文章编号:1004-0609(2010)12-2401-05

磷酸处理提高氢氧化铝热稳定性的机理

李昌林,周向阳,张太康,伍上元,李 劼

(中南大学 冶金科学与工程学院,长沙 410083)

摘 要:研究磷酸改性对氢氧化铝物相、形貌、表面基团及热稳定性的影响,并从动力学与热力学角度分析磷酸改善氢氧化铝热稳定性的机理。采用磷酸改性处理可提高氢氧化铝粉体的热稳定性,其直接的原因是改性后粉体表面形成耐热铝盐包覆层;改性氢氧化铝热稳定性提高的动力学原因是,颗粒受热分解产生的水蒸气在向外扩散时,除需克服分解产物层的扩散阻力外,还要克服其在包覆层中的动力学阻碍;改性氢氧化铝热稳定性提高的热力学原因是,包覆层使氢氧化铝内核表面的水分子浓度提高,使得氢氧化铝分解反应的平衡水蒸气分压增大,从而相应提高分解温度。

关键词:氢氧化铝;磷酸改性;包覆层;热稳定性;机理

中图分类号:TQ133.1 文献标志码:A

Mechanism of raising thermal stability of aluminum hydrate modified by

phosphoric acid

LI Chang-lin, ZHOU Xiang-yang, ZHANG Tai-kang, WU Shang-yuan, LI Jie

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of modification by phosphoric acid on phases, morphologies, surface groups and thermal stability of aluminum hydrate (AH) were investigated, and the mechanism of phosphoric acid improving thermal stability of AH was analyzed from views of kinetics and thermodynamics. The modification by phosphoric acid can improve thermal stability of AH, which attributes to the formation of heat resistant aluminum salt coating on the surface of AH particles caused by the inter-reaction between phosphoric acid and AH particles. The mechanism of improving thermal stability of modified AH is that, according to kinetics of the water vapor produced by decomposing modified AH diffuses, it has to get over not only the diffusion resistance of decomposed product, but also the kinetics resistance of coating layer. According to thermodynamics, AH decomposing the water vapor on the surface of AH kernel increases the equilibrium press of water vapor, thus, the decomposing temperature rises.

Key words: aluminum hydrate; phosphoric acid modification; coating; thermal stability; mechanism

氢氧化铝具有优异的阻燃性能,但其分解温度低(一般在180~200 ℃)的不足严重阻碍其在工程塑料等领域的深广应用[1-3]。许多研究者采取部分脱水[4]、超细微细化与高纯化[5-7]、同其它化合物复合[8-9]以及表面包覆改性[10-11]等处理方法来改善其热稳定性。在这些处理方法中,表面包覆改性是一种最简单、易行的方法,但有关表面包覆改性改善氢氧化铝热稳定性的机理分析很少见文献报道。在此,本文作者主要研究磷酸改性处理前、后氢氧化铝的热稳定性等指标的变化,并从热力学与动力学角度探讨磷酸改性处理提高氢氧化铝热稳定性的机理。

1 实验

1.1 实验样品的制备

本实验所采用的主要原料有氢氧化铝微粉(由山东铝业股份有限公司提供),浓磷酸(浓度85%,分析纯),去离子水;主要设备有:恒温水浴系统,SHB-ⅢA循环水式多用真空泵(郑州长城科工贸有限公司生产)及鼓风干燥箱等。

周向阳等[11]详细研究了磷酸改善氢氧化铝热稳定性的工艺,本实验样品的制备与该文献中的相同,具体描述为:将浓度为10%的磷酸溶液搅拌、加热至90 ℃,加入适量氢氧化铝,控制反应体系液固比为1:1(液体为1 mL,固体为1 g),反应75 min后过滤,滤饼用去离子水洗涤4次后在120 ℃烘干12 h即得实验样品。

1.2 实验样品的性能检测与表征

粉体的物相用XRD(仪器型号D8-advance,扫描速度8(°)/min)来分析;采用傅里叶红外光谱仪(型号NEXUS 470 FT-IR)分析粉体的表面基团; 样品的形貌利用SEM(日本电子公司生产的(JEOL)JSM5600型扫描仪)来观察;用DSC-DTA测试技术(仪器型号SDT Q600)分析样品在不同温度下的质量损失情况。

2 结果与讨论

2.1 磷酸改性对氢氧化铝粉体性能的影响

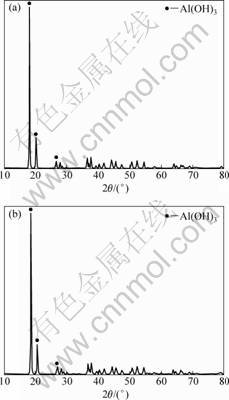

图1所示为改性处理前后粉体的XRD谱。显然,改性处理并没有改变粉体的氢氧化铝的结构,但改性后粉体的主要衍射峰强度均有不同程度的降低,这表明改性后粉体的表面可能覆盖了一层其它物质。

图2所示为改性处理前、后粉体的红外光谱。从图2可知在3 620~3 200 cm-1,两个样品均有4个伸缩振动吸收峰,这应该是粉体表面存在羟基的缘 故[12-13]。这些羟基有可能来自粉体表面的游离水,也有可能来自粉体的结晶水;对改性粉体而言,这些羟基还有可能来自改性剂磷酸。对比3 620~3 200 cm-1振动峰的强度可知,磷酸的改性处理使得这些峰的强度有所减弱,这可能是—OH与P相连,导致—OH的极性减弱所致。对比两个样品在1 200~600 cm-1的吸收峰可发现,磷酸改性处理后,粉体在1 111 cm-1波

图1 磷酸改性处理前、后Al(OH)3粉体的XRD谱

Fig.1 XRD patterns of Al(OH)3 powder before (a) and after (b) phosphoric acid modification

图2 磷酸改性处理前、后Al(OH)3粉体的红外光谱

Fig.2 FTIR spectra of Al(OH)3 powder before (a) and after (b) phosphoric acid modification

段处额外出现了一个尖的振动峰。此峰应归于粉体表面P—O—P键的存在[14],也就是说,改性处理使粉体表面形成了含磷化合物。

图3所示为改性处理前、后粉体的SEM像。不难发现,磷酸改性处理后粉体颗粒有不同程度的长大,并且还有尺寸较大的团聚粒子出现,这可能是由于磷酸与氢氧化铝反应在颗粒表面形成了一层铝的磷酸盐包覆层,从而使得粉体颗粒长大;包覆层中具有粘接性能的磷酸二氢铝类组分将不同颗粒粘接在一起,从而造成了大团聚粒子的出现。

图3 磷酸改性处理前后Al(OH)3粉体的SEM像

Fig.3 SEM images of Al(OH)3 powder before (a) and after (b) phosphoric acid modification

从上面的分析可以推断,磷酸改性处理后氢氧化铝颗粒表面形成了一层含铝磷酸盐。

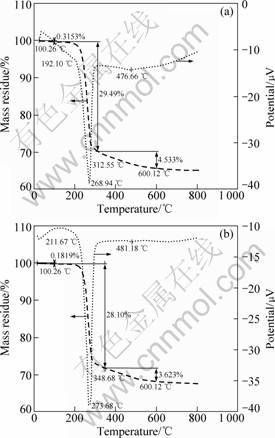

图4所示为改性处理前、后粉体的DSC-TGA曲线。普通氢氧化铝阻燃剂受热时分解过程分段进行:1) Al(OH)3转变为(AlOOH)0.25(Al(OH)3)0.75;2) (AlOOH)0.25(Al(OH)3)0.75转变为(AlOOH)2/3(Al2O3)1/3;3) (AlOOH) 2/3(Al2O3)1/3转变为Al2O3[15],在分解过程中3个过程分别失去0.5、2和0.5个结晶水。由于氢氧化铝颗粒细小,第一步和第二步分解时的质量损失台阶连为一体,质量损失率共为29.49%,第三步分解时质量损失率为4.533%。在DSC曲线上形成2个吸热峰,其中峰值温度为268.94 ℃的吸热峰对应第一步和第二步分解脱水,峰值温度为476.66 ℃的吸热峰对应第三步分解脱水。改性前粉体在100 ℃到600 ℃之间的总质量损失率约为34%,但改性后样品的质量损失率却较改性前的约小2.3%,这应该是改性处理后不可热解磷酸铝盐存在的缘故。改性处理后氢氧化铝分解时在DSC曲线上形成的吸热峰位置不同程度地向高温方向偏移;粉体失去初始结晶水的温度由改性前的192.10 ℃提高到了改性后的211.67 ℃,说明磷酸改性处理可有效提高氢氧化铝微粉的热稳定性。根据TGA曲线,粉体在100 ℃到215 ℃之间的质量损失率由改性前的0.975%降到了改性后的0.221%,这说明改性处理可延缓粉体的分解进程。另外,两种粉体样品在100 ℃前均有一定的质量损失,这应该是粉体吸附空气中水分所导致。综合前面的分析可知,磷酸改性处理可改善氢氧化铝热稳定性的直接原因是改性后粉体表面形成了含铝磷酸盐包覆层。

图4 磷酸改性处理前、后Al(OH)3粉体的DSC-TGA曲线

Fig.4 DSC-TGA curves of Al(OH)3 powder before (a) and after (b) phosphoric acid modification

2.2 磷酸盐包覆层改善氢氧化铝热稳定性的机理 分析

从前面的研究可知,磷酸改性提高氢氧化铝热稳定性的直接原因是粉体表面形成了一层含铝磷酸盐。本部分将从动力学与热力学两方面来分析磷酸改善氢氧化铝热稳定性的机理。

因本文作者所研究的氢氧化铝是作为阻燃剂使用的,这里只讨论Al(OH)3从受热到分解为(AlOOH)0.25- (Al(OH)3)0.75这一过程中的动力学和热力学情况,并假设氢氧化铝颗粒为球形,改性后粉体表面形成了一层均匀的包覆层。

2.2.1 氢氧化铝颗粒分解的动力学过程分析

动力学主要用来研究反应的速度及各种因素对反应速度的影响情况[16]。对未包覆的单个氢氧化铝颗粒而言,分解反应(1)开始后将形成Al(OH)3/(AlOOH)0.25- (Al(OH)3)0.75相界面。随着反应的进行,该相界面逐渐向氢氧化铝颗粒内核推进,分解反应(1)所产生的H2O气体经过(AlOOH)0.25(Al(OH)3)0.75产物层向外界扩散。在初始分解阶段,其分解产物(AlOOH)0.25(Al(OH)3)0.75疏松多孔,H2O在(AlOOH)0.25(Al(OH)3)0.75产物层中扩散速度较快,分解反应阶段是氢氧化铝分解反应的限制性环节;随着分解反应的进行,氢氧化铝内核逐渐变小,(AlOOH)0.25(Al(OH)3)0.75产物层逐渐变厚、并逐渐致密,H2O在产物层中的扩散速度逐渐变慢。

Al(OH)3=(AlOOH)0.25(Al(OH)3)0.75+0.5H2O (1)

对包覆后的单个粉体颗粒而言,分解反应的进行同样会促使Al(OH)3/(AlOOH)0.25(Al(OH)3)0.75相界面逐渐向氢氧化铝颗粒内核的推进,与未包覆颗粒的主要不同之处在于:式(1)所产生的H2O气体除了要克服其在(AlOOH)0.25(Al(OH)3)0.75产物层的扩散阻力外、还要克服其在包覆层中的动力学阻碍才能扩散到外界,H2O气体在包覆层中的这种动力学阻碍,会降低其向外界的扩散速率,也会使得在Al(OH)3/(AlOOH)0.25- (Al(OH)3)0.75相界面上的H2O气体浓度较高;这种动力学阻碍还可能使反应控制步骤很快由氢氧化铝分解反应转变为混合控制或扩散控制,此时反应(1)的分解速率将减慢。这也是前面图4所示的、在相同热分解时间和热分解温度段内(因升温速率相同,所以在100~215 ℃的热分解时间也相同)改性粉体的质量损失率大大低于未改性粉体的根本原因。

2.2.2 氢氧化铝颗粒分解的热力学分析

物质的分解温度与热力学相关[17]。本部分将从热力学角度分析改性前后氢氧化铝粉体热稳定性差异的原因。

对于式(1)而言,反应的标准平衡常数:

(2)

(2)

式中: 和

和 分别表示(AlOOH)0.25(Al(OH)3)0.75和Al(OH)3的活度,当(AlOOH)0.25(Al(OH)3)0.75和Al(OH)3均为纯物质处于标准状态时,则它们的活度均为1;pΘ为标准压力,将式(2)代入等温方程,整理后有

分别表示(AlOOH)0.25(Al(OH)3)0.75和Al(OH)3的活度,当(AlOOH)0.25(Al(OH)3)0.75和Al(OH)3均为纯物质处于标准状态时,则它们的活度均为1;pΘ为标准压力,将式(2)代入等温方程,整理后有

(3)

(3)

式中Δr /RT为反应式(1)的标准吉布斯自由能变化值。

/RT为反应式(1)的标准吉布斯自由能变化值。

因为本研究的反应物和生成物的温度均在不发生相变的温度范围内,Δr 与温度的关系可近似用直线表示:

与温度的关系可近似用直线表示:

Δr =A+BT (4)

=A+BT (4)

故式(3)可改写为

(5)

(5)

其中:C=-Δr /(2.303R),D= B/(2.303R)。

/(2.303R),D= B/(2.303R)。

式中:Δr 为分解反应(1)的标准摩尔焓变化,其为正值。

为分解反应(1)的标准摩尔焓变化,其为正值。

式(5)表示的是H2O气体分压与分解温度的关系,显然,分解温度与H2O气体分压有着密切联系,H2O气体分压的增大将会促使分解温度提高。从前面的分析可知,包覆层的存在,促使了Al(OH)3/ (AlOOH)0.25- (Al(OH)3)0.75相界面上的H2O气体分压的提高,因而导致包覆后粉体的分解温度较包覆的前高。

3 结论

1) 磷酸改性处理没有改变氢氧化铝粉体的氢氧化铝结构,但会导致氢氧化铝颗粒的长大。

2) 磷酸改性处理可提高氢氧化铝的热稳定性,热重测试结果表明粉体的初始失去结晶水由改性前高的192 ℃提高到211 ℃;热稳定性得到改善的直接原因是改性使粉体表面形成了耐热磷酸铝盐包覆层。

3) 磷酸改性提高氢氧化铝热稳定性的动力学原因是,氢氧化铝颗粒受热分解产生的水蒸气在逸出颗粒表面时,除需克服分解产物层的扩散阻力外、还要克服其在包覆层中的动力学阻碍;磷酸改性提高氢氧化铝热稳定性的热力学原因是,包覆层使氢氧化铝内核表面的水分子浓度提高,即使氢氧化铝分解反应的平衡水蒸气分压增大,从而使分解温度相应得到提高。

REFERENCES

[1] 王庆伟, 夏 忠, 刑曙亚, 赵文瑛. 一种氢氧化铝阻燃剂的制备方法: CN 02153734.8[P]. 2002-12-03.

[2] WANG Qing-wei, XIA Zhong, XING Shu-ya, ZHAO Wen-ying. Preparation of aluminum hydrate flame retardant: CN 02153734.8[P]. 2002-12-03.

[3] ZHOU Xiang-yang, LI Chang-lin, HUO Deng-wei, LI Jie, WU Shang-yuan. Thermal stability and oil absorption of aluminum hydroxide treated by dry modification with different modifiers[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 908-912.

[4] ZHOU Xiang-yang, LI Chang-lin, HUO Deng-wei, LI Jie, WU Shang-yuan, LIU Ye-xiang. Thermal stability and oil absorption of aluminum hydroxide treated by dry modification with phosphoric acid[J]. Journal of Central South University of Technology, 2007, 14(6): 779-782.

[5] NEIL B, MICHAEL A. Nonhygroscopic thermally stable aluminum hydroxide: US 6280839 B1[P]. 1999-08-28.

[6] 董 均. 无机氢氧化物阻燃剂的应用与发展趋势[J]. 中国西部科技, 2004(6): 16-18.

[7] DONG Jun. Applications and development current of Inorganic hydrate flame retardant in polymers[J]. Science and Technology of West China, 2004(6): 16-18.

[8] CHEN Jian-feng, SHAO Lei, GUO Fen, WANG Xing-ming. Synthesis of nano-fibers of aluminum hydroxide in novel rotating packed bed reactor[J]. Chemical Engineering Science, 2003, 2/3: 569-575.

[9] 黄 东, 南 海, 吴 鹤. 氢氧化铝的阻燃性质与应用研究[J]. 材料开发与应用, 2003, 19(3): 33-37 .

[10] HUANG Dong, NAN Hai, WU He. Flame retardancy property and application of Al(OH)3[J]. Materials Exploitation and Application, 2003, 19(3): 33-37.

[11] 马淑花, 郭 奋, 陈建峰. 氢氧化铝的化学改性研究[J]. 北京化工大学学报, 2004, 31(4): 19-22.

[12] MA Shu-hua, GUO Fen, CHEN Jian-feng. Chemical modification of aluminum hydroxide[J]. Journal of Beijing University of Chemical Technology, 2004, 31(4): 19-22.

[13] 任庆利, 罗 强, 陈寿田, 吴洪才. 针状纳米晶镁铝水滑石阻燃剂结晶状况的优化[J]. 西安交通大学学报, 2004, 38(10): 1000-1004.

[14] REN Qing-li, LUO Qiang, CHEN Shou-tian, WU Hong-cai. Crystallization optimization of a flame retardant agent aciculate nanocrystalline Mg,Al-hydrotalcite[J]. Journal of Xi’an Jiaotong University, 2004, 38(10): 1000-1004.

[15] 四季春, 郑水林, 路迈西. 氢化铝的表面改性及应用研究[J].粉体表面改性, 2005, 11(2): 17-20.

[16] SI Ji-chun, ZHENG Shui-lin, LU Mai-xi. Surface modifying and applied research of aluminum hydroxide[J]. Powder Surface Modification, 2005, 11(2): 17-20.

[17] 周向阳, 李昌林, 霍登伟, 李 劼, 伍上元. 磷酸改性处理后氢氧化铝的热稳定性[J]. 中国有色金属学报, 2006, 16(12): 2115-2119.

[18] ZHOU Xiang-yang, LI Chang-lin, HUO Deng-wei, LI Jie, WU Shang-yuan. Thermal stability of aluminum hydrate modified by phosphoric acid[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(12): 2115-2119.

[19] 蒋先明, 何伟平. 简明红外光谱识谱法[M]. 桂林: 广西师范大学出版社, 1992.

[20] JIANG Xian-ming, HE Wei-ping. Concise infrared spectrum identifying method[M]. Guilin: Guangxi Normal University Press, 1992.

[21] 董庆华. 红外光谱法[M]. 北京: 石油化学工业出版社, 1977.

[22] DONG Qing-hua. Infrared spectroscopy[M]. Beijing: Petrochemical Industry Press, 1977.

[23] EFIMOV A M. IR fundamental spectra and structure of pyrophosphate glasses along the 2ZnO·P2O5-2Me2O?P2O5 join (Me being Na and Li)[J]. Journal of Non-Crystalline Solids, 1997, 209(4): 209-226.

[24] 顾志山. 工业氢氧化铝的热分解行为[J]. 无机盐工业, 1984(12): 18-20.

[25] GU Zhi-Shan. Thermal decomposition of industrial aluminum hydroxide[J]. Inorganic Chemicals Industry, 1984(12): 18-20.

[26] 李洪桂. 冶金原理[M]. 北京: 科学出版社, 2005.

[27] LI Hong-gui. Metallurgy principle[M]. Beijing: Science Press, 2005.

[28] 傅崇说. 有色冶金原理[M]. 北京: 冶金工业出版社, 1993.

[29] FU Chong-yue. Nonferrous metal metallurgy principle[M]. Beijing: Metallurgy Industry Press, 1993.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(50974136);湖南省研究生科研创新资助项目(CX2009B037)

收稿日期:2010-01-28;修订日期:2010-05-25

通信作者:周向阳,教授,博士;电话:0731-88836329;E-mail:zxy13908482918@163.com