Trans. Nonferrous Met. Soc. China 22(2012) 761-767

Dynamic recrystallization of Ti-6Al-2Zr-1Mo-1V in β forging process

OUYANG De-lai1, 2, WANG Ke-lu1, CUI Xia1

1. School of Materials Science and Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. School of Materials Science and Technology, Nanjing University of Aeronautics and Astronautics,Nanjing 210016, China

Received 1 April 2011; accepted 8 October 2011

Abstract: The dynamic recrystallization (DRX) behavior of Ti-6Al-2Zr-1Mo-1V alloy was investigated at deformation temperature of 1000-1100 ℃ and strain rate of 10-3-1.0 s-1 by using compression test. The results show that discontinuous dynamic recrystallization (DDRX) is the predominant recrystallization mechanism at temperature higher than 1050 ℃ and strain rate lower than 0.01 s-1. Meanwhile, continuous dynamic recrystallization is the main mechanism observed at temperature below 1050 ℃ and strain rate above 0.01 s-1, mixed with a few DDRX grains. In addition, decreasing strain rate and increasing deformation temperature are found to facilitate the progress of DRX and refinement of grains in the Ti alloy in β forging process.

Key words: dynamic recrystallization; Ti-6Al-2Zr-1Mo-1V alloy; b forging process; compression test

1 Introduction

Ti-6Al-2Zr-1Mo-1V alloy is a kind of near-α alloy with moderate room temperature and high temperature strength, good thermal stability and weldability. It is now emerging as an important aerospace material with increasing application potentials in aerospace industries [1]. Recently, β forging process is introduced for the fabrication of this alloy due to its good workability by forging process. The alloy is forged above (α+β)/β transus temperature so that the β forged Ti-6Al-2Zr-1Mo-1V alloy has lamellar (α+β) microstructure with very attractive creep resistance and fracture properties. However, the grains of this alloy can rapidly grow when the alloy is heated up to the (α+β)/β transus temperature [2]. Since the mechanical properties of the alloy strongly depend on the prior β grain size [3], the study on the grain refinement of the alloy in β forging process is of greatly practical interest. To generate fine microstructure, dynamic recrystallization (DRX) is an important approach, which frequently takes place in hot working of the materials with low or medium stacking fault energy.

Ti alloys are generally considered the materials with high stacking-fault energy (SFE), which are expected to be dynamically softened by dynamic recovery (DRV) instead of DRX [4]. The occurrence of DRX in Ti alloys has been investigated, such as Ti- 10V-4.5Fe-1.5Al alloy by BALASUBRAHMANYAM and PRASAD [5], Ti-6Al-4V alloy by DING and GUO [6], and the near α alloy IMI834 by WANJARA et al [7]. The DRX in some Ti-alloys may be attributed to their composition and their SFE can be decreased greatly compared to pure titanium. There is evidence from prior research that the alloying of Ti with Al decreases the SFE markedly [8]. To articulate the relationship of SFE and the content of Al, GUO et al [9] proposed the relationship between SFE (γ) and aluminum concentration (NAl) for Ti-Al alloys: γ=0.00093/ [0.003exp(0.133NAl)]. Based on the equation, the SFE value for Ti-6Al-2Zr-1Mo-1V with 6.3%Al (mass fraction) is determined to be 0.134 J/m2. The SFE for pure titanium was reported to be in the range of 0.30-0.35 J/m2 [10]. This implies that DRX may take place in this alloy with its SFE decreasing to the medium level and thus the hot working process accompanied by DRX should be a promising method for the grain refinement in β forging process. Therefore, the in-depth research is needed as there is few prior researches conducted.

In this study, the deformation behavior and quantitative characterization of the DRX related microstructure evolution were investigated, and the DRX nucleation mechanisms of Ti-6Al-2Zr-1Mo-1V alloy in β forging process were studied.

2 Experimental

The as-received Ti alloy was the ingot forged below the β-transus temperature of 982 ℃. Its chemical composition (mass fraction, %) was 6.3Al, 1.32Mo, 1.68V, 1.9Zr, and balance Ti. The cylindrical specimens with size of d8 mm×12 mm were machined with flat bottomed grooves on both end surfaces of the specimens for holding lubricant to reduce the friction between die and workpiece. Hot compression tests were conducted in the temperature range of 1000-1100 ℃ and strain rate range of 0.001-1.0 s-1 in a Thermecmaster-Z hot simulator. Upon the completion of hot compression, the samples were quenched directly by helium gas, followed by sectioning along the longitudinal axis direction. The sectioned samples were finally prepared for the microstructure examination by optical microscopy.

3 Results and discussion

3.1 Hot deformation behavior

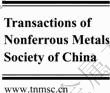

The typical stress—strain curves of the Ti alloy generated via hot compression tests are shown in Fig. 1. At higher deformation temperature or lower strain rate, the characteristic of the true stress—strain curve is that the flow stress increases to a peak value first and then decreases to a steady state at higher deformation temperature, such as 1075 and 1100 ℃, and lower strain rate of 0.01 and 0.001 s-1, as shown in Figs. 1(a) and (b). At lower temperature or higher strain rate, the characteristic of true stress—strain curve, however, is that there is a little drop after the peak stress with further deformation at lower temperature, such as 1000 and 1050 ℃, and higher strain rate of 0.1 and 1.0 s-1, as shown in Figs.1(c) and (d).

3.2 Microstructure evolution

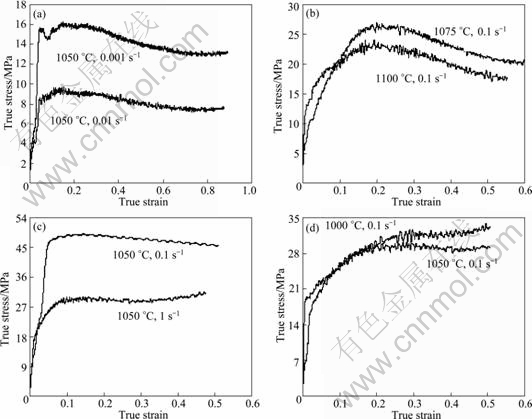

Figure 2 shows the microstructure evolution of the Ti alloy β forged at 1050 ℃ and strain rate of 0.1 s-1. The initial microstructure in Fig. 2(a) shows fairly uniform grain boundaries. After the deformation reaches strain of 0.14, a few DRX grains nucleate at original grain boundaries, especially at triple junctions, as shown in Fig. 2(b). With the increase of strain to 0.36 and 0.51, more DRX grains occur and a “necklace” structure is formed, as shown in Figs. 2(c) and (d)). When the strain is 0.92, the volume fraction of the recrystallized grains reaches 70% and significant grain refinement takes place (Fig. 2(e)). With the strain of 1.2, the DRX grains are dominative, result in that the DRX grains take up about 85% (volume fraction) of the total grains and the grain size apparently decreases (Fig. 2(f)).

Fig. 1 True stress—true strain curves of Ti-6Al-2Zr-1Mo-1V under different deformation conditions

Fig. 2 Optical microstructures of Ti alloy deformed to different strains at 1050 ℃ and strain rate of 0.1 s-1: (a) ε=0; (b) ε=0.14; (c) ε=0.36; (d) ε=0.51; (e) ε=0.92; (f) ε=1.2.

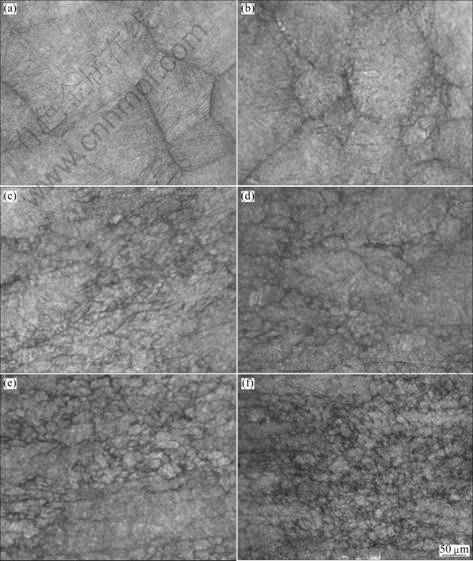

Figure 3 presents the microstructure evolution of the Ti alloy deformed at different temperature and strain rate with strain of 1.2. It is found that the volume fraction of the DRX grains and the size of the recrystallized grains increase with deformation temperature at the given strain rate and strain. This can be explained by the fact that the higher temperature drives the nucleation of DRX and the migration of DRX grain boundaries. With the increase of strain rate, on the other hand, the volume fraction of DRX is decreased and the grain size of the Ti alloy becomes smaller and smaller. At higher temperature, such as 1100 ℃ in Fig. 3(c), and at the lower strain rate, such as 0.001 s-1 in Fig. 3(d), the grain refinement by DRX thus becomes less effective. It can be attributed to the rapid grain growth which cancels out the positive effect of DRX under the deformation conditions.

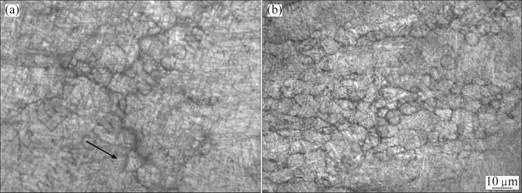

3.3 DRX mechanism

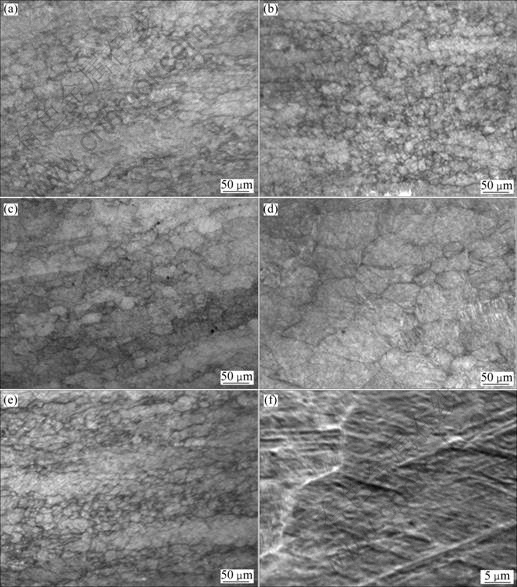

Regarding the nucleation mechanism of DRX, there are two types of nucleation mechanisms. One is the discontinuous DRX (DDRX) nucleated by bulging [11] and the other is the continuous DRX (CDRX) nucleated by subgrain rotating [12]. From the microstructure evolution and flow stress behavior perspective, it is found that both DDRX and CDRX occur at the investigated temperatures and strain rates for the Ti alloy. Figure 4 shows the evolution of grain boundaries, revealing the occurrence of DDRX. At a lower strain as shown in Fig. 4(a), the grain boundaries become serrated and bulged. Some small and new DRX grains are observed at the grain boundaries, especially at the triple junctions (as the arrow marked in Fig. 4(a)). With the increase of strain, many new DRX grains and incomplete necklace structures appear along the origin boundaries (Fig. 4(b)). Such grain boundary morphology indicates that the recrystallized mechanism is DDRX [13].

Fig. 3 Optical microstructure of Ti alloy deformed to strain of 1.2 under different deformation conditions: (a) 0.1 s-1, 1000 ℃; (b) 0.1 s-1, 1050 ℃; (c) 0.1 s-1, 1100 ℃; (d) 0.001 s-1, 1050 ℃; (e) 1 s-1, 1050 ℃; (f) Local amplification of Fig. 3(e) showing the presence of martensite in grain interior

Fig. 4 Evolution of grain boundaries with increasing strain at 1075 ℃ and strain rate of 0.01 s-1: (a) ε=0.05; (b) ε=0.10

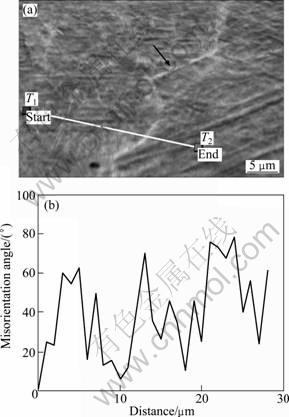

To have a clear insight into the mechanism of DDRX of the Ti alloy, a misorientation angle distribution analysis is conducted based on the EBSD results, as shown in Fig. 5. The bulging of the original grain boundaries can be observed in Fig. 5(a) and there are some low angle (<15°) boundaries near the original bulging grain boundaries in Fig. 5(b). This would suggest that the bulging of the original grain boundaries lead to the development of substructure with the misorientation below 15°. The misorientation analysis further implies that a bridging low-angle boundary is developed behind the bulged section and a gradual rise in the misorientation of low-angle boundaries results in the bulged section being completely “pinched off”, namely, the formation of new grains, as indicated by the arrow in Fig. 4(a).

Fig. 5 EBSD measurement revealing occurrence of DDRX in Ti-6Al-2Zr-1Mo-1V deformed at 1050 ℃ and strain rate of 0.01 s-1: (a) Optical image showing bulging grain boundary (indicated by arrow); (b) Point-to-point misorientations measured along line from T1 to T2 marked in Fig. 5(a)

The initiation of DRX in the Ti alloy at higher temperature (1075 ℃ and above) and lower strain rate (0.01 s-1 and below) is characterized by the extensively serrated grain boundaries. The grain growth is illustrated in Figs. 3(c) and (d). It suggests that the DDRX, as a predominant mechanism, takes place under these deformation conditions. The characteristics of the corresponding stress—strain curves shown in Figs. 1(a) and (b) exhibit a remarkable stress peak, which supports this observation.

BELYAKOV et al [14] proposed the nucleation steps of DDRX, as shown in Fig. 6. During the early hot deformation stage, the grain boundary shearing leads to the evolution of the serrated boundaries (Fig. 6(a)). The increasing strain results in the gradual accumulation of the misorientations of dislocation subboundaries by grain rotation, and further leads to the evolution from middle to high angle subboundaries and the development of heterogeneously local strain gradients along the boundaries (Fig. 6(b)). Consequently, the strain induced subboundaries could be changed to high angle boundaries by absorbing dislocation and separating the bulging part from its parent grains (Fig. 6(c)). The DDRX, on the other hand, involves the nucleation and growth of new grains and results in the reduction of work hardening rate and flow softening, which further leads to a peak in stress—strain curves.

Fig. 6 Schematic model for nucleation of DRX grain at grain boundary: (a) Boundary corrugation accompanied by evolution of subboundaries; (b) Partial grain boundary shearing, leading to development of inhomogeneous local strain; (c) Bulging out of serrated grain boundary and evolution of strain induced subboundaries due to grain boundary shearing, leading to formation of new DRX grain [14]

It is worth noting that CDRX, as a predominant mechanism, is expected to occur at lower temperature (1050 ℃ and below) and higher strain rate (0.1 s-1 and above) despite of the fact that there are some manifestations of DDRX reported. For CDRX, it involves the formation of subgrains and subgrains rotating to new grains by absorbing dislocations, which leads to a little boundary migration and grain growth [15]. Moreover, the stress—strain curve is nearly flat although there is a small drop of stress after the peak value [16]. From the optical microstructures presented in Figs. 2 and 3(a), (b) and (e), it is found that the DRX grains are very fine and nucleated massively. This implies that the DRX involves a little bit boundary migration or grain growth, which is an evidence to support the fact that the CDRX is a predominant mechanism under these deformation conditions. The corresponding stress—strain curves which exhibit the feature of nearly flat line after peak stress shown in Fig. 1(b) further support this finding. Unfortunately, due to the martensitic transformation in β phase in quenching process after deformation, as shown in Fig. 3(f), it is difficult to carry out further study to determine the detail of the dislocation substructure in grain interior by TEM analysis for the confirmation of CDRX in microscopic scale.

3.4 Grain refinement

Ti-6Al-2Zr-1Mo-1V alloy exhibits a typical DRX behavior during the β process, which produces remarkable grain refinement. Figure 7(a) shows the change of grain size with strain. Being deformed at 1050 ℃, the DRX grain size decreases fast at first and then slowly with increasing strain. As the strain reaches a sufficiently high level, the DRX grains are much finer at high strain rate than at low strain rate. According to the DRX kinetic curves shown in Fig. 7(b), the steady state of complete DRX reaches at strain of 0.92, 1.2, 1.56 and 2.93 with strain rate of 0.001, 0.01, 0.1 and 1 s-1 respectively, which indicates that the steady strain increases with increasing strain rate. Although much finer grains can be acquired at higher strain rate, a much heavier deformation has to be applied so that complete DRX takes place in the alloy.

4 Conclusions

1) Dynamic recrystallization occurrs in hot deformation of Ti-6Al-2Zr-1Mo-1V alloy at 1000-1100 ℃ and the strain rate of 10-3-1.0 s-1. The decrease of strain rate and the increase of deformation temperature facilitate the progress of DRX.

2) The DRX- and DRV-type of stress—strain curves are found and the type is changed from DRX- to

Fig. 7 Influence of strain on DRX average grain size (a) and DRX volume fraction (b) at 1050 ℃

DRV-type with the decrease of deformation temperature or the increase of strain rate.

3) The DDRX as a predominant nucleation mechanism via grain boundary bulging is observed at higher temperature and lower strain rate, while the CDRX occurs at lower temperature and higher strain rate.

4) The average grain size is related to strain, stain rate and deformation temperature, and the remarkable grain refinement of deformed β grains can be attained via dynamic recrystallization at high strain rate and large strain.

References

[1] SUN Zhi-chao, YANG He. Microstructure and mechanical properties of TA15 titanium alloy under multi-step local loading forming [J]. Materials Science and Engineering A, 2009, 523(1-2): 184-192.

[2] MA Ying-jie, LIU Jian-rong, LEI Jia-feng, LIU Yu-yan, YANG Rui. β-grain growth and influence of its grain size on damage-tolerance property in titanium alloy [J]. Rare Metal Materials and Engineering, 2009, 38(6): 976-981. (in Chinese)

[3] PRASAD Y, SESHACHARYULU T, MEDEIROS S, FRAZIER W. Effect of prior β-grain size on the hot deformation behavior of Ti-6Al-4V: Coarse vs coarser [J]. Journal of Materials Engineering and Performance, 2000, 9(2): 153-160.

[4] WEISS I, SEMIATIN S L. Thermomechanical processing of alpha titanium alloys—An overview [J]. Materials Science and Engineering A, 1999, 263(2): 243-256.

[5] BALASUBRAHMANYAM V V, PRASAD Y. Deformation behaviour of beta titanium alloy Ti-10V-4.5 Fe-1.5 Al in hot upset forging [J]. Materials Science and Engineering A, 2002, 336(1-2): 150-158.

[6] DING R, GUO Z X. Microstructural evolution of a Ti-6Al-4V alloy during β-phase processing: experimental and simulative investigations [J]. Materials Science and Engineering A, 2004, 365(1-2): 172-179.

[7] WANJARA P, JAHAZI M, MONAJATI H, YUE S. Influence of thermomechanical processing on microstructural evolution in near-α alloy IMI834 [J]. Materials Science and Engineering A, 2006, 416(1-2): 300-311.

[8] METZBOWER E. Stacking fault probability determinations in HCP Ti-Al alloys [J]. Metallurgical and Materials Transactions, 1971, 2(11): 3099-3103.

[9] GUO Z, MIODOWNIK A P, SAUNDERS N, SCHILLE J P. Influence of stacking-fault energy on high temperature creep of alpha titanium alloys [J]. Scripta Materialia, 2006, 54(12): 2175-2178.

[10] MIODOWNIK A P. Structural and phase stability of alloys [M]. New York: Plenum Press, 1992: 151-165.

[11] NUTTING J, SWANN P R. The influence of stacking-fault energy on the modes of deformation of polycrystalline copper alloys [J]. Journal of Institute of Metals, 1961, 90(8): 133-138.

[12] BELYAKOV A, SAKAI T, MIURA H, TSUZAKI K. Continuous recrystallization in austenitic stainless steel after large strain deformation [J]. Acta Materialia, 2002, 50(6): 1547-1557.

[13] FATEMI-VARZANEH S M, ZAREI-HANZAKI A, BELADI H. Dynamic recrystallization in AZ31 magnesium alloy [J]. Materials Science and Engineering A, 2007, 456(1-2): 52-57.

[14] BELYAKOV A, MIURA H, SAKAI T. Dynamic recrystallization under warm deformation of a 304 type austenitic stainless steel [J]. Materials Science and Engineering A, 1998, 255(1-2): 139-147.

[15] TAN J C, TAN M J. Dynamic continuous recrystallization characteristics in two stage deformation of Mg-3Al-1Zn alloy sheet [J]. Materials Science and Engineering A, 2003, 339(1-2): 124-132.

[16] TSUJI N, MATSUBARA Y, SAITO Y. Dynamic recrystallization of ferrite in interstitial free steel [J]. Scripta Materialia, 1997, 37(4): 477-484.

Ti-6Al-2Zr-1Mo-1V合金β锻动态再结晶

欧阳德来1, 2, 王克鲁1, 崔 霞1

1. 南昌航空大学 材料科学与工程学院,南昌 330063;

2. 南京航空航天大学 材料科学与技术学院,南京 210016

摘 要:通过热压缩实验研究Ti-6Al-2Zr-1Mo-1V钛合金在变形温度为1000~1100 ℃,应变速率为10-3~1.0 s-1的条件下的动态再结晶行为。结果表明:在变形温度高于1050 ℃、应变速率低于0.01 s-1时,合金的动态再结晶机制以不连续动态再结晶为主;在变形温度低于1050 ℃、应变速率高于0.01 s-1时,合金的动态再结晶机制以连续动态再结晶为主,同时存在少量的不连续动态再结晶。此外,降低应变速率和升高变形温度均能促进动态再结晶进程并使β变形晶粒细化。

关键词:动态再结晶;Ti-6Al-2Zr-1Mo-1V钛合金;b锻;热压缩实验

(Edited by FANG Jing-hua)

Foundation item: Project (2007CB613803) supported by the National Basic Research Program of China; Project (2010GQC0170) supported by the Natural Science Foundation of Jiangxi Province, China; Project (GJJ11159) supported by the Educational Committee of Jiangxi Province, China

Corresponding author: OUYANG De-lai; Tel/Fax: +86-791-83863039; E-mail: ouyangdelai@163.com

DOI: 10.1016/S1003-6326(11)61242-9