Influences of hot stamping parameters on mechanical properties and microstructure of 30MnB5 and 22MnB5 quenched in flat die

来源期刊:中南大学学报(英文版)2018年第4期

论文作者:王宝雨 慕延宏 周靖 黄旭 李俊玲

文章页码:736 - 746

Key words:high strength boron steel; mechanical properties; microstructure; hot stamping parameter

Abstract: The influences of hot stamping parameters such as heating temperature, soaking time, deformation temperature and cooling medium on the phase transformation, microstructure and mechanical properties of 30MnB5 and 22MnB5 are investigated and analyzed in this work. The quenching experiment, tensile testing, hardness measurement and microstructure observation were conducted to obtain the mechanical and microstructural data. The results indicate that 30MnB5 possesses a higher tensile strength but a lower elongation than 22MnB5, if hot stamped at the same process parameter. The tensile strength and hardness of the hot stamped specimens decrease under inappropriate heating conditions for two reasons, insufficient austenitization or coarse austenite grains. The austenitic forming rate of 30MnB5 is higher than that of 22MnB5, because more cementite leads to higher nucleation rate and diffusion coefficient of carbon atom. More amount of fine martensite forms under the higher deformation temperature or the quicker cooling rate.

Cite this article as: MU Yan-hong, WANG Bao-yu, ZHOU Jing, HUANG Xu, LI Jun-ling. Influences of hot stamping parameters on mechanical properties and microstructure of 30MnB5 and 22MnB5 quenched in flat die [J]. Journal of Central South University, 2018, 25(4): 736–746. DOI: https://doi.org/10.1007/s11771-018-3778-8.

J. Cent. South Univ. (2018) 25: 736-746

DOI: https://doi.org/10.1007/s11771-018-3778-8

MU Yan-hong(慕延宏), WANG Bao-yu(王宝雨), ZHOU Jing(周靖),HUANG Xu(黄旭), LI Jun-ling(李俊玲)

School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Abstract: The influences of hot stamping parameters such as heating temperature, soaking time, deformation temperature and cooling medium on the phase transformation, microstructure and mechanical properties of 30MnB5 and 22MnB5 are investigated and analyzed in this work. The quenching experiment, tensile testing, hardness measurement and microstructure observation were conducted to obtain the mechanical and microstructural data. The results indicate that 30MnB5 possesses a higher tensile strength but a lower elongation than 22MnB5, if hot stamped at the same process parameter. The tensile strength and hardness of the hot stamped specimens decrease under inappropriate heating conditions for two reasons, insufficient austenitization or coarse austenite grains. The austenitic forming rate of 30MnB5 is higher than that of 22MnB5, because more cementite leads to higher nucleation rate and diffusion coefficient of carbon atom. More amount of fine martensite forms under the higher deformation temperature or the quicker cooling rate.

Key words: high strength boron steel; mechanical properties; microstructure; hot stamping parameter

Cite this article as: MU Yan-hong, WANG Bao-yu, ZHOU Jing, HUANG Xu, LI Jun-ling. Influences of hot stamping parameters on mechanical properties and microstructure of 30MnB5 and 22MnB5 quenched in flat die [J]. Journal of Central South University, 2018, 25(4): 736–746. DOI: https://doi.org/10.1007/s11771-018-3778-8.

1 Introduction

Increasing advanced high strength steels are widely used to produce parts of body-in-white (BIW) under the pressing needs of light weight and passenger safety. Boron steels are very popular to be formed anti-collision parts because of its excellent mechanical properties. One of the most common boron steels is 22MnB5 steel, and the full martensitic parts have the tensile strength of about 1500 MPa and elongation of no less than 5% [1–3]. New grades of boron steel containing more carbon, such as 27MnCrB5, 30MnB5, 37MnB4 and 38MnB5, have been designed to meet the requirement for higher strength [4, 5]. Among these steels, the boron steel 30MnB5 is regarded as the most promising material of updating 22MnB5 because of its potential of mass production.

GULER et al [6] investigated effects of heating temperature and dwell time on the microstructural and mechanical properties of quenchable 30MnB5 steel and determined the optimum process parameters of dwell time of 15 min at 850 °C. Furthermore, they also researched the hot ductility of 30MnB5 in different temperatures, obtaining a good understanding of deformation and fracture mechanisms of 30MnB5 at elevated temperatures [7]. CHENG et al [8, 9] investigated the microstructure evolution and mechanical properties of 30MnB5 when quenched and tempered at 200–600°C, and they also characterized the orientation relationship with parent phase and the misorientation evolution of martensite variants by EBSD. Moreover, some studies focused on the wear behavior of 30MnB5 steel [10, 11], but further research on 30MnB5 applied in hot stamping process still needs to be carried out for a good prospect of application in automobile market.

Microstructure of the parts is an important factor that influences their mechanical properties. In order to obtain parts that have fine mechanical properties, some researches on the evolution of their microstructure under different process conditions have been performed [12, 13]. Two methods to simulate the hot stamping process, thermal simulation by nitrogen cooling [14, 15] and heat treatment by water quenching [16, 17], were used in past investigations. However, using these two methods is difficult to guarantee a consistent cooling rate with the real process and lack hot deformation during the experiments. LI et al [18] studied the effect of cooling path on phase transformation of 22MnB5 and found that different cooling rates resulted in different microstructures of ferrite, bainite and martensite. Furthermore, BARCELLONA et al [19] investigated the effect of plastic hot deformation on the hardness and continuous cooling transformation of 22MnB5, which indicated that the increasing degree of hot deformation results in lower hardness at the same cooling rate. Thus, it can be inferred that cooling rate and hot deformation are two crucial factors determining the mechanical properties of parts. A method considering the actual cooling rate and hot deformation of hot stamping should be adopted to investigate the effects of process parameters. This paper presents a comparative study of boron steels 30MnB5 and 22MnB5, which aims to investigate the mechanical properties and microstructure at different process parameters.

2 Experimental

2.1 Apparatus

In industrial hot stamping process, the sheet blank is austenitized first, and then formed and quenched in the die. In this study, we adopted a flat die as shown in Figure 1 to make the experiment close to the actual plant environment. The flat die mounted on the press platform consists of upper die, lower die, guide pillars and springs. The springs prevent the blank from contacting with the lower die before stamping to obtain a higher deformation temperature. The contact pressure and punch velocity are constant for all experiments, which are 3 MPa and 50 mm/s respectively.

2.2 Material and specimen

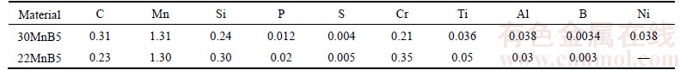

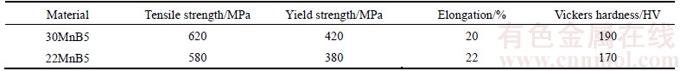

The investigated materials in this study are the hot-rolled sheets of 30MnB5 and 22MnB5 with the same thickness of 1.5 mm, which are provided by SSAB and Shougang group respectively. The chemical composition of the as-received materials is given in Table 1, and their mechanical properties are presented in Table 2. The optical micrographs of the investigated materials are shown in Figure 2, and they both consist of ferrite and pearlite.

Tensile strength, elongation and hardness are usually used to characterize the mechanical properties of materials. As shown in Figure 3, a circular plate with the diameter of 52 mm was used to simulate hot stamping process in all kinds of conditions. Three tensile specimens were cut from every circular plate after hot stamping, and the tensile strength and elongation were averaged by taking three measurements using tensile testing machine at room temperature. The hardness and microstructure specimens were respectively cut into a square with the length of 5 mm from the circular plate. The testing force of hardness was 500 N load, and an average hardness value was calculated by taking five measurements in every specimen. The microstructure specimen was rubbed with grinding papers, polished using diamond abrasive paste and etched in 3 vol% nital. The microstructure was observed and analyzed by using a scanning electron microscope.

Figure 1 Tool set and schematic diagram of flat die

Table 1 Chemical compositions of investigated 30MnB5 and 22MnB5 steels (mass fraction, %)

Table 2 Mechanical properties of as-received 30MnB5 and 22MnB5 steels

Figure 2 Optical micrographs of as-received steels:

Figure 3 Dimensions of circular plate, tensile testing specimen, hardness specimen and microstructure specimen(Unit: mm)

2.3 Experimental procedure

During hot stamping process, heating stage controls the austenitization of the heating blank and die quenching stage influences the martensitic transformation, which jointly determine the microstructure and mechanical properties of hot stamping parts. In this study, four main process parameters: heating temperature, soaking time, deformation temperature and cooling medium, were investigated by a flat die stamping. The experimental arrangements are given in Table 3.

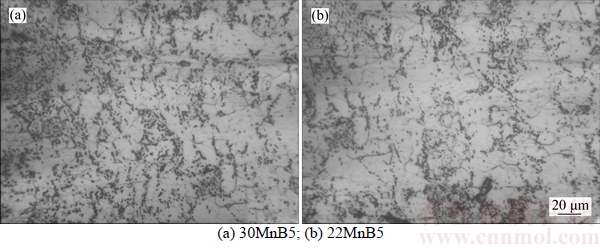

The experimental procedure is shown in Figure 4 with the following five steps.

1) Heat the circular plate to different austenitizing temperatures (800/850/900/950/ 1000°C) in a furnace.

2) Hold the circular plate at the target austenitizing temperature for different soaking time (1/3/5/10/20 min).

3) Transfer the circular plate from the furnace to the flat die and adjust the transfer time to form different deformation temperatures (700/750/800/ 850°C).

4) Clamp the die immediately with dwell time of 15 s. If the die cooling is not applied, the heating blank will be put into corresponding cooling media, which are air, oil and water, respectively.

5) Cut as-quenched specimens into different samples to perform tensile tests, hardness measurements and microstructure observations, and analyze the effect of different process parameters on mechanical properties and microstructure.

3 Results and discussion

3.1 Influence of heating temperature

Figure 5(a) shows the tensile strength and elongation of as-quenched 30MnB5 and 22MnB5 specimens at different heating temperatures. It can be seen that 30MnB5 has higher tensile strength but lower elongation than 22MnB5 at the same heating temperature. This is attributed to that the increase of carbon content increases the lattice distortion during martensite formation and decreases movement of dislocations [20]. When the heating temperature varies from 800 °C to 1000 °C, the tensile strength firstly increases and then decreases. When the heating temperature is 900 °C, the tensile strength of 30MnB5 and 22MnB5 respectively reaches the peak value of 1946 MPa and 1596 MPa. The elongation of 30MnB5 decreases from the maximum value of 11.33% to the minimum value of 8.27% with the increase of heating temperature from 800 °C to 900 °C. But it increases with increasing heating temperature within the scope of 900 °C to 1000 °C.

The variation of Vickers hardness of as- quenched specimens with the heating temperature is given in Figure 5(b). It can be seen that, the hardness of these two steels firstly increases with the heating temperature increasing, but it starts to decrease with the increasing temperature when the heating temperature exceeds certain value. When the temperature is 900 °C, the hardness respectively reaches the maximum of 601 HV and 471 HV.

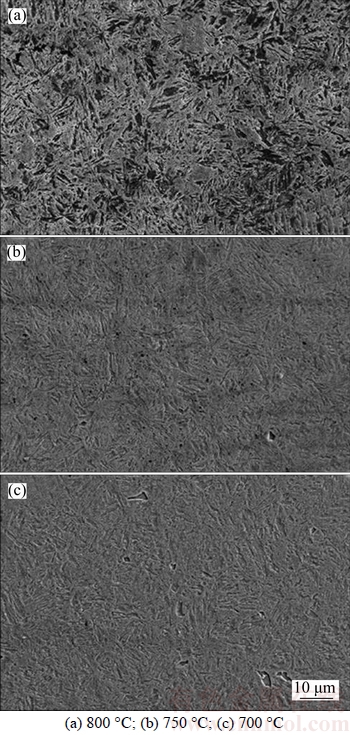

The microstructures of as-quenched specimens heated to different temperatures are given in Figure 6. It can be found that the microstructure consists of partial martensite and a large number of ferrite at 800 °C, and the existence of ferrite results in the decline of tensile strength, but it improves ductility [21]. At the low heating temperature, a part of ferrite can not be transformed to austenite. When this kind of heating specimen is quenched rapidly,the austenite is transformed to martensite, which is surrounded by untransformed ferrite, so mixed microstructure consisting of ferrite and martensite is formed. The microstructure of the specimen heated to 850 °C consists of more martensite, but still exists a few ferrite, which indicates that the specimen is still not fully austenitized at 850 °C. For the hot stamping with tailored properties, lower heating temperature can be chosen to obtain low tensile strength region with partial ferrite microstructure. When heated to 950 °C and 1000 °C, the specimen has been fully austenitized, which consists of full lath martensite. Table 4 shows the quantitative metallographic data of 30MnB5 specimens heated at different temperatures. The ferrite fraction is respectively 10.2% and 3.4% at 800 °C and 850 °C, while the microstructure consists of full martensite when the specimen is heated at above 900 °C. Furthermore, it is interesting that the martensite becomes much coarser with the increasing heating temperature, which leads to the decline of tensile strength and hardness. The average martensite length increases from 2.2 μm to 9.8 μm when the heating temperature varies from 800 °C to 1000 °C. In order to obtain the automobile parts with high strength and fine martensite microstructure, the heating temperature should be chosen about 900 °C.

Table 3 Experimental arrangements for flat die hot stamping tests

Figure 4 Schematic illustrations of experimental procedure

Figure 5 Tensile strength and elongation (a) and Vickers hardness (b) of as-quenched specimens at different heating temperatures

Figure 6 Microstructures of as-quenched 30MnB5 specimens at different heating temperatures:

Table 4 Quantitative metallographic data of 30MnB5 specimens at different heating temperatures

3.2 Influence of soaking time

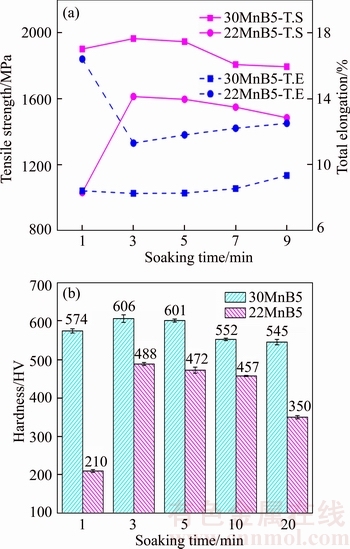

The variation of the tensile strength and elongation of 30MnB5 and 22MnB5 with the soaking time is shown in Figure 7(a). It can be seen that the tensile strength first increases and then decreases with the increasing soaking time. When kept warm at 900 °C for 3 min, the tensile strength of these two steels reaches the maximum of 1964 MPa and 1612 MPa. The elongation has opposite variation tendency with the tensile strength at different soaking time. It can be found from Figure 7(b) that the variation of hardness with the increasing soaking time is similar to the variation of the tensile strength. The maximum hardnesses of HV 606 and HV 488 occur when the soaking time is 3 min. When the soaking time is 1 min, the hardness of 30MnB5 is HV 574,about HV 32 less than the maximum, but the hardness of 22MnB5 is just HV 210, about HV 278 less than the maximum.

The microstructures of as-quenched specimens of 30MnB5 and 22MnB5 at different soaking time are shown in Figure 8. When the soaking time is 1 min, the 30MnB5 microstructure is basically full martensite; however, the microstructure of 22MnB5 consists of a mass of undissolved ferrite and a small amount of martensite. This is because that the amount of cementite increases with increasing carbon content, which makes the phase interfacial area larger, leading to higher nucleation rate. Meanwhile, the increase of cementite decreases the diffusion distance of carbon atom, which enlarges the diffusion coefficient of carbon and iron atoms. The both factors above increase the forming velocity of austenite, so 30MnB5 can be fully austenitized during 1 min. On the contrary, the original ferrite of 22MnB5 has not fully transformed to the martensite due to insufficient soaking time. The microstructure of as-quenched specimen soaked for above 3 min consists of complete martensite, but the martensite morphology becomes much bulkier with increasing soaking time resulting from the primary austenite grain size growth, which causes decrease of tensile strength and hardness. Moreover, the material possesses smaller flow stress and higher forming limit when the morphology of austenite is finer. So soaking time of 3–5 min should be chosen in industrial hot stamping process taking both formability and mechanical property into consideration.

Figure 7 Tensile strength and elongation (a) and Vickers hardness (b) of as-quenched specimens at different soaking time

Figure 8 Microstructures of as-quenched specimens of 30MnB5 and 22MnB5 at different soaking time:

3.3 Influence of deformation temperature

During the actual hot stamping process, the sheet is heated and kept warm in a furnace for a period, and then transformed to press tool. The temperature of the sheet will gradually decrease due to heat transfer with air during the transfer process, so the actual deformation temperature is affected by transfer time. In this study, the specimen was deformed at different deformation temperature by adjusting different transfer time and the temperature of the sheet was monitored by the thermocouples soldered on the surface of the sheet.

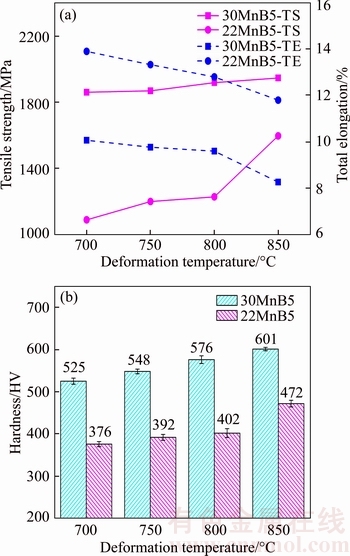

Figure 9(a) shows the tensile strength and elongation of as-quenched 30MnB5 and 22MnB5 specimens when deformed at different temperatures. We can find that the tensile strength increases with increasing deformation temperature and the maximum value of these two steels is respectively 1945 MPa and 1596 MPa at the deformation temperature of 850°C. So the transfer time of sheets from the furnace to the press should be decreased as much as possible in order to obtain higher tensile strength. However, the elongation presents opposite variation tendency with the tensile strength and the maximum values of 10.07% and 13.9% occur when the deformation temperature is 700 °C. As shown in Figure 9(b), the variation of as-quenched specimen’s hardness with deformation temperature is that hardness increases with the increasing deformation temperature.

The microstructures of as-quenched specimens at different deformation temperatures are given in Figure 10. It can be seen that the specimen deformed at 800 °C consists of full martensite, but a few ferrite can be observed in the microstructure of specimens deformed at 750 °C and 700 °C. This is because that lower deformation temperature and longer transfer time enhance the possibility of bainitic and ferritic transformation and require more driving force for the martensitic transformation [22, 23]. The formation of ferrite results in decrease of the tensile strength and hardness. When deformed at a lower temperature, the segregation of impurity occurs in addition to precipitation of laminar ferrite and carbides in the austenite grain boundary, which also causes the decrease of mechanical properties [24]. Furthermore, flow strength and work hardening rate decrease with increasing deformation temperature, so the transfer time should be controlled as short as possible to ensure enough high deformation temperature.

Figure 9 Tensile strength and elongation (a) and Vickers hardness (b) of as-quenched specimens at different deformation temperatures

3.4 Influence of cooling medium

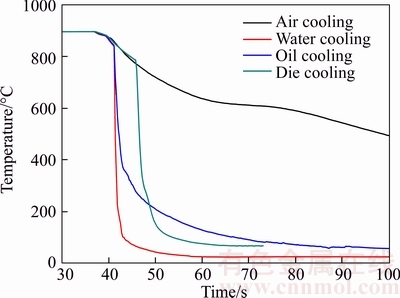

Cooling rate is a crucial hot stamping parameter, which can influence different phase transformations to determine the mechanical properties of hot stamping parts. Cooling history was recorded when the sheet was placed in four different cooling media by using thermocouples. It can be seen from Figure 11 that cooling rate is the slowest when the sheet is placed in air. The average cooling rate is 13 °C/s when the temperature decreases from 900 °C to 600 °C and it is only 3.5 °C/s at the range of 600 °C to 300 °C. It is interesting that the cooling rate slows down apparently when the temperature is about 600 °C, which results from the latent heat of phase transition. When the sheet is cooled from contact with the cooling medium to 200 °C, the average cooling rate in this process reaches up to 690 °C/s when quenched in water, and the average cooling rates of the sheet quenched in die and oil are 178 °C/s and 65 °C/s, respectively.

Figure 10 Microstructures of as-quenched 30MnB5 specimens at different deformation temperatures:

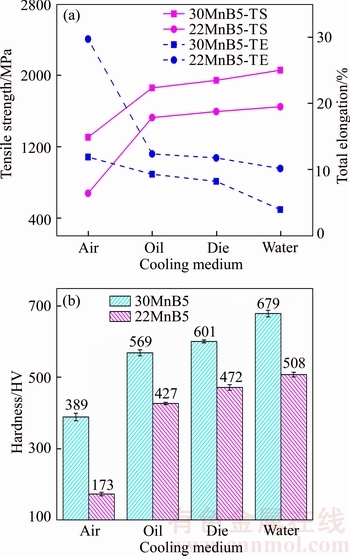

The tensile strength and elongation of specimens quenched in four different cooling media are shown in Figure 12(a). When the 30MnB5 specimen is cooled in air, the tensile strength is the minimum of 1307 MPa, but the elongation reaches up to the maximum of 11.93%. The tensile strength of 30MnB5 specimens quenched in oil and die is respectively 1861 MPa and 1946 MPa, with the elongation value of 9.33% and 8.26%. The maximum value of the tensile strength is 2059 MPa and the minimum value of elongation is just 4% when the 30MnB5 specimen is quenched in water. The 22MnB5 specimens have the similar variation tendency that tensile strength increases and the elongation decreases with the increasing cooling rate.

Figure 11 Temperature–time curves of sheets quenched in different cooling media

The Vickers hardness of specimens quenched in four different cooling media is given in Figure 12(b). It can be seen that the Vickers hardness increases with the cooling rate increasing. When the specimen is cooled in air, the hardness of 30MnB5 and 22MnB5 specimens is respectively HV 389 and HV 173, which can not meet the application requirements of automobile parts. When quenched in water, the hardness of these two steels both reach up to the maximum of HV 679 and HV 508, which can result in high brittleness and bad toughness. The Vickers hardness of specimens quenched in oil and die is close to each other due to similar cooling rate.

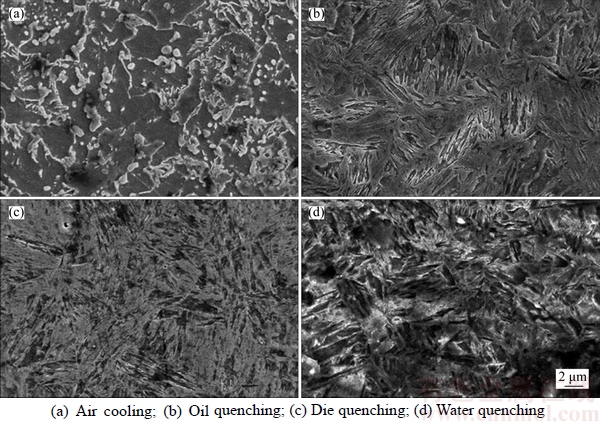

Figure 13 shows the microstructure of 30MnB5 specimens quenched in four different cooling media. When the specimen fully austenitized is cooled to the room temperature in air, the microstructure is a mixed structure consisting of ferrite, bainite and martensite. When the specimen is slowly cooled to the bainite formation temperature range, it tends to form granular bainite,whose microstructure is blocky ferrite containing carbon-rich austenite and austenite transformation product (pearlite and martensite) islands. All microstructures of specimens quenched in oil, die and water consist of full martensite, but the difference of martensite morphology exists. The specimens quenched in oil and die consist of a lath structure, but packet and lath martensite structures are formed when quenched in water.

Figure 12 Tensile strength and elongation (a) and Vickers hardness (b) of as-quenched specimens in different cooling media

4 Conclusions

1) Different microstructures and mechanical properties of as-quenched specimens can be obtained with changing heating temperature, soaking time, deformation temperature and cooling rate, which can give instructions to control and produce parts with tailored properties by hot stamping process.

2) The 30MnB5 specimen possesses higher tensile strength but lower elongation than 22MnB5 when hot stamped at the same process parameter, so 30MnB5 owns higher intrusion resistance ability but lower energy absorption capacity than 22MnB5. The highest tensile strength of 1964 MPa is obtained for the 30MnB5 specimen deformed on the flat die at 850 °C after a soaking time of 3 min at 900 °C, which occurs due to forming full fine martensitic microstructure.

Figure 13 Microstructures of as-quenched 30MnB5 specimens in different cooling media:

3) The lower and higher heating temperatures and soaking time both result in decrease of tensile strength and hardness, but increase of elongation, which is attributed to insufficient austenitization or the growth of grains.

4) The steel 30MnB5 possesses higher austenitic formation rate than 22MnB5, this is because that the more cementite increases the phase interfacial area and decreases the diffusion distance of carbon atom, which results in higher nucleation rate and diffusion coefficient of carbon atom.

5) Fully fine martensitic microstructure can be obtained at higher deformation temperature and cooling rate, so the transfer time of industrial hot stamping should be as short as possible and the cooling rate should be ensured enough high through the reasonable design of cooling channels in the die.

References

[1] MERKLEIN M, LECHLER J. Investigation of the thermo-mechanical properties of hot stamping steels [J]. Journal of Materials Processing Technology, 2006, 177: 452–455.

[2] MERKLEIN M, LECHLER J, STOEHR T. Investigations on the thermal behavior of ultra-high strength boron manganese steels within hot stamping [J]. International Journal of Material Forming, 2009, 2: 259–262.

[3] NADERI M, KETABCHI M, ABBASI M, BLECK W. Analysis of microstructure and mechanical properties of different boron and non-boron alloyed steels after being hot stamped [J]. Procedia Engineering, 2011, 10: 460–465.

[4] KARBASIAN H, TEKKAYA A E. A review on hot stamping [J]. Journal of Materials Processing Technology, 2010, 210: 2103–2118.

[5] TAYLOR T, FOURLARIS G, EVANS P, BRIGHT G. New generation ultrahigh strength boron steel for automotive hot stamping technologies [J]. Materials Science and Technology, 2014, 30: 818–826.

[6] GULER H, ERTAN R, OZCAN R. Effect of heat treatment on the microstructure and mechanical properties of 30MnB5 boron steel [J]. Materials and Technology, 2014, 48: 971–976.

[7] GULER H, ERTAN R, OZCAN R. Characteristics of 30MnB5 boron steel at elevated temperatures [J]. Materials Science and Engineering A, 2013, 578: 417–421.

[8] CHENG Jun-ye, ZHAO Ai-min, CHEN Yin-li, WANG Zhi-gang, CAO Jia-li. Effect of tempering temperature on the microstructure and mechanical properties of 30MnB5 hot stamping steel after quenching [J]. Journal of Science and Technology Beijing, 2013, 35: 1150–1157. (in Chinese)

[9] CHENG Jun-ye, ZHAO Ai-min, CHEN Yin-li, DONG Rui. EBSD studies of 30MnB5 hot stamping steel tempered at different temperature [J]. Acta Metallurgica Sinica, 2013, 49: 137–145. (in Chinese)

[10] YAZICI A. Investigation of the reduction of mouldboard ploughshare wear through hot stamping and hardfacing processes [J]. Turkish Journal of Agriculture and Forestry, 2011, 35: 461–468.

[11] YAZICI A. Wear behavior of carbonitride-treated ploughshares produced from 30MnB5 steel for soil tillage applications [J]. Metal Science and Heat Treatment, 2011, 53: 248–253.

[12] WEN Yu-hui, ZHU Guo-ming, DAI Si-yu, KANG Yong-lin. Effect of Ti on microstructure and strengthening behavior in press hardening steels [J]. Journal of Central South University, 2017, 24: 2215–2221.

[13] MU Yan-hong, WANG Bao-yu, ZHOU Jing, KANG Yi, LI Xue-tao. Heating parameters optimization of hot stamping by partition heating for tailored properties [J]. ISIJ International, 2017, 57: 1442–1450.

[14] ZHOU Jing, WANG Bao-yu, HUANG Ming-dong, CUI Dong. Effect of hot stamping parameters on the mechanical properties and microstructure of cold-rolled 22MnB5 steel strips [J]. International Journal of Minerals, Metallurgy, and Materials, 2014, 21: 544–555.

[15] GULER H, OZCAN R, YAUNZ N. Comparison of the mechanical and microstructural properties of heat-treated boron steel in different cooling media [J]. Materialwissenschaft und Werkstofftechnik, 2014, 45: 894–899.

[16] MIN Jun-ying, LIN Jian-ping, LI Jia-yue. Effect of deformation temperature on the microstructure of boron steel 22MnB5 [J]. Advanced Science Letters, 2011, 4: 938–942.

[17] AZIZ N, AQIDA S N. Optimization of quenching process in hot press forming of 22MnB5 steel for high strength properties [J]. IOP Conference Series: Materials Science and Engineering, 2013, 50: 1088–1094.

[18] LI Fang-fang, FU Ming-wang, LIN Jian-ping. Effect of cooling path on phase transformation of boron steel 22MnB5 [J]. Procedia Engineering, 2014, 81: 1707–1712.

[19] BARCELLONA A, PALMERI D. Effect of plastic hot deformation on the hardness and continuous cooling transformations of 22MnB5 microalloyed boron steel [J]. Metallurgical and Materials Transactions A, 2009, 40: 1160–1174.

[20] KRAUSS G. Steels: heat treatment and processing principles [M]. Geauga: ASM International, 1990: 12.

[21] NADERI M, KETABCHI M, ABBASI M, BLECK W. Analysis of microstructure and mechanical properties of different high strength carbon steels after hot stamping [J]. Journal of Materials Processing Technology, 2011, 211: 1117–1125.

[22] ABBASI M, SAEED-AKBARI A, NADERI M. The effect of strain rate and deformation temperature on the characteristics of isothermally hot compressed boron-alloyed steel [J]. Materials Science and Engineering A, 2012, 538: 356–363.

[23] NADERI M, SAEED-AKBARI A, BLECK W. The effects of non-isothermal deformation on martensitic transformation in 22MnB5 steel [J]. Materials Science and Engineering A, 2008, 487: 445–455.

[24] MEJIA I, BEDOLLA-JACUINDE A, MALDONADO C, CABRERA J M. Hot ductility behavior of a low carbon advanced high strength steel (AHSS) microalloyed with boron [J]. Materials Science and Engineering A, 2011, 528: 4468–4474.

(Edited by HE Yun-bin)

中文导读

热冲压工艺参数对30MnB5和22MnB5钢板成形淬火后力学性能和微观组织的影响

摘要:本文旨在研究加热温度、保温时间、变形温度和冷却介质等热冲压工艺参数对30MnB5和22MnB5高强钢板相变、微观组织和力学性能的影响规律。使用平板模具模拟了硼钢热冲压冷模具淬火过程,并对淬火后的零件试样进行了拉伸测试、硬度测量和微观组织观测。研究结果表明,在相同的热冲压工艺参数下,淬火后的30MnB5比22MnB5具有更高的抗拉强度、更低的伸长率;不合适的加热参数由于不充分奥氏体化或奥氏体晶粒粗大等原因导致淬后零件抗拉强度和硬度的降低;30MnB5的奥氏体化速率高于22MnB5的奥氏体化速率,这是由于更多的渗碳体导致了更高的形核率和碳原子扩散率;较高的成形温度和较快的冷却速率易于在淬后零件中形成细小的马氏体组织。

关键词:高强钢;力学性能;微观组织;热冲压参数

Foundation item: Projects(51705018, U1564202) supported by the National Natural Science Foundation of China

Received date: 2016-09-06; Accepted date: 2016-12-14

Corresponding author: WANG Bao-yu, PhD, Professor; Tel: +86–13511007379; E-mail: bywang@ustb.edu.cn; ORCID: 0000-0003- 0462-9511