断裂韧性和扫描电镜对导航陀螺仪转子体材料失效的分析

来源期刊:中南大学学报(自然科学版)1982年第2期

论文作者:黄建忠 童子锜

文章页码:81 - 92

关键词:应变断裂韧性; 扫描电镜; 陀螺仪转子; 材料失效; 重合金; 合金材料; 转子体; 表面裂纹; 断裂力学; 粘结相

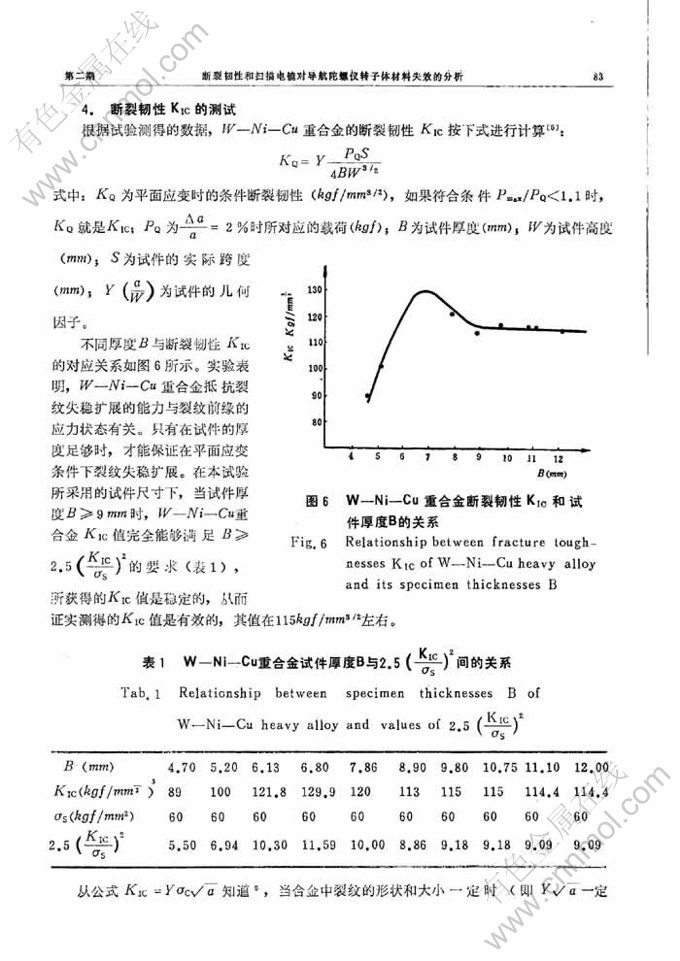

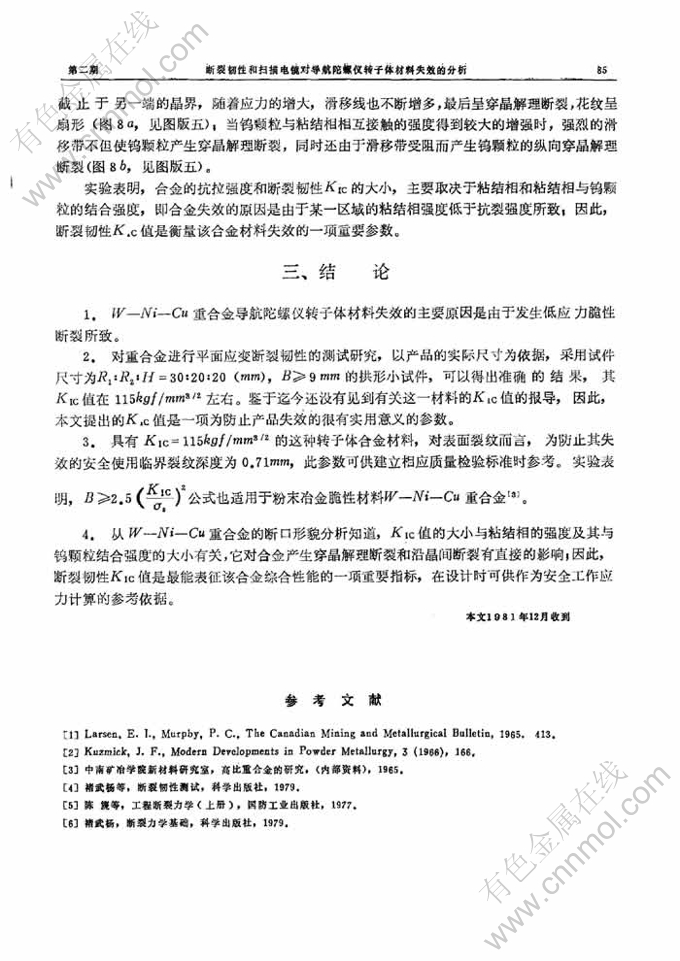

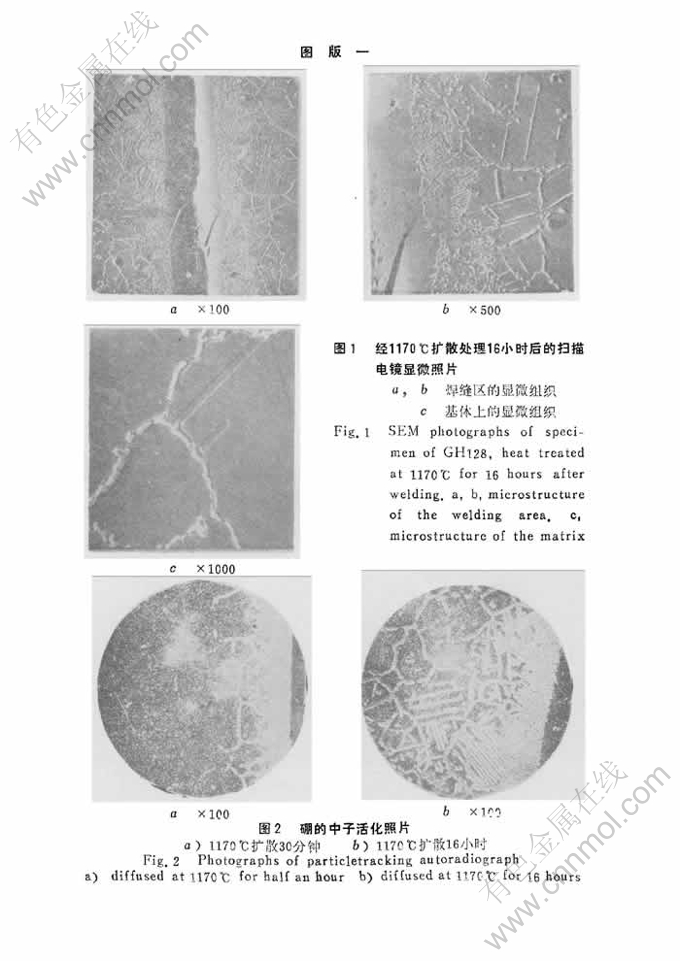

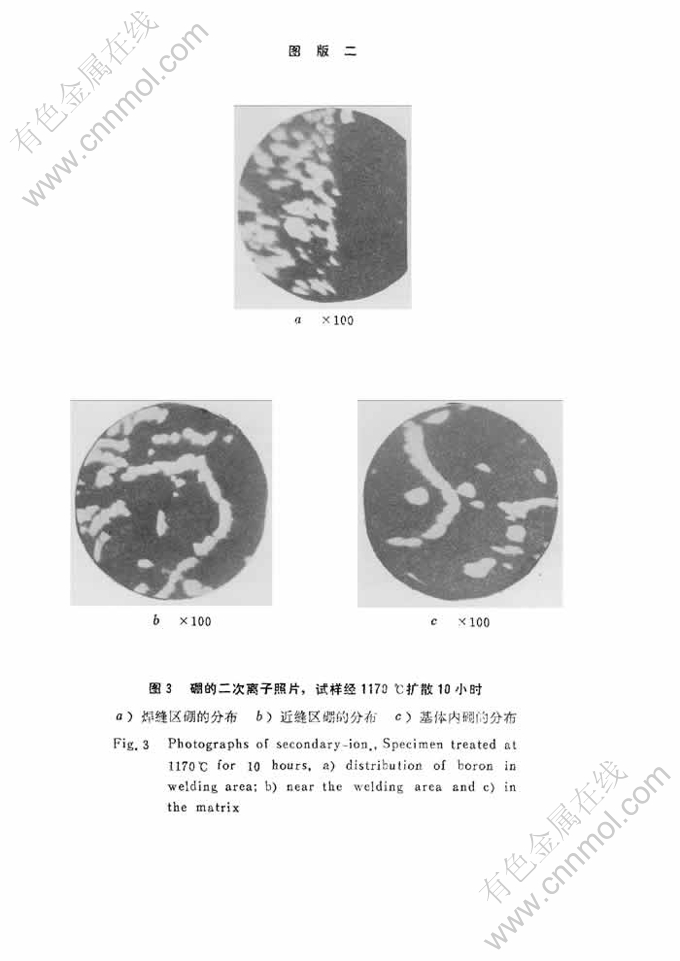

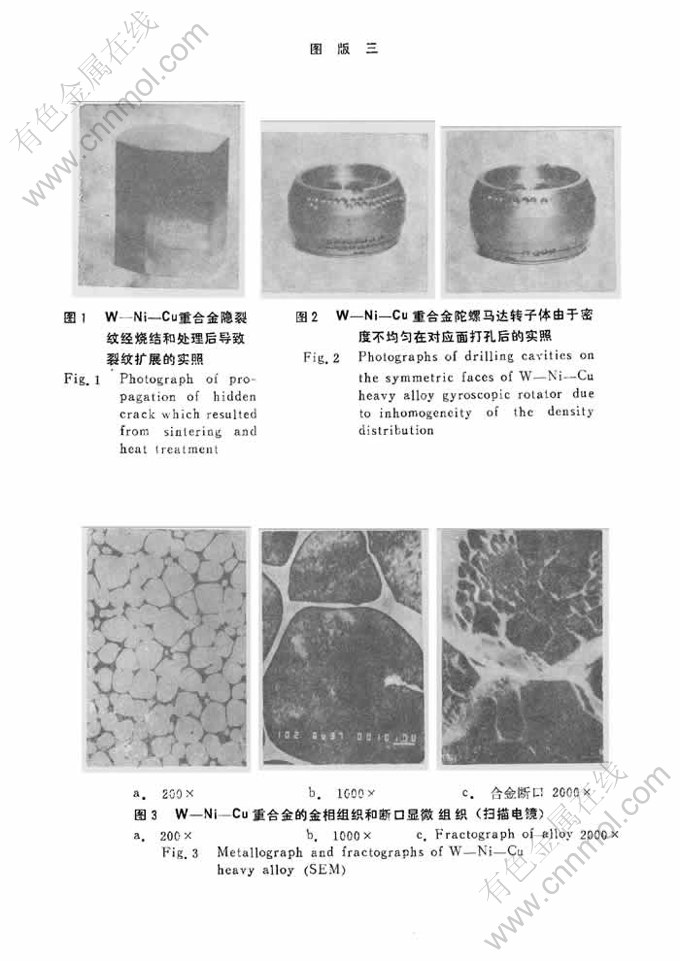

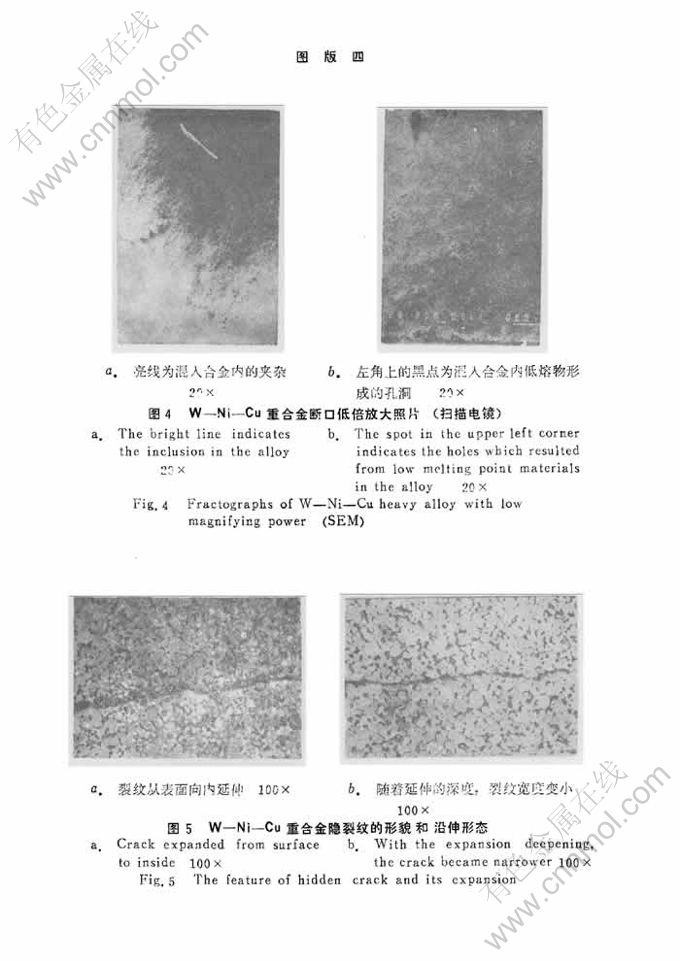

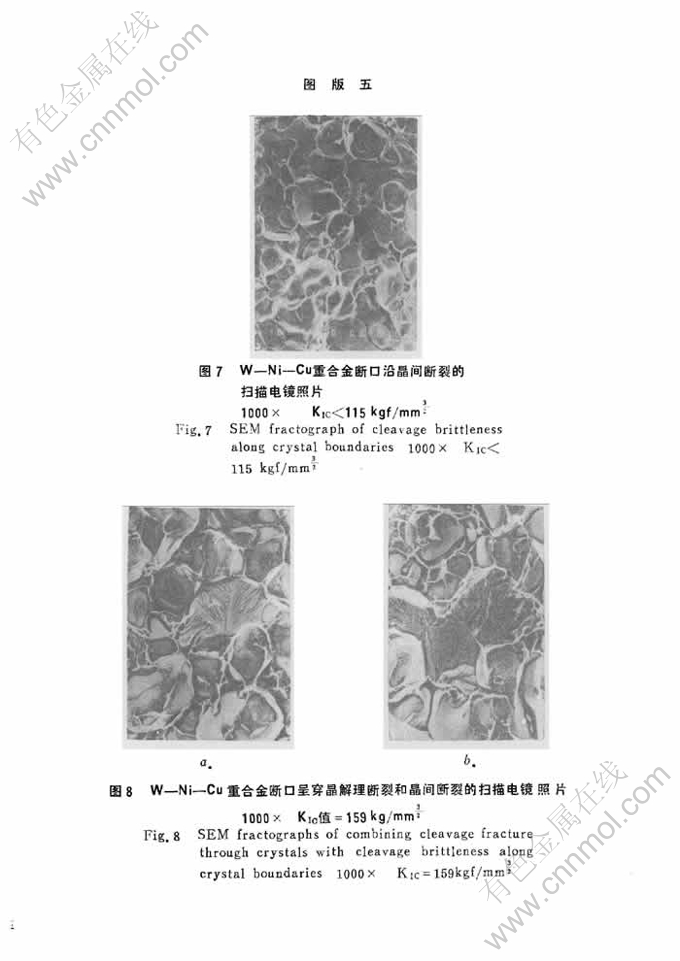

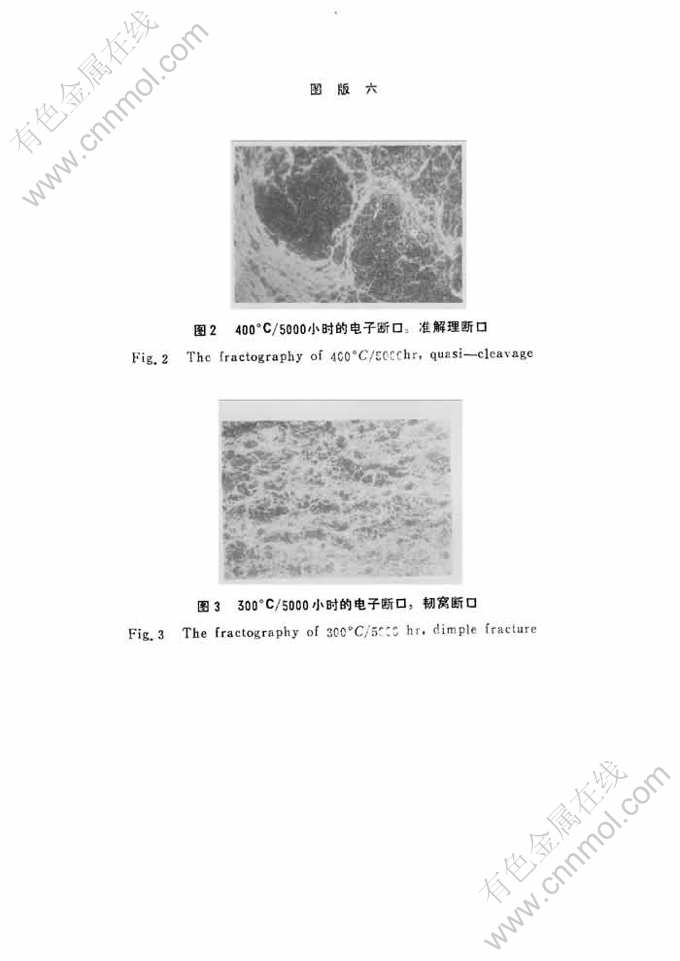

摘 要:本文应用断裂力学和扫描电镜的分析方法,对曾发生的脆断失效事故,进行了综合的研究和分析。结果表明,陀螺仪转子体材料失效的主要原因,是由于合金密度的不均匀性和内部存在隐裂纹所致。当马达动平衡高速旋转时产生共振、疲劳,致使裂纹迅速失稳扩展,造成低应力脆性飞裂。实验表明,断裂韧性KIC值是表征该种合金综合性能的一项重要指标,也是衡量材料失效的重要参数。

Abstract: The W--Ni--Cu heavy-alloy is an ideal material for the gyroscopicrotator of the guiding system and pilot apparatus, which has been widelyused for inertial guide gyroscope and other gyros in the past ten ycars. Inrecent years, however, some brittle-fly-rupture accidents took place sud-denly at the beginning stage of the dynamic balance of the gyroscope rotatingat a high rotary rate. A study and a synthesis analysis of these failures havebeen made by means of fracture mechanics, analysis and SEM observation inthis work. The investigation results showed that the main reasons for thefailure of the gyroscopic rotator material were due to the inhomogeneity ofthe density distribution and the internal hidden cracks (including crack-like-inclusions and micropores) of the material. Resonance and fatigue tookplace, when the gyroscopic motor rotated at a high velocity during dynamicbalance so that the cracks became unstable and propagated, and then re-sulted in a low-stress brittle-fly-rupture. Experimental results indicatedthat the fracture toughness KIC is an important parameter showing the syn-thesis property of the alloy and is an important factor for the material fail-ure estimate as well.