DOI: 10.11817/j.issn.1672-7207.2020.06.001

砷硫铁的脱除对高砷金精矿氰化浸金的影响

张霜华1,郑雅杰1,曹攀1,赖慎志2,张华军2

(1. 中南大学 冶金与环境学院,湖南 长沙,410083;

2. 西部黄金伊犁有限责任公司,新疆 伊犁,835100)

摘要:通过焙烧脱砷和硫,并采用硫酸浸出金焙砂脱铁,研究不同条件下砷、硫和铁的脱除对高砷金精矿氰化浸金的影响。研究结果表明:金精矿中,砷、硫和铁的质量分数分别为3.20%,27.35%和23.50%;在焙烧温度为500 ℃,焙烧时间为4 h和空气流量为0.2 m3/h条件下,砷和硫脱除率分别达到51.53%和79.16%;所得金焙砂经过质量分数为30%硫酸浸出,铁浸出率高达98.12%,酸浸渣中砷、硫和铁质量分数分别为0.10%,0.55%和0.44%;采用质量分数为6‰的氰化钠溶液浸出酸浸渣,金浸出率达98.05%;经过对砷、硫和铁进行脱除,金品位从32.98 g/t增加到68.22 g/t;金焙砂通过酸浸,单体金和裸露金总质量分数从93.87%增加到96.66%;低温焙烧和酸浸适合高砷金精矿氰化浸金。

关键词:金精矿;砷;硫;铁;脱除率;氰化浸金

中图分类号:TF831 文献标志码:A

文章编号:1672-7207(2020)06-1471-10

Effects of removal of arsenic, sulfur and iron on cyanide leaching of high-arsenic gold concentrate

ZHANG Shuanghua1, ZHENG Yajie1, CAO Pan1, LAI Shenzhi2, ZHANG Huajun2

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Western Golden Yili Co. Ltd., Yili 835100, China)

Abstract: Arsenic and sulfur were removed by roasting, and gold calcine was leached with sulfuric acid to remove iron.The effects of the removal of arsenic, sulfur and iron on gold cyanide leaching of high-arsenic gold concentrate were studied. The results show that mass fractions of arsenic, sulfur and iron in gold concentrate are 3.20%, 27.35% and 23.50%, respectively. Under the conditions of roasting temperature of 500 ℃, roasting time of 4 h and air velocity of 0.2 m3/h, the removal rates of arsenic and sulfur are 51.53% and 79.16%, respectively. After gold calcine is leached by 30% of sulfuric acid, the leaching rate of iron is 98.12%, and the mass fraction of arsenic, sulfur and iron in acid leaching residue are 0.10%, 0.55% and 0.44%, respectively. The acid leaching residue is leached with 6% of sodium cyanide solution, and the gold leaching rate reaches 98.05%. After removing arsenic, sulfur and iron, Au grade increases from 32.98 g/t to 68.22 g/t. The total mass fraction of monomer gold and bare gold increases from 93.87% to 96.66% after acid leaching of gold calcine. Roasting in low temperature and acid leaching are suitable for cyanide leaching of high-arsenic gold concentrate.

Key words: gold concentrate; arsenic; sulfur; iron; removal rate; gold cyanide leaching

随着金矿的大规模开采,采用氰化法易处理的金矿日益枯竭,而难处理金矿已成为黄金工业的主要矿产资源,据统计,目前全世界黄金总产量的1/3产自难处理金矿,而已探明的黄金储量中,有30%为难处理金矿[1-3]。为了从这类矿石中有效地提取金,必须先对矿石进行预处理,从而提高金的浸出率。常用焙烧氧化法、加压氧化法、生物氧化法和化学氧化法对难处理金矿进行预处理,其中焙烧氧化法应用最广泛[4-6]。预处理的实质就是打开难处理金矿中的包裹体使金粒裸露,使其与浸出剂接触从而被浸出[7] 。难处理金矿预处理的效果主要表现为[8-9]:打开硫化物包裹体,使金矿形成多孔状,这有利于氰化物溶液与金粒最大限度地接触;除去砷、硫、有机碳等妨碍氰化浸金的有害杂质并改变其理化性能;抑制或消除有害组分对氰化浸金过程的干扰。焙烧氧化法是最先应用于难处理金矿特别是含砷和含硫较高的金矿石处理的一种方法。目前,氧化焙烧主要采用一段焙烧和两段焙烧[5,10]。一段高温氧化法主要用于处理含碳金矿,焙烧温度为730 ℃左右,该方法脱碳彻底,硫氧化完全,但能耗高,易烧结;另外,高温易使某些成分熔化而使金被包裹以及形成致密铁氧化物颗粒,从而使金的回收率降低。二段焙烧氧化法中,第一段采用弱氧低温焙烧除砷,第二段采用氧化高温焙烧脱硫,该方法适用于处理高砷高硫金矿,但对操作参数及给料成分非常敏感,易造成过烧或欠烧,使得金氰化浸出率不高,且操作复杂,工艺流程长,对设备要求高。针对目前氧化焙烧法对难处理金矿预处理的不足,本文作者提出一段低温焙烧后硫酸浸出,在500 ℃下焙烧金精矿后经质量分数为30%硫酸浸出的方法。

1 实验

1.1 实验原料

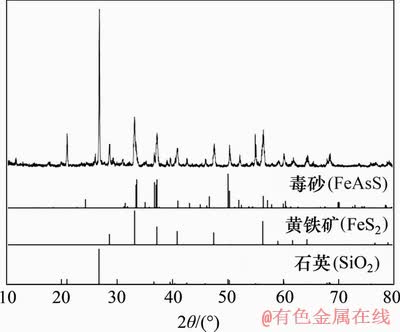

实验所用的金精矿为新疆伊犁某金矿提供的金精矿粉,粒度低于0.074 mm,呈致密的深灰色粉末状。金精矿主要矿物组成如表1所示,其中,金精矿中黄铁矿质量分数达80.34%,毒砂质量分数达5.16%,为典型的高砷难冶金矿。采用矿物解离分析仪(MLA)分析矿物组成以及金的赋存状态发现,这些硫化物常呈星散浸染状、稀疏浸染状或细脉浸染状分布于矿石中。金矿物主要为自然金,少量为银金矿,金矿物粒度较小,为常规镜下难以分辨的微粒金和超显微镜金,自然金和银金矿呈包体状赋存于黄铁矿、毒砂等硫化矿物和石英中,部分赋存于石英或硫化物的粒间、裂隙中,多呈微粒状。银矿物主要为自然银,其次为辉银矿。金精矿(水分质量分数小于1%)主要化学成分和XRD图分别如表2和图1所示。

表1 金精矿中主要矿物质量分数

Table 1 Mass fraction of major minerals in gold concentrate %

表2 金精矿主要化学成分(质量分数)

Table 2 Main chemical composition of gold concentrate

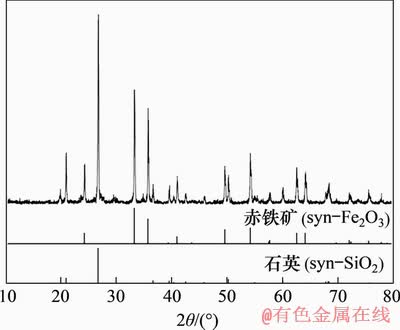

由表2可知:金精矿中金质量分数为32.98 g/t,银质量分数为56.86 g/t,硫和砷元素质量分数分别为27.35%和3.20%。由图1可知:砷主要以毒砂(FeAsS)形式存在,而硫主要以黄铁矿(FeS2)形式存在,其次为石英(SiO2)。

图1 金精矿的XRD图

Fig. 1 XRD pattern of gold concentrate

1.2 实验方法

1) 焙烧。每次称取一定质量的金精矿平铺在石英反应槽中,然后放置在管式炉中。使用空气压缩机向反应管中通入空气,在一定焙烧温度下焙烧得到金焙砂。

2) 硫酸浸出。将金焙砂放入质量分数为30%的硫酸中进行浸出,在液固比为3:1、温度为90 ℃条件下浸出4 h,过滤后洗涤,洗涤后在95 ℃环境中干燥得到酸浸渣。

3) 氰化浸金。将金焙砂或酸浸渣加入质量分数为6%的氰化钠溶液中,液固比为4:1,搅拌速率为300 r/min,pH为11.5,通入空气后在室温下浸出48 h,过滤得到氰化渣和含金贵液。

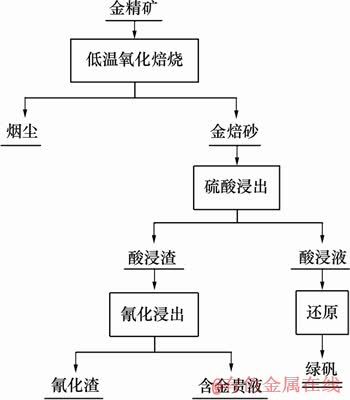

工艺流程如图2所示。

1.3 分析与检测

采用高频红外碳硫分析仪(HCS-140,DEKAI INSTRUMENTS)对金精矿原料、金焙砂和酸浸渣中的硫进行分析;采用电感耦合等离子体发射光谱仪(ICP-OES, iCAP 7000 Series, Thermo Scientific)测定溶液中砷质量分数;采用火试金法(GB/T 11066.1—1989)测定金精矿原料、金焙砂和酸浸渣中的金质量分数;采用X线衍射仪(XRD,D/max-TTR III,Rigaku)分析固体产物的物相组成;采用扫描电镜(SEM,JSM-IT300, JEOL)分析固体产物的形貌;采用矿物解离分析仪(MLA,FEI. Quanta 600. JKtech MLA suite)对矿物组成进行分析。

图2 金精矿低温焙烧与酸浸后氰化浸金工艺

Fig. 2 Process of low-temperature roasting of gold concentrate and gold cyanide leaching after acid leaching

2 结果与讨论

2.1 金精矿的焙烧

2.1.1 焙烧温度对砷和硫脱除率的影响

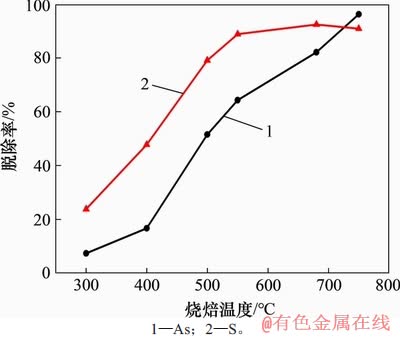

金精矿在焙烧时间为4 h和空气流量为0.2 m3/h条件下进行焙烧,焙烧温度对砷和硫脱除率的影响如图3所示。由图3可知:焙烧温度对砷和硫脱除率的影响较大;随焙烧温度升高,砷和硫的脱除率均逐渐增大;当焙烧温度从300 ℃上升到750 ℃时,砷脱除率从7.36%增加到96.28%,而硫脱除率从23.80%增加到90.94%。

印万忠等[11]研究了黄铁矿和毒砂等硫化矿物的热分解和相转变特点,认为焙烧可有效破坏金的包裹状态。在空气气氛下对黄铁矿进行TG-DTA测试,当温度升至550 ℃以上时,有质量分数为90%的Fe2S转化为Fe2O3,而在氧气气氛下,当温度在500 ℃以上时,黄铁矿全部被氧化[12] 。对于金精矿氧化焙烧,含砷难处理金精矿中的FeS2,FeS和FeAsS发生的主要反应如下[12-14]:

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

结合图3可知,砷脱除率随焙烧温度升高而增大,其原因是金精矿中砷与氧气结合形成易挥发的三氧化二砷,而温度升高有利于三氧化二砷挥发进入烟尘。硫的脱除主要是由于金精矿中的硫化物中硫以SO2形式进入烟气中,硫脱除率最后保持在90%左右是因为温度过高使物料烧结,形成硫酸盐,从而减少了硫进一步脱除。

图3 焙烧温度对金精矿中砷和硫的脱除率的影响

Fig. 3 Effect of roasting temperatures on removal rate of arsenic and sulfur in gold concentrate

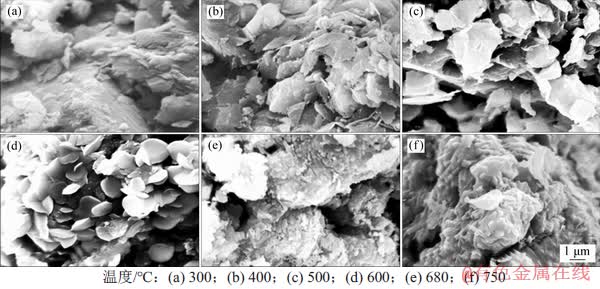

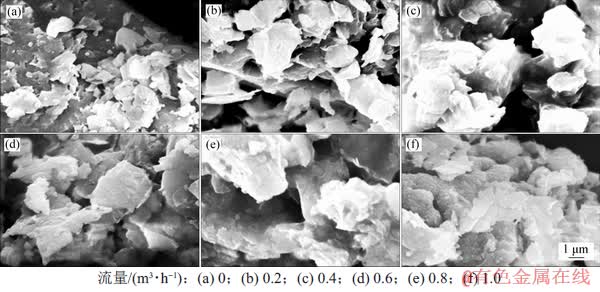

图4所示为金精矿在不同温度下焙烧所得金焙砂的SEM图。由图4可知:金精矿随着焙烧温度升高,矿物形貌发生显著变化;当焙烧温度为300 ℃时,金焙砂呈大块状,表面无空隙,而当温度升至400 ℃时,金焙砂表面开始疏松,有空隙产生;当焙烧温度达到500 ℃时,金焙砂呈无规则片状;当焙烧温度继续升高至600 ℃时,金焙砂呈粒径相对均一的片状;当焙砂温度不小于680 ℃时,金焙砂转化为孔隙度小、疏松性变差的大块状颗粒,且团聚严重,这与图3所示硫脱除结果相一致,说明温度过高使物料烧结。

在300~750 ℃时,金精矿中FeAsS中砷以三氧化二砷形式进入烟尘。焙烧过程中产生的SO2经回收用于系统制酸,而硫化物中的铁转化为赤铁矿,使得金精矿中大部分包裹金解离。结合图3、图4和焙烧过程能耗,金精矿氧化焙烧适宜温度为500 ℃。

图4 不同焙烧温度下所得金焙砂的SEM图

Fig. 4 SEM images of gold calcine obtained at different roasting temperatures

2.1.2 焙烧时间对砷和硫脱除率的影响

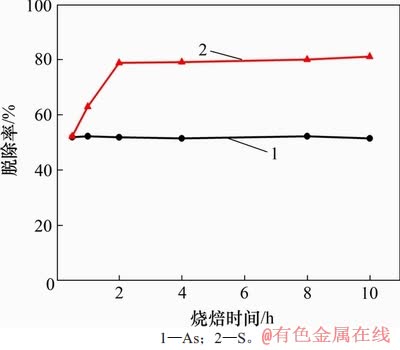

在焙烧温度为500 ℃和空气通气量为0.2 m3/h条件下进行焙烧,焙烧时间对砷和硫脱除率的影响如图5所示。由图5可知:砷脱除率随焙烧时间的延长变化不大,砷脱除率约为52%;当焙烧时间从0.5 h增加到2.0 h时,硫脱除率从52.26%增加到78.84%;继续延长焙烧时间,硫脱除率变化不大。由此可见:砷脱除率受焙烧时间的影响不大,而延长焙烧时间在一定程度上有利于硫的脱除。

图5 焙烧时间对金精矿中砷和硫的脱除率的影响

Fig. 5 Effect of roasting time on removal rate of arsenic and sulfur in gold concentrate

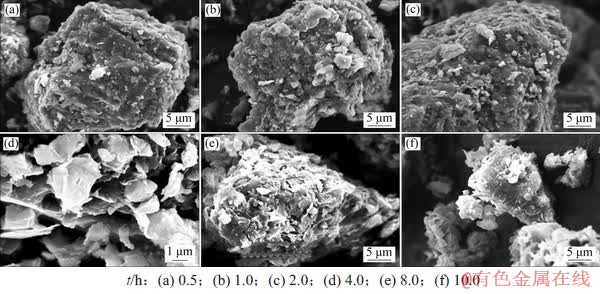

图6所示为不同焙烧时间下所得金焙砂的SEM图。从图6可见:当焙烧时间为0.5~2.0 h时,金焙砂颗粒粒径较大,颗粒表面紧实,无空隙,不疏松,存在细小颗粒附着;当焙烧时间为4.0 h时,金焙砂颗粒呈片状,颗粒之间存在明显的孔结构,这有利于后续金的浸出;而当焙烧时间大于4.0 h时,颗粒片状不明显,存在团聚现象。结合图5和6可知,适宜焙烧时间为4.0 h。

图6 不同焙烧时间下所得金焙砂的SEM图

Fig. 6 SEM images of gold calcine obtained at different roasting time

2.1.3 空气流量对砷和硫脱除率的影响

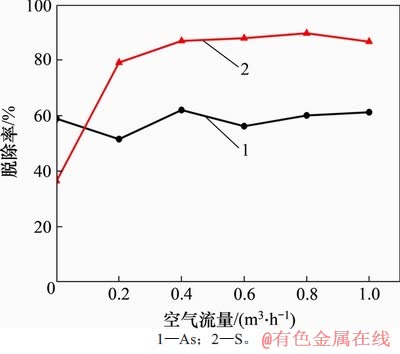

金精矿在焙烧温度为500 ℃和反应时间为4.0 h条件下进行焙烧,空气流量对砷和硫脱除率的影响如图7所示。在不同空气流量下焙烧时,金精矿焙砂形貌如图8所示。由图7可知:砷脱除率随空气流量的增加变化不大,在51%~62%之间;而硫脱除率随空气流量的增大而增大,当空气流量从0 m3/h增加到0.2 m3/h时,硫脱除率从36.46%增加到79.16%;继续增大空气流量,硫脱除率增加幅度变小。可见,增大空气流量有利于硫的脱除。

图7 空气流量对金精矿中砷和硫脱除率的影响

Fig. 7 Effect of air velocity on removal rate of arsenic and sulfur in gold concentrate

由图8可知:不通空气时,所得金焙砂含少量片状黏附在大块固体颗粒上面,且孔隙度小;当空气流量为0.2 m3/h时,金焙砂颗粒呈片状,而当空气流量大于0.2 m3/h时,所得金焙砂呈大块颗粒状,团聚严重。因此,选择适宜的空气流量为0.2 m3/h。

图8 不同空气流量下金焙砂SEM图

Fig. 8 SEM images of gold calcine obtained at different air velocities

当金精矿在焙烧温度为500 ℃,焙烧时间为4.0 h和空气流量为0.2 m3/h条件下焙烧时,砷脱除率为51.53%,硫脱除率为79.16%,所得金焙砂颗粒呈疏松片状,这有利于酸浸和氰化浸金。图9所示为金焙砂的XRD图,可识别的主要物相为Fe2O3和SiO2。结合图1所示的金精矿XRD图可知,经氧化焙烧,金精矿中黄铁矿和毒砂转变为赤铁矿。

图9 金精矿焙烧所得金焙砂的XRD图

Fig. 9 XRD pattern of gold calcine obtained by gold concentrate roasting

2.2 金精矿焙烧对金焙砂酸浸的影响

金焙砂中部分金被包裹于含铁物相(尤其是铁氧化物)中,铁包裹会降低金焙砂的金浸出率。为改善提金效果,预处理的关键在于防止包裹结构形成[4] ,因此,破坏金焙砂的铁包裹结构是较直接的途径。研究表明,采用硫酸除铁可进一步解离金,降低渣量;另外,浸出液中铁可用于制备铁氧化物、铁盐、铁精矿和聚合硫酸铁净水剂[15-18]。

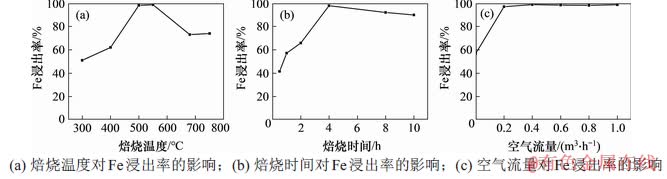

将金精矿在不同条件下焙烧所得金焙砂用质量分数为30%的硫酸进行浸出,其结果如图10所示。

由图10(a)可知:金焙砂中铁浸出率随金精矿焙烧温度的升高先逐渐增大,后又减少,最后趋于稳定;当焙烧温度从300 ℃上升到500 ℃时,铁浸出率从51.01%增加到98.12%;当焙烧温度大于等于550 ℃时,铁浸出率随焙烧温度的增加而下降。这是由于焙烧温度过高使物料烧结,从而减少了铁的浸出。由此可知,金精矿氧化焙烧在一定程度上有利于铁的浸出,适宜的焙烧温度为500 ℃。

由图10(b)可知:金焙砂中铁浸出率随金精矿焙烧时间的延长先逐渐增大;当焙烧时间从0.5 h增加到4.0 h时,铁浸出率从41.43%增加到98.12%;继续延长焙烧时间,铁浸出率稍减少;金精矿在焙烧过程中砷和硫的脱除有利于铁的浸出,当焙烧时间大于4.0 h时,铁浸出率稍下降,这是因为焙砂由片状转变为大块状,这不利于铁的浸出。

由图10(c)可知:不通入空气时,铁浸出率为57.40%;当空气流量增大到0.2 m3/h时,铁浸出率增加到98.12%;继续增大空气流量,铁浸出率变化不大。在金精矿焙烧过程中通入空气,在一定程度上可增大金精矿中砷和硫的脱除,促进黄铁矿和毒砂中铁转化为Fe2O3,这有利于铁的浸出。

图10 金精矿焙烧过程中焙烧温度、焙烧时间和空气流量对金焙砂酸浸的影响

Fig. 10 Effect of roasting temperature, roasting time and air velocity during roasting process of gold concentrate on acid leaching of gold calcine

金精矿在焙烧温度为500 ℃,焙烧时间为4.0 h和空气流量为0.2 m3/h条件下焙烧得到的金焙砂进行酸浸,铁浸出率为98.12%。金焙砂为疏松的片状体,且含铁矿物主要为赤铁矿,这有利于硫酸浸出铁。金焙砂酸浸涉及的主要反应为[19]

(6)

(6)

2.3 焙烧和酸浸对氰化浸金的影响

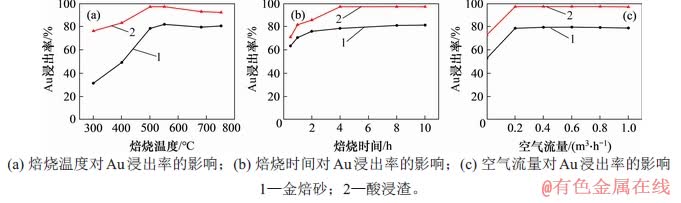

氰化法是当今普遍采用的提金方法[2] ,本实验采用氰化钠溶液分别对金焙砂和酸浸渣中的金进行浸出。不同焙烧条件下所得焙砂以及其焙烧酸浸后氰化浸金结果分别如图11所示。

图11 金精矿焙烧过程中焙烧温度、焙烧时间和空气流量对金焙砂和酸浸渣浸金的影响

Fig. 11 Effect of roasting temperature, roasting time and air velocity during roasting process of gold concentrate on gold leaching of gold calcine and acid leaching residue

由图11(a)可知:在空气流量为0.2 m3/h,焙烧时间为4 h,焙烧温度从300 ℃增加到500 ℃时,焙砂的金浸出率从31.68%加到79.26%,而相应酸浸渣的金浸出率从77.04%增加到98.05%;继续增大焙烧温度,金焙砂金浸出率变化不大,为81%左右,而酸浸渣金浸出率降至93.12%。可见,金焙砂进行酸浸有利于金的浸出。

由图11(b)可知:对焙砂和酸浸渣氰化浸金,当空气流量为0.2 m3/h,焙烧温度为500 ℃,焙烧时间从0.5 h增加到10.0 h时,焙砂金浸出率从64.01%增加到82.12%,而酸浸渣金浸出率从71.66%增加到98.10%。由此可知:焙烧时间的延长在一定程度上有利于金的浸出,而酸浸可进一步促进金的浸出。

由图11(c)可知:对焙砂和酸浸渣氰化浸金,当焙烧温度为500 ℃,焙烧时间为4 h,空气流量从0 m3/h增加到0.2 m3/h时,焙砂金浸出率从53.26%增加到79.26%,而酸浸渣金浸出率从73.55%增加到98.05%;继续增大空气流量,焙砂与酸浸渣金浸出率基本保持不变。

从图11可以看出:酸浸渣的金浸出率高于金焙砂的金浸出率。这是由于酸浸可将铁从矿石中解离,打开矿石铁氧化物的包裹,从而有利于金的浸出。

金精矿在温度为500 ℃,空气流量为0.2 m3/h条件下焙烧4.0 h得金焙砂,再经质量分数为30%的硫酸浸出得酸浸渣,其金焙砂和酸浸渣的主要化学成分(质量分数)如表3所示。对比表3与表2所示结果可知:金精矿经过焙烧和酸浸,Au和Ag得到有效富集,酸浸渣中Au和Ag的品位(质量分数)分别从32.98 g/t和56.86 g/t增大到68.22 g/t和92.71 g/t。这是由于金精矿中As,S和Fe得到有效脱除。然而,金焙砂通过酸浸,脉石组分SiO2质量分数从33.30%提高到84.27%。金精矿通过氧化焙烧和酸浸,实现了As,S和Fe的高效脱除,金得到有效富集,也有利于金的氰化浸出。

金焙砂为红褐色粉砂状固体颗粒,而酸浸渣为显淡粉红色粉末状颗粒,经仪器MLA对金焙砂和酸浸渣的矿物质量分数进行分析,结果如表4所示。从表4可见:金焙砂中金属矿物主要是赤铁矿(质量分数为52.41%),脉石矿物主要为石英(质量分数为26.29%),而酸浸渣中金属矿物矿物质量分数很低,主要以脉石矿物石英(质量分数为78.33%)为主。与表1中金精矿中矿物质量分数相比较可知:金精矿经过焙烧,绝大部分黄铁矿和毒砂转变为赤铁矿;经酸浸后,铁矿物质量分数显著降低,其他金属矿物质量分数也有所下降,而脉石矿物石英质量分数显著上升;金焙砂通过酸浸,金属矿物质量分数降低,渣量减少,这使得氰化试剂消耗量和固废质量分数减少,因而对环境的危害减小。

表3 金焙砂和酸浸渣的主要化学成分(质量分数)

Table 3 Main chemical composition of gold calcine and acid leaching residue

表4 金焙砂和酸浸渣的主要矿物的质量分数

Table 4 Mass fraction of major minerals in gold calcine and acid leaching residue %

经MLA测定,金焙砂中金矿物以自然金为主,其次为银金矿,其金矿物的平均成色为902.7‰;而酸浸渣中金矿物均为自然金,平均成色为951.2‰。酸浸渣中金的品位和金矿物的平均成色的提高有利于金的氰化浸出。金矿物的产出形式是指金矿物与载体矿物空间上的镶嵌关系,本研究对金焙砂和酸浸渣进行了砂光片和MLA检测,其金矿物的产出形式如表5所示。

由表5可知:金焙砂中金矿物的产出形式为单体金、裸露金、裂隙金和包裹金共4种类型,这些金矿物主要以铁矿物作为载金体,其中单体金、裸露金和裂隙金质量分数合计为89.25%,而包裹金占10.75%(质量分数,下同),其中赤铁矿包裹金8.45%,石英包裹金2.30%;酸浸渣中仅存在单体金、裸露金和包裹金,其金矿物主要呈单体产出;酸浸渣金矿物中单体金占92.47%,不存在赤铁矿包裹金;石英和云母包裹金仅占4.80%,经过酸浸,总的包裹金质量分数从10.75%下降到4.80%,说明酸浸后赤铁矿包裹金得到了有效解离。因此,酸浸有利于提高金浸出率。

表5 金焙砂和酸浸渣中金矿物的产出形式

Table 5 Output forms of gold minerals in gold calcine and acid leaching residue

采用碘浸取法对金焙砂(样品粒度低于0.074的质量分数为65%)和酸浸渣(样品粒度低于0.074的质量分数为70%)进行金矿物的解离分析,结果表明:金焙砂和酸浸渣中单体金以及裸露金所占总质量分数分别为93.87%和96.66%;酸浸渣中单体金以及裸露金质量分数较高,主要是由于酸浸使包裹在铁矿物中的金矿物解离。

3 结论

1) 金精矿焙烧适宜工艺条件如下:焙烧温度为500 ℃,焙烧时间为4 h,空气流量为0.2 m3/h。在该条件下,砷脱除率为51.53%,硫脱除率为79.16%;所得金焙砂为疏松的片状体,且焙烧过程中金精矿中黄铁矿转化为赤铁矿。

2) 采用质量分数为30%的硫酸对金焙砂浸出,铁浸出率可达98.12%。金焙砂酸浸后更有利于金的氰化浸出,金的浸出率从79.26%增加到98.05%。

3) 金精矿经过焙烧得焙砂以及焙砂酸浸后得酸浸渣,Au品位从32.98 g/t增加到68.22 g/t;金焙砂经酸浸后,金矿物的平均成色从902.7‰增加到951.2‰,包裹金质量分数从10.75%降低到4.80%,其中赤铁矿包裹金质量分数从8.45%降到0。

参考文献:

[1] 李俊萌. 难处理金矿石预处理工艺现状与发展[J]. 湿法冶金, 2003, 22(1): 1-8.

LI Junmeng. The current status and dvelopment tendency of pretreatment process for refractory gold ores[J]. Hydrometallurgy of China, 2003, 22(1): 1-8.

[2] 朱海玲, 邓海波. 含硫低品位金精矿浸出渣综合利用工艺研究[J]. 矿冶工程, 2015, 35(3): 51-54.

ZHU Hailing, DENG Haibo. Comprehensive utilization of sulphureous low-grade gold-leaching residue[J]. Mining and Metallurgical Engineering, 2015, 35(3): 51-54.

[3] ZHANG Shuanghua, ZHENG Yajie, CAO Pan,et al. Process mineralogy characteristics of acid leaching residue produced in low-temperature roasting-acid leaching pretreatment process of refractory gold concentrates[J]. International Journal of Minerals,Metallurgy and Materials, 2018, 25(10): 1132-1139.

[4] ESPITIA S L M, LAPIDUS G T. Pretreatment of a refractory arsenopyritic gold ore using hydroxyl ion[J]. Hydrometallurgy, 2015, 153: 106-113.

[5] 田庆华, 王浩, 辛云涛, 等. 难处理金矿预处理方法研究现状[J]. 有色金属科学与工程, 2017, 8(2): 83-89.

TIAN Qinghua, WANG Hao, XIN Yuntao, et al.Research status of pretreatment of refractory gold ore[J]. Nonferrous Metals Science and Engineering, 2017, 8(2): 83-89.

[6] ZHANG Duchao, XIAO Qingkai, LIU Weifeng, et al.Acid leaching decarbonization and following pressure oxidation of carbonic refractory gold ore[J]. Journal of Central South University, 2016, 23(7): 1584-1590.

[7] TAN H, FENG D, LUKEY G C, et al. The behaviour of carbonaceous matter in cyanide leaching of gold[J]. Hydrometallurgy, 2005, 78(3/4): 226-235.

[8] 马方通, 高利坤, 董方, 等. 难处理金矿预处理及强化氰化技术研究现状及进展[J]. 黄金, 2016, 37(4): 51-55.

MA Fangtong, GAO Likun, DONG Fang, et al. Pretreatment of refractory gold ores and current research status and progress of intensified cyanidation process[J]. Gold, 2016, 37(4): 51-55.

[9] 邓文, 伍荣霞, 刘志成, 等. 焙烧预氧化-硫代硫酸盐浸出某难处理金精矿[J]. 矿冶工程, 2017, 37(3): 114-117.

DENG Wen, WU Rongxia, LIU Zhicheng, et al. Treatment of refractory gold concentrate by oxidation roasting-thiosulfate leaching[J]. Mining and Metallurgical Engineering, 2017, 37(3): 114-117.

[10] LIU Xiaoliang, LI Qian, ZHANG Yan, et al. Simultaneous removal of S and as from a refractory gold ore in a single stage O2-enriched roasting process[J]. Metallurgical and Materials Transactions B, 2019, 50(4): 1588-1596.

[11] 印万忠, 洪正秀, 马英强, 等. 国内外含砷硫金矿预处理技术的研究进展[J]. 现代矿业, 2011, 27(2): 1-8.

YIN Wanzhong, HONG Zhengxiu, MA Yingqiang, et al. Research progress of pretreatment technology for As, S-bearing gold ore concentrate at home and abroad[J]. Modern Mining, 2011, 27(2): 1-8.

[12] DUNN J G.The oxidation of sulphide minerals[J]. Thermochimica Acta, 1997, 300(1/2): 127-139.

[13] 殷书岩, 赵鹏飞, 李少龙, 等. 难处理金矿预处理技术的选择[J]. 中国有色冶金, 2018, 47(2): 30-34.

YIN Shuyan, ZHAO Pengfei, LI Shaolong, et al. Selection of pretreatment technology of refractory gold ore[J]. China Nonferrous Metallurgy, 2018, 47(2): 30-34.

[14] HU Nan, CHEN Wei, DING Dexin, et al. Role of water contents on microwave roasting of gold bearing high arsenic sulphide concentrate[J]. International Journal of Mineral Processing, 2017, 161: 72-77.

[15] CHEN Zhenguo, WANG Xiaojun, GE Qilong, et al. Iron oxide red wastewater treatment and recycling of iron-containing sludge[J]. Journal of Cleaner Production, 2015, 87: 558-566.

[16] YANG Yang, WANG Xuewen, WANG Mingyu, et al. Recovery of iron from red mud by selective leach with oxalic acid[J]. Hydrometallurgy, 2015, 157: 239-245.

[17] 王威, 柳林, 冯安生, 等. 直接还原焙烧-弱磁选回收河南某金冶炼渣中铁[J]. 金属矿山, 2015(12): 169-172.

WANG Wei, LIU Lin, FENG Ansheng, et al. Recovery of iron from gold smelting slag from Henan by direct reduction roasting-low intensity magnetic separation process[J]. Metal Mine, 2015(12): 169-172.

[18] WU Zhichao, FANG De, CHENG Qiao, et al. Preparation and performance characterization of solid polyferric sulfate(SPFS) water purifier from sintering dust[J]. Materials Research Express, 2019, 6(7): 075503.

[19] 占寿祥, 郑雅杰. 硫铁矿烧渣酸浸反应动力学研究[J]. 化学工程, 2006, 34(11): 36-39.

ZHAN Shouxiang, ZHENG Yajie. Study on leaching kinetics of pyrite cinder[J]. Chemical Engineering, 2006, 34(11): 36-39.

(编辑 陈灿华)

收稿日期: 2019 -12 -24; 修回日期: 2020 -03 -12

基金项目(Foundation item):新疆高新技术研究发展计划项目(201515108);新疆维吾尔族自治区战略性新兴产业专项资金资助项目(201552) (Project(201515108) supported by Program of Xinjiang High Technology Research and Development; Project(201552) supported by the Fund of Xinjiang Uygur Autonomous Region's Strategic Emerging Industries)

通信作者:郑雅杰,博士,教授,从事有色金属冶金和污染控制等研究;E-mail: zyj@csu.edu.cn