文章编号:1004-0609(2008)06-1005-07

多向锻造ME20M镁合金的组织演化与力学性能

简炜炜,康志新,李元元

(华南理工大学 机械工程学院,金属材料成形及装备教育部工程研究中心,广州 510640)

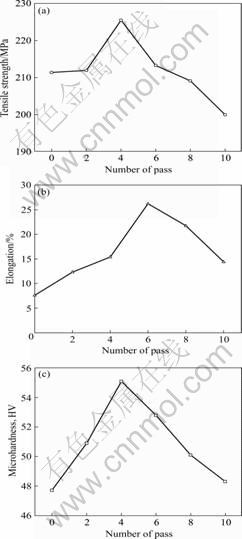

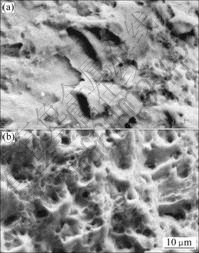

摘 要:通过金相组织观察、显微硬度测试、扫描电镜分析和应变速率为5×10-5 /s的室温拉伸力学性能实验,分别探讨多向锻造中ME20M镁合金的显微组织演化机制和力学性能变化规律。结果表明:显微组织演化分为3个不同阶段,分别对应3种不同机制:第一阶段在真应变量ε≤0.60时,为机械式击碎细化机制,晶粒尺寸由45 μm细化到12 μm;第二阶段在真应变量0.60<ε≤0.80时,为形变诱导动态再结晶细化机制,晶粒进一步细化至2.1 μm;第三阶段在真应变量ε≥1.50时,为热激活晶粒长大机制,部分晶粒长大至65 μm。经多向锻造加工,镁合金室温力学性能显著提高,其伸长率、抗拉强度和显微硬度的最大值分别为26.25%、225.52 MPa、HV 55.1,比初始状态分别提高了245%、6.7%和15.5%。拉伸断口SEM观察发现,第6道次前断口韧窝尺寸明显减小且其数量随应变量的增加而增多,使材料延性改善;第6道次后韧窝尺寸变大,其塑性降低。

关键词:镁合金;多向锻造;显微组织演化;力学性能;显微硬度

中图分类号:TG 316 文献标识码:A

Microstructural evolution and mechanical property of ME20M magnesium alloy processed by multidirectional forging

JIAN Wei-wei, KANG Zhi-xin, LI Yuan-yuan

(Engineering Research Center of Metallic Materials Processing and Equipment, Ministry of Education, School of Mechanical Engineering, South China University of Technology, Guangzhou 510640, China)

Abstract: Microstructural evolution and mechanical property of ME20M magnesium alloy processed by multidirectional forging (MF) were analyzed through OM, microhardness, SEM and mechanical tensile test at room temperature with the strain rate of 5×10-5 /s. The experimental results show that the microstructural evolution is divided into three stages according to different evolution mechanisms: the mechanical splitting mechanism with the grain size fined from 45 μm to 12 μm; the deformation- induced dynamic recrystallization mechanism with the average grain size of 2.1 μm and thermal activated grain growth mechanism with maximum grain size reached to 65 μm, when the true strains are ε≤0.60, 0.60<ε≤0.80 and ε≥1.50, respectively. After MF, mechanical property of ME20M magnesium alloy is greatly improved. The maximum value of elongation, tensile strength and microhardness are 26.25%, 225.52 MPa and HV 55.1, which are 245%, 6.7% and 15.5% more than those of as-received Mg alloy, respectively. The density and size of ductile dimples on tensile fractured surface of the MF magnesium alloy increase with increasing strain before the sixth pass, which demonstrates that the ductility is improved, and then the ductile dimples enlarged result in the decreasing of plasticity.

Key words: magnesium alloy; multidirectional forging; microstructural evolution; mechanical property; microhardness

镁是最轻的金属材料之一,其合金作为结构材料具有解决能源危机和环境问题的巨大潜力[1-3]。然而,镁合金与其它常用结构材料如铝合金、钢铁相比,其力学性能相对较低,同时镁合金晶格为密排六方晶格,滑移系较少,塑性较低,很难通过常规加工方法制备较大的结构部件[4-5],这些都极大地限制了镁合金的应用。

近年来,通过剧塑性变形(severe plastic deformation, SPD)制备微米或纳米级块体材料已经引起了人们的广泛兴趣。目前已成功开发的SPD技术包括等通道角挤压(equal-channel angular pressing, ECAP)[6-9]、高压扭转变形(high-pressure torsion, HPT)[10-11]、累积叠焊(accumulative roll-bonding, ARB)[12-13]、多向锻造(multiple forging, MF)[14-15]等。剧塑性变形所获得的超微晶组织具有大角度晶界并且在试样的整个体积中所形成的纳米组织是均匀一致的,因而所制备的材料性能极其稳定[6]。HAN等[16]对Mg-0.55%Zr合金进行6道次的等通道角挤压后发现,该合金在温度为773 K、应变率为4.2×10-5 /s的拉伸实验中表现出超塑性,其最大伸长率高达380%。LUGO等[17]将等通道角挤压和高压扭转变形接合起来,制备出了微观组织极均匀的高纯铜,并且极大地提高了其力学性能。KRALLICS[12]等对含碳量为 0.002%的超低碳钢进行多道次的累积叠焊,该钢屈服强度和抗拉强度提高了200%~300%。

多向锻造技术是一种在大块试样中形成纳米组织的方法。它最先是由SALISHCHEV及其同事们提出的[18]。多向锻造实质为多次自由锻造:墩粗、拔长,变形力的轴方向总是变化。该工艺可允许在脆性材料中获得纳米组织,因为加工是在较高的温度下开始的,并且只需在用具上施加不大的比载荷。目前多向锻造剧烈塑性变形法已用来对一系列金属进行组织细化,如TiAl 合金[19]、不锈钢[20]、铝合金[21]等。然而,与等通道挤压变形和高压扭转变形的研究比起来,关于镁合金的多向锻造剧烈塑性变形技术的研究还非常少。针对这一现状,本文作者采用多向锻造工艺制备了不同晶粒尺寸的ME20M镁合金锻坯,并研究了该合金组织演化机制和力学性能变化规律。

1 实验

1.1 实验材料

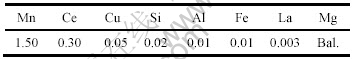

实验用镁合金为退火态ME20M镁合金轧制板材,板厚为22 mm, 其化学成分如表1所列。

表1 MEZOM镁合金的化学成分

Table 1 Chemical composition of ME20M alloy (mass fraction, %)

1.2 多向锻造工艺过程

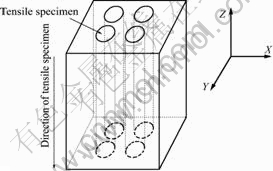

初始锻坯长为60 mm,横截面尺寸为22 mm×22 mm。初始锻坯长轴平行于原始板材轧制方向。多向锻造试验过程如图1所示,空气锤锤头先沿Z轴方向锻造A面,锻坯高度由h1减小为h2,此为第一锻造工步。旋转锻坯,沿Z轴方向锻造B面,此为第二锻造工步。继续旋转锻坯并沿Z轴方向锻造C面,此为第三锻造工步。上述3个工步的锻造称为一个道次锻造。重复以上锻造实验1至10道次,制备不同晶粒尺寸大小的锻坯。空气锤空载落锤速度为50 mm/s。每一锻造工步前锻坯均置于电阻炉(炉温为(400±2) ℃)内保温10 min,随后迅速取出试样并在20 s内完成锻造以确保终锻温度不低于380 ℃。锻造结束后,试样立即淬水冷却以消除余热对高温变形组织的影响。为保证实验数据的可靠性和可重复性,每道次锻造试样数量均为3个。在锻造过程中,试样若有开裂即重新更换新试样进行锻造实验。试验中锻造应变量采用真应变 =ln(h1/h2)计算,其中h1和h2分别表示试样锻前和锻后的高度。每一道次真应变为该道次中3个工步的真应变的代数和。

=ln(h1/h2)计算,其中h1和h2分别表示试样锻前和锻后的高度。每一道次真应变为该道次中3个工步的真应变的代数和。

图1 多向锻造工艺过程示意图

Fig.1 Schematic diagram of MF process

1.3 显微组织观察及力学性能测定

锻造实验结束后,在各试样中心部位沿垂直于初始长轴方向取样进行显微组织观察。金相试样在机械抛光后用苦味酸酒精混合溶液进行腐蚀。晶粒尺寸大小采用直线截点法(GB/T 6394—2002)测量,为保证数据的准确性,被测量晶粒数为80至100个。棒状拉伸试样长度为51 mm、直径为4 mm,取样部位如图2所示。室温拉伸实验应变速率为5×10-5/s。各道次拉伸实验均重复8次,实验数据取其平均值。拉伸实验结束后,用LEO1530VP扫描电子显微镜观察拉伸试样断口形貌。维氏硬度测试压力为0.49 N,选取锻坯中间部位垂直于锻造轴的平面作为测试部位,选取15个均分点作为测量点,如图3所示,取平均值作为实验数据。

图2 拉伸试样取样位置及方向示意图

Fig.2 Sampling position and direction for tensile test specimens

图3 显微硬度测试取样点

Fig.3 Selected points for Vickers hardness test

2 结果与分析

2.1 显微组织特征及演化机制

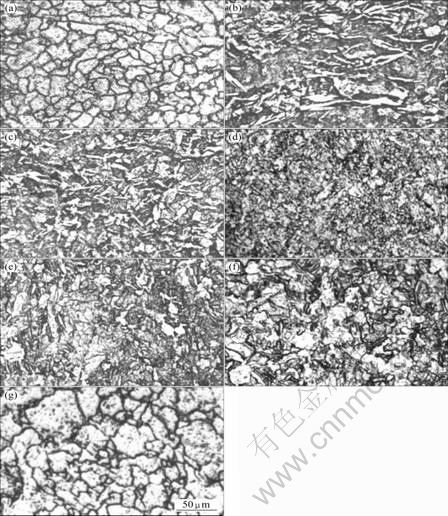

实验镁合金多向锻造前后的光学显微组织如图4所示。由图4(a)可见,合金初始显微组织为粗大晶粒和相对细小晶粒所构成的混合组织,平均晶粒尺寸大小约为45 μm,其中条状晶粒长度约为125 μm。该组织整体上呈流线状,晶粒分布极不均匀。经1道次锻造变形后,即真应变 ≈0.30时,粗大晶粒均被击碎,如图4(b)所示,此时平均晶粒尺寸为24 μm。随着变形量的增加,显微组织进一步细化,在第2道次时,即真应变量

≈0.30时,粗大晶粒均被击碎,如图4(b)所示,此时平均晶粒尺寸为24 μm。随着变形量的增加,显微组织进一步细化,在第2道次时,即真应变量 ≈0.60,平均晶粒尺寸约为12 μm,长条状晶粒尺寸减小,晶粒分布较均匀,如图4(c)所示。图4(d)所示为第4道次锻造后实验合金显微组织,此时真应变量

≈0.60,平均晶粒尺寸约为12 μm,长条状晶粒尺寸减小,晶粒分布较均匀,如图4(c)所示。图4(d)所示为第4道次锻造后实验合金显微组织,此时真应变量 ≈0.80,晶粒进一步细化,晶粒分布更均匀,平均晶粒尺寸约为2.1 μm,出现大量平均晶粒尺寸约为0.8 μm的等轴状再结晶晶粒。同时,多数晶界呈弯曲状,晶界角度增大。在随后的锻造过程中,晶粒尺寸并未随变形量的增加而减小,晶粒长大倾向明显,部分晶粒出现异常长大现象,到第10道次时,最大晶粒尺寸已达65 μm,如图4(e)、(f)和(g)所示。

≈0.80,晶粒进一步细化,晶粒分布更均匀,平均晶粒尺寸约为2.1 μm,出现大量平均晶粒尺寸约为0.8 μm的等轴状再结晶晶粒。同时,多数晶界呈弯曲状,晶界角度增大。在随后的锻造过程中,晶粒尺寸并未随变形量的增加而减小,晶粒长大倾向明显,部分晶粒出现异常长大现象,到第10道次时,最大晶粒尺寸已达65 μm,如图4(e)、(f)和(g)所示。

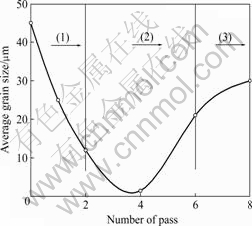

图5所示为实验镁合金平均晶粒尺寸大小与多向锻造道次之间的关系。综合图4和图5可发现,该镁合金在多向锻造过程中显微组织演化过程分为3个不同阶段,对应于3种不同的演化机制。

第一阶段显微组织演化发生在第2道次前,其机制为单纯的机械式击碎细化机制,晶粒尺寸由45 μm细化至12 μm。在该机制的作用下,粗大晶粒都被击碎成细长条状晶粒,初始小晶粒也得到一定程度的细化,几乎未出现再结晶晶粒。镁合金晶体结构为密排六方结构,变形过程中可启动的滑移系较有限,晶界附近变形协调能力较差。在变形过程中,变形带首先在粗大晶粒内部沿大于临界剪切应力的滑移方向产生,晶粒将沿变形带变形。因此,可以推断在图4(b)中出现的细长条状晶粒为原始粗大晶粒沿其内部变形带变形细化而来。

图4 ME20M镁合金初始态及各道次多向锻造后显微组织

Fig.4 Optical microstructures of ME20M magnesium alloy: (a) As-received; (b) 1st pass; (c) 2nd pass; (d) 4th pass; (e) 6th pass; (f) 8th pass; (g) 10th pass

图5 晶粒尺寸与多向锻造道次的关系和各阶段晶粒细化机制

Fig.5 Curve of grain size vs. number of MF pass and different grain refinement mechanism: (1) Mechanical splitting mechanism; (2) Deformation-induced dynamic recrystallization mechanism; (3) Thermal activated grain growth mechanism

第二阶段显微组织演化发生在第2道次到第4道次之间,其机制为形变诱导动态再结晶细化机制,晶粒尺寸由12 μm细化至2.1 μm,如图4(d)所示。晶界处出现大量平均晶粒尺寸为0.8 μm的等轴再结晶晶粒,显微组织更加细小且分布较均匀,同时多数晶界呈弯曲状,晶界角度增大。再结晶驱动力为位错储存能,位错密度随着应变量的增加而增加。在变形过程中,少数取向有利的晶粒将优先变形,这种晶粒变形的不同时性将会极大地增加位错密度

[22]。此外,镁合金是多晶体结构,各晶粒在变形时因需要相互协调而使得整个试样中形变分布极不均匀,这种形变不均匀性也促使位错密度的增加。在本实验中应变量存在一个临界值ε

C≈0.60,当累积真应变ε≥0.60时,将发生动态再结晶,如图4(c)所示。一旦动态再结晶现象发生,位错密度将在这些区域急剧增加,在接下来的变形过程中,位错将不断积累,动态再结晶晶粒数量将进一步增加,如图4(d)所示。

然而,实验镁合金晶粒细化程度与累积真应变量大小并不总成正比关系,如图4(e)和(f)所示,当变形进行到第6道次后,即真应变量ε≥1.50时,镁合金晶粒长大趋势明显,部分晶粒异常长大。到第10道次时,最大晶粒尺寸已达到65 μm,再结晶晶粒也有一定程度的长大,经测量其平均晶粒尺寸2.0 μm。在第4道次锻造后,晶界角度增大,晶界附近位错密度累积增大,因而,晶界表面能量升高。然而,表面能有自发降低的趋势,尤其是在热激活的作用下,这一过程将加速进行。本实验进行到第6道次和第8道次时,累积加热时间已经分别达到3和4 h,累积热能足以驱动晶界由一个晶粒向另一个晶粒迁移以降低表面能。尽管此时形变诱导动态再结晶机制仍在不断细化镁合金晶粒,但是这一机制的细化效果已经不足以抵消热激活所引起的晶粒长大趋势。因此,第三阶段显微组织演变机制以热激活晶粒长大机制为主,同时伴随着形变诱导动态再结晶机制。

2.2 各锻造道次的力学性能变化规律

根据初始态和典型道次锻造后实验镁合金室温拉伸真应力应变曲线的测试结果,相应的力学性能见图6。图6(a)和(c)所示分别为抗拉强度、显微硬度与锻造道次的关系曲线。由图6(a)可见,材料抗拉强度经前两道次锻造后几乎未有增加,在第4道次达到最大值225.52 MPa后又逐渐降低,其中第8和第10道次抗拉强度值低于初始态抗拉强度值211.39 MPa。由图6(c)可见,材料的显微硬度曲线以第4道次为临界点,第4道次前材料显微硬度曲线随锻造道次的增加而上升,而4道次后,曲线反而下降,材料显微硬度减小。

图6 不同锻造道次对ME20M镁合金力学性能的影响

Fig.6 Mechanical properties of ME20M magnesium alloy after MF pass: (a) Tensile strength; (b) Elongation; (c) Microhardness

多晶材料的力学及物理性能与众多因素有关,然而在这些因素中材料的平均晶粒尺寸起着至关重要的作用。由Hall-Petch公式[23-24]可知,多晶材料强度随着晶粒尺寸的减小而增加。本实验中,在第4道次锻造前,在机械式击碎细化机制和动态再结晶细化机制先后作用下,实验合金平均晶粒尺寸逐渐减小,如图4和5所示,同时材料的强度也逐渐增加,如图6(a)所示。在第4道次时,平均晶粒尺寸达到最小值,晶粒分布十分均匀,此时材料强度也达到最大值。从第6道次开始,晶粒在热激活作用下长大趋势明显,合金平均晶粒尺寸增大,同时其强度也迅速降低。由以上分析可知,本实验结果较好地符合Hall-Petch公式。同时由图4(d)可见,第4道次锻造后显微组织中大多数晶界呈弯曲状。在塑性变形时,这些晶界起钉扎作用而使滑移受阻,其宏观表现为变形抗力增加,抗拉强度增大。

图6(b)所示为伸长率与锻造道次的关系。由图6(b)可见,实验合金初始态下伸长率仅为7.60%,经2道次和4道次多向锻造,伸长率有较大提高,分别达到 12.35%和15.40%。实验合金经6道次多向锻造后,其伸长率达到最大值26.25%,约为初始状态伸长率的3.45倍。实验合金伸长率并不总随着锻造道次的增加而增加,在第8道次和第10道次锻造后,伸长率反而有所降低,其值分别为21.75%和14.40%。

图7所示为多向锻造前后镁合金的拉伸断口形貌。初始态试样断口为解理断裂,存在高度不一的解理面和解理台阶,同时在部分解理面附近有少量韧窝,如图7(a)所示,此时材料脆性较大。经多向锻造后,断口解理面消失,出现大量韧窝,并且大韧窝内还有许多小韧窝,如图7(b)所示,说明此时合金的断裂属于韧性断裂,合金的塑性有较大提高。

图7 多向锻造前后镁合金断口形貌

Fig.7 Fractured surface morphologies of magnesium alloy: (a) As-received; (b) 6th pass

通过金相组织观察与分析,伸长率的提高主要归因于动态再结晶晶粒体积分数的增大和其等轴化程度的增加。初始状态下,粗大晶粒和相对细小晶粒所组成的混合组织在塑性变形时应力分布极不均匀,容易造成局部应力集中,材料的塑性变形能力较低。从第2道次锻造开始,动态再结晶晶粒开始出现,显微组织得到细化,塑性变形能力增加,伸长率增大。由图4(e)观察发现,在第6道次多向锻造后,虽然出现部分晶粒长大现象,但同时动态再结晶晶粒等轴化程度增加,晶界更加圆滑,同时大晶粒晶界附近的再结晶晶粒数量增加。在塑性变形时,等轴再结晶晶粒之间的晶界滑移更容易开动和协调,变形阻力减小,可承受的塑性变形量增加,因而伸长率达到最大值,塑性得到极大提高。

3 结论

1) ME20M镁合金在多向锻造过程中显微组织演化分为3个不同阶段:第一阶段真应变量ε≤0.60,其晶粒细化机制为单纯的机械式击碎细化机制,晶粒尺寸由初始状态的45 μm细化到12 μm,几乎未出现再结晶细晶粒;第二阶段真应变量0.60<ε≤0.80时,其晶粒细化机制为形变诱导动态再结晶细化机制,平均晶粒尺寸减小至2.1 μm,显微组织更均匀细小,晶界变形呈弯曲状,晶界角度也逐渐增大;第三阶段真应变量ε≥1.50,此时晶粒演化机制为热激活晶粒长大为主导同时伴随着形变诱导动态再结晶细化机制,部分镁合金晶粒异常长大,最大晶粒尺寸达到65 μm。

2) 本实验中应变量存在一个临界值εC≈0.6,当累积真应变ε≥0.60时,将发生动态再结晶生成细小等轴状再结晶晶粒。

3) 室温抗拉强度、伸长率和显微硬度分别在第4、第4和第6道次锻造后达到最大值,分别为225.52 MPa、26.25%和HV 55.1,其中伸长率增加最为明显,约为初始状态伸长率的3.45倍。多向锻造道次过多,保温时间过长,该镁合金晶粒反而异常长大,导致镁合金力学性能下降。

REFERENCES

[1] MORDIKE B L, EBERT T. Magnesium properties, applications and potential[J]. Mater Sci Eng A, 2001, 302: 37-45.

[2] ELIEZER D, AGHION E, FROES F H. Magnesium science, technology and applications[J]. Advanced Performance Materials, 1998, 5(3): 201-212.

[3] KANG Z X. Research and application of wrought magnesium alloys, proceedings of the 2005 international conference on nanotechnology and advanced materials[C]// Hong Kong: FMM, 2005: 1-34.

[4] KUBOTA K, MABUCHI M, HIGASHI K. Processing and mechanical properties of fine-grained magnesium alloys[J]. Journal of Materials Science, 1999, 34(10): 2255-2262.

[5] MATSUBARA K, MIYAHARA Y, HORITA Z, LANGDON T G. Developing superplasticity in a magnesium alloy through a combination of extrusion and ECAP[J]. Acta Materialia, 2003, 51(11): 3073-3084.

[6] VALIEV R Z, LANGDON T G. Principles of equal-channel angular pressing as a processing tool for grain refinement[J]. Progress in Materials Science, 2006, 51(7): 881-981.

[7] 陈彦博, 赵晶磊, 李英龙, 宋 丹, 温景林. 连续ECAP技术制备超细晶铝[J]. 中国有色金属学报, 2006, 16(12): 2054-2059.

CHEN Yan-bo, ZHAO Jing-lei, LI Ying-long, SONG Dan, WEN Jing-lin. Preparation of ultrafine grained aluminium by continuous equal channel angular pressing[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(12): 2054-2059.

[8] JIAN W W, KANG Z X, LI Y Y. Effect of hot plastic deformation on microstructure and mechanical property of Mg-Mn-Ce magnesium alloy[J]. Trans Nonferrous Met Soc China, 2007, 17(6): 1158-1163.

[9] AGNEW S R, MEHROTRA P, LILLO T M, STOICA G M LIAW P K. Texture evolution of five wrought magnesium alloys during route A equal channel angular extrusion: experiments and simulations[J]. Acta Materialia, 2005, 53(11): 3135-3146.

[10] XU C, HORITA Z, LANGDON T G. The evolution of homogeneity in processing by high-pressure torsion[J]. Acta Materialia, 2007, 55(1): 203-212.

[11] ZHAO Y H, LIAO X Z, ZHU Y T, HORITA Z, LANGDON T G. Influence of stacking fault energy on nanostructure formation under high pressure torsion[J]. Mater Sci Eng A, 2005, 410/411: 188-193.

[12] KRALLICS G, LENARD J G. An examination of the accumulative roll-bonding process[J]. Journal of Materials Processing Technology, 2004, 152(2): 154-161.

[13] KITAZONO K, KIKUCHI Y, SATO E, KURIBAYASHI K. Anisotropic compressive behavior of Al-Mg alloy foams manufactured through accumulative roll-bonding process[J]. Materials Letters, 2007, 61(8/9): 1771-1774.

[14] IMAYEV V M, SALISHCHEV G A, SHAGIEV M R, KUZNETSOV A V, IMAYEV R M, SENKOV O N, FROES F H. Low-temperature superplasticity of submicro-crystalline Ti-48Al-2Nb-2Cr alloy produced by multiple forging[J]. Scripta Materialia, 1998, 40(2): 183-190.

[15] MIRONOV S Y, SALISHCHEV G A, MYSHLYAEV M M, PIPPAN R. Evolution of misorientation distribution during warm ‘abc’ forging of commercial-purity titanium[J]. Mater Sci Eng A, 2006, 418: 257-267.

[16] HAN B Q, LANGDON T G. Improving the high-temperature mechanical properties of a magnesium alloy by equal-channel angular pressing[J]. Mater Sci Eng A, 2005, 410/411: 435-438.

[17] LUGO N, LLORCA N, CABRERA J M, HORITA Z. Microstructures and mechanical properties of pure copper deformed severely by equal-channel angular pressing and high pressure torsion[J]. Mater Sci Eng A, 2007, 477: 366-371.

[18] SALISHCHEV G A, VALIAKHMETOV O R, GALEYEV R M. Formation of submicrocrystalline structure in the titanium alloy VT8 and its influence on mechanical properties[J]. Journal of Materials Science, 1993, 28(11): 2898-2902.

[19] IMAYEV V M, IMAYEV R M, SALISHCHEV G A. On two stages of brittle-to-ductile transition in TiAl intermetallic[J]. Intermetallics, 2000, 8(1): 1-6.

[20] BELYAKOV A, SAKAI T, MIURA H, KAIBYSHEV R, TSUZAKI K. Continuous recrystallization in austenitic stainless steel after large strain deformation[J]. Acta Materialia, 2002, 50(6): 1547-1557.

[21] SITDIKOV O, SAKAI T, GOLOBORODKO A, MIURA H. Grain fragmentation in a coarse-grained 7475 Al alloy during hot deformation[J]. Scripta Materialia, 2004, 51(2): 175-179.

[22] LI Y Y, ZHANG D T, CHEN W P, LIU Y, GUO G W. Microstructure evolution of AZ31 magnesium alloy during equal channel angular extrusion[J]. Journal of Materials Science, 2004, 39(11): 3759-3761.

[23] HALL E O. The deformation and ageing of mild steel: Ⅲ discussion of results[J]. Proceedings of the Physical Society of London, Section B, 1951, 64(9): 747-753.

[24] PETCH N J. The cleavage strength of polycrystals[J]. Journal of the Iron and Steel Institute, 1953, 174(5): 25-28.

基金项目:广东省科技攻关计划资助项目(2005B10301020)

收稿日期:2007-09-12;修订日期:2007-12-22

通讯作者:康志新, 副教授,博士;电话:020-87112933;E-mail: zxkang@scut.edu.cn

(编辑 何学锋)