of thixoforged AZ63 magnesium alloy [J]. Materials Science and Technology, 2014, 30(1): 96-108.

[21] CHEN T J, HUANG L K, HUANG X F, MA Y, HAO Y. Effects of mould temperature and grain refiner amount on microstructure and tensile properties of thixoforged AZ63 magnesium alloy [J]. Journal of Alloys and Compounds, 2013, 556: 167-177.

[22] CHEN C P, TSAO C Y. Semisolid deformation of aluminium alloy 356 with non-dendritic structure [J]. Materials Science and Technology, 1999, 15(9): 981-985.

[23] CHEN C P, TSAO C Y. Semi-solid deformation of non-dendritic structures—I. Phenomenological behavior [J]. Acta materialia, 1997, 45(5): 1955-1968.

[24] CHEN T J, HAO Y, SUN J, LI Y D. Effects of processing parameters on tensile properties and hardness of thixoformed ZA27 alloy [J]. Materials Science and Engineering A, 2004, 382(1): 90-103.

[25] CHEN T J, WANG R Q, MA Y, HAO Y. Effects of processing parameters on microstructure and ultimate tensile strength of thixoformed AM60B magnesium alloy [J]. Materials Research, 2012, 15(4): 687-697.

[26] HUANG H J, CHEN T J, MA Y, HAO Y. Microstructural evolution during solution treatment of thixoformed AM60B Mg alloy [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(4): 745-753.

[27] CHEN T J, LU W B, MA Y, HUANG H J, HAO Y. Semisolid microstructure of AM60B magnesium alloy refined by SiC particles [J]. International Journal of Materials Research, 2011, 102(12): 1459-1467.

陈玉狮,陈体军,张素卿,李普博

兰州理工大学 有色金属先进加工与再利用国家重点实验室,兰州730050

摘 要:提出一种制备颗粒增强金属基复合材料的新技术—粉末触变成形, 并利用该技术对基体6061铝合金进行触变模锻。首先,将雾化的6061合金粉末冷压成块,压出的块体作为初始锭料,经部分重熔后再进行触变模锻。研究重熔时间、模具温度和重熔温度对触变模锻6061合金微观组织与力学性能的影响。结果表明,这3个加工工艺参数对微观组织与力学性能均有较大影响;合金的断裂机理是由不同加工工艺参数下的微观组织决定的;此外,裂纹往往起源于缩松和夹杂处,沿着二次凝固组织或者初生相颗粒扩展;经触变模锻得到的合金的抗拉强度、伸长率和硬度分别可达196 MPa、11.0% 和HV 55.7。

关键词:6061铝合金;半固态粉末触变模锻;力学性能;拉伸性能;硬度;微观组织

(Edited by Xiang-qun LI)

Foundation item: Project (2014-07) supported by the Basic Scientific Fund of Gansu University, China; Project (NCET-10-0023) supported by the Program for New Century Excellent Talents in University of China; Project supported by the Program for Hongliu Outstanding Talents of Lanzhou University of Technology, China

Corresponding author: Ti-jun CHEN; Tel: +86-931-2976573; E-mail: chentj@lut.cn; chentj1971@126.com

DOI: 10.1016/S1003-6326(15)63655-X