纤维体积分数对炭/炭复合材料摩擦磨损性能的影响

左劲旅, 张红波, 李江鸿, 熊 翔

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要: 通过化学气相沉积法将纤维体积分数分别为23%,30%和40%的3种炭纤维针刺毡预制件增密至1.50 g·cm-3,再浸渍树脂进一步增密至1.80 g·cm-3,进行热处理后制成炭/炭复合材料,观察3种试样的金相显微结构,测试3种试样在不同刹车压力下的摩擦磨损性能;采用扫描电子显微镜对其磨损表面进行观察。研究结果表明:对于热解炭为非典型粗糙层结构的炭/炭复合材料,纤维体积分数增大,其摩擦曲线相对较平稳,磨损量较大;当纤维体积分数超过30%后,磨损量显著增加;在相同的刹车压力下,纤维体积分数对摩擦因数无显著影响。刹车压力低时试样的摩擦因数比刹车压力高时的摩擦因数大;作为摩擦炭/炭复合材料,纤维积分数为30%左右较适宜。

关键词: 纤维体积分数; 炭/炭复合材料; 热解炭; 摩擦; 磨损

中图分类号:TB332 文献标识码:A 文章编号: 1672-7207(2005)04-0555-05

Effect of fiber volume fraction on friction and wear properties of C/C composites

ZUO Jin-lü, ZHANG Hong-bo, LI Jiang-hong, XIONG Xiang

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: C/C composites were prepared by needled felt with 23%, 30% and 40% fibre volume fraction through redensifying to density of 1.80 g·cm-3 by resin impregnation after redensifying to density of 1.50 g·cm-3 by chemical vapour deposit method. The friction and wear properties of C/C composites after high treatment were studied and the effect of braking pressure was also analyzed .And the microstructures and the morphologies of the worn surfaces were observed through optical microscopy and scanning electron microscopy, respectively. The results show that for the C/C composites in which pyrolytic carbon is not representative rough laminar, the wear loss and stability of C/C composites increase with increasing the fibre volume fraction; when the fibre volume fraction exceeds 30%, the increase of wear loss is very distinct; fibre volume fraction does not have obvious influence on the friction coefficient under the same braking pressure; the friction coefficients under lower braking pressure have higher values; as the C/C composites for friction,the suitable fibre volume fraction is about 30%.

Key words: fiber volume fraction; C/C composites; pyrolitic carbon; friction; wear

炭/炭复合材料具有轻质、摩擦磨损性能及热物理性能优异等特点,被广泛用作航空刹车材料。影响炭/炭复合材料摩擦磨损性能的因素很多,如基体炭的结构、刹车压力和刹车速度等[1-5]。人们主要从基体炭的种类、材料的石墨化度、实验条件等方面研究炭/炭复合材料的摩擦磨损性能的影响因素。目前,大部分航空刹车用的炭/炭复合材料以炭纤维针刺形成的预制件为增强体,进行化学气相沉积增密或浸渍补充增密制成。显然,预制件的结构对炭/炭复合材料的性能具有较大影响。作者用不同纤维体积分数的预制件制成的炭/炭复合材料模拟航空刹车条件进行摩擦磨损性能试验,并对其磨损机理进行分析。

1 实 验

1.1 样品制备

通过化学气相沉积将针刺毡结构炭纤维预制件增密至1.50 g·cm-3,再采用浸渍树脂补充增密至1.80 g·cm-3,然后进行高温热处理制成炭/炭复合材料。3种样品均由炭纤维、热解炭和树脂炭组成,且热解炭质量分数较大,其组成见表1。

表 1 3种样品的组成

Table 1 Compositions of three kinds of samples

1.2 检测方法

将炭/炭复合材料采用冷镶的方法制成金相样品,用MeF3A型金相显微镜在偏光下观察样品的微观结构;用JR-3型热物性测试仪测定样品平行方向和垂直方向的导热系数;用日本理学3014型X射线衍射仪测试样品的石墨化度;用JSM-5600LV型扫描电子显微镜对磨损表面进行观察。

1.3 摩擦性能试验

将3种炭/炭复合材料分别制成摩擦试环(外径为75 mm,内径为53 mm,厚为15 mm)在MM-1000型摩擦试验机上采用环对环的方式进行摩擦试验,试验参数见表2。在试验过程中记录相应的力矩、摩擦因数—时间关系曲线,测量试验前、后摩擦试环的厚度及质量变化,计算线性磨损和质量损失,根据线性磨损和质量损失计算其氧化质量损失。

表 2 摩擦试验参数

Table 2 Parameters of friction test

2 结果与分析

2.1 试样的显微结构及热物理性能

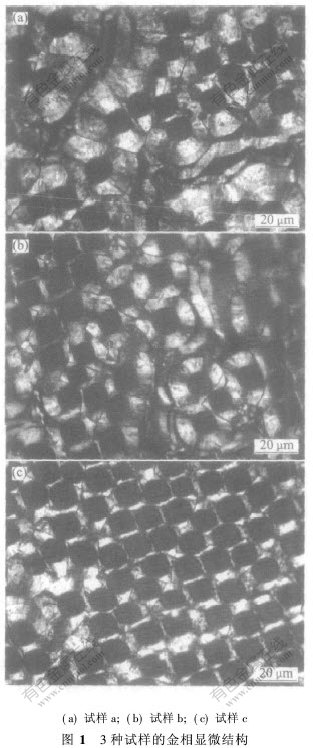

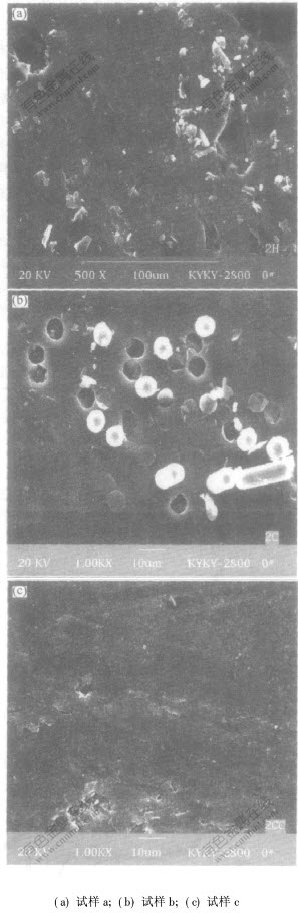

图1所示为3种试样在偏光下的金相显微结构,表3所示为3种试样的热物理性能。可见,3种试样的热解炭微观结构相似,同为非典型的粗糙层结构[6]。3种试样经过相同温度热处理后的石墨化度(见表3)相近也可进一步证实这一点。

图 1 3种试样的金相显微结构

Fig. 1 Microstructures of three kinds of samples

2.2 摩擦性能

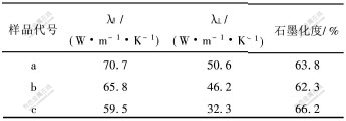

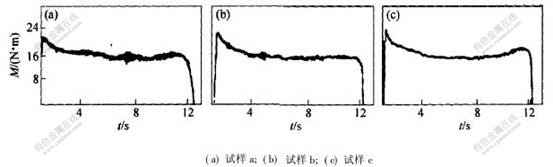

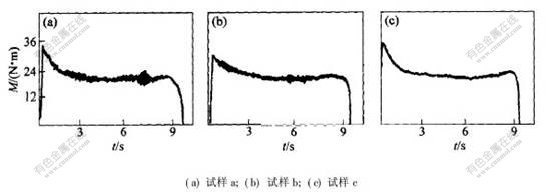

表4所示为不同刹车压力下3种试样的摩擦磨损试验结果;图2和图3所示为相应的典型刹车力矩曲线。从表4可以看出,当刹车压力为0.6 MPa和1.0 MPa时,3种材料摩擦因数分别为0.39~0.41和0.34~0.36;在相同的刹车压力下3种材料的摩擦因数相近,表明纤维体积分数对炭/炭复合材料的摩擦因数没有明显影响;随着刹车压力的增大,3种材料的摩擦因数均下降,线性磨损和质量磨损均增加。在相同的刹车压力下,3种材料的线性磨损和质量磨损从大至小的顺序为:试样c、试样b、试样a,而且后者比前者磨损量增加的幅度更大,表明在相同的刹车压力下,纤维体积分数大的炭/炭复合材料的磨损量比纤维体积分数低的炭/炭复合材料的磨损量大;且当纤维体积分数超过30%后,磨损量增大更为显著。从图2和图3可以看出,无论是在低刹车压力还是在高刹车压力下,刹车力矩曲线都存在轻微的拖尾现象,曲线振动较大,试样c的刹车力矩曲线的线形和平稳性较好,试样b的刹车力矩曲线没有拖尾现象,但曲线的平稳性不如试样c,表明对于热解炭为非典型粗糙层结构及纤维体积分数为23%~40%的炭/炭复合材料,随着纤维体积分数的增加,摩擦曲线的线形和平稳性相对较好。

表 3 3种试样的热物理性能

Table 3 Calorific capabilities of three kinds

表 4 在不同刹车压力下3种试样的摩擦性能

Table 4 Friction properties of three kinds of sample under different braking pressures

图 2 刹车压力为0.6 MPa时3种材料的典型刹车力矩曲线

Fig. 2 Representative curves for brake-moment of three kinds of samples under braking pressure of 0.6 MPa

图 3 3种材料刹车压力为1.0 MPa时的典型刹车力矩曲线

Fig. 3 Representative curves for brake-moment of three kinds of sample under braking pressure of 1.0 MPa

试样a的磨损较小,但其摩擦曲线的线形和平稳性较差;试样c的磨损较大,但其摩擦曲线的线形和平稳性较好;试样b则介于试样a和试样c两者之间。综合考虑3种材料的摩擦和磨损性能,制备摩擦用的针刺毡炭/炭复合材料时,纤维体积分数选取在30%左右较为适宜。

2.3 分析与讨论

2.3.1 刹车压力的影响

炭/炭复合材料是具有一定孔隙的假塑性体,根据粘着理论[7],当载荷较小时,两摩擦表面处于弹性状态,此时实际接触面积与载荷的2/3次方成正比,摩擦力与实际接触面积成正比,故摩擦因数与载荷的1/3次方成正比。因此,当其他条件相同时,刹车压力越大,摩擦因数越小[8];同时,在高刹车压力下产生的温度越高,氧化质量损失越大,且氧化引起摩擦表面炭结构削弱,使机械磨损也增大,导致总的质量磨损增大[9]。

2.3.2 刹车力矩曲线分析

图4所示为3种试样在1.0 MPa的刹车压力下摩擦表面的扫描电子显微形貌。3种试样的摩擦表面均覆盖了一层摩擦膜,这是由于压碎的基体炭与剪断的纤维在压应力与摩擦应力的共同作用下压制而成。样品c(见图4(c))的摩擦表面的摩擦膜较厚且较平滑完整,基体形貌不清晰。所以,在图3所示的刹车曲线中,样品c的刹车曲线线形很平稳。样品a(见图4(a))的摩擦表面的摩擦膜不连续,所以,其刹车曲线线形较差[10-12]。样品b(见图4(b))的摩擦表面的摩擦膜介于样品a和样品c二者之间,所以其刹车曲线线形也介于这两者之间。

2.3.3 磨损分析

在3种材料中,样品c的线性磨损与质量磨损较大,样品a的线性磨损与质量磨损较小,这有两方面的原因:一方面,样品c的纤维体积分数较大,热解炭质量分数较低,而纤维比基体炭硬度高、脆性大[13],所以,摩擦过程中产生更多的断裂纤维切削基体炭,导致其线性磨损大;样品a的纤维体积分数较小,热解炭的比例较高,所以,其线性磨损较小;另一方面,样品c 的热解炭比例较低,热导率较低(见表3),致使摩擦表面温升增大,故其氧化磨损大[14,15],而氧化磨损又可削弱摩擦表面,导致样品的线性磨损增加;样品a 的热解炭质量分数较大,热导也较高,使其摩擦表面温升较小。故其氧化磨损较小,3种材料中,试样a的质量磨损最小。

图 4 刹车压力为1.0 MPa时3种材料的摩擦表面的SEM形貌

Fig. 4 SEM images of worn surfaces of three kinds of samples under braking pressure of 1.0 MPa

3 结 论

a. 对于热解炭结构为非典型粗糙层及纤维体积分数为23%~40%的炭/炭复合材料, 纤维体积分数越高,其摩擦曲线相对较平稳,磨损量相对较大;当纤维体积分数超过30%时,磨损率显著增大。

b. 在同样的刹车压力下,纤维体积分数对材料的摩擦因数无明显影响;随着刹车压力的提高,3种材料的摩擦因数均呈下降趋势。

c. 作为航空刹车用的针刺毡结构炭/炭复合材料,其纤维体积分数为30%左右较适宜。

参考文献:

[1]Buckley J D. Carbon-carbon: an overview[J]. America Ceramic Society Bull, 1988, 67(2): 364-368.

[2]徐慧娟, 熊翔, 黄伯云, 等. 不同能载水平下C/C复合材料的摩擦特性[J]. 中南工业大学学报(自然科学版), 2003, 34(3): 221-224.

XU Hui-juan, XIONG Xiang, HUANG Bai-yun, et al. Friction properties of C/C composites in different energy conditions[J]. Journal of Central South University of Technology(Natural Science), 2003, 34(3): 221-224.

[3]李江鸿, 熊翔, 徐慧娟, 等. 炭/炭复合材料的摩擦磨损性能[J]. 中南工业大学学报(自然科学版), 2002, 33(2): 173-176.

LI Jiang-hong, XIONG Xiang, XU Hui-juan, et al. Friction and wear properties of the C/C composites [J]. Journal of Central South University of Technology(Natural Science), 2002, 33(2): 173-176.

[4]Fitzer E. The future of carbon-carbon composites[J]. Carbon, 1987, 25(2): 163-190.

[5]Awathi S, Wood J L. C/C composite material for aircraft[J]. Advanced Ceramics Material, 1988, 3(5): 449-451.

[6]Oh S M , Lee J Y. Effects of matrix structure on mechanical properties of carbon/carbon composites[J]. Carbon, 1998, 36(2): 769-776.

[7]全永昕, 施高义. 摩擦磨损原理[M]. 杭州: 浙江大学出版社, 1988.

QUAN Yong-xin, SHI Gao-yi. The theory of friction and wear[M]. Hangzhou: Zhejiang University Press, 1988.

[8]Ju C P, Tsai W T. A review on microstructure and Interfaces of carbon-carbon composites at high-energy sliding contact[J]. Chinese Journal of Materials Science, 1990, 22(2): 98-111.

[9]Yen B K, Ishihara T. On temperature-dependent tribological regimes and oxidation of carbon-carbon composites up to 1800 ℃[J]. Wear, 1996, 196(1-2): 254-262.

[10]Murdie N, Ju C P, Don J, et al. Microstructure of worn pitch/resin/CVI C/C composites[J]. Carbon, 1991, 29(3): 335-342.

[11]Yen B K, Ishihara T. Surface morphology and structure of carbon-carbon composites at high-energy sliding contact[J]. Wear, 1994, 174(1-2): 111-117.

[12]Toby J, Hutton T J. Structure studies of wear debris from carbon-carbon composites aircraft brakes[J]. Carbon, 1999, 37(6): 907-916.

[13]Yen B K. An investigation of friction and wear mechanisms of carbon-carbon composites in nitrogen and air at elevated temperatures[J]. Carbon, 1996, 34(4): 489-498.

[14]Mckee D W. Oxidation behavior of matrix-inhibited carbon-carbon composites[J]. Carbon, 1988, 26(3): 659-665.

[15]Byrne C, Wang Z Y. Influence of thermal properties on friction performance of carbon composites[J]. Carbon, 2001, 39(5): 1789-1801.

收稿日期:2004-09-31

基金项目:国家重点工业试验性项目(计高技[1998]-1817)

作者简介:左劲旅(1969-),男,湖南常德人,高级工程师,从事C/C复合材料及应用研究

论文联系人: 左劲旅,男,博士研究生;电话:0731-8830939(O);E-mail: zuojinlv@126.com