等径通道挤压铝在较宽温度和 应变率下的单轴压缩行为

来源期刊:中国有色金属学报(英文版)2014年第8期

论文作者:汤忠斌 索 涛 张部声 李玉龙 赵 峰 范学领

文章页码:2447 - 2452

关键词:超细晶材料;等经通道挤压;铝;力学性能;应变率敏感性;温度依赖性;激活体积

Key words:ultrafine-grained materials; equal channel angular pressing; Al; mechanical behavior; strain rate sensitivity; temperature dependence; activation volume

摘 要:在较宽温度和应变率范围内,对等径通道挤压(ECAP)方法制备的超细晶铝进行单轴压缩试验,研究温度对流动应力、应变硬化率和应变率敏感性的影响。结果表明:ECAP铝与粗晶粒度铝相比,温度对其流动应力和应变率敏感性的影响更大,超细晶铝的温度敏感性较粗晶粒度铝弱。根据试验结果,估计了不同温度和应变率下的表观激活体积。ECAP铝在准静态应变率下,与林位错相互作用是主导的热激活机制,而粘曳在高应变率下起着更重要的作用。

Abstract: Uniaxial compressive experiments of ultrafine-grained Al fabricated by equal channel angular pressing (ECAP) method were performed at wide temperature and strain rate range. The influence of temperature on flow stress, strain hardening rate and strain rate sensitivity was investigated experimentally. The results show that both the effect of temperature on flow stress and its strain rate sensitivity of ECAPed Al is much larger than those of the coarse-grained Al. The temperature sensitivity of ultrafine-grained Al is comparatively weaker than that of the coarse-grained Al. Based on the experimental results, the apparent activation volume was estimated at different temperatures and strain rates. The forest dislocation interactions is the dominant thermally activated mechanism for ECAPed Al compressed at quasi-static strain rates, while the viscous drag plays an important role at high strain rates.

Trans. Nonferrous Met. Soc. China 24(2014) 2447-2452

Zhong-bin TANG1, Tao SUO1, Bu-sheng ZHANG1, Yu-long LI1, Feng ZHAO1, Xue-ling FAN2

1. School of Aeronautics, Northwestern Polytechnical University, Xi’an 710072, China;

2. School of Aerospace, Xi’an Jiaotong University, Xi’an 710049, China

Received 13 June 2013; accepted 25 March 2014

Abstract: Uniaxial compressive experiments of ultrafine-grained Al fabricated by equal channel angular pressing (ECAP) method were performed at wide temperature and strain rate range. The influence of temperature on flow stress, strain hardening rate and strain rate sensitivity was investigated experimentally. The results show that both the effect of temperature on flow stress and its strain rate sensitivity of ECAPed Al is much larger than those of the coarse-grained Al. The temperature sensitivity of ultrafine-grained Al is comparatively weaker than that of the coarse-grained Al. Based on the experimental results, the apparent activation volume was estimated at different temperatures and strain rates. The forest dislocation interactions is the dominant thermally activated mechanism for ECAPed Al compressed at quasi-static strain rates, while the viscous drag plays an important role at high strain rates.

Key words: ultrafine-grained materials; equal channel angular pressing; Al; mechanical behavior; strain rate sensitivity; temperature dependence; activation volume

1 Introduction

In the past 30 years, the ultrafine-grained and nanocrystalline (UFG/NC) materials which possess grains with size of several hundred nanometers or even tens of nanometers have attracted considerable attentions, especially in the search for lightweight and strong materials [1], which show many unique mechanical and physical properties. The classical Hall-Petch relationship is commonly used to explain the trend of enhanced yield stress with reduction of grain size [2,3]. However, such relationship is shown to break down when the grain size is tens of nanometers [4]. This kind of “softening” effect is believed to emerge from the activated processes, such as grain rotation.

Similar to coarse grained (CG) metals, the plastic deformation of UFG materials is also thermally activated process with temperature and strain rate (or loading rate) dependence [1,5]. However, such unique microstructures as high fraction of non-equilibrium grain boundary (GB) and high dislocation density make the dependence of mechanical behaviors on temperature and strain rate much more complex than that for coarse grained materials. It is generally observed that for metals with face-centered cubic (FCC) crystal structure, the strain rate sensitivity (SRS) increases with the reduction of grain size. In some UFG FCC metals, strain rate sensitivity factor as high as 0.1-0.3 was even reported [1,6,7]. Such high SRS values were usually achieved at extremely low strain rates or high temperatures, at which such process as coble creep was supposed to mediate plastic deformation [1,8-10].

Since plastic deformation of metals can be regarded as thermally activated process, which always depends on both strain rate and temperature, the sensitivity of mechanical properties of UFG materials to temperature associated with applied loading is also necessary to investigate to extend our understanding about these unusual solids. Experimental evidences have shown that similar to the SRS the flow stress of FCC UFG/NC metals strongly depends on temperature compared with their CG counterparts [11-14]. Such enhancement is also attributed to the reduction in thermal activation volume as the grain size is refined into UFG/NC regime [13,15-17].

While great progresses have been made in the past few years, to understand the strain rate and temperature coupling effects on the mechanical behavior of UFG/NC metals, there remain many issues need that further effort. The coupling effects of strain rate and temperature on uniaxial compressive behaviors of UFG aluminum (UFG-Al) were investigated, the strain rate and temperature sensitivity, as well as thermal activation volume are determined at quasi-static and dynamic strain rates, respectively, over a wide range of temperatures range. Based on these experimentally determined parameters, the rate-controlling mechanisms for thermal activated plastic deformation were discussed.

2 Experimental

The UFG aluminum was fabricated via equal channel angular pressing (ECAP) method using a die with inner angle of 120° and an outer arc of 20°. To achieve homogenous microstructure, each billet was pressed 8 times using the pressing route Bc. After that, microstructure of UFG-Al was examined using a Hitachi H-800 transmission electron microscope (TEM) operating at 200 kV. The disk form specimens with the diameter of 3 mm for TEM were cut from the section perpendicular to the longitudinal axis of the ECAPed billets. These small disks were polished mechanically to a thickness of about 50 μm before they were thinned to perforation using a vacuum ion sputter. The TEM micrograph of UFG-Al show a homogenous ultrafine grained microstructure characterized by grain size of about 1 μm, sharp grain boundaries and a larger mis-orientation angle. The specimens for both quasi-static and dynamic compressive tests were taken from the center part of the rod and machined to cylinders with dimension of d4 mm×4 mm. The loading direction was parallel to the ECAPed rod axis.

The deformation behavior was studied in the temperature range between 77 and 473 K (0.057-0.423Tm, Tm is the melting point of Al) at the strain rates from 10-3 to 103 s-1. Quasi-static compression experiments were performed using an electronic universal testing machine with a maximum load capacity of 10 kN. The split Hopkinson pressure bar (SHPB), situated in Northwestern Polytechnical University, was employed for high strain rate experiments. According to the one dimensional elastic stress wave theory, the strain, stress and strain rate of tested specimen can be calculated as [18]

,

,  ,

,  (1)

(1)

where εt and εr are the transmitted and reflected strain pulses which can be measured by the strain gages stuck on the input and output bars, respectively; C0, E and A denote the longitudinal elastic wave velocity, elastic modulus and cross-sectional area of the loading bars; ls and As are the length and cross-sectional area of the specimen, respectively.

3 Results

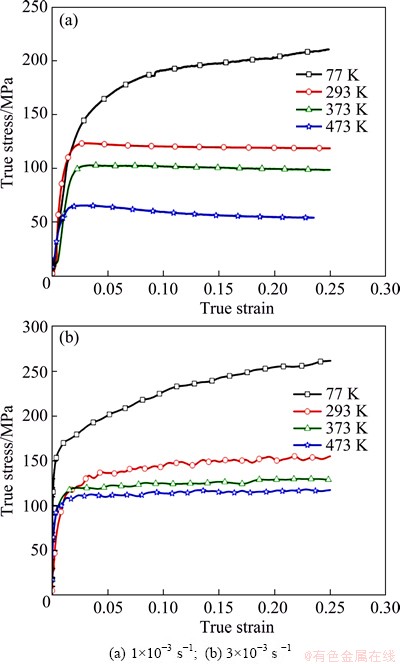

Figure 1 shows the typical true stress versus true strain curves of UFG-Al tested at elevated temperatures and strain rates of 1×10-3 s-1 and 3×10-3 s -1. In contrast to conventional coarse grained aluminum with high purity which usually shows low yield strength as well as remarkable strain hardening, the UFG-Al displays higher strength while remarkable strain hardening is only observed at 77 K. Such capacity is close to being exhausted at temperatures above 293 K. At high temperatures, obvious reduction in flow stress is even found in case of strain rate 1×10-3 s-1 with increasing strain. With increasing strain rate, the strain hardening rate tends to increase slightly. The strain softening at high temperatures is not observed in case of being tested at high strain rate.

Figure 2 shows the flow stresses of UFG-Al at a fixed strain of 10% determined at elevated temperatures.

Fig. 1 True stress-true strain curves of UFG-Al tested at elevated temperatures and different strain rates

The experimental data on CG Al in the strain rate range of 1×10-3-3×103 s-1 are shown in Fig. 2. Compared to its coarse grained counterpart, the flow stress of UFG-Al displays more remarkable sensitivity to testing temperature over current strain rate range. Similar trends are also observed in UFG FCC metals, such as UFG-Al, NC-Ni [13,14,16,19].

Fig. 2 Relationship between flow stress of annealed CG-Al and UFG-Al and temperature at fixed strain of 0.10

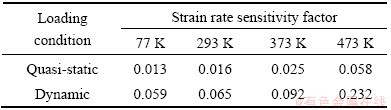

Figure 3 gives the flow stress at a fixed true strain of 10% as a function of logarithmic strain rate for UFG-Al at elevated temperatures. A stronger effect of the strain rate on the flow stress can be clearly seen compared to the annealed coarse grained Al. Meanwhile, when the dynamic deformation tests (at strain rates higher than 103 s-1) are applied, a sudden increase in flow stress strain rate sensitivity can be observed. Following the definition of strain rate sensitivity (SRS) factor m (m= ) [20], the values of SRS can be determined approximately by using log-log flow stress versus strain rate plots. Table 1 lists the SRS values for UFG-Al determined at quasi-static and dynamic strain loading conditions, respectively.

) [20], the values of SRS can be determined approximately by using log-log flow stress versus strain rate plots. Table 1 lists the SRS values for UFG-Al determined at quasi-static and dynamic strain loading conditions, respectively.

Fig. 3 Relationship between flow stresses and strain rate of UFG-Al at strain of 0.1

Table 1 SRS values of UFG-Al under different conditions

Obviously, SRS of the UFG-Al is strongly enhanced compared to that of annealed CG-Al. Such enhanced SRS is commonly observed for several FCC materials when the grain size is refined into UFG or NC regime [1,20]. Moreover, SRS of UFG-Al increases obviously under whatever quasi-static or dynamic loading condition with increasing temperature. For our UFG-Al, in case of quasi-static deformation the SRS increases from 0.013 (77 K) to 0.058 (473 K). In case of dynamic loading, the SRS shows up to a factor of 3 which is higher than quasi-static value.

4 Deformation mechanism

For studying the physical mechanism of plastic deformation of crystals, an effective method is thermal- activation analysis. Employing the concept of thermal- activation theory, the following equation can be derived to describe the strain rate sensitivity of metals [20]:

(2)

(2)

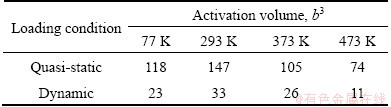

Based on Eq. (2), a linear fit can be used to estimate the apparent activation volume. Table 2 shows the estimated apparent activation at elevated temperatures. Overall, in case of quasi-static compression, the apparent activation volumes for UFG-Al are in the range of 70b3-150b3, where b=2.86×10-10 m is the Burger’s vector of aluminum. When the dynamic strain rates are applied, the UFG-Al gives values of V* of 10b3-30b3. Meanwhile, the experimentally determined apparent activation volumes of UFG-Al display a non- monotonous variation in current range of temperature. Under whatever quasi-static or dynamic loading condition, at temperatures below 293 K, V* increases slightly with temperature rising, while in case of temperatures above 293 K, it shows an opposite trend. Comparing with its coarse grained counterpart, such are at least one to two orders of magnitude lower.

Table 2 Activation volume of UFG-Al under different loading conditions

The fully annealed metals with FCC structure usually have a large activation volume, i.e. 102b3-103b3, and the dominant rate-controlling process is the intersection of moving dislocations cutting through forest dislocations. In case that the grain size is reduced to ultrafine level (100 nm-1 μm) or nano-grain regime (grain size below 100 nm), grain boundary related processes, such as Coble creep [7,21], grain boundary sliding and shear mediated by grain boundary diffusion [22,23], and dislocation-boundary interactions [16,17,24] are considered the possible rate-controlling mechanisms. Among these mechanisms, the Coble creep and grain-boundary diffusion can be ruled out firstly based on the SRS and activation volume values obtained experimentally. When such mechanisms dominate, the plastic deformation should occur at a relatively low stress and a high homologous temperature and activation volume is usually in the order of 1b3-10b3 [16].

For metals with larger grain size (above the critical value associated with grain boundary diffusion), dislocation-grain boundary interaction is believed to dominate the plastic deformation [16]. In the case of coarse grained materials, these unusual activated processes are insignificant but their contributions increase with decreasing grain size, and possibly become dominant in UFG or NC materials. However, it seems that such dislocation-grain boundary interaction processes are not applicable since the grain size in the present UFG-Al is still too large to activate such scenarios associated with the interaction of dislocations with grain boundaries.

Since such processes as Coble creep, grain boundary sliding and shear and dislocation-grain boundary interactions can be ruled out as the dominant mechanism for plastic deformation, when such mechanism operates, the activation volume can be estimated from

(3)

(3)

According to Eq. (3), to achieve an activation volume value 150b3, the corresponding dislocation density should be about 3.6×1014 m-2. This value is a little higher but still comparable with the results for UFG-Al reported in Refs. [25,26]. If considering the fact that in UFG metals developed by severe plastic deformation method, dislocations may concentrate in the vicinity of grain boundaries or in the so-called “GB affect zone” [27-30], while the interior of the grains is usually very low in the density of dislocations, during plastic deformation moving dislocations may travel almost unimpeded through the lattice of the interior of the grains, but slow down and spend most of time on fighting against the forest dislocations near and at grain boundaries. Thus, the rate-controlling mechanism may be medicated by dislocations intersection near and at grain boundaries [17,22,31]. Therefore, one possibility for the larger value of estimated dislocation density in the presence UFG-Al compared to results reported in literatures might be the dislocation arrangement near and at the submicron grain boundaries [22,32].

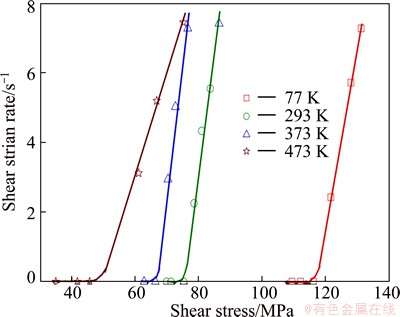

It is also worth mentioning that, under dynamic loading, the activation volumes are of an order lower than those under quasi-static loading. This may indicate the variation in thermally activated deformation mechanism when the applied strain rate is increased from quasi-static to dynamic regime. Conventionally, for coarse grained FCC metals with high purity, in case of high strain rate deformation (e.g. the strain rate above 103 s-1), viscous drag becomes an important obstacles to moving dislocations. In this case, the flow stress becomes dependent on the drag exerted by the lattice vibrations or the conduction electrons, and smaller values of activation volumes are expected [33]. Meanwhile, the velocity of moving dislocation is proposed to be a linear function of stress. In Fig. 4, the strain rate versus flow stress curves are plotted for UFG-Al from which the linear relationship between stress and strain rate at high strain rate without any deviation can be observed. This suggests that some regarding viscous drag is acting on the dislocations in case of dynamic deformation of UFG-Al.

Fig. 4 Linear dependence of shear stress on shear strain rate at high strain rates for UFG-Al deformed at elevated temperatures

5 Conclusions

1) Strong effects of strain rate and temperature on the deformation behavior are clearly seen with increasing the flow stress strongly and strain rate and reducing temperature. The strain rate sensitivity also displays apparent dependence on temperature.

2) Based on analysis of experimentally determined parameters, such mechanisms as Coble creep, grain boundary sliding and shear, and the interaction of dislocations with grain boundaries are ruled out as the major rate-controlling mechanism accommodating the plastic flow.

3) The conventional thermally activated cutting of forest dislocations in coarse grained FCC metals is proposed to be more likely to occur in the higher dislocation-density structure adjacent to the grain boundaries.

4) The linear relationship between stress and strain rate suggests that some regarding viscous drag force which is proportional to the dislocation velocity is acting on the dislocations under dynamic loading condition.

Acknowledgement

The author Tao SUO would like to thank Dr. Q. WEI (University of North Carolina, USA), Y. ZHANG and C.Q. CHEN (The Johns Hopkins University, USA) for useful discussions.

References

[1] MEYERS M A, MISHRA A, BENSON D J. Mechanical properties of nanocrystalline materials [J]. Progress in Materials Science, 2006, 51(4): 427-556.

[2] HALL E O. The deformation and ageing of mild steel: III. Discussion of results [J]. Proceedings of the Physical Society Section B, 1951, 64(9): 747.

[3] PETCH N J. The cleavage strength of polycrystals [J]. J Iron Steel Inst, 1953, 174: 25-28.

[4] Van SWYGENHOVEN H. Grain boundaries and dislocations [J]. Science, 2002, 296(5565): 66-67.

[5] LI J C M. Mechanical properties of nanocrystalline materials [M]. New York, USA: Pan Stanford Publishing, 2011.

[6] MAY J,  Strain rate sensitivity of ultrafine-grained aluminium processed by severe plastic deformation [J]. Scripta Materialia, 2005, 53(2): 189-194.

Strain rate sensitivity of ultrafine-grained aluminium processed by severe plastic deformation [J]. Scripta Materialia, 2005, 53(2): 189-194.

[7] CHINH N Q, SZOMMER P,  T, LANGDONT G. Flow processes at low temperatures in ultrafine-grained aluminum [J]. Materials Science and Engineering A, 2006, 434(1): 326-334.

T, LANGDONT G. Flow processes at low temperatures in ultrafine-grained aluminum [J]. Materials Science and Engineering A, 2006, 434(1): 326-334.

[8] WANG Y M, BRINGA E M, MCNANEY J M, et al. Deforming nanocrystalline nickel at ultrahigh strain rates [J]. Applied physics Letters, 2006, 88(6): 061917.

[9] WANG Y M, OTT R T, BESSER M F, HAMZA A V. Temperature-dependent competing deformation mechanisms in nanocrystalline metals [J]. Physical Review B, 2012, 85(14): 144122.

[10] ZHANG X F, FUJITA T, PAN D, YU J S, SAKURAI T, CHEN M W. Influences of grain size and grain boundary segregation on mechanical behavior of nanocrystalline Ni [J]. Materials Science and Engineering A, 2010, 527(9): 2297-2304.

[11] FARROKH B, KHAN A S. Grain size, strain rate, and temperature dependence of flow stress in ultra-fine grained and nanocrystalline Cu and Al: Synthesis, experiment, and constitutive modeling [J]. International Journal of Plasticity, 2009, 25(5): 715-732.

[12] JIANG Qing-wei, XIAO Lin, LI Xiao. A comparison of temperature-dependent compressive deformation features of ultrafine-grained Ti and Cu produced by ECAP [J]. Materials Science Forum, 2011, 682: 41-45.

[13] SUO Tao, Li Yu-long, ZHAO Feng, FAN Xue-ling, GUO Wei-guo. Compressive behavior and rate-controlling mechanisms of ultrafine grained copper over wide temperature and strain rate ranges [J]. Mechanics of Materials, 2013, 61: 1-10.

[14] SUO Tao, Li Yu-long, XIE Kui, ZHAO Feng, ZHANG Ke-shi, LIU Yuan-yong. The effect of temperature on mechanical behavior of ultrafine-grained copper by equal channel angular pressing [J]. Materials Science and Engineering A, 2010, 527(21): 5766-5772.

[15] BARAI P, WENG G J. Mechanics of very fine-grained nanocrystalline materials with contributions from grain interior, GB zone, and grain-boundary sliding [J]. International Journal of Plasticity, 2009, 25(12): 2410-2434.

[16] WANG Y M, HAMZA A V, MA E. Temperature-dependent strain rate sensitivity and activation volume of nanocrystalline Ni [J]. Acta Materialia, 2006, 54(10): 2715-2726.

[17] MALYGIN G A. Analysis of the strain-rate sensitivity of flow stresses in nanocrystalline FCC and BCC metals [J]. Physics of the Solid State, 2007, 49(12): 2266-2273.

[18] KOLSKY H. An investigation of the mechanical properties of materials at very high rates of loading [J]. Proceedings of the Physical Society Section B, 1949, 62(11): 676.

[19] HUANG Z, GU L Y, WEERTMAN J R. Temperature dependence of hardness of nanocrystalline copper in low-temperature range [J]. Scripta Materialia, 1997, 37(7): 1071-1075.

[20] WEI Q. Strain rate effects in the ultrafine grain and nanocrystalline regimes—Influence on some constitutive responses [J]. Journal of Materials Science, 2007, 42(5): 1709-1727.

[21] JIANG Zhong-hao, ZHANG Han-zhou, GU Chang-dong, JIANG Qing, LIAN Jian-she. Deformation mechanism transition caused by strain rate in a pulse electric brush-plated nanocrystalline Cu [J]. Journal of Applied Physics, 2008, 104(5): 053505.

[22] CONRAD H, YANG D. Plastic deformation kinetics of electrodeposited Cu foil at low and intermediate homologous temperatures [J]. Journal of Electronic Materials, 2002, 31(4): 304-312.

[23] CONRAD H, JUNG K. On the strain rate sensitivity of the flow stress of ultrafine-grained Cu processed by equal channel angular extrusion (ECAE) [J]. Scripta Materialia, 2005, 53(5): 581-584.

[24] DALLA TORRE F, LAPOVOK R, SANDLIN J, THOMSON P E, DAVIES C H J, PERELOMA E V. Microstructures and properties of copper processed by equal channel angular extrusion for 1-16 passes [J]. Acta Materialia, 2004, 52(16): 4819-4832.

[25] GUBICZA J, CHINH N Q,  G, SCHILLER I, UNGA R T. Microstructure of ultrafine-grained FCC metals produced by severe plastic deformation [J]. Current Applied Physics, 2006, 6(2): 194-199.

G, SCHILLER I, UNGA R T. Microstructure of ultrafine-grained FCC metals produced by severe plastic deformation [J]. Current Applied Physics, 2006, 6(2): 194-199.

[26] QIAO X G, GAO N, STARINK M J. A model of grain refinement and strengthening of Al alloys due to cold severe plastic deformation [J]. Philosophical Magazine, 2012, 92(4): 446-470.

[27] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nanostructured materials from severe plastic deformation [J]. Progress in Materials Science, 2000, 45(2): 103-189.

[28] MEYERS M A, BENSON D J,  O, KAD B K, XUE Q, FU H. Constitutive description of dynamic deformation: Physically-based mechanisms [J]. Materials Science and Engineering A, 2002, 322(1): 194-216.

O, KAD B K, XUE Q, FU H. Constitutive description of dynamic deformation: Physically-based mechanisms [J]. Materials Science and Engineering A, 2002, 322(1): 194-216.

[29] ZHU Y T, HUANG J Y, GUBICZA J, UNGAR T, WANG Y M, MA E, VALIEV R Z. Nanostructures in Ti processed by severe plastic deformation [J]. Journal of Materials Research, 2003, 18(8): 1908-1917.

[30] LI J, WENG G J. A secant-viscosity composite model for the strain-rate sensitivity of nanocrystalline materials [J]. International Journal of Plasticity, 2007, 23(12): 2115-2133.

[31] ZHU Y T, LANGDON T G. Influence of grain size on deformation mechanisms: An extension to nanocrystalline materials [J]. Materials Science and Engineering A, 2005, 409(1): 234-242.

[32] HANSEN N, RALPH B. The strain and grain size dependence of the flow stress of copper [J]. Acta Metallurgica, 1982, 30(2): 411-417.

[33] KUMAR A, KUMBLE R G. Viscous drag on dislocations at high strain rates in copper [J]. Journal of Applied Physics, 2003, 40(9): 3475-3480.

汤忠斌1,索 涛1,张部声1,李玉龙1,赵 峰1,范学领2

1. 西北工业大学 航空学院,西安 710072;

2. 西安交通大学 航天航空学院,西安 710049

摘 要:在较宽温度和应变率范围内,对等径通道挤压(ECAP)方法制备的超细晶铝进行单轴压缩试验,研究温度对流动应力、应变硬化率和应变率敏感性的影响。结果表明:ECAP铝与粗晶粒度铝相比,温度对其流动应力和应变率敏感性的影响更大,超细晶铝的温度敏感性较粗晶粒度铝弱。根据试验结果,估计了不同温度和应变率下的表观激活体积。ECAP铝在准静态应变率下,与林位错相互作用是主导的热激活机制,而粘曳在高应变率下起着更重要的作用。

关键词:超细晶材料;等经通道挤压;铝;力学性能;应变率敏感性;温度依赖性;激活体积

(Edited by Yan-hong LI)

Foundation item: Projects (11272267, 11102168, 10932008) supported by the National Natural Science Foundation of China; Project (B07050) supported by Northwestern Polytechnical University

Corresponding author: Tao SUO; Tel: +86-29-88494859; Fax: +86-29-88491208; E-mail: suotao@nwpu.edu.cn

DOI: 10.1016/S1003-6326(14)63369-0