文章编号:1004-0609(2007)07-1107-05

2A12铝合金形变热处理工艺在旋压工艺中的应用

刘黎明,陶 华

(西北工业大学 机电工程学院,西安 710072)

摘 要: 采用工艺实验研究2A12铝合金形变热处理工艺中时效温度和室温塑性变形量对材料性能的影响。结果表明:经固溶/淬火+8%室温塑性变形+(140±5) ℃,15 h,及空冷人工时效工艺处理后,2A12铝合金获得良好的强塑性配合;在2A12铝合金热挤压管材旋压工艺中采用形变热处理技术,可以使旋压工件材料的综合性能得到明显提高。

关键词:2A12铝合金;形变热处理;旋压

中图分类号:TG 30; TG 146.2 文献标识码:A

Application of thermo-mechanical treatment process on 2A12 aluminum alloy in craft of rotary extrusion

LIU Li-ming, TAO Hua

(College of Electrical Engineering, University of Northwest Polytechnical, Xi’an 710072, China)

Abstract: The effect of aging temperature and room temperature plastic deformation ratio of thermo-mechanical treatment alloy on material performance process for 2A12 aluminum alloy was investigated. The results indicate that the processing of solution/hardening+8% room temperature plastic deformation+(140±5) ℃, 15 h, air cooling artificial aging on 2A12 aluminum alloy result in a good combination match of plastic with strength. The thermo-mechanical treatment after rotary compressing increases in the overall performance of 2A12 aluminum alloy hot extrusion tube obviously.

Key words: 2A12 aluminum alloy; thermo-mechanical treatment; rotary compressing

形变热处理是将塑性变形的变形强化和热处理时的相变强化相结合,使成形工艺与获得的最终性能统一起来的一种综合方法[1-4]。形变热处理强化既不是简单地形变强化和相变强化的叠加,也不是任何变形与热处理的组合,而是变形与相变既互相影响又相互促进的一种工艺。合理的形变热处理工艺将有利于发挥材料潜力,是金属材料强韧化的重要方法之一[5-10]。

2A12铝合金属Al-Cu-Mg系是可热处理强化的加工铝合金,广泛用作航空航天飞行器的结构材料[3],如飞行器的蒙皮、隔框、翼肋、翼梁和铆钉等。旋压成形工艺是制造金属薄壁筒形件、锥形件和其它具有回转表面工件的常用工艺方法[11-14],采用旋压成形工艺制造的工件具有较高的强度、较为精确的形状尺寸精度和良好的表面粗糙度,生产效率较高,适合于小批量多品种生产模式,广泛应用于航空航天、兵器等领域。随着战术导弹采用蒙皮与骨架一体的整体式舱段结构,旋压成形工艺也越来越多地应用于导弹舱段研制生产[15]。

本文作者通过实验研究2A12铝合金形变热处理工艺中室温塑性变形程度和人工时效温度对材料性能的影响规律,在此基础上,将形变热处理工艺与旋压成形工艺相结合,即在旋压成形的最后一道次旋压前进行固溶/淬火处理,随后进行最后一道次旋压加工,完成形变热处理所需的塑性变形,工件达到要求的形

状尺寸,然后进行人工时效,完成形变热处理。这样使工件材料在最终使用状态时具有优良的性能,达到控制工件形状尺寸和工件材料性能的目的。

1 实验

1.1 2A12铝合金形变热处理工艺实验方法

采用规格为1 000 mm×2 000 mm×2.9 mm的2A12铝合金板材,用剪板机将原始板材切割成矩形试片,试片尺寸为240 mm×166 mm×2.9 mm,准备进行形变热处理。

首先将试片进行固溶/淬火处理,固溶处理在箱式电炉中进行,热处理工艺参数为:(498±3) ℃,60 min,水冷。

固溶/淬火处理后再进行室温塑性变形。为了研究室温塑性变形量对形变热处理强化效果的影响,将试片按照不同的变形量进行精确轧制,选定的变形量分别为4%,5%,6%,8%,10%和15%,所有轧制均在试片淬火后1 h内一个道次完成。

每个试片在轧制完成后1 h内在箱式电炉中进行人工时效。为了研究时效温度对形变热处理强化效果的影响,将试片分别在不同的温度进行人工时效。人工时效处理制度分别为:(100±5) ℃,15 h,空冷;(120±5) ℃,15 h,空冷;(140±5) ℃,15 h,空冷;(160±5) ℃,15 h,空冷;(190±5) ℃,15 h,空冷。

将完成形变热处理的试片用电火花线切割加工成标准矩形拉伸试样,按照《GB228—87金属拉伸试验方法》的规定在材料力学性能试验机上测试试样的抗拉强度、屈服强度和伸长率等力学性能。

1.2 旋压形变热处理工艺实验

采用2A12铝合金热挤压管材(GB4437—84)车削加工为旋压毛坯,毛坯直径为360 mm,毛坯壁厚为6 mm。旋压工艺流程如下:

毛坯退火→第一道次旋压(变形量46.7%)→退火 →第二道次旋压(变形量46.8%)→淬火→第三道次旋压(变形量9%)→人工时效。

退火工艺参数为:随炉升温至360 ℃,保温90 min,随炉冷却至200 ℃,空冷。

淬火工艺参数为:(498±3) ℃,60 min,水冷。

人工时效工艺参数为:(140±5) ℃,15 h,空冷。

在旋压工件上沿轴线方向切取标准矩形拉伸试样,按照《GB228—87金属拉伸试验方法》在材料力学性能试验机上测试试样的抗拉强度、屈服强度和伸长率。

2 结果与讨论

2.1 形变热处理

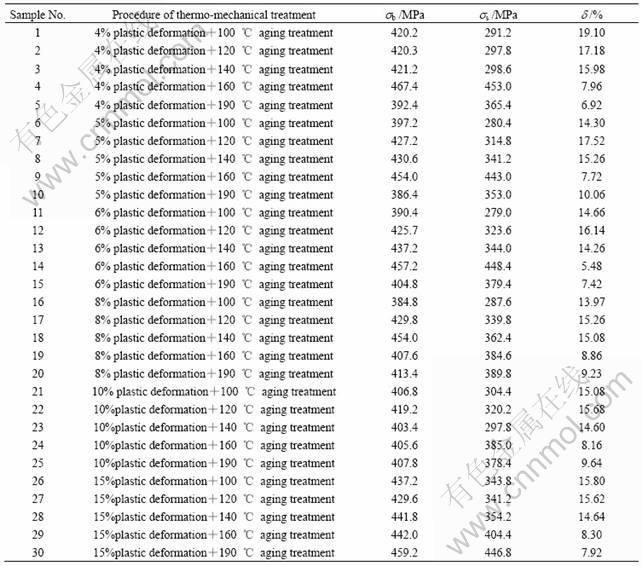

2A12铝合金经过不同形变热处理工艺处理后的抗拉强度、屈服强度和伸长率等力学性能列于表1。

2.1.1 时效处理温度对材料性能的影响

图1~3所示分别为时效温度对2A12铝合金的抗拉强度、屈服强度和伸长率的影响。

从图1和2中可以看出,当室温变形量不同时,时效温度对材料强度的影响呈现不同的规律:当变形量较小时,材料强度随着时效温度的升高先提高后降低,在160 ℃左右出现峰值;当变形量较大时,材料强度随着时效温度的升高而提高。按照时效有关原理,

图1 时效温度对材料抗拉强度的影响

Fig.1 Effects of aging temperature on tensile strength of material

图2 时效温度对材料屈服强度的影响

Fig.2 Effects of aging temperature on yield strength of material

表1 2A12铝合金形变热处理后的力学性能

Table 1 Mechanical properties of 2A12 aluminium alloy after different thermo-mechanical treatments

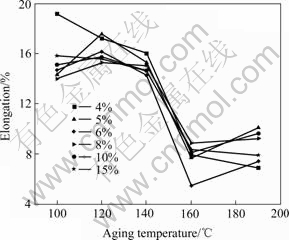

图3 时效温度对材料伸长率的影响

Fig.3 Effects of aging temperature on material elongation

当变形量较小时,材料组织中的晶体缺陷密度较低,时效温度升高能够促进强化相的形核析出,提高材料的强度;但是在时效温度较高时,变形组织会发生明显的回复,缺陷密度降低,减弱了变形强化的效果。当变形量较大时,在材料内部产生的缺陷密度较高,在时效过程中回复作用不明显,所以材料的强度随着时效温度的升高而提高。

从图3中可以看出,不同的变形量的材料伸长率随着时效温度的变化规律基本一致。随着时效温度的升高,材料的伸长率呈现波浪式变化,在时效温度为130 ℃左右伸长率最高,材料具有良好的塑性;在 160 ℃左右伸长率相对较低,材料的塑性有所降低。

因此,为了取得材料良好的综合性能(较高的强度和较好的塑性),对于2A02铝合金材料时效温度确定为130 ℃,15 h比较合适。

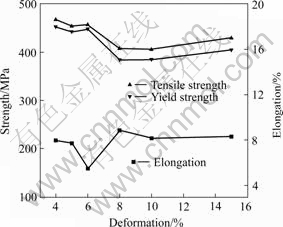

2.1.2 室温变形量对材料力学性能的影响

图4~6所示分别为时效温度为120,140和160 ℃时,室温变形量对2A12铝合金抗拉强度、屈服强度和伸长率的影响。

从图4和5中可以看出,在时效温度较低时,材料的强度随着变形量的增加而提高。变形量低于8%时,强度随着变形量提高的趋势比较明显,在变形量为10%时材料强度略有下降,此后强度随着变形量的变化趋于平缓。材料伸长率随着变形量的增加呈下降趋势,但是变化趋势平缓,说明材料仍然保持着良好的加工塑性。

从图6中可以看出,在时效温度较高时,材料的强度随着变形量的增加变化比较平缓,但是材料伸长率随着变形量的增加呈升高趋势。说明在时效温度较高时,材料内部的回复作用明显。

图4 时效温度为120 ℃时变形量与材料性能的关系

Fig.4 Relationships between elongation and performances of material while aging at 120 ℃

图5 时效温度为140 ℃时变形量与材料性能的关系

Fig.5 Relationships between elongation and material performances while aging at 140 ℃

图6 时效温度为160 ℃时变形量与材料性能的关系

Fig.6 Relationships between elongation and material performances while aging at 160 ℃

综合上述作用,2A12铝合金材料在室温变形量8%,时效温度在140 ℃时,可以取得较好的形变热处理效果。

2.2 旋压形变热处理

2A12铝合金经过旋压形变热处理工艺处理后的抗拉强度、屈服强度和伸长率等力学性能列于表2。其退火态与旋压形变热处理工艺处理后的微观组织如图7所示。

图7(a)所示为热挤压管材退火后状态的微观组织。工艺参数为:随炉升温至360 ℃,保温90 min,随炉冷却至200 ℃,空冷。由图可见,组织为比较均匀的退火组织。图7(b)所示为旋压形变热处理工艺处理后的微观组织。合金经过旋压变形后,晶粒被拉长而产生变形织构。晶粒在变形的过程中由于变形而储能,在退火、淬火、人工时效等热处理工序加热时,它是再结晶、晶粒长大的能量来源。晶粒长大的程度与加热的温度和时间密切相关。

按照GB4437—84标准2A12铝合金热挤压管材在淬火状态(T4)材料力学性能列于表3。

通过对比表2和表3可以看出,2A12铝合金热挤压管材经过旋压形变热处理后,材料的抗拉强度、

表2 2A12铝合金旋压形变热处理后的力学性能

Table 2 Mechanical properties of 2A12 Aluminium alloy after rotary extrusion and thermo-mechanical treatment

图7 2A12铝合金退火态与旋压形变热处理工艺处理后的微观组织

Fig.7 Microstructures of 2A12 Al alloy after annealed, and rotary compressed then thermo-mechanical treated

表3 2A12铝合金热挤压管材T4状态的力学性能

Table 3 Mechanical properties of 2A12 aluminium alloy hot extrusion tube in T4 state

屈服强度和伸长率分别提高了13.2%,38.9%和27.5%,特别是材料的屈服强度比由原来的0.6提高为0.85,材料的综合性能明显提高。

REFERENCES

[1] 张宝昌. 有色金属及其热处理[M]. 西安: 西北工业大学出版社, 2000.

ZHANG Bao-chang. Nonferrous and its heat treatment[M]: Xi’an: Northwest Polytechnical University Press, 2000.

[2] 《有色金属及其热处理》编写组. 有色金属及其热处理[M]. 北京: 国防工业出版社, 1981.

Group of compile《Nonferrous Metals and its heat treatment》. Nonferrous metals and its heat treatment[M]. Beijing: National Defence Industry Press, 1981.

[3] Singh A K, Saha G G, Gokhale A A. Evolution of texture and microstructure in a thermo-mechanically processed Al-Li-Mg alloy[J] .Metall Mater Trans, 1998, 294: 665-675.

[4] Adrien J, Maire E, Estevez R, Ehrstrom J C, Warner T. Influence of the thermomechanical treatment on the microplastic behaviour of a wrought Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2004, 52(6): 1653-1661.

[5] 田荣璋, 王祝堂. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2000.

TIAN Rong-zhang, WANG Zhu-tang. Aluminum alloy and it handbook of processing[M]. Changsha: Center South University Press, 2000.

[6] 王建华, 易丹青, 陈康华. 形变热处理对2618铝合金性能的影响[J]. 热加工工艺, 2001, 1(2): 13-14.

WANG Jian-hua, YI Dan-qing, CHEN Kang-hua. Effect of thermomechanical treatment to 2618 aluminum alloy[J]. Technology of Hot-Forming, 2001, 1(2): 13-14.

[7] 柏振海, 黎文献. Al-Mg-Si合金的形变热处理研究[J]. 轻合金加工技术, 2003, 31(8): 39-41.

BO Zheng-hai, LI Wen-xian. Thermomechanical treatment investigation of Al-Mg-Si alloy[J]. Process Technology of Light Alloy, 2003, 31(8): 39-41.

[8] 王赛玉, 石其年. 形变热处理Al-Li合金组织和性能的影响[J]. 材料热处理学报, 2005, 26(5): 84-88.

WANG Sai-yu, SHI Qi-nian. Effect of thermomechanical treatment to Al-Li alloy microstructure and performance[J]. Journal of Material Heat Treatment, 2005, 26(5): 84-88.

[9] Bergsma S C, Li X, Kassner M E. Effects of thermal processing and copper additions on the mechanical properties of aluminum alloy ingot AA 2618[J]. Journal of Materials and Engineering & Performance , 1996, 5(1): 100.

[10] Oguocha I N A , Yannacopolos S. The structure of AlFeNI phase in Al-Cu-Mg-Fe-Ni alloy (AA 2618) [J]. Journal of Material Science, 1996, 31: 5615.

[11] Gable B M, Zhu A W, Csontos A A, Starke E A Jr. The role of plastic deformation on the competitive microstructure evolution and mechanical properties of a novel Al-Li-Cu-X alloy[J]. Journal of Light Metals, 2001(1): 1-14.

[12] Drozd Z K, Zuzanka T A, Kudela S. Deformation behaviour of Al-Li-Mg alloys[J]. Journal Alloys and Compounds, 2004, 378: 192-195.

[13] Katgerman L, Dom F. Rapidly solidified aluminium alloys by meltspinning[J]. Mater Sci Eng A, 2004, A375/377(15): 1212-1216 .

[14] Karabay S, Yilmaz M, Zeren M. Investigation of extrusion ratio effect on mechanical behaviour of extruded alloy AA-6101 from the billets homogenised-rapid quenched and as-cast conditions[J]. Journal of Materials Processing Technology, 2005, 160(2): 138-147.

[15] 高 曙, 许明华, 蒋为吉. 铝合金形变热处理的电镜组织分析[J]. 宇航材料工艺, 1995(4): 44-48.

GAO Shu, XU Ming-hua, JIANG Wei-ji. SEM fabric analysis of aluminum alloy thermomechanical treatment[J]. Technology of Space Navigation Material, 1995(4): 44-48.

(编辑 陈爱华)

收稿日期:2006-12-28;修订日期:2007-04-11

通讯作者:刘黎明, 博士研究生; 电话: 010-68376720; E-mail: liuzhyuru@tom.com