文章编号:1004-0609(2009)02-0303-05

喷射沉积70%Si-Al合金电子封装材料的组织与性能

李 超,彭超群,余 琨,王日初,杨 军,刘 溶

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用喷射沉积与热压相结合的方法制备电子封装用70%Si-Al合金坯料,采用扫描电镜和金相显微镜观察合金的显微组织。结果表明:采用喷射沉积与热压相结合的方法可获得直径为76.2 mm、厚度为6 mm的70%Si-Al合金样品;合金中初晶Si的长大受到抑制,初晶Si相的尺寸仅为20~50 μm,分布均匀且形成连续骨架;Al相围绕Si相间隙呈连续网络分布,这种结构有利于提高材料热导率,降低其线膨胀系数;通过与后续热压相结合制备的70%Si-Al合金样品,其室温热导率达到110 W/(m·K),400 ℃时线膨胀系数仅为9.6×10?6/K。

关键词:70%Si-Al合金;电子封装;热导率;喷射沉积

中图分类号:TB 331 文献标识码:A

Microstructure and properties of spray deposition 70%Si-Al alloy for electronic packaging applications

LI Chao, PENG Chao-qun, YU Kun, WANG Ri-chu, YANG Jun, LIU Rong

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: 70%Si-Al alloy was prepared by spray deposition and hot pressing technology. The microstructures of the alloy were investigated by scanning electron microscopy and metallographic microscopy. The results show that by spray deposition and hot pressing technology 70%Si-Al alloy with a diameter of 76.2 mm and a thickness of 6 mm can be obtained. The growth of primary silicon in 70%Si-Al alloy can be inhibited, and its grain size is only 20~50 μm. The distribution of primary silicon forms a continuous framework and the Al phase encircles the interval of Si phase continuously. The increase of thermal conductivity and decrease of the coefficient thermal expansion are mainly because of this structure. Its thermal conductivity reaches up to 110 W/(m?K) at room temperature and the coefficient of thermal expansion is just 9.6×10?6/K.

Key words: 70%Si-Al alloy; electronic packaging; thermal conductivity; spray deposition

高Si含量的Si-Al合金材料是一种新型电子材料,它具有与用作芯片的Si、GaAs等半导体材料接近的热膨胀系数、良好的导热性能、较高的强度、很低的密度(<2.5g/cm3),在电子封装材料领域具有广阔的应用前景[1?5]。

高Si含量Si-Al合金中Si的含量高达50%以上,通过调整Si含量可改善材料的综合性能,其中常用于电子封装领域的是70%Si-Al合金[6?7]。为了满足电子封装材料高热导率、低线膨胀系数的使用要求,针对Si-Al合金,要求得到第二相Si均匀分布、金属基体Al网络状包裹Si相这种理想的微观组织[8]。但是,在常规铸造条件下,随着Si含量的不断增加,初晶Si相变得很粗大,共晶相Si-Al也呈粗大针状,导致材料的物理、力学性能很差,如导热能力急剧下降等, 使材料无法作为封装材料使用。因此,采用先进材料制备技术,改善材料中Si相和Al相的形态、大小和分布,制备满足电子封装使用的性能优异的新型电子材料,近年来已成为国内外材料界的研究热点[6, 9]。其中,采用快速凝固技术制备高Si含量的Si-Al合金锭坯,可以获得组织和性能优异的电子封装材料。例如英国Osprey公司采用喷射沉积技术制备的一系列不同Si含量的Si-Al合金材料[10],具有目前报道的最佳物理性能和力学性能。本文作者采用喷射沉积技术,获得比常规熔炼铸造高4~5个数量级的快速凝固效果,通过与后续热压致密化工艺相结合,制备出直径为76.2 mm、厚度为6 mm的70%Si-Al合金样品,研究其组织和性能特征,为进一步研究和开发Si-Al合金封装材料提供实验数据和技术支撑。

1 实验

实验选用Si(纯度为99.5%)和Al(纯度为99.8%)为原料,采用感应加热熔炼,熔炼温度为1 500 ~1 700℃。熔化后的合金液通过环型喷嘴被高压气体(N2)雾化分散(雾化压力为0.5 MPa),沉积到运动的沉积盘上(沉积距离为400 mm),冷凝成d120 mm×300 mm圆锭。然后,从锭坯上切取直径为76.2 mm、厚度为6.5 mm的圆片进行热压,热压温度为570 ℃。

采用JR?3激光热导仪测定试样的室温导热系数,试样尺寸为d10 mm×(3~4) mm;采用TAS?100热分析仪测定25~400 ℃试样的线膨胀系数,升温速度为150 ℃/h,试样尺寸为d5 mm×20 mm;采用双桥法测量试样电阻率,试样尺寸为50 mm×10 mm×4 mm;采用阿基米德排水法测量材料的密度,由70%Si-Al合金理论密度2.43 g/cm3,根据公式ρ=ρr/ρt×100%换算材料的相对密度。其中,ρr为相对密度,ρt为理论密度。采用CCS—44100电子万能试验机测量材料的力学性能,试样尺寸为38 mm×6 mm×6 mm;采用POLYVAR—MET宽视野金相显微镜和KYKY?2800、JSM?5600Lv型扫描电镜观察材料的显微组织。

2 结果与讨论

2.1 冷却速度对70%Si-Al合金组织的影响

液滴飞行过程中的冷却速率ε与液滴尺寸r的关系如下[11]:

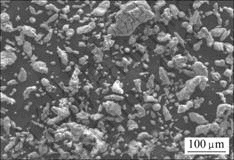

式中 aΣ为界面综合传热系数;c为质量比热容;Tp为液滴温度;Tc为环境温度。由式(1)可知,液滴在飞行过程中的冷却速率与液滴和环境的温度差及界面综合换热系数成正比,与合金的质量比热容及液滴尺寸成反比。因此,增加液滴与环境的温差或减小液滴尺寸是提高雾化冷却速率的主要途径。图1所示为喷射沉积70%Si-Al合金粉末的显微形貌,粉末颗粒尺寸范围主要集中在20~50 μm,根据式(1)可以判断冷却速率约为105 K/s。而普通熔炼铁模铸造并空冷材料的冷却速度约为1 K/s[12]。

图1 喷射沉积70%Si-Al合金粉末显微形貌

Fig.1 SEM micrograph of 70%Si-Al powder by spray deposition

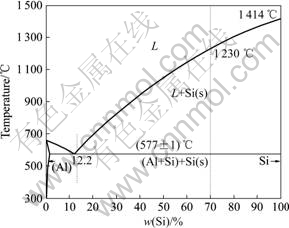

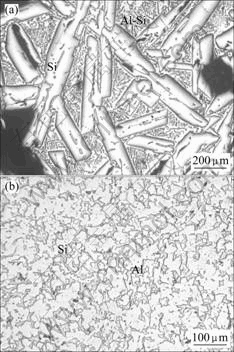

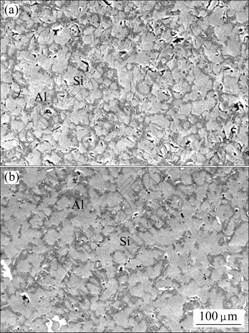

图2所示为Al-Si系的相图[13],可以看出,Al和Si的熔点相差很远,且共晶温度仅为577 ℃;当冷却速度低(铸造空冷)时,初晶Si相首先形核长大并粗化成板条状(见图3(a)),尺寸达几毫米。当冷却到共晶温度时,发生共晶反应,出现如图3(a)中Al-Si共晶与Si初晶并存的显微组织。又由于初晶Si相的粗化,使铸造态70%Si-Al合金中产生大量孔洞,材料致密度大大降低。

图2 Al-Si二元相图[13]

Fig.2 Equibrium phase diagram of Al-Si system[13]

当快速凝固喷射沉积时,初晶Si细小且分布弥散(见图3(b)),灰色Al相填充Si骨架,呈连续网络分布。产生这种现象的主要原因是:在喷射沉积过程中,Si-Al合金熔体被高压气体破碎成直径为20~50 μm的液滴,这些液滴在雾化气体的作用下快速冷却(冷却速度达105 K/s),当沉积到距离喷嘴一定距离的沉积坯表面(或基板)上时,会形成一薄层半固态的液膜,气流和基板的强制冷却作用使之迅速凝固[14],形成如图3(b)所示的细小初晶Si组织。另一方面,由于后续合金不断沉积,总可以使沉积表面保持这层半固态的液膜,使得凝固过程连续进行。由于整个过程冷却速度非常快,形成的初晶Si相的粗化长大被明显抑制[15],因此,Si相粒子细小且分布均匀,且材料中孔洞较少,致密度高。

图3 熔炼铸造和喷射沉积70%Si-Al合金显微组织

Fig.3 Optical micrographs of as-cast (a) and spray formed 70%Si-Al alloy (b)

利用快速凝固喷射成型技术,通过快速冷却抑制初晶Si的长大,获得Si相仅为20~50 μm的超细组织。这种快速凝固的初晶Si呈连续骨架形均匀分布,Al相围绕Si相间隙呈连续网络分布。这种三维网络结构有利于提高材料热导率,降低线膨胀系数[16],从而使70%Si-Al合金能够满足电子封装对高热导、低线膨胀系数的要求。采用快速凝固喷射成型技术通优化制备工艺能够制备出尺寸较大、组织均匀的锭坯,使得采用该方法制备的70%Si-Al合金材料的大规模应用成为可能。

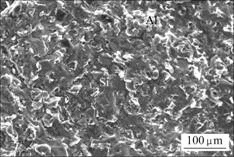

2.2 热压对喷射沉积70%Si-Al合金材料显微组织的影响

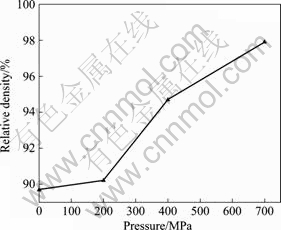

喷射沉积材料中存在一些细小的孔洞。这是由于影响喷射沉积锭坯质量的因素很多,包括熔体温度、雾化器结构、雾化气体类型、雾化气体压力、喷射距离、导流管孔径、基底材料、沉积距离、基底运动方向及方式等,任何一个环节出现问题都会对材料性能产生影响。对于电子封装用70%Si-Al合金,喷射沉积态致密度仅为90%左右,难以满足电子封装对其热导率和气密性的要求,必须经过后续加工提高其致密度。图4所示为570 ℃时热压致密度随压力的变化曲线,可以看出:随热压压力提高,材料致密度大幅度增加,在700 MPa时,材料致密度提高到98%左右。图5所示为喷射沉积及热压70%Si-Al合金的显微组织。由图可知,经700 MPa热压后材料中孔洞显著减少,且初晶Si相并未显著长大。在压力和温度的作用下,Al相流动填充材料中的细小孔洞,从而提高材料的致密度。

图4 致密度与热压压力的关系曲线

Fig.4 Relation between relative density and pressure

图5 喷射沉积及热压70%Si-Al的显微组织

Fig.5 Microstructures of spray formed and hot pressed 70%Si-Al alloy: (a)Spray formed; (b)Spray formed and hot pressed at 570 ℃ and 700 MPa

2.3 喷射沉积与热压结合法制备材料的性能

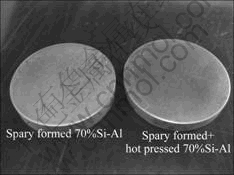

图6所示为喷射沉积热压后70%Si-Al合金断口形貌。由图6可知,材料的断裂是Si相的脆性断裂和Al相的韧性断裂,由于材料中Si质量分数达到70%,因此,材料的断裂以Si相的脆性断裂为主。经适当机械加工后,材料能够具有良好的外观形貌,结果如图7所示。

图6 喷射沉积热压后70%Si-Al合金断口组织照片

Fig.6 Fractograph of spray deformed and hot pressed 70%Si-Al alloy

图7 喷射沉积与喷射沉积热压后70%Si-Al合金宏观照片

Fig.7 Photo of spray formed and hot pressed 70%Si-Al alloy

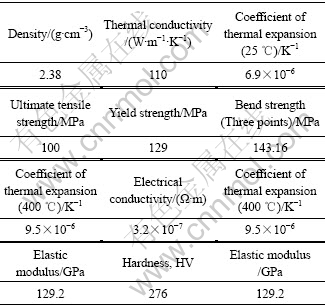

采用喷射沉积与热压结合法制备的70%Si-Al合金材料的主要性能如表1所示,可以看出此法制备的材料具有良好的物理和力学性能,特别是良好的导热性能,能够作为热沉材料满足电子封装的要求。

表1 70%Si-Al合金主要性能

Table 1 Main performance parameters of 70%Si-Al

3 结论

1) 采用快速凝固喷射成型技术,通过快速冷却抑制初晶Si的长大,获得Si相尺寸仅为20~50 μm的超细组织。这种快速凝固的初晶Si呈连续骨架形均匀分布,Al相围绕Si相间隙呈连续网络分布。这种结构有利于提高材料热导率和降低线膨胀系数。

2) 通过与后续热压相结合制备的70%Si-Al合金,室温热导率达到110 W/(m?K),400 ℃时线膨胀系数仅为9.6×10?6/K。

3) 采用喷射沉积与热压结合法制备出直径达76.2 mm、厚度为6 mm的70%Si-Al合金。

REFERENCES

[1] HARPER C A. Electronic materials and processes handbook[M]. New York: Mc Graw-Hill Companies, Inc, 2004: 404?412.

[2] 田 冲, 陈桂云, 杨 林, 赵九洲, 张永昌. 喷射沉积新型电子封装用70%Si-Al材料的研究[J]. 粉末冶金技术, 2005, 23(2): 108?111.

TIAN Chong, CHEN Gui-yun, YANG Lin, ZHAO Jiu-zhou, ZHANG Yong-chang. Study of novel 70%Si-Al alloy for electronic packaging prepared by the spray deposition technique [J]. Powder Metallurgy Technology, 2005, 23(2): 108?111.

[3] HOGG S C, LAMBOURNE A, OGILVY A, GRANT P S. Microstructural characterization of spray formed Si-30Al for thermal management applications[J]. Scripta Materialia, 2006, 55: 111?114.

[4] CHEN C W. Effects of Si size and volume faction on properties of Al/Sip composites[J]. Materials letters, 2002, 52: 334?341.

[5] LIN Jun-ping, ZHANG Yong, CHEN Guo-liang. Microstructures and properties of skeleton reinforced composite[J]. Material Engineering, 2006, 6: 20?21.

[6] 甘卫平, 陈招科, 杨伏良, 周兆锋. 高硅铝合金轻质电子封装材料研究现状及发展[J] . 材料导报, 2004, 18(6): 79?82.

GAN Wei-ping, CHEN Zhao-ke, YANG Fu-liang, ZHOU Zhao-feng. Research status and development of high silicon aluminium alloy for lightweight electronic package materials[J]. Materials Review, 2004, 18(6): 79?82.

[7] 杨伏良, 易丹青, 刘 泓, 陈智虎. 高硅铝合金材料高温充氧氧化工艺[J]. 中南大学学报: 自然科学版, 2007, 38(5): 820?824.

YANG Fu-liang, YI Dan-qing, LIU Hong, CHEN Zhi-hu. Oxidating processes in high temperature oxygenation of high-silicon aluminum alloy[J]. Journal of Central South University: Science and Technology, 2007, 38(5): 820?824.

[8] 张济山. 新型喷射成形轻质、高导热、低膨胀Si-Al电子封装材料[J]. 材料导报, 2002, 16(9): 1?4.

ZHANG Ji-shan. New spray formed light weighted Si-Al electronic packaging materials with low thermal expansion and high heat conducting[J]. Materials Review, 2002, 16(9): 1?4.

[9] 杨培勇, 郑子樵, 蔡 杨, 李世晨, 冯 曦. Si-Al电子封装材料粉末冶金制备工艺研究[J]. 稀有金属, 2004, 28(1): 160?165.

YANG Pei-yong, ZHENG Zi-qiao, CAI Yang, LI Shi-chen, FENG Xi. PM Process of Si-Al electronic packaging materials[J]. Chinese Journal of Rare Metals, 2004, 28(1): 160?165.

[10] JACOBSON D M, OGILVY A J W. Spray-deposited Al-Si alloys and their properties[J]. Mat.-wiss. u. Werkstofftech, 2003, 34: 381?384.

[11] 陈 光, 傅恒志. 非平衡凝固新型金属材料[M]. 北京: 科学出版社, 2004: 49?50.

CHEN Guang, FU Heng-zhi. Advanced materials fabricated by non-equilibrium solidification process[M]. Beijing: Science Press, 2004: 49?50.

[12] 唐仁政. 物理冶金基础[M]. 北京: 冶金工业出版社, 1997: 47?48.

TANG Ren-zheng. The basis of physical metallurgy[M]. Beijing: Metallurgical Industry Press, 1997: 47?48.

[13] 田荣璋. 铸造铝合金[M]. 长沙: 中南大学出版社, 2006: 40.

TIAN Rong-zhang. Aluminum casting alloy[M]. Changsha: Cenntral South University Press, 2006: 40.

[14] 彭超群. 喷射成形技术[M]. 长沙: 中南大学出版社, 2004: 101.

PENG Chao-qun. Spray forming technology[M]. Changsha: Central South University Press, 2004: 101.

[15] YU Kun, LI Chao, WANG Ri-chu, YANG Jun. Production and properties of a spray formed 70%Si-Al alloy for electronic packaging applications[J]. Materials Transactions JIM, 2008, 49(3): 685?687.

[16] WANG Xiao-feng, WU Gao-hui, WANG Ri-chu, YU Kun. Fabrication and properties of Si/Al interpenetrating phase composites for electronic packaging[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(2): 1039?1042.

基金项目:08国家大学生创新性实验计划支持项目(081053311)

收稿日期:2008-07-15;修订日期:2008-09-02

通讯作者:彭超群,教授,博士;电话:0731-8877197;E-mail: pcq2005@163.com

(编辑 龙怀中)