文章编号: 1004-0609(2005)05-0700-05

紫铜-黄铜搅拌摩擦焊接头的组织与力学性能

刘小文, 杨宁宁, 穆耀钊, 鄢君辉

(西北工业大学 材料学院, 西安 710072)

摘 要: 研究了紫铜和黄铜搅拌摩擦焊接的可行性, 对焊接接头的金相组织进行了分析, 并通过拉伸实验、 硬度分析、 弯曲实验, 对接头的性能进行了验证。 结果表明: 紫铜-黄铜具有良好的搅拌摩擦焊接性能, 可获得与母材等强度的搅拌摩擦焊接接头。 焊合区在热力偶合作用下获得动态再结晶组织, 接头黄铜一侧热影响区沿厚度方向上下不同, 下侧可分为再结晶区、 不完全再结晶区、 动态回复区; 上侧出现明显的偏析现象; 接头紫铜一侧热影响区出现明显的须状组织, 并有晶粒微溶的迹象。

关键词: Cu; 搅拌摩擦焊; 金相组织; 力学性能 中图分类号: TG407

文献标识码: A

Microstructure and mechanical properties of friction-stir welded joint of pure copper to brass

LIU Xiao-wen, YANG Ning-ning, MU Yao-zhao, YAN Jun-hui

(Institute of Materials, Northwestern Polytechnical University, Xian 710072, China)

Abstract: The microstructures of the friction-stir welded joints of pure copper to brass and their performance are examined through tension, hardness and bending tests. The results show that the pure copper and brass can be friction stir welded and the welded joints have the same strength as the base material. The nugget zone has dynamic recrystallization microstructure under the thermo-mechanical effect. The microstructure of the heat-affected zone in the joint on the side of brass has some differences between the upside and underside. The latter can be divided into recrystallization zone, incomplete recrystallization zone and dynamic recovery zone, and the former is of apparent segregation. There are some streamline microstructures and a slight grain melting in the heat affected zone on the side of pure copper.

Key words: copper; friction-stir welding; microstructure; mechanical properties

搅拌摩擦焊(friction stir welding)是英国焊接研究所于20世纪90年代发明的一种用于低熔点合金板材的新型固态连接技术。 它利用一种带有探针和轴肩的特殊形式的搅拌头, 将探针插入结合面, 轴肩紧靠工件上表面, 进行旋转搅拌摩擦, 摩擦热使探针周围金属处于热塑性状态, 探针前方的塑性状态金属在搅拌头的驱动下向后方流动, 在该处塑性融合, 从而使焊件在高速的热压状态下成为一个整体[1-6]。 搅拌摩擦焊除了具有普通摩擦焊的优点外, 还可进行多种接头形式和不同焊接位置的连接[7-15]。 目前国内外有关搅拌摩擦焊接技术的研究开发多为铝及其合金, 而在铜及其合金方面的研究报道则很少见到。 本文作者探讨了紫铜和黄铜的搅拌摩擦焊工艺, 对焊接接头的金相组织进行了分析, 并通过拉伸实验、 硬度分析、 弯曲实验, 对接头的力学性能进行了验证, 为进一步研究开发搅拌摩擦焊接工艺提供依据。

1 实验

本实验采用横截面积为100mm×3mm的紫铜板和黄铜板。 紫铜(T2)杂质总量(质量分数)低于0.1%, 黄铜(H62)杂质总量低于0.5%(Cu63.5Zn36)。 紫铜的导电及导热性能好, 在力学和工艺性能方面, 具有极好的塑性, 可承受各种形式的冷压力加工, 而黄铜的力学性能和耐蚀性能良好, 导电、 导热性也较高, 与紫铜相比, 价格低, 密度小, 色泽好, 易于熔铸和加工, 因而两者应用极为广泛。 铜的焊接性能受O, Pb, Bi, S, P等杂质的影响很大, 采用熔焊会产生较多缺陷, 因此, 有必要研究可避免这些缺陷产生的黄铜和紫铜的搅拌摩擦焊工艺。 搅拌摩擦焊接实验在自行改制的搅拌摩擦焊机上进行。 实验采用的搅拌头为圆台形, 材料为Ni基高温合金, 轴肩尺寸为10mm、 根部直径5.5mm、 顶端直径为3.5mm、 长度2.5mm。 利用压力传感器得出焊机工作台上升的位移和压力间的关系, 以此标定实验中的压力值。 金相实验是将焊接接头进行抛光、 腐蚀, 并在光学显微镜下观察。 用NEOPHOT-1型卧式显微照相系统显微照相仪对已腐蚀的试样进行拍照。 用HX-1000型维氏硬度计分别测定焊合区、 热影响区、 母材区的维氏硬度, 得到搅拌摩擦焊接头的维氏硬度分布规律。 拉伸实验在ZD10/90型电子拉伸实验机上进行, 拉伸试样的形状尺寸参照国标GB639-86。 弯曲实验在INSTRON公司伺服液压动态实验系统上进行。

2 结果与分析

2.1 接头宏观形貌

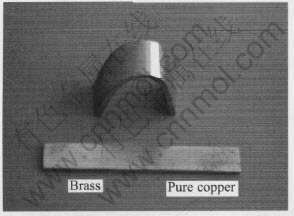

在优化的工艺下, 紫铜-黄铜搅拌摩擦焊接头的宏观形貌如图1所示。 图1(a)所示为接头正面形貌, 图1(b)所示为接头背面形貌, 可见接头正反两面成型良好。 实验中发现, 被焊两铜板虽有压板固定, 但两板端没有固定, 所以在焊接开始时, 由于搅拌头的下压钻入, 铜板起始端会因下压力而出现有一小的裂缝, 会影响焊接接头前端的焊接质量。 实验发现, 该缺陷大小与焊接压力成正比。

图1 紫铜-黄铜搅拌摩擦焊接头外观形貌

Fig.1 Photos of front(a) and back(b) sides of

friction-stir welded joints of pure copper to brass

2.2 金相分析

本实验对焊接接头采用擦拭腐蚀, 腐蚀剂为6gFeCl3, 10mLHCl, 90mLH2O。 焊接接头经腐蚀后可以看出焊接时搅拌头所处的位置为焊合区, 由于焊合区金属发生强烈的塑性变形和流动, 相互搅拌、 混和, 发生动态回复和再结晶等物理冶金和力学冶金过程, 所以焊合区晶粒比母材晶粒细小; 焊合区的两侧为过渡区, 过渡区是搅拌摩擦焊接过程中在热与力的共同作用下, 母材组织与性能发生变化的区域。 该区域温度场与应变场分布极不均匀, 愈靠近焊合区温度愈高, 塑性变形程度愈大。 在焊接过程中所受的热循环及应力应变决定了该区在焊后的组织与性能。

2.2.1 接头紫铜一侧微观组织

紫铜-黄铜搅拌摩擦焊接头紫铜一侧微观组织如图2所示。 图2(a)所示为母材组织照片, 母材晶粒较大, 由于其母材的层错能较低, 所以母材中有孪晶组织; 母材中所含杂质呈小黑点分布于母材基体上。 紫铜-黄铜焊合区组织如图2(b)所示, 其组织与母材有很大不同, 晶粒细小, 且已成为α, β两相组织。 这说明在焊接过程中, 由于搅拌头的搅拌作用, 黄铜和紫铜相互融合, 且在热与力的作用下发生塑性变形, 造成大量晶粒破碎, 破碎的晶粒重新再结晶, 这是搅拌摩擦焊的基本特征。 图2(c)所示为紫铜一侧焊接热影响区组织照片, 由于紫铜在空气中极易氧化, 照片中的黑色组织为氧化铜。 焊合区和热影响区没有很明显的分界, 但后者具有明显的须状组织, 这是由于在搅拌头的顺时针旋转前进过程中, 在应力作用下形成的所谓焊接流线。 另外从金相照片上可以看到有金属微熔的迹象。

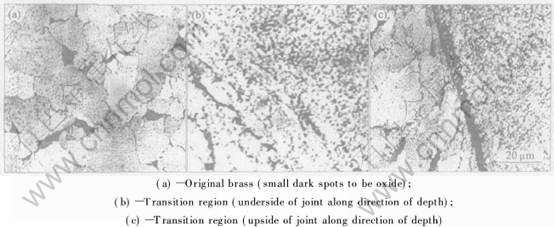

2.2.2 接头黄铜一侧微观组织

紫铜-黄铜搅拌摩擦焊接头黄铜一侧的微观组织如图3所示。 在黄铜母材中黑色是β相, 其中已经有不少的β相在退火中溶入到α相中。 分布在晶粒内的小黑点是由于铜在空气中易氧化产生的, 如图3(a)所示。 过渡区沿厚度方向有较大区别, 下侧组织如图3(b) 所示, 可以看到晶粒大小不均匀, 分成再结晶区、 不完全再结晶区、 动态回复区。 而在板厚方向上侧组织过渡比较突然, 且出现了晶间偏析现象, 如图3(c) 所示。 产生这些现象的主要原因是由于在焊接过程中, 上部金属不仅受到搅拌头的搅拌作用, 而且搅拌头轴肩与金属表面摩擦生热, 使上部金属的热力偶合作用比较充分, 黄铜是两相组织, 在快速加热冷却过程中β相来不及溶入, 便出现偏析。 而在板厚方向下部, 由于搅拌头比母材厚度稍短, 热力偶合作用较小, 组织过渡比较均匀。

2.3 拉伸实验

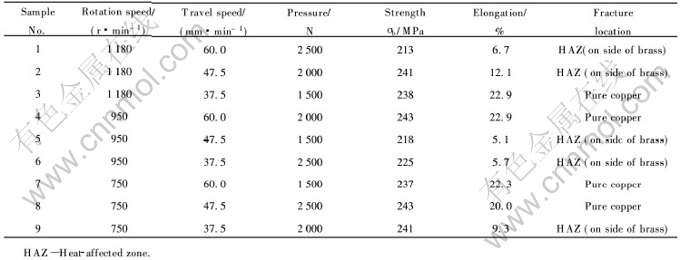

对不同参数下搅拌摩擦焊接试样进行拉伸实验得到结果列于表1。 拉伸实验结果表明, 试样1, 2, 5, 6, 9在拉伸过程中首先在紫铜一侧发生缩颈, 然后脆断于黄铜一侧热影响区, 而试样3, 4, 7, 8在拉伸过程中塑性断裂于紫铜母材区。 拉伸试样照片如图4所示。 断裂产生于黄铜热影响区的拉伸试样, 其主要原因是热影响区晶粒很不均匀, 且有偏析现象存在, 导致强度较低。 断口较齐, 并且断口处已经明显分层, 上层与搅拌头轴肩接触的金属断裂类似于断于母材的塑性断裂的断口, 下层属于脆性断裂。 其原因是搅拌头尺寸略小于板材厚度, 在焊缝底层金属未参与搅拌, 而是靠搅拌头尖端搅拌的热量传至底层金属, 焊合区金属在热的作用下发生扩散、 结合而并未发生动态再结晶。 因此底层金属比较薄弱, 易发生脆断, 搅拌焊接头的这种分层导致了强度的降低。 断口上层位于焊缝热影响区是由于热影响区是不同尺寸、 不同形态、 不同组织的晶粒的混合区, 是焊缝比较薄弱的区域, 所以拉伸实验时接头起裂于焊缝底层, 终断于热影响区。 断于紫铜母材的拉伸试样, 发生屈服后断裂, 断口有明显的延性断裂的特征, 断口为乳红色。 实验表明, 优化搅拌摩擦焊接工艺可获得与母材等强度的搅拌摩擦焊接头。

图2 紫铜一侧的微观组织

Fig.2 Microstructures of pure copper and on side of pure copper in joint

图3 黄铜一侧的微观组织

Fig.3 Microstructures of original brass and on side of brass at joint of original copper

表1 拉伸实验结果

Table 1 Results of tensile experiments

图4 拉伸试件照片

Fig.4 Photos of tensile samples broken at

pure copper(a) and broken at HAZ on side of brass (b)

2.4 维氏硬度分析

在穿过试样焊合区、 热影响区和母材的直线进行维氏硬度测试。 得到的硬度测量结果如图5所示。 从图中可以看出, 紫铜-黄铜搅拌摩擦焊接后接头维氏硬度波动较大, 这是由于焊件为异种材料的焊接, 紫铜和黄铜的维氏硬度本身差异较大而形成的。 焊合区的维氏硬度比紫铜母材的维氏硬度要高, 而比黄铜母材的维氏硬度略低, 这是由于焊合区金属在组织上已经成为两相合金, 且在焊接过程中晶粒细化所致。 但在热影响区, 由于焊接热循环的作用, 发生不完全动态再结晶, 晶粒分布很不均匀, 黄铜一侧热影响区的硬度甚至高于黄铜母材的硬度。

图5 维氏硬度曲线

Fig.5 Curve of Vickers hardness

2.5 弯曲性能实验

紫铜和黄铜搅拌摩擦焊接头的弯曲性能很好, 弯曲破坏试样照片如图6所示。 图中试样跨距为20mm , 几乎达到160°的弯曲角度仍未断裂, 说明搅拌摩擦焊接可获得很好的接头弯曲性能。 由于紫铜和黄铜本身具有很好的塑性, 经过搅拌摩擦焊焊接后, 晶粒细化, 接头焊合部位硬度提高(高于紫铜, 但低于黄铜), 接头的拉伸强度高于紫铜母材, 而且接头延伸率高, 因此不能用弯曲实验破坏试样。

图6 紫铜-黄铜搅拌摩擦焊接头弯曲试样照片

Fig.6 Photo of bending samples of

friction-stir welded joints of pure copper to brass

3 结论

1) 紫铜和黄铜搅拌摩擦焊接头焊合区在热力偶合作用下, 获得动态再结晶超细晶组织。

2) 紫铜和黄铜搅拌摩擦焊接头两侧热影响区不对称, 紫铜一侧有微溶迹象, 黄铜一侧有层状偏析。

3) 拉伸、 硬度、 弯曲性能实验结果表明, 紫铜和黄铜具有良好的搅拌摩擦焊接性能。

REFERENCES

[1]Shigematsu I, Kwon Y J, Suzuki K, et al. Joining of 5083 and 6061 aluminum alloys by friction stir welding[J]. Mater Sci Let, 2003, 22(5): 353- 356.

[2]LIU Hui-jie, Fujii H, Maeda M, et al. Heterogeneity of mechanical properties of friction stir welded joints of 1050-H24 aluminum alloy[J]. Mater Sci Let, 2003, 22(6): 441- 444.

[3]Ma Z Y, Mishra R S, Mahoney M W. Superplastic deformation behaviour of friction stir processed 7075Al alloy[J]. Acta Mater, 2002, 50(17): 4419-4430.

[4]Dawes C J. Thomas W M. Friction stir process welding aluminum alloys[J]. Welding Journal, 1996, 75(3): 41-45.

[5]Rhodes C G, Mahoney M W, Bingel W H, et al. Effects of friction stir welding on microstructure of 7075 aluminum[J]. Scr Mater, 1997, 36(1): 69-75.

[6]Benavides S, Li Y, Murr L E, et al. Low temperature friction-stir welding of 2024 aluminum[J]. Scr Mater, 1999, 41(8): 809-815.

[7]邢丽, 柯黎明, 周细应, 等. 防锈铝LF6的固态塑性连接工艺[J]. 中国有色金属学报, 2002, 12(6): 1162-1166.

XING Li, KE Li-ming, ZHOU Xi-ying, et al. Solid-state plasticized joining for aluminum alloy LF6[J]. The Chinese Journal of Nonferrous Metals, 2002,12(6): 1162-1166.

[8]Shi Y W, Tang W. The principle and application of friction stir welding[J]. Electric Welding Machine, 2001, 30(1): 6-9.

[9]Liu H, Maeda M, Fujii H, NOGI. Tensile properties and fracture locations of friction-stir welded joints of 1050-H24 aluminum alloy[J]. Mater Sci Let, 2003, 22(15): 41-43.

[10]Murr L E, Liu G, Mcclue J C. Dynamic recrystallization in friction-stir welding of aluminium alloy 1100[J]. Mater Sci Let, 1997, 16: 1801-1803.

[11]Murr L E, Ying Li, Flores R D, et al. Intercalation vortices and related microstructural features in the friction-stir welding of dissimilar[J]. Mater Res Innoval, 1998, 2: 150.

[12]Murr L E, Flores R D, Flores O V, et al. Friction-stir welding: microstructural characterization[J]. Mater Res Innoval, 1998, 1: 211-223.

[13]LIU Hui-jie, Fujii H, Maeda M, et al. Tensile properties and fracture locations of friction-stir welded joints of 6061-T6 aluminum alloy[J]. Journal of Materials Science Letters, 2003, 22: 1061-1063.

[14]Sutton M A, Reynolds A P, Wang Q D, et al. A study of residual stresses and microstructure in 2024-T3 aluminum friction stir butt welds[J]. Journal of Engineering Materials and Technology, 2002, 124(2): 215-221.

[15]Rhodes C G, Mahoney M W, Bingel W H, et al. Fine-grain evolution in friction-stir processed 7050 aluminum[J]. Scripta Materialia, 2003, 48(10): 1451-1455.

基金项目: 国家自然科学基金资助项目(50275123)

收稿日期: 2004-09-29; 修订日期: 2005-03-08

作者简介: 刘小文(1955-), 女, 副教授.

通讯作者: 刘小文, 副教授; 电话: 029-88492654; E-mail: liuxiaowen616@sina.com

(编辑陈爱华)