文章编号:1004-0609(2013)S1-s0081-05

TiNi形状记忆合金的冷轧非晶化行为

李君涛,崔 跃,周 瑾,杨 华,缪卫东,朱 明

(北京有色金属研究总院,有研亿金新材料股份有限公司,北京 102200)

摘 要:为研究冷轧对TiNi形状记忆合金性能的影响,采用差示扫描量热仪(DSC)和X线衍射(XRD)对不同冷轧变形量下TiNi形状记忆合金的非晶化行为进行研究,并利用硬度测试方法研究TiNi形状记忆合金非晶晶化对硬度的影响。结果表明:在第一次加热曲线上,在低温(293~373 K)范围内没有相应的马氏体相变吸热峰,却在(623~693 K)温度范围内有1个明显的放热峰,该放热峰对应着非晶区域的晶化过程,这与XRD结果相一致。研究发现变形量超过30%以后出现非晶化现象,冷轧非晶的体积随变形量的增加而增大,其中冷轧60%的TiNi合金的非晶体积分数可达30%左右。且在623 K左右发生非晶晶化,这与硬度测试结果相一致。

关键词:形状记忆合金;冷轧;差示扫描量热仪;非晶化;

中图分类号:TG139.6 文献标志码:A

Amorphisation behavior of TiNi shape memory alloys during cold rolling

LI Jun-tao, CUI Yue, ZHOU Jin, YANG Hua, MIAO Wei-dong, ZHU Ming

(GRIKIN Advanced Materials Co., Ltd., General Research Institutes for Nonferrous Metals, Beijing 102200, China)

Abstract: In order to investigate the effect of cold rolling on properties of TiNi shape memory alloy, the amorphization behavior of TiNi shape memory alloys under different deformation was studied by differential scanning calorimeter (DSC) and X-ray diffraction(XRD). The effect of recrystallization with different heat treatment was studied by hardness test. Results show that the reverse martensitic transformation peak is not observed during the first heating at the rate of 20 K/min in the as-rolled samples, but one exothermic peak is observed at 623-693 K, which is associated with the amorphous crystallization process. And that mechanical amorphisation by cold rolling occurs above 30% deformation and the volumetric fraction of amorphous increasing with deformation increasing, in which with the volumetric fraction of 30% amorphous in the 60% rolled deformation sample. And that the amorphous regions recrystallise at 623 K, which agree with hardness test.

Key words: shape memory alloy; cold rolling; differential scanning calorimeter (DSC); amorphisation

形状记忆合金因其室温下具有较好的非晶化性能而引起材料学者的广泛关注[1-3],由美国学者KOIKE等[4]首次提出。当时,观察到变形量为30%~60%冷轧试样的微观结构有纳米尺寸的晶体和非晶相,且在二者之间存在的位错高达1013~1014/cm2密度,但并未进行深入的研究。随着大变形技术的不断发展,近年来国内外学者利用不同变形手段对形状记忆合金的非晶化进行一些初步的探索。例如,等通道角挤压[5-7]、高压扭转[8-9]、离子注入[10]、喷丸[11]、剪切变形和冷轧[12-16]等等。由于非晶态的自由能比平衡态的高,在热力学上是非平衡的亚稳态结构,有向平衡态转变的趋势,在一定的条件下,会发生非晶结构向晶态的转变即发生晶化。尤其值得关注的是,这种方法通过冷轧非晶化后的随即热处理过程来达到纳米晶级别,可获得非常有用的大块状态,而非薄膜状态,其相变行为、力学特性等都非常值得进行研究。以往非晶TiNi合金研究中只是注重材料非晶结构的研究,对非晶晶化后的性能变化的研究较少。为通过非晶晶化控制方法达到优化组织结构的目的,对非晶晶化过程的研究又提出更进一步的要求。

本文作者将选取TiNi合金为研究对象,综合采用差热分析、X线衍射来分析该材料非晶及其晶化过程的相关规律,进而通过硬度测试来进一步确认非晶及其晶化对性能的影响。

1 实验

将直径为12 mm的Ti50%Ni合金棒在真空炉经873 K退火1 h,随后放入液氮中以确保试样处于完全马氏体状态,然后在室温下进行变形量为15%、20%、30%、35%、40%和60%的冷轧变形。采用Netzsch DSC 2004 Phoenix 型示差扫描热分析仪对冷轧TiNi合金非晶晶化过程进行DSC测试,所用的加热速率分别为20 K/min,整个热分析测量过程均在高纯氩气保护下进行。利用BDX-3200X型X衍射分析仪对不同冷轧变形量的试样进行X线衍射分析,采用Cu Kα靶,扫描速率为8(°)/s。在432 SVD维氏硬度计上测试硬度,加力98 N,作用时间为30 s。

2 结果与分析

2.1 热效应分析

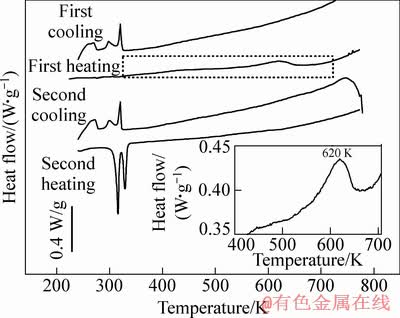

图1所示为冷轧60%TiNi合金非晶晶化的DSC结果。由图1可见:2次DSC加热曲线明显不同。第一次加热曲线上,在低温(293~373 K)范围内没有相应的马氏体相变吸热峰,并不意味着试样中的马氏体丧失逆转变为母相的能力,而是冷轧缺陷和变形诱导结构对M/P界面有着强烈的钉扎作用,从而作为约束使得马氏体的逆相变扩展到一个相当大温度范围[17],几乎在DSC观察不到的缘故。值得注意的是,在(623~693 K)温度范围内有1个明显的放热峰,其中小图为虚线框的放大图,其放热峰峰值温度为620 K。根据EWERT等[8, 18]的研究结果,该放热峰对应着冷轧60%下TiNi合金中非晶区域的晶化过程,这可以从XRD结果得到进一步验证。

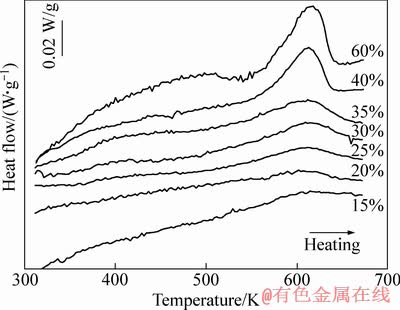

图2所示为不同冷轧变形量下TiNi合金非晶晶化的DSC曲线。可以看到,随着变形量的增加晶化峰的面积逐渐增大,表明冷轧致非晶的体积也随变形量的增加而增大。

图1 冷轧60%下TiNi合金非晶晶化的DSC曲线

Fig. 1 DSC curves of amorphous-to-nanocrystalline in 60% rolled sample

图2 不同冷轧变形量下TiNi合金冷轧非晶晶化的DSC曲线

Fig. 2 DSC curves of amorphous-to-nanocrystalline after different cold-rolling deformed levels

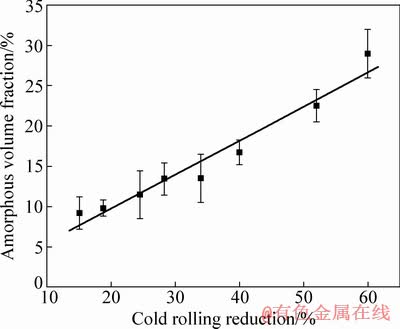

EWERT等[5]通过DSC和TEM测量观察非晶的体积分数,根据其研究结果,可以利用完全非晶合金的晶化热焓ΔH≈-1 000 J/mol作为基准,估算冷轧变形造成非晶的体积分数结果如图3所示。由图3可见:冷轧60%的TiNi合金的非晶体积分数达30%左右。

2.2 XRD分析

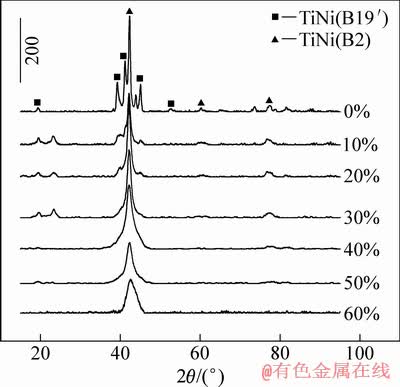

为确定TiNi合金冷轧变形量对非晶化的影响,从微观结构上进一步确认TiNi合金非晶化的存在,这里对不同变形量的TiNi合金进行X射线衍射分析。图4 所示为不同变形量的TiNi合金中的衍射谱。X射线衍射的结果表明:在未经冷轧变形的样品中,样品主要由马氏体相(B19′)和母相(B2)两相组成。在冷轧变形量超过30%的样品X射线衍射结果中出现峰的宽化现象,结合国内外学者的研究结果[12-15],表明冷轧大变形造成样品晶粒细化,形成部分非晶。

图3 TiNi合金非晶体积分数与冷轧变形量的关系

Fig. 3 Volumetric fraction of amorphous versus different cold-rolling deformed levels of TiNi alloy

图4 TiNi合金不同冷轧变形量后的X射线衍射图谱

Fig. 4 X-ray diffraction(XRD) patterns after different cold-rolling deformed levels

2.3 维氏硬度分析

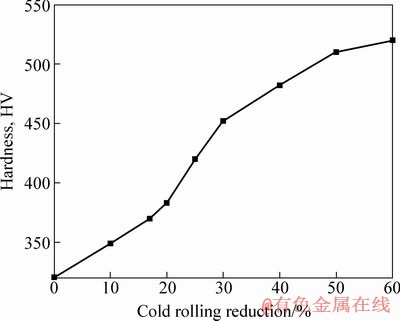

由图5可知,随冷轧变形量的增加,板材硬度值持续增加,当变形量超过40%时,硬度增速变缓。当冷轧压下量增加到60%时,硬度增加200,平均每增加1%轧制压下量,硬度近似增加3.3。

图5 不同冷轧变形量下TiNi合金的维氏硬度

Fig. 5 HV hardness of TiNi alloys after different cold-rolling deformed levels

图6 不同温度退火后TiNi合金的硬度变化

Fig. 6 Change of hardness of TiNi alloy after different annealing temperatures

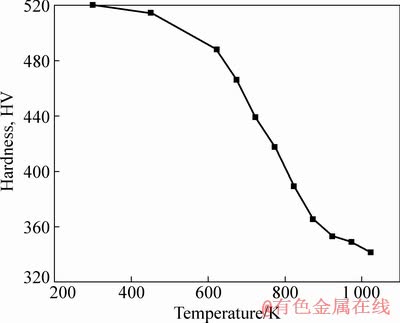

取60%冷轧量下板材进行不同温度退火后淬水测定硬度值。从图6可知,当热处理温度为450 K时,硬度较冷轧态略有下降。随热处理温度升高,板材硬度缓慢下降,当热处理温度达到623 K时,硬度值急剧下降,在873 K温度以上继续升高退火温度,硬度缓慢下降。与DSC结果比较可知,冷轧非晶发生晶化的开始温度约为620 K,进行充分再结晶的温度约为873 K。

KOIKE等[4]发现在室温下冷轧量达60%时Ti-50.8Ni合金内部发生了晶体-非晶的转变。这个也被EWERT等[12-13, 18]所证实。在TiNi合金中通过冷轧所导致的非晶化过程如下:第一阶段,(~20%)孪晶细化和其导致的位错密度迅速增加;第二阶段, (~40%)在稳定化的母相中主要由于固着位错引起的位错密度的增加,一些局部非晶化也可能发生;第三阶段,剪切带的形成导致非晶带的形成。

通过对位错密度的详细分析,发现在非晶的状态区域附近,位错密度高达1013~1014/cm2,这与再结晶能量是等效的。为什么位错能堆积如此高的高密度呢? NAKAYAMA等[8]认为是由于孪晶界的阻碍。TSUCHIYA等[1]同样认为孪晶细化导致在马氏体中位错密度显著增加,其原理是奥罗万-泰勒方程S=KbpL,其中:S是应变,K为取向依赖常数,p位错密度,b是柏氏矢量,L为位错平均滑移距离。该方程表明当滑移距离一定时,为得到某一应变,位错密度必须增加。具体过程如下:冷轧-孪晶细化-位错滑移距离减少-根据奥罗万-泰勒方程知位错密度增加-最后导致维氏硬度增加。

DSC测量和TEM结果表明,严重的冷轧变形使试样的马氏体转变和母相稳定化受到抑制。也有一个可能是在马氏体中位错的柏氏矢量与母相中的不同,马氏体中的位错在母相中作为固着位错保存下来,这些位错也能减小位错滑移距离。 因而他们认为,非晶化的主要驱动力是位错堆积。 此外,因为非晶的状态出现在剪切带中,他们推断非晶的状态是由于位错密度相关的剪切不稳定造成的。

KOIKE等[4]发现在室温下Ti-50.8%Ni合金冷轧量达60%时合金内部发生晶体-非晶的转变,退火处理导致试样发生晶化、再结晶以及晶粒长大等现象。这个现象也被NAKAYAMA等[13]和EWERT等[18]随后所证实。综上所述,结合XRD谱和DSC结果,对于本研究中冷轧超过30%的TiNi试样,在试样内部出现非晶。冷轧60%的TiNi试样随后的热处理过程造成试样的非晶晶化和再结晶,这是造成硬度-温度关系变化的主要原因。

3 结论

1) 冷轧60% TiNi合金2次DSC加热曲线明显不同。第一次加热曲线上,在低温(293~373 K)范围内没有相应的马氏体相变吸热峰,这并不意味着试样中的马氏体丧失逆转变为母相的能力,而是冷轧缺陷和变形诱导结构对M/P界面有着强烈的钉扎作用,从而作为约束使得马氏体的逆相变扩展到一个相当大的温度范围,几乎在DSC观察不到的缘故。值得注意的是,在623~693 K温度范围内有1个明显的放热峰,其放热峰峰值温度为620 K。该放热峰对应着冷轧60%TiNi合金中非晶区域的晶化过程,这可以从XRD结果得到进一步验证。

2) 随着变形量的增加晶化峰的面积逐渐增大,表明冷轧致非晶的体积也随变形量的增加而增大。冷轧60% TiNi合金的非晶体积分数达30%左右。

3) 随冷轧变形量的增加,硬度值持续增加,不同温度退火后淬水测定硬度值与DSC结果比较可知,冷轧非晶发生晶化的开始温度约为620 K,进行充分再结晶的温度约为873 K。

REFERENCES

[1] TSUCHIYA K, INUZUKA M, TOMUS D. Martensitic transformation in nanostructured TiNi shape memory alloy formed via severe plastic deformation[J]. Materials Science and Engineering A, 2006, 438: 643-648.

[2] JIANG Shu-yong, ZHANG Yan-qiu, ZHAO Li-hong, ZHENG Yu-feng. Influence of annealing on NiTi shape memory alloy subjected to severe plastic deformation[J]. Intermetallics, 2013, 32: 344-351.

[3] PUSHIN V G, STOLYAROV V V, VALIEV R Z. Nanostructured TiNi-based shape memory alloys processed by severe plastic deformation[J]. Materials Science and Engineering A, 2005, 410/411: 386-389.

[4] KOIKE J, PARKIN D M, NASTASI M. Crystal-to-amorphous transformation of NiTi induced by cold rolling[J]. J Mater Res, 1990, 5: 1414-1418.

[5] LI Z, CHENG X. Deformation temperature and postdeformation annealing effects on severely deformed TiNi alloy by equal channel angular extrusion[J]. Journal of University of Science and Technology Beijing: Mineral, Metallurgy, Material, 2007, 14(6): 533-537.

[6] LI Z, XIANG G, CHENG X. Effects of ECAE process on microstructure and transformation behavior of TiNi shape memory alloy[J]. Materials & Design, 2006, 27(4): 324-328.

[7] KHMELEVSKAYA I Y, PROKOSHKIN S D, TRUBITSYNA I B. Structure and properties of Ti-Ni-based alloys after equal-channel angular pressing and high-pressure torsion[J]. Materials Science and Engineering A, 2008, 481/482: 119-122.

[8] SERGUEEVA A V, SONG C, VALIEV R Z. Structure and properties of amorphous and nanocrystalline NiTi prepared by severe plastic deformation and annealing[J]. Materials Science and Engineering A, 2003, 339(1/2): 159-165.

[9] PROKOSHKIN S D, KHMELEVSKAYA I Y, DOBATKIN S V, TRUBITSYNA I B, TATYANIN E V, STOLYAROV V V, PROKOFIEV E A. Alloy composition, deformation temperature, pressure and post-deformation annealing effects in severely deformed Ti-Ni based shape memory alloys[J]. Acta Materialia, 2005, 53(9): 2703-2714.

[10] MOINE P, POPOOLA O, VILLAIN J P. Wear behaviour of N+ implanted NiTi alloys[J]. Scripta Metallurgica, 1986, 20(3): 305-310.

[11] GRANT D M, GREEN S M, WOOD J V. The surface performance of shot peened and ion implanted NiTi shape memory alloy[J]. Acta Metallurgica et Materialia, 1995, 43(3): 1045-1051.

[12] NAKAYAMA H, TSUCHIYA K, UMEMOTO M. Crystal refinement and amorphisation by cold rolling in TiNi shape memory alloys[J]. Scripta Materialia, 2001, 44(8/9): 1781-1785.

[13] NAKAYAMA H, TSUCHIYA K, LIU Z G. Process of nanocrystallization and partial amorphization by cold rolling in TiNi[J]. Materials Transactions, 2001, 42(9): 1987-1993.

[14] PROKOSHKIN S D, BRAILOVSKI V, INAEKYAN K E. Structure and properties of severely cold-rolled and annealed Ti-Ni shape memory alloys[J]. Materials Science and Engineering A, 2008, 481/482: 114-118.

[15] KOIKE T, WATANABE S, HOSHINO M. Dynamical study of spatio-temporal structural fluctuations in the intermetallic compound nickel-titanium during radiation-induced crystalline-to-amorphous transformation[J]. Materials Transactions, 2002, 43(7): 1716-1718.

[16] 冯昭伟, 米绪军, 王江波, 袁志山, 缪卫东, 周 瑾. 冷轧变形量及退火温度对Ni47Ti44Nb9板材织构和性能的影响[J]. 中国有色金属学报, 2013, 23(3): 756-764.

FENG Zhao-wei, MI Xu-jun, WANG Jiang-bo, YUAN Zhi-shan, MIAO Wei-dong, ZHOU Jin. Influence of cold rolling reduction and annealing temperature on texture and properties of Ni47Ti44Nb9 plate[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 756-764.

[17] ZHENG Y J, CUI L S. Martensite fraction-temperature diagram of TiNi wires embedded in an aluminum matrix[J]. Intermetallics, 2004, 12(12): 1305-1309.

[18] EWERT J C, BOEHM I, PETER R. The role of the martensite transformation for the mechanical amorphization of NiTi[J]. Acta Materialia, 1997, 45: 2197-2206.

(编辑 邓履翔)

基金项目:支持实验室经济发展加快产学研一体化科技创新课题(CP20110117)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:李君涛,高级工程师,博士;电话:010-80103388-8356;E-mail:ljtdxr@sohu.com