文章编号:1004-0609(2008)07-1223-08

摩擦制动条件对列车制动闸片材料摩擦性能的影响

符 蓉,宋宝韫,高 飞,运新兵

(大连交通大学 材料科学与工程学院,大连 116028)

摘 要:采用粉末冶金技术制备铜基陶瓷强化材料,通过定速摩擦实验机和1:1制动实验台测试了材料在多种摩擦条件下摩擦磨损性能的变化。结果表明:摩擦条件对摩擦磨损性能有明显影响,摩擦顺序、摩擦速度、摩擦压力的不同,造成摩擦表面温度不同;温度增高有利于形成连续致密的表面第三体,这种高温第三体组织对基体有良好保护,起到增加和稳定摩擦因数、降低磨损量的作用;定速摩擦顺序与惯性摩擦顺序在温升条件相似时,摩擦因数的变化具有相似性;在湿摩擦条件下,摩擦因数略有降低且稳定性好,原因在于水分对摩擦表面具有冷却及润滑作用;所研制材料摩擦因数的变化程度处于国际铁路联盟标准控制范围内。

关键词:铜基摩擦材料;闸片材料;第三体;摩擦性能

中图分类号:TF 125 文献标识码:A

Effect of friction conditions on friction properties of

braking materials used for trains

FU Rong, SONG Bao-yun, GAO Fei, YUN Xin-bing

(College of Materials Science and Engineering, Dalian Jiaotong University, Dalian 116028, China)

Abstract: The friction and wear properties of particle-reinforced copper matrix composites fabricated by powder metallurgy, were measured by friction tester and 1:1 test bench, respectively. The results show that the friction conditions have strong effects on the friction properties of the materials in terms of different surface temperatures caused by various friction mode, friction speeds and braking pressures. Under high temperatures, the continuous and compact third bodies form easily on the surfaces, which protect the substrate, increase and stabilize the friction coefficient,and reduce the wear. The friction coefficient at constant speeds changes similarly to that at the inertial friction style, in case of similar temperature conditions. The friction coefficient of the present studied materials is low under wet condition, due to the fact that the moisture decreases the temperature of the surface and lubricates it as well. The friction coefficients of the materials are well within the scope ruled by the UIC Code.

Key words: Cu-based friction material; braking materials; third body; friction properties

随着列车速度的增加,制动工况越来越复杂。因此,对制动摩擦副材料的性能提出越来越高的要求。当速度为300 km/h的高速列车在实施紧急制动时,摩擦速度相当于45 m/s,摩擦因数大于0.35,每个制动盘所消耗的最高制动能达23 MJ,制动盘体的温度可达600 ℃,盘面最高温度超过800 ℃[1?2]。在这种条件下,铜基陶瓷强化材料由于使用温度高、摩擦因数稳定、磨损率小而成为高速列车普遍采用的闸片材 料[3?4]。制动闸片材料性能除考虑列车的结构外,还必须考虑各种气候环境和使用条件,因此,研究不同运行条件对制动闸片材料的性能影响很有意义。在测试材料摩擦磨损性能方面,通常采用如下两种实验方法测试材料的摩擦磨损性能:1) 采用与列车制动条件类似的惯性实验机测试材料在整个制动过程摩擦磨损性能的变化情况,这种测试方法可以确切地模拟出实际制动中摩擦因数的变化[3]。然而,这种测试方法最大的局限性在于制动速度、制动温度、制动功率和制动能量等参数牵连在一起,难以独立研究某一参数的作用[4?5];2) 定速摩擦实验[6?9],这种测试方法可以测出一个确定速度下的摩擦磨损性能,对于诸如功率、速度和温度等参数对摩擦磨损性能的影响可以分别考虑。由于这两种测试方法的不同,对表面的摩擦组织的影响不同,因此,测出的摩擦因数有一定的差别。而有关这两种测试方法的比较研究报道很少,尤其是摩擦条件与摩擦表面第三体组织的关系、第三体组织特点与摩擦磨损性能的关系[10?12],还没有引起人们应有的重视。

本文作者针对铜基粒子强化材料,利用定速摩擦实验机研究摩擦压力、速度、温度、干湿条件以及摩擦顺序等对摩擦因数的影响,考虑摩擦条件与摩擦第三体的关系,并与1:1惯性制动实验台的测试结果进行比较,分析在两种测试方式下材料的摩擦磨损性能特点。

1 实验

铜基陶瓷强化摩擦材料的成分由金属基体、陶瓷粒子和润滑粒子组成,金属基体的成分主要为铜、锡、铁、铝以及其它微量合金元素。陶瓷粒子的主要成分为SiO2,润滑组分以石墨为主。

材料经混合后在400~500 MPa的压力下压制成型,在烧结炉中加压烧结,烧结压力为2~3 MPa,烧结温度为850~900 ℃,保温时间1 h。制成的试样规格有如下两种:一种为d 17 mm×15 mm,用于定速摩擦实验;另一种为d 40 mm×20 mm,制成标准闸片,用于1?1惯性摩擦实验。

定速摩擦磨损实验在GF150D型定速摩擦机上进行,摩擦单位压力为0.45~0.90 MPa。摩擦对偶盘材料为4Cr5MoV1Si,摩擦半径为150 mm,模拟列车速度范围为30~300 km/h。湿摩擦条件下的滴水速度为0.68 mL/s。惯性摩擦实验在1?1制动动力实验台上进行,模拟列车最高速度达200 km/h。

定速摩擦机测定的是某恒定速度下的摩擦因数,形成相应的表面摩擦组织,当进行下一个速度条件的测试时,前道次摩擦形成的表面组织状态,往往影响随后摩擦速度的摩擦因数。同时,如果两次实验间的实验间隔非常短,摩擦副没有充分冷却,温度条件对摩擦性能仍有影响。因此,为研究这方面的影响,进行的摩擦过程以如下4种方式进行:A. 实验顺序为从低速开始向高速进行,每次摩擦的起始温度为室温;B. 实验顺序为从高速开始向低速进行,每次摩擦的起始温度为室温;C. 实验顺序从低速开始向高速进行,每一转速完成后,停留1~2 s直接进行下一转速的摩擦;D. 实验顺序从高速开始向低速进行,每一转速完成后,停留1~2 s直接进行下一转速的摩擦。对于摩擦顺序A和B,测量每个速度条件下的磨损量,对于摩擦顺序C和D,在各速度完成后测量各速度下的累计磨损量。每个速度条件下的摩擦时间为40~60 s。

2 结果与讨论

2.1 摩擦顺序对摩擦磨损性能的影响

图1所示为在定速干摩擦实验条件下,随摩擦速度的改变,摩擦因数的变化情况。由图可知,当模拟速度处于200 km/h左右时,摩擦因数处于较高值,在模拟速度处于50 km/h左右,摩擦因数出现最低值,这与许多摩擦材料的摩擦因数随摩擦速度降低而增加的情况略有不同[5]。

图1 摩擦压力0.5 MPa时摩擦顺序对摩擦因数的影响

Fig.1 Effect of friction mode on friction coefficient at friction pressure of 0.5 MPa

摩擦中,磨损产生的磨屑覆盖在摩擦表面,这层磨屑随摩擦速度和摩擦顺序的不同,形成的组织状态有所不同,这层组织被称为第三体[10?13],第三体的形态、与基体的结合状态是影响材料摩擦磨损性能的一个重要因素。

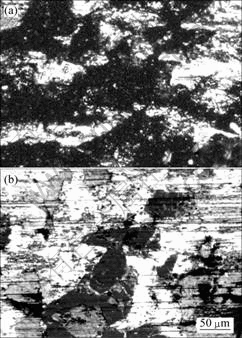

图2所示为在摩擦顺序为B的情况下,随摩擦速度的变化,摩擦表面第三体的变化情况。由图可知,在定速干摩擦条件下,材料经40~60 s时间的高速摩擦,第三体在高速高温的作用下,被剪切挤压形成一致密层覆盖在基体上。这层第三体与基体的结合强度随摩擦速度的高低而有所不同。当第三体破碎脱离基体时,会在基体上形成剥落坑,剥落坑的底部由于凸凹不平反光性差而在显微镜下显示为黑色斑点。当摩擦速度较高时,摩擦表面第三体致密、连续性好、剥落坑少。随摩擦速度的降低,表面温度降低,第三体的流动性降低,对表面的覆盖性差,表现出摩擦表面粗糙程度增加,致密第三体的剥落面积增大。第三体的这种形态变化必然对摩擦因数产生影响。在模拟速度为200 km/h左右时(见图2(a)),第三体的致密性好,相应的摩擦因数高,说明这种状态的第三体是形成较高摩擦因数的一个原因。随着摩擦速度的降低,致密第三体的结合性降低、剥落程度增加(见图2(b)和(c)),摩擦因数降低(见图1)。当模拟速度为50 km/h时,摩擦因数出现最低值,产生这一结果的原因可能在于摩擦表面缺少致密第三体的良好保护。这是由于摩擦速度的降低,致密连续的第三体逐渐剥离脱落(见图2),剥落处的基体往往是石墨组分的富集区(石墨与第三体的结合性差使这个区域的第三体容易剥落)。因此,这些区域的石墨被摩擦破碎后形成许多石墨微粒弥散到摩擦表面,石墨微粒的润滑作用可能是造成这一速度条件下摩擦因数较低的一个原因。当速度更低时,表面微凸体间的良好啮合作用有利于增加摩擦因数,这可能在一定程度上减小了石墨微粒对摩擦因数的降低作用。另外,处于高速摩擦条件下,石墨微粒容易被抛离摩擦面而降低了润滑作用。这说明石墨微粒对摩擦因数的影响与摩擦速度有关。

图2 不同速度摩擦顺序为B时摩擦表面致密第三体的形貌

Fig.2 SEM images of compact third body on friction surface at different friction speeds (friction mode B): (a) 200 km/h; (b) 100 km/h; (c) 50 km/h

由图1可知,摩擦顺序不同对材料的摩擦因数有明显影响。当摩擦由高速开始向低速进行时(摩擦顺序B和D),摩擦因数出现较高值。同样都是由低速开始向高速进行的摩擦顺序,但摩擦顺序A的摩擦因数比摩擦顺序C的摩擦因数低很多。摩擦因数随摩擦顺序不同而发生变化可能与摩擦表面第三体形貌的变化有关。图3所示为模拟速度为300 km/h的摩擦表面形貌,尽管都是由低速向高速摩擦,但由于摩擦过程不同,摩擦表面第三体形貌表现出不同特点。在摩擦顺序A的条件下,在进行每个速度的摩擦测试时,试样和制动盘均是在室温条件下开始进行,摩擦副温度较低。相对而言,摩擦顺序C是在每个速度摩擦后仅停留1~2 s、摩擦副的温度尚来不及冷却而直接进行下一个速度的摩擦。因此,两种摩擦条件的不同实际上就是摩擦温度的不同,也就是说,摩擦顺序A的摩擦温度较低,摩擦顺序C的摩擦温度较高。当摩擦温度较高时,第三体与基体的粘着性好,表面第三体致密连续,不容易剥落,形成的剥落坑数量少(见图3(b));当摩擦温度较低时,表面第三体的致密性差,容易与基体分离,形成的剥落坑的数量较多(见图3(a))。剥落坑数量的不同,造成摩擦副间真实接触面积不同,大量剥落坑的出现,减少了摩擦真实作用面积,这是造成摩擦顺序A摩擦因数较低的一个原因(见图1)。

图3 速度300 km/h时摩擦顺序对表面第三体形貌的影响

Fig.3 Effect of friction mode on third bodies at speed of 300 km/h: (a) Friction mode A; (b) Friction mode C

材料的摩擦过程决定摩擦表面状态,表面状态又将影响摩擦磨损性能。图4所示为摩擦顺序A和摩擦顺序B与表面第三体的关系。摩擦时,起始摩擦表面状态由前道次摩擦条件决定。在摩擦顺序A条件下,当进行模拟速度为200 km/h的摩擦时,前道次的模拟摩擦速度低(150 km/h),这时表面第三体致密程度低且连续性差。这样,当进行模拟速度为200 km/h的摩擦时,摩擦面处于这样一个初始状态下,因此,表面第三体的剥落坑相对较多(见图4(a)),导致摩擦因数较低(见图1)。在摩擦顺序B条件下,前道次摩擦条件是模拟摩擦速度高(250 km/h),表面温度高,形成的第三体致密程度高、氧化物含量大,在这种表面状态下进行模拟速度为200 km/h的摩擦时,表面第三体的剥落坑较少(见图4(b)),导致摩擦因数高于前者(见图1)。

图4 速度200 km/h时摩擦顺序对表面第三体形貌的影响

Fig.4 Effect of friction mode on third bodies at speed of 200 km/h: (a) Friction mode A; (b) Friction mode B

图5所示为摩擦压力0.5 MPa时摩擦顺序对磨损量的影响。由图可知,摩擦顺序对磨损量的影响显著。摩擦顺序A的磨损量大于摩擦顺序B的磨损量。摩擦顺序B总是建立在表面第三体较致密的基础上进行摩擦,由于致密第三体的保护作用,因此,使磨损量处于较低情况。相反,当摩擦速度由低速向高速进行时,低速条件下形成的第三体与基体的结合强度有限,容易在更高的摩擦速度条件下碎裂和破坏,结果造成磨损量增加。

图5 摩擦压力0.5 MPa时摩擦顺序与磨损量的关系

Fig.5 Relationship between friction mode and wear at friction pressure 0.5 MPa

由上述分析可以看出,当摩擦条件有利于形成致密而连续的第三体,即表面第三体的剥落坑数量和面积小时,材料的摩擦因数较高,磨损量较低。

2.2 摩擦压力对摩擦磨损性能的影响

通常来讲,摩擦压力增加,材料表面应力增加,摩擦力增加,摩擦功率增加,使摩擦表面温度升高时,这容易造成基体材料由于高温软化而使强度降低,结果表现出摩擦因数降低的现象[14]。当摩擦速度提高,高摩擦速度产生的高温同样会造成摩擦因数降 低[5, 15]。

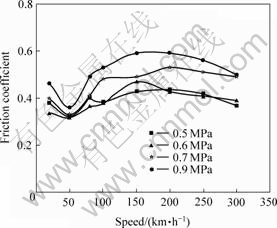

图6所示为摩擦顺序B时摩擦压力对摩擦因数的影响。由此可见,所研制的材料随压力提高,摩擦因数增加,摩擦因数随摩擦速度的增加变化不大。这表明所研制材料的基体组分的合金化程度好,具有良好的抗高温软化能力。同时,由于高温时第三体中的金属氧化程度大,硬质的氧化物含量增加同样容易提高摩擦因数,这两方面的因素均是造成摩擦因数没有降低的原因。

图6 摩擦顺序B时摩擦压力与摩擦因数的关系

Fig.6 Relationship between friction pressure and friction coefficient at friction mode B

图7所示为摩擦顺序B时摩擦压力与磨损量的关系。由图可知,在摩擦压力为0.9 MPa时,磨损量明显增加。在其它的摩擦压力下,磨损量变化不明显。随摩擦速度的提高,磨损量增加。在高速摩擦条件下,高的表面温度是产生高磨损量的一个重要原因,同时高温形成的粘着性好的第三体容易粘附到对偶盘上也是磨损量增加的因素。在进行模拟速度为50~100 km/h的摩擦时,磨损量较低。这可归因于在此摩擦条件下石墨微粒的润滑作用降低了摩擦因数。

图7 摩擦顺序B时摩擦压力与磨损量的关系

Fig.7 Relationship between friction pressure and wear rate at friction mode B

2.3 水分对摩擦磨损性能的影响

评价摩擦材料性能的一个重要指标是摩擦因数在淋水条件下的变化情况。图8所示为干摩擦和湿摩擦两种条件下摩擦因数的变化情况。由图可见,在模拟速度为50~300 km/h时,湿摩擦条件下的摩擦因数大都低于干摩擦条件的摩擦因数。湿摩擦条件下的摩擦因数几乎不随模拟速度的增加而变化,具有良好的稳定性。在模拟速度为300 km/h时,两者摩擦因数相近,原因在于高速摩擦的表面温度很高,水分蒸发快,所以摩擦因数相近。比较而言,干摩擦条件下的摩擦因数随速度的增加而波动程度较大,在模拟速度高于150~200 km/h以后,摩擦因数略有降低,原因在于随着摩擦速度的进一步提高,基体材料的高温强度降低以及第三体的高温流动性有利于降低摩擦因数。当模拟速度为150~200 km/h时,摩擦因数表现出最大值,原因在于前道次高速摩擦形成的高氧化物含量的第三体的作用以及温度降低导致基体强度的增加,均有利于提高摩擦因数。随着摩擦速度的进一步降低,致密连续第三体破裂剥落,使摩擦因数降低。在湿摩擦时,由于水分对表面的冷却作用,使表面温度随摩擦速度的变化不明显,同时,水膜的润滑作用并不随速度的变化而明显不同,这些因素使摩擦因数表现出良好的稳定性。

图8 摩擦顺序D、摩擦压力0.7 MPa时摩擦条件对摩擦因数的影响

Fig.8 Effect of friction conditions on friction coefficient at friction mode D and friction pressure 0.7 MPa

图9所示为模拟速度为20 km/h条件下干摩擦和湿摩擦时表面第三体形貌。由图可知,在低速干摩擦条件下,第三体层完全破裂并颗粒化(见图9(b))。在这种状态下,当表面有水膜存在时,部分第三体微细粒子溶到水膜中,水膜在离心力的作用下,不断地脱离摩擦面。这样,相当一部分第三体微粒被水带离摩擦表面,产生了清洗表面的作用,使摩擦基体缺少第三体的覆盖(见图9(a))。

图9 摩擦顺序B,速度20 km/h,摩擦压力0.6 MPa时摩擦条件下表面第三体形貌

Fig.9 SEM images of third body patterns at friction mode B, speed 20 km/h friction pressure 0.6 MPa: (a) Dry friction conditions; (b) Wet friction

2.4 惯性制动实验对材料摩擦磨损性能的影响

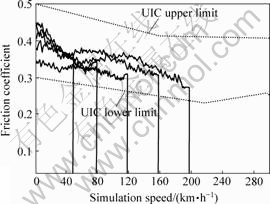

利用所研制的材料制造出高速列车用制动闸片,在1?1制动动力实验台进行最高时速200 km/h的制动实验,实验结果如图10和11所示。由图可知,在干摩擦条件下,当摩擦压力为0.75MPa时,随速度的降低,摩擦因数略有增加。在制动过程中,摩擦因数均处于国际铁路联盟(UIC)标准控制范围内。当摩擦压力为0.5MPa、模拟速度为40 km/h左右时,摩擦因数出现最低值,摩擦因数的这种变化趋势与定速摩擦制动实验曲线具有良好的相似性。这一结果表明,利用定速摩擦实验机在一定条件下可以模拟惯性条件下材料的摩擦性能。但值得注意的是,定速摩擦实验机测试的摩擦因数普遍高于1?1制动实验台的实验结果,同时,定速摩擦实验机测试的摩擦因数的波动程度较大。产生这些差别的一个重要原因可能仍是温度对摩擦因数的影响。这可以从摩擦顺序的角度分析这种差别。

图10 制动实验台1?1制动条件下摩擦因数的变化情况(干摩擦,摩擦压力0.75 MPa)

Fig.10 Relationship between friction coefficient and speed at a 1?1 friction test bench by dry friction at friction pressure of 0.75 MPa

图11 制动实验台1?1制动条件下摩擦因数变化情况(干摩擦,摩擦压力0.5 MPa)

Fig.11 Relationship between friction coefficient and speed at 1?1 friction test bench by dry friction at friction pressure of 0.5 MPa

在1?1制动实验条件下,摩擦速度的降低是一个连续过程。当摩擦压力高时,意味着制动功率大,高速条件下产生的制动热大都被制动盘吸收,随着摩擦速度的降低,制动盘吸收的热量仍在起作用,摩擦温度并没有随摩擦速度的快速降低而降低。这种高温条件下速度的连续变化有利于第三体形成,因此,稳定的第三体组织降低了摩擦因数的波动。同时,在高温低速摩擦条件下,有利于增加摩擦面上微凸体间的啮合程度,在低摩擦速度时起到增加摩擦因数的作用(见图10)。当摩擦压力低时,制动盘的温度较低,第三体的变化与定速摩擦实验条件下产生的第三体有相似性。在定速摩擦实验条件下观察到的第三体剥落现象可能在惯性实验条件下同样存在。其结果是,摩擦因数的变化与定速摩擦实验机测试的结果表现出相同的趋势。

在定速摩擦条件下,即使采用的摩擦顺序是由高速开始向低速进行,每个速度间隔中不进行冷却,但在停顿期间试样的降温程度不同,在这期间第三体发生一定程度的氧化,使第三体中的硬质氧化物含量增加,从而使摩擦因数增大,同时也增加了摩擦因数的波动程度。在摩擦速度降低时,高氧化物含量的第三体与基体的结合强度有限,这些高速条件下形成的第三体容易破碎剥落,由于缺少硬质第三体的阻摩作用,所以使摩擦因数在低速时有所降低。

3 结论

1) 材料的摩擦磨损性能与摩擦顺序、摩擦速度、摩擦压力、干湿状态等密切相关,所研制的铜基摩擦材料在定速实验中,处于干摩擦状态时,摩擦因数没有出现随摩擦速度、摩擦压力增加而降低的现象。摩擦因数的这种变化特点与摩擦表面第三体组织状态有关。当摩擦压力高、摩擦速度高、连续摩擦时,均有利于形成致密第三体,这对基体组织起到保护作用,从而改善了材料的耐磨性和降低了摩擦因数的波动。在湿摩擦条件下,摩擦因数略有降低且稳定性好。其原因在于水膜的润滑及冷却作用减少了摩擦温度的变化,使第三体组织变化不明显。

2) 在1?1制动实验台的测试条件下,产品的摩擦因数处于国际铁路联盟标准(UIC)控制范围内。当摩擦压力为0.5MPa时,摩擦因数的变化趋势与定速摩擦条件有良好的相似性。当摩擦压力为0.75MPa时,随摩擦速度降低,摩擦因数增加。产生这一差别的原因在于温度条件的不同。在惯性制动条件下,摩擦压力增加导致摩擦温度显著增加,低速高温的摩擦条件有利于提高摩擦面上微凸体间的啮合程度,使摩擦因数在低摩擦速度时明显增加。

3) 采用定速摩擦实验方式可以模拟惯性摩擦实验条件,但测得的摩擦因数略高,原因在于定速摩擦实验时,表面组织在各道次间停顿期的氧化增加了第三体中的氧化物含量。

REFERENCES

[1] RAISON J. Les materiaux de freinage[J]. Revue Generales Des Chemins De Fer, 1991(7/8): 27?36.

[2] COPIN, R. Braking tests on a reduced-scale test bench with a disc-pad couple used on the TGV-PBKA[C]// Proceedings of JEF1998. Lille: European Conference on Braking, 1998: 141?150.

[3] 高红霞, 刘建秀, 朱茹敏. 铜基粉末冶金列车闸瓦材料的摩擦磨损性能研究[J]. 材料科学与工程学报, 2005, 23(6): 871?874.

GAO Hong-xia, LIU Jian-xiu, ZHU Ru-min. Study on friction wear property of train brake materials by copper-based powder metallurgy[J]. Journal of Materials Science & Engineering, 2005, 23(6): 871?874.

[4] 白同庆, 王秀飞, 钟志刚, 李东生. 摩擦组元对粉末冶金摩擦材料摩擦性能的影响[J]. 粉末冶金材料科学与工程, 2006, 11(6): 345?348.

BAI Tong-qing, WANG Xiu-fei, ZHONG Zhi-gang, LI Dong-sheng. Effects of friction components on friction properties of powder metallurgy friction materials[J]. Materials Science and Engineering of Powder Metallurgy, 2006, 11(6): 345?348.

[5] 姚萍屏, 熊 翔, 李世鹏, 陈 洁, 黄伯云. Fe及SiO2对铜基刹车材料摩擦磨损性能的影响机制[J]. 摩擦学学报, 2006, 26(5): 478?483.

YAO Ping-ping, XIONG Xiang, LI Shi-peng, CHEN Jie, HUANG Bai-yun. Friction and wear behavior and mechanism of Fe and SiO2 in Cu-based P/M friction material[J]. Tribology, 2006, 26(5): 478?483.

[6] 林有希, 高诚辉, 黄健萌, 林 伟. 树脂基混杂纤维汽车制动材料的研制[J]. 汽车工程, 2005, 27(5): 612?614.

LIN You-xi, GAO Cheng-hui, HUANG Jian-meng, LIN Wei. The development of multi-fibers reinforced resin-based brake composites[J]. Automotive Engineering, 2005, 27(5): 612?614.

[7] 苏 堤, 罗 成, 潘运娟. 树脂基汽车复合摩擦材料的磨损机理[J]. 粉末冶金材料科学与工程, 2007, 12(4): 221?224.

SU Di, LUO Cheng, PAN Yun-juan. Wear mechanisms of a resin-based semi-metallic friction material for automotive[J]. Materials Science and Engineering of Powder Metallurgy, 2007, 12(4): 221?224.

[8] 刘君武, 吕 珺, 王建民, 汤文明, 郑治祥. 微量SiC 颗粒增强铁基合金的摩擦磨损性能研究[J]. 材料热处理学报, 2006, 27(1): 16?19.

LIU Jun-wu, L? Jun, WANG Jian-min, TANG Wen-ming, ZHENG Zhi-xiang. Study on tribological properties of sintered ferrous alloys reinforced by SiC particles[J]. Transactions of Materials and Heat Treatment, 2006, 27(1): 16?19.

[9] 符 蓉, 宋宝韫, 高 飞, 王延辉. Cu-SiO2烧结材料中第三体对摩擦磨损性能的影响[J]. 材料研究学报, 2008, 22(1): 31?36.

FU Rong, SONG Bao-yun, GAO Fei, WANG Yan-hui. Effects of SiO2 on the formation of third bodies in friction[J]. Chinese Journal of Materials Research, 2008, 22(1): 31?36.

[10] ERIKSSON M, JACOBSON S. Tribological surfaces of organic brake pads[J]. Tribology International, 2000, 33: 817?827.

[11] BERTHIER Y. Materials, mechanisms and practice[M]. Gwidon Stachowiack: Wiley, 2005: 291?316.

[12] BERTTHIER Y. Background on friction and wear, Lemaitre handbook of materials behavior models[M]. San Diego: Academic Press, 2001: 676?699.

[13] DESCARTES S, BERTHIER Y. Rheology and flows of solid third bodies: background and application to an MoS1.6 coating[J]. Wear, 2002, 252: 546?556.

[14] 钟志刚, 邓海金, 李 明, 李东生. Fe含量对Cu基金属陶瓷摩擦材料摩擦磨损性能的影响[J]. 材料工程, 2002(8): 17?23.

ZHONG Zhi-gang, DENG Hai-jin, LI Ming, LI Dong-sheng. Effects of Fe content on friction and wear properties of Cu-ceramet friction materials[J]. Journal of Materials Engineering, 2002(8): 17?23.

[15] 姚萍屏, 熊 翔, 李世鹏, 陈 洁, 黄伯云. 合金元素锌/镍对铜基粉末冶金刹车材料的影响[J]. 润滑与密封, 2006(4): 1?3.

YAO Ping-ping, XIONG Xiang, LI Shi-peng, CHEN Jie, HUANG Bo-yun. The Effects of alloy elements Zn/Ni on the properties of copper-based brake materials[J]. Lubrication Engineering, 2006(4): 1?3.

基金项目:国家高技术研究发展计划资助项目(2006AA03Z515);国家自然科学基金资助项目(50375025)

收稿日期:2007-10-25;修订日期:2008-04-11

通讯作者:高 飞,教授;电话:0411-84109429;传真:0411-84648572;E-mail: gaofei@djtu.edu.cn

`(编辑 龙怀中)