文章编号:1004-0609(2008)S1-0074-06

加压酸浸法回收黑色页岩中的钒

李旻廷,李存兄,邓志敢,吴惠玲,梁艳辉,魏 昶

(昆明理工大学 材料与冶金工程学院,昆明 650093)

摘 要:提出一种在加压条件下酸浸黑色页岩型矿提取钒的新工艺,研究浸出过程中各种工艺参数对钒浸出率指标的影响,同时进行了两段逆流浸出实验;利用电子探针分析矿石中钒在各物相中的分配情况,并在两段逆流浸出基础上进一步强化实验条件,考察了钒浸出率与矿石中钒赋存状态之间的关系。结果表明:该工艺的最佳工艺参数如下,即时间3 h、温度150 ℃、液固比1.2?1、硫酸用量25%、85%矿石粒度粒经小于0.095 mm;在此条件下,钒的一段浸出率为77%左右,而矿石经过两段逆流浸出后,钒浸出率可达90%;钒浸出率与矿石中难溶硅铝酸盐相中的钒占有率呈现消长关系。

关键词:石煤;氧压酸浸;硫酸亚铁;钒;浸出率

中图分类号:TF 841.3 文献标识码:A

Recovery of vanadium from black shale by means of pressure acid leaching

LI Min-ting, LI Cun-xiong, DENG Zhi-gan, WU Hui-ling, LIANG Yan-hui, WEI Chang

(College of Material and Metallurgical Engineering, Kunming University of Science and Technology, Kunming 650093, China)

Abstract: A new technique of recovery of vanadium from black shale by pressure acid leaching was investigated. The influences of changing parameters of pressure acid leaching process on the leaching rate of vanadium were discussed, and the experiment of two-step countercurrent leaching was developed. The distribution of vanadium in black shale was analyzed by SEM and the leaching conditions was strengthened on the foundation of two-step countercurrent leaching. The results show that the optimal parameters of this technique are as time of 3 h, temperature of 150 ℃, ratio of liquor to solid of 1.2?1, H2SO4 additions of 25%, 85% material granularity of 0.095 mm. The one-step leaching percent of vanadium can reach 77%, the leaching percent obtain 90% after two-step countercurrent leaching. The vanadium leaching percent have growth and decline relation to occupation ratio of vanadium in in-soluble silicoaluminate mineral.

Key words: black shale; acid pressure leaching; ferrous sulfate; vanadium; leaching rate

黑色页岩型钒矿(俗称石煤)是我国一种重要钒矿资源,广泛分布于我国南方诸省及西北地区,石煤中V2O5的总储量达1.1×108 t,为我国钒钛磁铁矿中钒总储量的6.7倍[1]。但石煤中V2O5品位达到0.80%~0.85%以上时,才具有工业开采和利用价值。

在国外,从石煤中提取钒,多采用酸浸或钠化焙烧—酸浸工艺流程[2]。美国矿业局从内华达州的风化页岩中(V2O5品位1%)提取钒采用的是钠盐焙烧—溶剂萃取一铵盐沉淀工艺流程[3];波兰从含五氧化二钒的石煤中回收钒采用的是在250 ℃下硫酸化培烧—水浸工艺。此外,从加拿大石油工业中产生的粉尘[4](V2O5品位3.6%~6.2%)、石油焦[5](V2O5品位 0.1%)等物料中回收钒,采用的工艺流程也大多为钠化焙烧—酸浸,钒浸出率为60%~85%。

在我国,石煤提钒传统工艺一般也沿用国外的钠盐焙烧—酸浸工艺,同时也有研究者采用改进型焙烧—酸浸工艺,如钙化焙烧—酸浸[6]、无盐焙烧—酸浸[7]。不管采用何种焙烧工艺,其过程不可避免会产生烟气或有害气体,对环境冲击较大,且V2O5回收率不高,普遍在40%~50%左右。近年来,一些科研人员对湿法提钒进行了大量研究[8-14],这些方法多采用常压浸出,钒浸出率普遍不高亦浸出时间较长(15~ 20 h)。

针对上述情况,本文作者提出一种在加压条件下从黑色页岩型矿中提取钒的新工艺,该工艺不需要焙烧,工艺流程简单。在加压条件下浸出时间大大缩短,且钒浸出率可达90%以上,为从黑色页岩型矿石中提取钒开辟一条新途径。

1 实验

1.1 矿石的化学成分

实验用矿样来自贵州某地,经破碎、磨细至粒径小于0.074 mm,其主要化学成分列于表1。

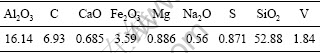

表1 矿样的主要化学成分分析结果

Table 1 Analysis results of main chemical components of materials (mass fraction, %)

1.2 试剂及装置

实验试剂如下:硫酸(分析纯)、氧化剂为工业纯氧;实验反应装置为WHF-2T小型永磁旋转搅拌钛质反应釜、真空泵、抽滤瓶。

1.3 实验方法

称取一定量的矿样,控制一定实验条件进行调浆。把浆料加入反应釜后,密闭反应釜,随后开始加热升温,同时向反应釜通入氧气,进行加压酸浸。待恒温结束后,真空抽滤取出浸出浆料进行液固分离,分析渣相中的钒含量,计算钒浸出率(渣计)。

2 结果及讨论

2.1 浸出时间的影响

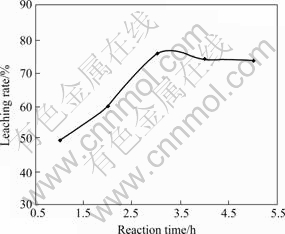

固定加压浸出温度180 ℃,液固比1.2?1,硫酸用量25%(矿量质量百分数),85%矿石粒径小于0.074 mm,搅拌转速580 r/min,通入工业纯氧,恒定过程总压力1.2 MPa。浸出时间对钒浸出率的影响如图1所示。

图1 浸出时间对钒浸出率的影响

Fig.1 Effect of leaching time on leaching rate of vanadium

从图1看出,随着时间的延长,钒浸出率迅速提高,在3 h达到峰值,为75.79%。此后再延长浸出时间,则钒浸出率略有下降的趋势。这可能是由于反应时间延长,促使被溶出的钒与某些成分又发生复杂的化学反应而产生新的固相物质,致使钒浸出率降低。因此浸出时间可控制在3 h左右。

2.2 浸出温度的影响

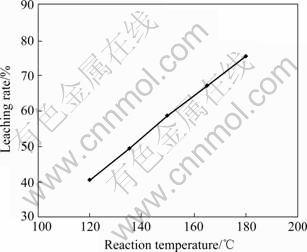

固定其余实验条件,改变浸出过程温度。温度对钒浸出率的影响如图2所示。

图2 温度对钒浸出率的影响

Fig.2 Effect of leaching temperature on leaching rate of vanadium

从图2 可知,浸出温度与钒浸出率基本上呈线性关系变化,180 ℃时,钒浸出最高可达75.3%。但工业生产中要考虑能耗的问题,浸出温度不可能无限增大。可以通过增加浸出次数来解决浸出率较低的问题,因此,温度选为150 ℃较为合适。在此温度下对反应釜的材质要求相对较低。

2.3 反应液固比的影响

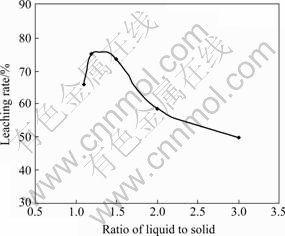

在相同初始硫酸加入量的条件下,固定其余实验条件。反应液固比(体积质量比)对钒浸出率的影响如图3所示。

图3 液固比对钒浸出率的影响

Fig.3 Effect of ratio of liquor to solid on leaching rate of vanadium

从图3可看到,在相同初始硫酸加入量的条件下增大液固比,亦即降低浸出剂的浓度,使扩散速率变慢,因而钒浸出率逐步降低。当液固比为1.1?1时的钒浸出率反而低于1.2?1。这是因为,当液固比为1.1?1时,浆料过于粘稠,不利于溶剂的扩散与传质,动力学条件变差,导致钒浸出率降低。因此液固比控制在1.2~1.5?1左右。

2.4 硫酸用量的影响

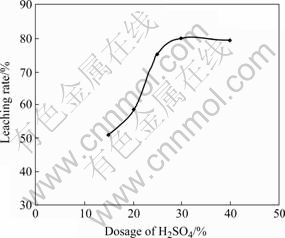

固定其余实验条件,硫酸用量对钒浸出率的影响如图4所示。

图4 硫酸用量对钒浸出率的影响

Fig.4 Effect of dosage of sulfuric acid on leaching rate of vanadium

从图4可知,随着硫酸用量的增加而钒浸出率迅速提高,当硫酸用量超过25%时,钒浸出率基本不再增加,因此硫酸用量在25%~30%较为合适。目前尚不清楚硫酸用量增加到一定程度后钒浸出率不再增加的原因,需要进一步深入的研究。

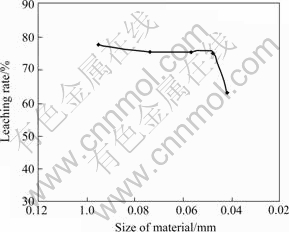

2.5 矿石粒度的影响

称取一定量原矿,进行10 min磨矿,然后进行筛分,而筛上物再磨矿10 min,筛分,如此循环直至矿石的筛下得率为85%,最后把筛下物与筛上物混合后作为实验原料。固定其余实验条件,矿石粒度对钒浸出率的影响如图5所示。

图5 矿石粒度对钒浸出率的影响

Fig.5 Effect of granularity of material on leaching rate of vanadium

从图5可知,矿石粒度越细,钒浸出率有下降的趋势;当矿物粒度小于0.048 mm时,钒浸出显著下降。这是因为,矿石粒度越细,细颗粒越容易发生团聚,使浸出剂难以达到矿石颗粒表面参与化学反应,致使浸出率降低。同时矿石粒度越细,加工过程所需的能耗越高。因而浸出过程中85%矿石粒度小于0.095 mm较为合适,此时钒浸出率最高,为77.51%。

根据上述条件实验,可得到一段浸出的最佳工艺参数,即时间3 h、温度150 ℃、液固比1.2?1、硫酸用量25%、矿石85%过0.095 mm筛。在此条件下,钒浸出率可达75%~77%左右。

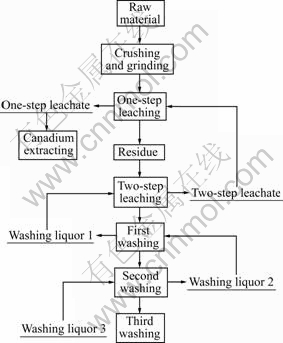

2.6 两段浸出综合实验

采用两段开路浸出的方法后,钒浸出率最高可达95.3%,为了提高溶液中的残余硫酸,本实验采用两段逆流浸出的方法,工艺流程如图6所示。Ⅰ段浸出实验条件:浸出温度150 ℃,浸出时间3 h,液固比1.2?1,硫酸用量25%,矿石粒度小于0.095 mm (>85%),搅拌转速580 r/min。Ⅱ段浸出实验条件:浸出温度150 ℃,浸出时间4 h,液固比1.2?1,硫酸用量35%,搅拌转速580 r/min。 两段浸出过程均通入工业纯氧,恒定过程总压力1.2 MPa。Ⅱ段浸出率为Ⅱ段浸出过程中被浸出来的钒量占原料中总钒的比率。实验结果如表2所列。

表2 逆流浸出实验结果

Table 2 Results of two-step countercurrent leaching experi- ment

图6 逆流浸出实验工艺流程图

Fig.6 Flow sheet of two-step countercurrent leaching experi- ment

从表2可知,采用两段浸出后,钒的浸出率可达到90%,比采用一段浸出方法的提高15%左右。实验中也考察了将工业纯氧替换成空气的情况,控制浸出过程空气压力为1.2 MPa。结果表明,钒浸出率无论是Ⅰ段、Ⅱ段还是两段浸出率变化均不大,仅比使用工业纯氧时的浸出率降低约1%~2%。因此,使用空气代替氧气作为浸出过程的氧化剂是完全可行的。

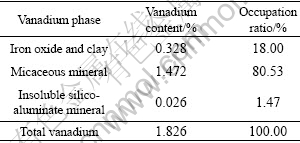

2.7 钒浸出率与矿石中钒赋存状态之间的关系

矿石中钒的物相分为3类[15]:氧化铁及粘土类,云母类矿石和难溶硅酸盐相。矿石中钒在各物相中的分配情况如表3所示。

表3 矿石中钒在各物相中的分配

Table 3 Distribution of phase and valence state in mineral

从表3可知,本实验用矿石中钒在这3类矿物中的占有率分别为:18.00%、80.53%、1.47%。而前期采用两段开路浸出的方法后,钒的总浸出率最高可达95.3%,这一结果与矿石中钒在氧化铁及粘土、云母类矿物中的占有率之和(98.53%)比较接近。因此,可以认为,矿石中氧化铁及粘土、云母类矿物中的钒是可溶性的钒,而难溶硅铝酸盐相中的钒是难溶性的钒。

为了进一步证实这一结论进行,在两段逆流浸出实验的基础上,对实验条件进行进一步强化。提高温度至170 ℃,Ⅰ和Ⅱ段浸出硫酸用量分别提高至30%和40%;通入O2,其余实验条件不变,做3组平行实验,取平均值。结果发现,钒浸出率可达97.4%,更接近于矿石中钒在氧化铁及粘土、云母类矿物中的占有率之和(98.53%)。至于两者之间存在的差异,可能是由于在此条件下,矿石中可溶性钒没有被完全溶出所致。因此,矿石中氧化铁及粘土类、云母类矿物中的钒是可溶性的钒,而难溶硅铝酸盐相中的钒是难以被溶出的,即钒浸出率与难溶硅铝酸盐相中钒占有率呈消长关系。当难溶硅铝酸盐相中钒的含量较高时,则很难获得较高的浸出率;反之,则可得到较高的浸出率。

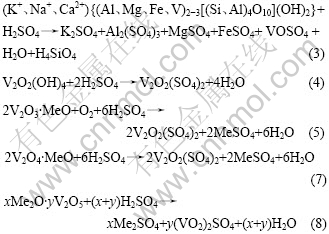

3 浸出反应机理

有资料表明[16-17],我国南方黑色页岩型钒矿石中大部分钒主要赋存于伊利石类粘土矿物中,在原样中钒绝大部分以V3+的形式存在于粘土矿物二八面体夹心层中,部分取代Al3+。这种硅铝酸盐结构较为稳定,通常矿石中V3+难以被水、酸或碱溶解,除非采用HF破坏粘土矿物晶体结构。而VO2可允许存在于伊利石类粘土矿物二八面晶格中.取代部分Al3+,这部分V4+同样不能被水、酸、碱浸出。即V3+和V3+都以类质同相形式取代部分的Al3+。

本文作者认为,对以类质同相形式存在于硅铝酸盐相中的钒来说,被溶出的关键是要破坏该矿物的晶体结构。而硅铝酸盐可分为难溶的和可溶的,当可溶性的硅铝酸盐相晶体结构破酸坏后,存在于该相中的钒就被释放出来;而对难溶硅铝酸盐来说,由于晶体结构很难被破坏,因此钒就不能被释放出来。

对以类质同相形式存在于可溶性的硅铝酸盐相中的V3+和V4+来说,可用H+进入晶格中置换Al3+,使离子半径发生变化,从而将钒释放出来,其反应式如下:

而对于不是以类质同相形式(游离的或结合态的)存在于氧化铁及粘土类、云母类矿石中的钒来说,同样可用H+分解矿物。在氧气氛下,使不溶于酸的V3+氧化转化为可溶于酸的V4+,矿石中V5+主要以游离态V2O5或结合态(xM2O?yV2O5)钒酸盐形式存在,同样可溶于酸,其反应式如下:

4 结论

1) 对于加压酸浸黑色页岩型钒矿一段浸出的最佳工艺条件为:浸出时间3 h,浸出温度150 ℃,液固比1.2?1,硫酸用量25%,85%矿石粒度粒经小于0.095 mm,浸出过程通入O2,控制总压力为1.2 MPa;对实验原料进行两段逆流浸出,钒的两段总浸出率可达90%,比一段浸出提高15%左右。

2) 矿石中难溶硅铝酸盐相中钒的占有率直接影响钒的浸出率,当该相中钒的占有率较小时,则可获得较高的钒浸出率。两段强化实验结果表明,钒浸出率可达97.4%,这一结果与矿石中可溶性钒的比例98.53%是相近的,证实了难溶硅铝酸盐相中的钒是不可溶的,即钒浸出率与矿石中难溶硅铝酸盐相中钒占有率呈消长关系。

REFERENCES

[1] 宾智勇. 石煤提钒研究进展与五氧化二钒的市场状况[J]. 湖南有色金属, 2006, 22(1): 16-20.

BIN Zhi-yong. Progress of the research on extraction of vanadium pentoxide from stone coal and the market of the V2O5 [J]. 2006, 22(1): 16-20.

[2] MOSKALYK R R, ALFANTAZI A M. Processing of vanadium: A review[J]. Minerals Engineering, 2003, 16: 793-805.

[3] GODARD J B. Salt roasting of vanadium ores[C]//Extr Metal Met Proc Symp, 1981, 127: 45.

[4] HOLLOWAY P C, ETSELL T H. Process for the complete utilization of oil sands fly ash [J]. Canadian Metallurgical Quarterly, 2005, 45(1): 25-32.

[5] HABIB S, MOUSSA A. Extraction of sulfur and vanadium from petroleum coke by means of salt-roasting treatment [J]. Fuel, 2006, 85: 878-880.

[6] 黄克桃, 王兴桐. 氧化钙化焙烧法应用于从钒云母矿中提取钒的研究[J]. 武汉钢铁学院学报, 1992, 15(4): 335-339.

HUANG Ke-tao, WANG Xing-tong. Extraction of vanadium from vanadium mica by liming roasting [J]. Journal of Wuhan Iron and Steel University, 1992, 15(4): 335-339.

[7] 邹晓勇, 欧阳玉祝, 彭清静, 田仁国. 含钒石煤无盐焙烧酸浸生产五氧化二钒工艺的研究[J]. 化学世界, 2001, 42(3): 117-119.

ZOU Xiao-yong, OUYANG Yu-zhu, PENG Qing-jing, TIAN Ren-guo. Study on the process of producing vanadium pentoxide from bone coal vanadium mine by no-salt-roasting and acid leaching [J]. Chemical World, 2001, 42(3): 117-119.

[8] 杨静翎, 金 鑫. 酸浸法提钒新工艺的研究[J]. 北京化工大学学报, 2007, 30(3): 254-257.

YANG Jing-ling, JIN Xin. A new way of recovering vanadium from iron/vanadium slag [J]. Journal of Beijing University of Chemical Technology, 2007, 30(3): 254-257.

[9] 郑祥明, 田学达, 张小云, 石 华, 邓益强. 湿法提取石煤中钒的新工艺研究[J]. 湘潭大学自然科学学报, 2003, 25(1): 43-45.

ZHENG Xiang-ming, TIAN Xue-da, ZHANG Xiao–yun, SHI Hua, DENG Yi-qiang. Extraction of vanadium pentoxide from stone coal with a wet chemical separation method [J]. Natural Science Journal of Xiangtan University, 2003, 25(1): 43-45.

[10] 梁建龙, 刘惠娟, 史文革, 胡鄂明, 李熙琪, 彭 军. 湿法冶金提钒浸出新工艺[J]. 中国矿业, 2006, 15(7):64-66.

LIANG Jian-long, LIU Hui-juan, SHI Wen-ge, HU E-ming, LI Xi-qi, PENG Jun. A study of a new technology leaching of vanadium ores with hydrometallurgy [J]. China Mining Magazine, 2006, 15(7): 64-66.

[11] 曹建兵, 欧阳玉祝, 李志平, 麻成金. 石煤矿渣中钒浸取工艺条件研究[J]. 湖南城市学院学报, 2005, 14(4): 54-56.

CAO Jian-bing, OUYANG Yu-zhu, LI Zhi-ping, MA Cheng-jin. Study on technological conditions for the extraction of vanadium from stone coal residue [J]. Journal of Hunan City University (Natural Science), 2005,14(4): 54-56.

[12] 常 娜, 顾兆林, 李 云. 石煤提钒浸出工艺研究[J]. 无机盐工业, 2006, 38(7): 7-59.

CHANG Na, GU Zhao-lin, LI Yun. Study on leaching vanadium from stone coal [J]. Inorganic Chemicals Industry, 2006, 38(7): 57-59.

[13] 段 炼. 我国钒资源的生产及应用研究进展[J]. 湖南有色冶金, 2006, 22(6): 17-20.

DUAN Lian. Review on production and utilization of vanadium resource in China[J]. Hunan Nonferrous Metals, 2006, 2(6): 7-20.

[14] 鲁兆伶. 用酸法从石煤中提取五氧化二钒的试验研究与工业实践[J]. 湿法冶金, 2002, 1(4): 175-183.

LU Zhao-ling. Investigation and industrial practice on extraction of V2O5 from stone coal containing vanadium by acid process [J]. Hydrometallurgy of China, 2002, 21(4): 175-183.

[15] 肖文丁. 广西上林石煤的矿物学和湿法提钒研究[J]. 有色金属, 2007, 59(3): 85-90

XIAO Wen-ding. Mineralogy of stoI/e coal from Shanglin of Guangxi and vanadium extraction with hydrometallurgical process [J]. Nonferrous Metals, 2007, 59(3): 85-90.

[16] 许国镇. 石煤中钒的价态及物质组成对提钒工艺的指导作用[J]. 煤炭加工与综合利用, 1989(5): 5-8.

XU Guo-zhen. Direction function of vanadium valence and material composition in stone coal versus extracting vanadium process [J]. Coal Processing & Comprehensive Utilization, 1989(5): 5-8.

[17] 许国镇, 张秀荣, 尹光衡. 江西玉山石煤烧结包裹与钒转化的研究[J]. 现代地质, 1993, 7(1): 109-117.

XU Guo-zhen, ZHANG Xiu-rong, YIN Guang-heng. Sintering of stone coal and the transformation of vanadium in Yusha Jiangxi Province [J]. Geoscience—Journal of Graduate School, China University of Geosciences, 1993, 7(1): 109-117.

基金项目:国家高技术研究发展计划资助项目(2006AA06Z130); 云南省科技厅资助项目(2007GA010)

通讯作者:魏 昶,教授;电话:0871-5188819;E-mail:weichang2008@sina.com

(编辑 龙怀中)