文章编号:1004-0609(2010)09-1829-07

攀枝花含钛高炉渣直接制备钛合金

邹星礼,鲁雄刚

(上海大学 上海市现代冶金与材料制备重点实验室,上海200072)

摘 要:采用固体透氧膜(SOM)法研究直接电解攀枝花含钛高炉渣制备钛硅合金。以经过1 150 ℃预烧2 h成型的攀枝花含钛高炉渣为阴极,以氧化锆管内碳饱和铜液为阳极,将两者置于CaCl2熔盐中,在1 100 ℃、电解电压3.5~4.0 V的条件下高温熔盐电解2~8 h。采用SEM、EDX和XRD等方法对电解产物进行分析。结果表明:含钛高炉渣电解还原后的产物为TixSiy系合金,含钛高炉渣中钙、镁和铝等金属元素被有效去除。

关键词:钛合金;含钛高炉渣;熔盐电解;固体透氧膜法

中图分类号: TG146.4 文献标志码:A

Preparation of titanium alloy by direct reduction of Ti-bearing blast furnace slag

ZOU Xing-li, LU Xiong-gang

(Shanghai Key Laboratory of Modern Metallurgy and Materials Processing, Shanghai University, Shanghai 200072, China)

Abstract: The TixSiy alloy was prepared by solid oxygen-ion membrane(SOM) process from Ti-bearing blast furnace slag. The Ti-bearing blast furnace slag powders sintered at 1 150 ℃ for 2 h were used as the cathode, and the carbon-saturated liquid copper loaded in zirconia tube was used as the anode, which were electrolyzed in a molten CaCl2 at 1 100 ℃ with a potential of 3.5-4.0 V for 2-8 h. The products were analyzed by SEM, EDX and XRD. The results show that Ti-bearing blast furnace slag is electrochemically reduced to TixSiy alloy in molten CaCl2, and the calcium, magnesium and aluminum are completely removed during electrolysis.

Key words: titanium alloy; Ti-bearing blast furnace slag; molten salt electrolysis; solid oxygen-ion membrane process

攀枝花含钛高炉渣综合利用一直面临着提钛难、工艺复杂和流程长等难点,目前该地区已累计含钛型高炉渣约6 000万t,并以每年约300万t的速度递增,目前主要采取堆放渣场的方式进行处理。堆放的炉渣对生态环境造成污染,但难以找到合理的有效利用途径[1-2]。高炉渣约占攀枝花钛资源总量的50%,找到提取出钛组分的技术成为合理利用钛资源的关键[3]。近年来,围绕从含钛高炉渣中提取钛组分这一研究新思路,研究者进行了大量研究和探索,如通过对含钛高炉渣中钙钛矿的结晶来选择性富集并分离钛组 分[4-5]、通过高温碳化低温氯化制取四氯化钛[6]以及利用酸碱处理化学分离含钛渣中钛组分[7]等,都取得不错的效果。特别前两种工艺,具有处理大量含钛渣的生产能力。但以上所述的工艺都面临工序复杂、流程长以及副产物处理难等问题。

本文作者提出利用固体透氧膜(SOM)法熔盐电解含钛高炉渣,直接提取钛及钛合金新思路,即从复合矿物短流程提取金属及合金,以实现能耗低、工艺简单、流程短、无污染的钛渣处理新技术,以期为我国攀枝花地区钛资源的利用开发出一条全新的技术流程。

1 实验

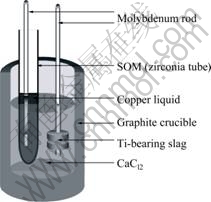

SOM法高温熔盐电解已经在制备金属如镁、钛、钽、铬、铌[8-10]等方面取得成功,电解含钛高炉渣实验装置如图1所示,其基本原理在文献[8-10]中有详细描述。其电极过程可表示如下:

阴极反应

MeOx+2xe=Me+xO2- ( 1 )

透氧膜/铜液界面:

O2-= [O]Cu+2e ( 2 )

阳极反应:

C+[O]Cu=CO(g) ( 3 )

总反应:

MeOx+xC=Me+xCO(g) ( 4 )

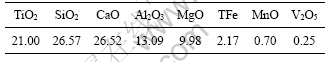

将攀枝花含钛高炉渣球磨数小时后筛分,获得颗粒细小均匀的含钛高炉渣细粉,实测成分如表1所列,主要含有氧化钛和氧化硅以及氧化钙和氧化铝等组元。

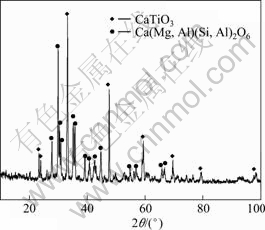

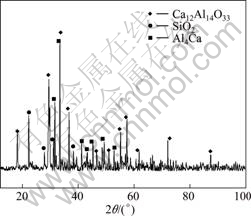

在细粉中加入添加剂聚乙烯醇缩丁醛(PVB),混合均匀后,利用粉末压样机,将含钛高炉渣粉料在10~15MPa的压力下压制为圆片(d15 mm×2 mm,1.5 g),然后在1 150 ℃的氧化性气氛中烧结2 h。烧结后高炉渣的XRD谱如图2所示。由图2可以看出,烧结后的钛渣中主要存在物相为钙钛矿(CaTiO3) 和透辉石(Ca(Mg, Al)(Si, Al)2O6)以及少量普通辉石等其他成分。

图1 含钛高炉渣电解实验装置示意图

Fig.1 Schematic diagram of cell setup electrolysis of Ti-bearing blast furnace slag

表1 含钛高炉渣实测化学成分

Table 1 Chemical component of Ti-bearing blast furnace slag (mass fraction, %)

图2 攀枝花含钛高炉渣烧结后XRD谱

Fig.2 XRD pattern of sintered Ti-bearing blast furnace slag

将烧结后的圆片用直径为0.2 mm的钼丝缠绕于直径为1.5 mm钼棒上制成阴极,阳极为固体透氧膜管内碳粉饱和的铜液,以CaCl2为熔盐电解质,石墨坩埚为反应容器。实验用固体透氧膜管为本实验室自制的8%(摩尔分数)氧化钇部分稳定氧化锆膜管(d20 mm×100 mm)。

实验体系采用高纯氩气保护,升温至1 100 ℃时先在2.5 V电压下进行预电解1 h,以脱除熔盐中残存杂质,然后将电解电压设定为3.5~4.0 V进行电解实验,记录电流随时间变化。电解温度为1 100 ℃,电解时间为2~8 h。电解后将阴极产物取出,用蒸馏水洗净熔盐并在低温烘干,利用日本理学D/max22500PC型X射线衍射仪分析电解阴极产物的相结构,用JSM-6700F型扫描电子显微镜对电解后阴极产物进行SEM和EDX分析。

2 结果与讨论

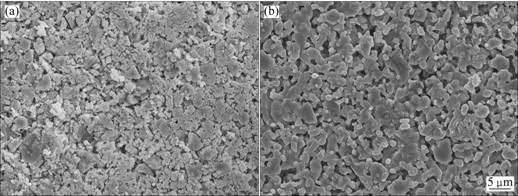

2.1 阴极片在电解前后的微观组织

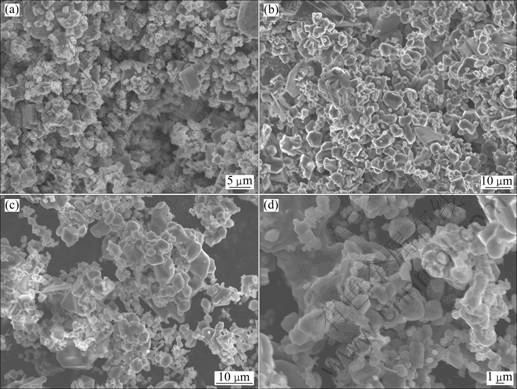

阴极片在烧结前后的SEM像如图3所示。由图3可以看出,烧结前颗粒大小形状不规则,颗粒较小且比较致密;烧结后的颗粒和孔隙率都有所增大,颗粒表面圆滑且颗粒间形成更多孔隙,为电解时熔盐传导氧离子提供了必要的通道。

图4 所示为含钛高炉渣不同电解时间的阴极产物SEM像。由图4可以看出,随着电解过程的进行,产物颗粒由初始的具有立方外形逐渐还原生长成圆形颗粒。通过EDX能谱分析可知,图4(a)中立方形颗粒为钙钛矿。由于电解2 h后的产物中还含有较多钙钛矿,因此在电解初期阶段进行的反应主要为透辉石(Ca(Mg, Al)(Si, Al)2O6)的分解和还原。随着电解时间的延长,钙钛矿开始被电解还原,产物颗粒之间也开始粘结长大,形貌疏松多孔,由电解6~8 h之后产物的孔隙率可以看出,电解过程中熔盐在块状阴极中是易于浸入的,这也保证了电解过程的高效进行。

2.2 电解后阴极产物的微观组织

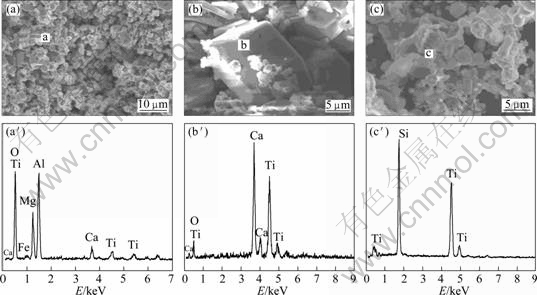

图5所示为电解后阴极产物的SEM像及能谱图。

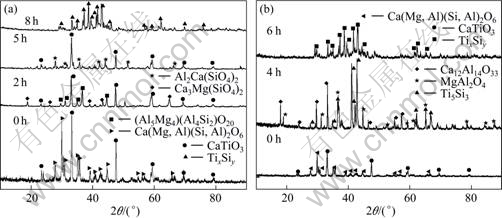

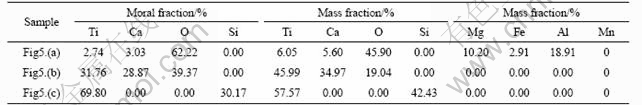

图5(a) 所示为电解2 h的微区形貌及能谱图,图5(b)所示为电解2 h的微区所含立方形颗粒的形貌及能谱图。从图5(a)和(b)可以看出,电解2 h后,钙钛矿以立方形颗粒形式存在于阴极中,而小圆形颗粒为镁、铝、硅等元素的复合氧化物。图5(c)所示为电解8 h的能谱图。由图5(c)和能谱结果(见表2)可以看出,此时阴极中只剩下钛和硅,其他元素已被去除。图6所示为在不同电解电压条件下,电解不同时间的阴极产物的XRD谱。图6(a)所示为在3.5 V条件下,分别电解2、5和8 h的产物的XRD谱,图6(b)所示为在4.0 V条件下分别电解4 h和6 h后的产物的XRD谱。由

图3 阴极片烧结前后的SEM像

Fig.3 SEM images of cathode pellets: (a) Before sintered; (b) After sintered at 1 150 ℃ for 2 h.

图4 阴极片电解不同时间后的SEM像

Fig.4 SEM images of cathode pellets after electrolyzed for different times: (a) 2 h; (b) 4 h; (c) 6 h; (d) 8 h

图 5 电解不同时间后阴极片的SEM像和能谱图

Fig.5 SEM images and EDX spectra of cathode pellets after electrolyzed for different times: (a), (a’) 2 h; (b), (b’) Cubical particle shown in Fig.5(a); (c), (c’) 8 h

图6 不同电解电压下电解不同时间的阴极片的XRD谱

Fig. 6 XRD patterns of cathode pellets deoxidized at different potential for different times: (a) At 3.5 V; (b) At 4.0 V

表 2 电解不同时间的阴极片的EDX结果

Table 2 EDX results of cathode pellets after electrolyzed for different times

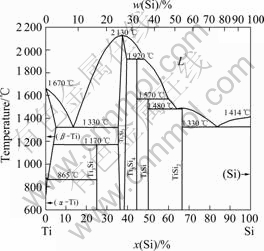

图6可知,首先是透辉石 (Ca(Mg,Al)(Si,Al)2O6)分解为Ca3Mg(SiO4)2、(Al5Mg4)(Al4Si2)O20、MgAl2O4以及Ca12Al14O33等中间产物,施加不同电解电压时得到的中间产物不同。随着电解的继续进行,钙钛矿进一步电解成低价钛氧化合物,然后被还原为单质钛[11-13],而其余钙镁铝等复合氧化物则进一步分解还原为单一氧化物。分析认为,由于单质钙、镁、铝等金属的熔点远低于1 100 ℃,在电解还原过程中,析出的钙、镁、铝等金属从固体阴极片进入熔盐中或挥发。最终,钛和硅由于具有相对较低的分解电压而析出,并生成稳定的TixSiy。由图6(a)可以看出,在3.5V电解电压条件下,从电解开始到电解5 h的时间内,钙钛矿一直存在,而斜辉石逐渐分解还原为Ca3Mg(SiO4)2和(Al5Mg4)(Al4Si2)O20;随着电解的进行,钙钛矿和硅组分逐渐被还原为钛硅合金。由钛硅二元合金相图[14](见图7)可知,钛和硅可以生成多种TixSiy(Ti3Si,Ti5Si3,Ti5Si4,TiSi,TiSi2)合金。

图7 钛硅二元合金相图[14]

Fig.7 Ti-Si alloy phase diagram

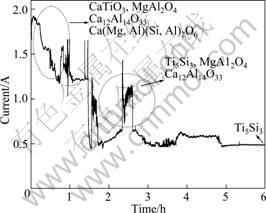

在3.5V电压下电解8 h的产物中,仅有钛和硅元素存在。在4.0 V的条件下,电解4 h的产物中主要有镁铝尖晶石(MgAl2O4)以及Ca12Al14O33,并开始生成Ti5Si3;而在电解6 h的产物中,主要物相为钛硅合金,如图6(b)所示。由此可见,在3.5 V条件下8 h能完全电解1.5 g含钛炉渣,而当电压提高到4.0 V时,6 h内就能完成电解。图8所示为在4.0 V条件下电解6 h的典型时间—电流曲线,结合图6(b)所示的XRD谱,可确定在电解不同时间后阴极片所包含的产物。在电解的过程中,由于杂质的去除使得阴极片变得疏松,导致电流的波动。对比之前固态氧化物直接熔盐电解的电流效率,SOM法在处理含钛高炉渣的实验中具有较高的电流效率,但由于成分的复杂以及电解过程中部分物质的散落,具体的电流效率无法精确算出。

在含钛高炉渣的电解过程中所发生的反应是复杂的多相多组分反应,SOM法选择性透过氧离子使它适用于电解复杂多元复合矿物,由于只有氧离子能通过透氧膜管,使得非氧化物成分在电解过程中不能反应,避免了副反应的发生。同时,由于氯离子不能通过透氧膜管,施加高于CaCl2的分解电压也不会导致熔盐的分解,从而能够使整个电解反应在高于CaCl2的分解电压之上进行。有效地提高了电解效率并使得SOM法具有电解处理较高分解电压的复杂氧化物的能力。

图8 电解含钛高炉渣典型时间—电流曲线

Fig.8 Typical current—time curve of electrolysis of Ti-bearing blast furnace slag (1 100 ℃, 4.0 V, 6 h)

2.3 钙、镁、铝元素的去向分析

在电解后的阴极产物中,未发现钙、镁、铝等元素的痕迹。MA等[15]利用FFC法对高钛渣进行电脱氧实验时发现,金属杂质铝和镁可以被部分甚至全部除去,即使将TiO2与Al2O3混合也难以生成金属铝及铝合金;并认为金属元素之间的相互作用、不同氧化物还原先后顺序和析出金属的熔点、密度、溶解度等,是影响最终成分的重要因素。有些研究者[15-17]认为,在CaCl2熔盐电解过程中存在去除部分金属杂质元素的趋势;若要形成合金,则该合金的成分必须具备一定的物理化学性能,如熔点不能相差太大,以及不能溶解于熔盐等。

针对此现象,本研究设计了实验以探究上述元素的去向。在电解池内放入小坩埚,再将阴极片悬空于小坩埚内进行电解,小坩埚全部没入熔盐中,以此来收集电解过程中阴极产物进入熔盐的成分,具体的实验装置简图如图9所示。电解后将坩埚内收集物质进行XRD检测,结果如图10所示。从图10可以看出,电解过程中钙、铝以及部分硅元素都逐渐进入熔盐中,而并未在熔盐中发现镁元素。

根据计算得到的各氧化物在1 100 ℃时的理论分解电压[18]如表3所列。虽然含钛高炉渣中所含物相为复合氧化物,但在电解过程中,复杂的复合氧化物在反应中会分解转化成单一或者简单的复合氧化物,而后进一步电解析出单质金属和合金。前期实验发现,

图9 改进实验装置示意图

Fig.9 Schematic diagram of improved cell setup

图10 小坩埚内收集物质的XRD谱

Fig.10 XRD pattern of mixture collected by crucible

表3 1 100 ℃时钛渣中氧化物理论分解电压

Table 3 Decomposition voltage of oxides in Ti-bearing blast furnace slag at 1 100 ℃

电解过程中硅、钛金属先被还原,优先析出的金属钛和硅开始生成TixSiy。由于钙钛矿分解产生的氧化钙在CaCl2熔盐中具有很高的溶解度[16],导致生成的氧化钙溶解于熔盐中。随着电解的继续进行,阴极中氧化铝、氧化镁等复合氧化物开始电解,但生成的单质铝、钙熔点分别为660.1和839 ℃,且根据二元相图可知[19],在钛、硅、镁、铝、钙这5种元素之间,在1 100 ℃理论上能形成的二元合金只有TixSiy 、TixAly 、CaxSiy 及MgxSiy。但电解实验的最终检测结果并未发现TixAly 、CaxSiy及MgxSiy等合金的生成。这可能是因为在电解过程中,先析出的硅和钛已经生成了较为稳定的TixSiy,后续出现的铝、镁、钙等金属由于具有低于1 100 ℃的熔点,故难以在阴极中生成其合金。而进入熔盐中的镁、铝、钙等金属元素中,镁会因沸点较低 (1 090 ℃)而随保护气体挥发出系统。钙、铝金属元素部分形成Al4Ca,而小坩埚内收集到的Ca12Al14O33则是由于电解过程中,阴极逐渐被还原,形成疏松多孔的结构,部分中间产物散落到熔盐中。最终的结果表明,SOM法在电解含钛高炉渣时能较为完全地去除钙、镁、铝等杂质元素,从而获得TixSiy合金。

3 结论

1) 利用SOM法可在高温熔盐中电解处理攀枝花含钛高炉渣。在1 100 ℃、3.5~4.0 V的实验条件下分别电解8 和6 h,可由含钛高炉渣获得钛硅系列合金产物。

2) 含钛高炉渣中所含镁、铝、钙等金属元素可在1 100 ℃高温熔盐电解中被有效去除。

3) SOM法具有高效率、无污染、流程短等优点,能用于多种氧化物以及复合氧化物的高温电解还原。针对我国攀枝花地区大量含高附加值金属的低品味矿藏的开发利用,可望提出一条全新的工艺。

REFERENCES

[1] 刘松利, 杨绍利. 攀枝花高钛型高炉渣综合利用研究现状[J]. 轻金属, 2007(7): 48-50.

LIU Song-li, YANG Shao-li. Present state and perspectives of complex utilization on Panzhihua BF slag[J]. Light Metals, 2007(7): 48-50.

[2] 王 志, 袁章福. 中国钛资源综合利用技术现状与新进展[J]. 化工进展, 2004, 23(4): 349-352.

WANG Zhi, YUAN Zhang-fu. Progress and status reporting on the comprehensive utilization technology of titanium resources in china[J]. Chemical Industry and Engineering Progress, 2004, 23(4): 349-352.

[3] 祝淑芳, 鲁礼林. 含钛高炉渣综合利用与钛组分析出技术的进展[J]. 矿业快报, 2008(3): 9-11.

ZHU Shu-fang, LU Li-lin. Developments of study on comprehensive utilization of Ti-bearing blast furnace slag and selective separation technology of Ti component[J]. Express Information of Mining Industry, 2008(3): 9-11.

[4] 李玉海, 娄太平, 隋智通. 含钛高炉渣中钛组分选择性富集及钙钛矿结晶行为[J].中国有色金属学报, 2000, 10(5): 719-722.

LI Yu-hai, LOU Tai-ping, SUI Zhi-tong. Selective enrichment of Ti component in Ti-bearing blast furnace slag and precipitation behavior of perovskite phase[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(5): 719-722.

[5] 隋智通, 郭振中, 张 力, 张林楠, 王明玉, 娄太平, 李光强. 含钛高炉渣中钛组分的绿色分离技术[J]. 材料与冶金学报, 2006, 5(2): 93-97.

SUI Zhi-tong, GUO Zhen-zhong, ZHANG Li, ZHANG Lin-nan, WANG Ming-yu, LOU Tai-ping, LI Guang-qiang. Green separation technique of Ti component from Ti-bearing blast furnace slag[J]. Journal of Materials and Metallurgy, 2006, 5(2): 93-97.

[6] 杨 平, 陈德明. 攀枝花钛渣组合式流化床氯化制备TiCl4的研究[J]. 钢铁钒钛, 2007, 28(2): 48-52.

YANG Ping, CHEN De-ming. Preparing titanium tetrachloride by chlorinating Panzhihuan titanium slag with combined fluidized bed[J]. Iron Steel Vanadium Titanium, 2007, 28(2): 48-52.

[7] 熊 瑶, 李 春, 梁 斌, 谢 军. 盐酸浸出自然冷却含钛高炉渣[J]. 中国有色金属学报, 2008, 18(3): 557-563.

XIONG Yao, LI Chun, LIANG Bin, XIE Jun. Leaching behavior of air cooled Ti-bearing blast-furnace slag in hydrochloric acid[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 557-563.

[8] KRISHNAN A, PAL U B, LU X G. Solid oxide membrane for magnesium production directly from magnesium oxide[J]. Metallurgical and Materials Transactions B, 2005, 36(4): 463-473.

[9] 程红伟, 鲁雄刚, 李谦, 刘建民, 丁伟中, 周国治. 固体透氧膜法制备金属钽[J]. 金属学报, 2006, 42(5): 500-504.

CHENG Hong-wei, LU Xiong-gang, LI Qian, LIU Jian-min, DING Wei-zhong, ZHOU Guo-zhi. Preparation of metal tantalum by solid oxygen-ion membrane[J]. Acta Metallurgica Sinica, 2006, 42(5): 500-504.

[10] 赵志国, 鲁雄刚,丁伟中, 周国治. 利用固体透氧膜提取海绵钛的新技术[J]. 上海金属, 2005, 27(2): 40-43.

ZHAO Zhi-guo, LU Xiong-gang, DING Wei-zhong, ZHOU Guo-zhi. A new technology of using SOM process to produce titanium sponge[J]. Shanghai Metals, 2003, 27(2): 40-43.

[11] CHEN G Z, FRAY D J, FARTHING T W. Direct electrochemical reduction of titanium dioxide to titanium in molten calcium chloride[J]. Nature, 2000, 407(21): 361-364.

[12] SCHWANDT C, ALEXANDER D T L, FRAY D J. The electro-deoxidation of porous titanium dioxide precursors in molten calcium chloride under cathodic potential control[J]. Electrochimica Acta, 2009, 54: 3819-3829.

[13] SCHWANDT C, FRAY D J. Determination of the kinetic pathway in the electrochemical reduction of titanium dioxide in molten calcium chloride[J]. Electrochimica Acta, 2005, 51: 66-76.

[14] MASSALSKI T B, SUBRAMANIAN P R, OKAMOTO H, KACPRZAK L. Binary alloy phase diagrams[M]. 2nd ed. Materials Park, OH:ASM International, 1990.

[15] MA Meng, WANG Di-hua, HU Xiao-hong, JIN Xian-bo, CHEN G Z. Extraction of titanium from different titanium precursors by the FFC Cambridge process[J]. Journal of Alloys and Compounds, 2006, 420: 37-45.

[16] PENY G S, SHAW S J. Solubility of calcium in CaO-CaC12[R]. AWE Report No.O-16/90, AWE-Aldermaston, Reading, UK, 1990.

[17] JIN Xian-bo,GAO Pei,WANG Di-hua, HU Xiao-hong,CHEN G Z. Electrochemical preparation of silicon and its alloys from solid oxides in molten calcium chloride[J]. Angewandte Chemie-International Edition,2004, 43(6): 733-736.

[18] WANG Di-hua, JIN Xian-bo, CHEN G Z. Solid state reactions: an electrochemical approach in molten salts[J]. Annual Reports on the Progress of Chemistry Section C, 2008, 104: 189-234.

[19] 唐仁政, 田荣璋. 二元合金相图及中间相晶体结构[M]. 长沙: 中南大学出版社, 2009: 48-62.

TANG Ren-zheng, TIAN Rong-zhang. Binary Alloy Phase Diagrams and crystal structure of the intermediate phase[M]. Changsha: Central South University Press, 2009: 48-62

(编辑 何学锋)

基金项目:国家重点基础研究发展计划资助项目(2007CB613606);国家自然科学基金资助项目(50774052);攀枝花市科委资助项目(2008CY-G-6)

收稿日期:2009-06-03 修订日期:2010-04-22

通信作者:鲁雄刚,教授,博士;电话:021-56335768;Email:luxg@shu.edu.cn