挤压速度对6063铝合金管材焊合强度的影响

来源期刊:中国有色金属学报2017年第9期

论文作者:李世康 李落星 刘志文 王冠

文章页码:1775 - 1785

关键词:铝合金;挤压;多孔分流模;焊合;有限元

Key words:aluminum alloy; extrusion; porthole die; weld; finite element analysis

摘 要:通过建立6063铝合金多孔分流模挤压过程的三维有限元模型,研究不同挤压速度下挤压力、焊合面温度、焊合压力和材料有效应力等参数的演变规律及其对焊合质量的影响,建立预测铝合金方管焊合质量的评价模型,并采用膨胀实验验证模型的准确性。结果表明:随着金属流入分流孔、焊合室和定径带,挤压力逐渐增大并达到峰值,而后缓慢降低;随着挤压速度的增大,焊合面温度、焊合压力和有效应力逐渐升高,焊合质量系数k值逐渐降低。膨胀结果表明,最大载荷处的位移与k值呈正相关,说明所建立的k值模型具有较高的精度。

Abstract: The evolution of extrusion pressure, temperature, welding pressure and effective stress of 6063 aluminum alloy were investigated under different extrusion pressures through building up three-dimensional FE simulation during porthole extrusion, and their effect on the quality of the weld seams were evaluated. The evaluation welding quality model was established and its accuracy was verified by expanding tests. FE simulation results reveal that the extrusion pressure increases with the metal flowing into the inlet ports, welding chamber and die bearing. Over the pressure peak, the extrusion pressure decreases continuously. As ram speed increasing, the temperatures, the mean stresses and the effective stresses on the welding plane in the welding chamber increase. k value shows downward trend with the ram speed increasing. Expanding tests confirm that the extrusion at higher ram speed leads to a bad bonding at the longitudinal weld seams, which corresponds to the k value.

DOI:10.19476/j.ysxb.1004.0609.2017.09.03

李世康1, 2,李落星1, 2,刘志文1, 2,王 冠3

(1. 湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082;

2. 湖南大学 机械与运载工程学院,长沙 410082;

3. 宁夏大学 机械工程学院,银川 750021)

摘 要:通过建立6063铝合金多孔分流模挤压过程的三维有限元模型,研究不同挤压速度下挤压力、焊合面温度、焊合压力和材料有效应力等参数的演变规律及其对焊合质量的影响,建立预测铝合金方管焊合质量的评价模型,并采用膨胀实验验证模型的准确性。结果表明:随着金属流入分流孔、焊合室和定径带,挤压力逐渐增大并达到峰值,而后缓慢降低;随着挤压速度的增大,焊合面温度、焊合压力和有效应力逐渐升高,焊合质量系数k值逐渐降低。膨胀结果表明,最大载荷处的位移与k值呈正相关,说明所建立的k值模型具有较高的精度。

关键词:铝合金;挤压;多孔分流模;焊合;有限元

文章编号:1004-0609(2017)-09-1775-10 中图分类号:TG376.9 文献标志码:A

最近几年,市场对空心型材的需求与日俱增,空心型材主要应用于陆上、航海和航空等交通领域的轻质部件,以达到减少燃料消耗和提高载荷的作用[1-4]。作为一种高效的生产工艺,多孔分流模挤压技术被广泛应用在铝合金空心型材加工领域[5-7]。多孔分流模挤压过程中纵向焊缝的形成过程是一种固态焊合过程,焊缝质量依赖于焊合室内复杂的热学和力学参数的组合,特别是挤压工艺参数和模具几何参数的影响[8]。YU等[9]研究了多孔分流模挤压过程焊缝及其附近组织的演变,发现挤压过程发生了明显的几何动态再结晶。SHI等[10]在传统分流模具的分流通道内设计了等通道转角工艺,预测了不同通道转角对P-ECAP工艺挤出板材的废料长度变化的影响。侯文荣等[11]基于质点逆向追踪研究铝合金空心型材横断面温度的不均匀性,通过模具结构设计和挤压工艺参数优化,使空心型材横断面温度分布不均匀性得到改善。GAGLIARDI等[12]结合工业生产研究了型材厚度和挤压速度对型材组织和力学性能的影响,并在此基础上优化了模具尺寸。

在挤压过程中直接观察多孔分流模内材料的流动和焊缝的形成以及记录复杂的热力学参数是不实际的。基于有限元的计算机模拟技术在展示焊合室内温度、挤压力、金属流动速度以及有效应力的变化和分布上发挥着独特的作用[13-17]。DONATI等[18]运用DEFORM 3D软件分析了H形AA6082铝合金型材挤压过程中挤压工艺参数和模具几何尺寸对焊缝质量的影响。侯文荣等[19]采用焊合区网格重构技术,解决了包括分流与焊合过程中空心型材分流模挤压成形全过程温度场模拟问题,以一种典型大断面铝合金空心型材分流模挤压成形为实例,分析了挤压速度和材料温度对模孔出口处型材最高温度及型材横断面温度分布的影响,提出了合理的材料温度和挤压速度范围。LIU等[20]运用DEFORM 3D软件分析了AZ31薄壁方形管材瞬态和稳态挤压过程中材料在多孔分流模中的流动,研究了多孔分流模挤压过程中焊缝的形成以及影响焊缝质量的因素。而焊缝在多孔分流模生产过程中是不可避免的,分流模挤出空心型材在机械测试中优先失效于焊缝或者近焊缝处[21-22]。BAKKER等[23]研究了多孔分流模横向焊缝对材料力学性能的影响,并从失效方面进行了阐述与讨论,但未考虑焊缝的形成与影响因素。ZHAO等[24-25]以焊合质量评判准侧为重点,研究了多孔分流模挤压过程焊合质量,进一步优化了评定准则。FAN等[26]对多孔分流模挤压过程型材的组织演变进行了研究,重点研究了焊缝处的组织演变。但其都未考虑挤压工艺对焊合质量以及型材组织演变的影响。目前,对焊缝形成及其质量的研究多基于冶金方面考虑,对于提高焊缝质量的方法通常与模具设计相关[27-29],并且多数研究都是在有限元模拟技术上进行的,缺少系统的实验研究。

本文作者运用黏塑性有限元模型分析铝合金多孔分流模挤压过程中材料的流动,探明不同挤压速度对焊合面温度、焊合压力和材料有效应力的影响规律,建立多孔分流模挤压过程中纵向焊缝焊合质量的定量评估模型,并通过实验与仿真相结合验证模型的准确性。

1 有限元模拟建模与验证实验

1.1 材料及材料模型

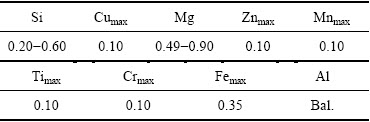

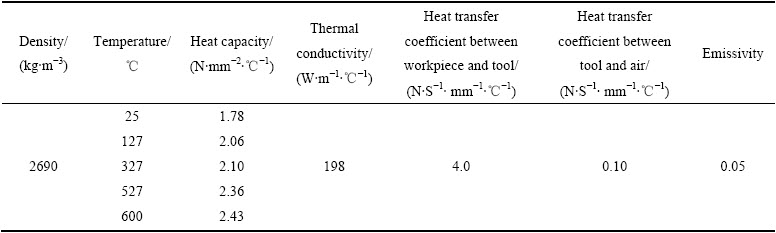

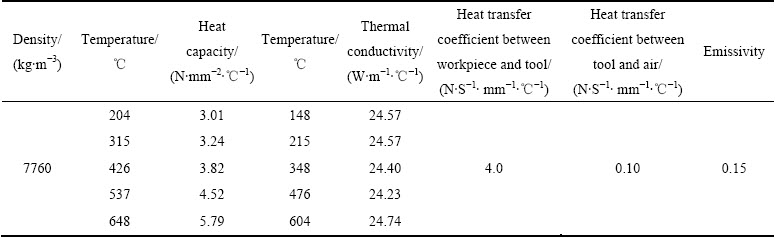

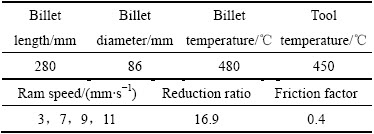

三维有限元模拟和实验所用材料为6063铝合金,其名义成分如表1和2所示。6063铝合金为圆柱形铸坯,经均匀化处理后去除表皮,每一个铝锭的高度为280 mm,直径为86 mm,比挤压筒内径90 mm小4 mm,以便圆柱形铸锭的放入。挤压型材横截面为方形空心型材,方形型材边长为40 mm,壁厚为2.5 mm。挤压筒、模具和挤压垫所用材料均为H13工具钢,其物理性质[13]如表3所示。铝合金铸锭和挤压工具温度分别设定为480 ℃和450 ℃,挤压工具温度比材料温度低30 ℃以便挤压过程塑性变形及摩擦产生的热量能够及时通过模具扩散出去。挤压比为16.9,挤压杆速度分别为3、7、9和11 mm/s,挤压杆速度本研究统称挤压速度。铸锭尺寸以及有限元模拟挤压过程挤压工艺参数如表4。

铝合金铸锭和挤压工具分别采用粘塑性模型和热刚性模型。通过热压缩实验测得6063铝合金在不同应变、应变速率和温度下的流变应力,铸锭温度为400~520 ℃,应变速率为0.01~10 s-1,将实验数据进行温升修正以消除变形热对材料性能的影响。铝锭和挤压工具之间设定为剪切摩擦,其摩擦因子可以表示为

(1)

(1)

式中:τ剪切摩擦应力;σ为材料的有效流变应力,模拟过程材料和挤压工具之间的摩擦因子设定为0.4。

表1 6063铝合金名义成分质量分数

Table 1 Chemical composition of 6063 alloy (mass fraction, %)

表2 6063铝合金各项物理性能

Table 2 Physical properties of 6063 aluminum alloy

表3 H13工具钢各项物理性能

Table 3 Physical properties of H13 tool steel

表4 材料尺寸与有限元模拟过程工艺参数

Table 4 Billet dimensions and process parameters used in numerical simulation

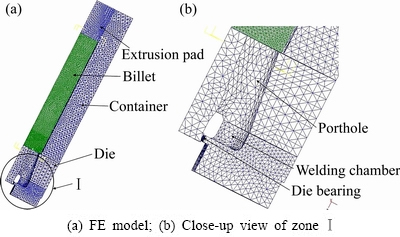

图1所示为方形管材挤压的有限元模型,方形管材挤压过程所用有限元模型中材料和挤压工具均采用四面体网格进行网格化,挤压工具和材料之间允许热传递。有限元模拟的参数与边界条件如表5。为了提高有限元模拟的效率和计算的精度,局部区域网格密度较大,特别是模具分流部分。由于坯料、挤压工具(挤压垫、挤压筒和挤压模具)和挤出型材都具有对称结构,为了节约模拟时间,模拟过程采用1/8模型进行模拟。对称面设置为刚性面,不允许材料的流动。为保证有限元模拟的准确性和稳定性,采用绝对网格画法来使单位长度上网格数近似为常数[31]。

1.2 验证实验

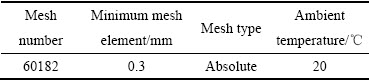

为了验证有限元模拟结果的正确性,挤压实验在XJ-800型挤压机上进行。挤压工具材料、尺寸和挤压条件均与有限元模拟一致。挤压实验过程中挤压力、挤压筒温度和模具温度被实时监控,并用AE3000高温传感器测量和记录模具出口400 mm处型材挤出温度。型材挤出后立即进行水淬,并在180 ℃下时效8 h。挤出型材经电解抛光和阳极覆膜后在MM-6型卧式金相显微镜上分别观察型材样品的显微组织形貌。电解液为70%(质量分数)的高氯酸和无水乙醇混合溶液(体积比为1:9),抛光时电压为25 V,电解时间为3~8 s;阳极覆膜液为5 g氟硼酸和200 mL水的混合溶液,覆膜电压为20V,覆膜时间约为3 min。铸态合金的平均晶粒尺寸和挤压变形后实验合金的平均晶粒尺寸均采用截线法测量。每张晶粒图片均采用水平和垂直的两组截线进行测量,取平均值;每种工艺条件下取3个不同位置晶粒图进行测量,而后再取平均值。铝锭均匀化组织呈粗大的等轴晶,晶粒尺寸约为198 μm,如图2所示。

图1 挤压有限元模型初始网格(1/8模型)

Fig. 1 Initial meshes of billet, container, die and extrusion pad (one-eight models)

表5 模拟参数与边界条件

Table 5 Simulation parameters and boundary conditions

空心型材纵向焊缝的质量通过膨胀试验测得[21],图3所示为膨胀试验所用工具的外形和尺寸。焊缝质量可以由最大载荷位移来测得。室温胀形实验在 INSTRON3369型电子万能材料试验机上进行,下压速率为2 mm/min。

图2 6063铝合金均匀化显微组织

Fig. 2 Optical micrograph of as-homogenized 6063 alloy

2 结果与讨论

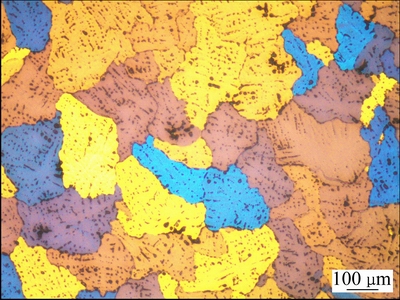

2.1 材料在多孔分流模内的流动

在挤压过程中,材料首先流经分流桥进入焊合室,最后通过定径带成形。图4所示为金属流动的3/4模型,从图4(a)可以看出,金属首先被墩粗,并伴随分流的初期阶段,后经分流孔进入焊合室(见图4(b)),之后在焊合室重新焊合,形成纵向焊缝(见图4(c)),最后通过定径带挤出空心型材(见图4(d))。

图3 锥形模的示意图

Fig. 3 Schematic diagram of conical mandrel used in expanding tests (Unit: mm)

图4 金属在挤压过程中的流动

Fig. 4 Metal flow through the porthole die

2.2 挤压力变化

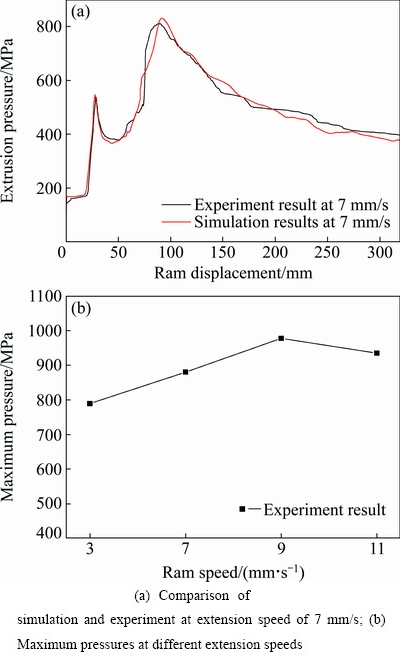

图5(a)所示为挤压速度为7 mm/s时有限元模拟和实验过程中挤压力随着挤压垫位移的变化。从图5(a)中二者对比结果可以看出,有限元模拟峰值比挤压试验所测值高出2.5%左右,这可能是由于在有限元模拟过程中忽略了坯料和挤压工具弹性变形以及过高地评估坯料与挤压工具之间的摩擦(坯料与挤压工具设定为全粘着摩擦,摩擦因子为1)引起的。除此之外,预测的挤压力变化与实验所测相吻合,说明有限元模拟过程中材料模型、材料参数和有限元模型的合理性。挤压过程挤压力达到峰值以后,预测值和实验值都趋于收敛,二者之间的差异也随着材料的缩短和材料与挤压筒之间摩擦力的降低而减小。在挤压的终了阶段,挤压力值只有峰值的50%左右,这是由于随着挤压过程的进行,材料长度逐渐变短,挤压筒和材料之间的摩擦力逐渐降低,使挤压力不断降低。另外,根据LI等[13]的研究结果,挤压过程的热效应和动态再结晶等组织变化对挤压力的降低也起到了重要作用。由此可知,最大压力后的挤压过程并不是真正的稳态挤压过程。

图5(b)所示为不同挤压速度时挤压力峰值随挤压速度的变化。由图5(b)可看出,随着挤压速度的增加,挤压力峰值呈现先增大后降低的趋势。挤压速度从3 mm/s增大到7 mm/s时,峰值挤压力由789 MPa增加到880 MPa;当挤压速度继续升高到9 mm/s,挤压力峰值由880 MPa迅速上升到977 MPa;继续增加挤压速度到11 mm/s,挤压力峰值降低为934 MPa。这是因为在挤压过程中,材料内部同时进行着加工硬化和动态软化两个相互竞争的过程[30]。

图5 挤压力变化

Fig. 5 Change of extrusion pressure

2.3 焊合室内温度分布

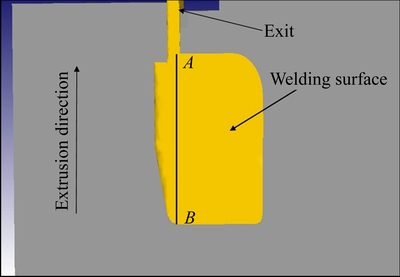

图6所示为焊合室内金属焊合面图,焊合面温度、平均应力和有效应力都是由A-B线上所提取。

图6 焊合室内金属焊合面

Fig. 6 Welding plane and A-B line from top to bottom of welding chamber (ZA=-3; ZB=17)

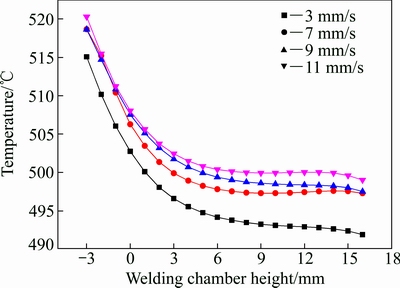

图7所示为焊合面A-B线上温度的变化。由图7可看出,最高温度出现在定径带的入口处,受挤压速度影响较大,挤压速度从3 mm/s增加到11 mm/s,最高温度从515 ℃增加到520 ℃,温升明显。这是由于在挤压过程中挤压速度的升高,材料的应变速率增大,有效应力增加,这时需要更大的机械能才能使金属进一步流动,机械能转化为更多的热量,使材料温度升高。在同一挤压速度下,从焊合室的顶部到焊合室的底部温度先平缓上升后迅速增大,而在定径带入口处温度最高。这是因为在定径带入口处,材料的应变速率最大,材料的变形也更加剧烈,并伴随材料流经定径带产生了强烈的摩擦,材料温度升高,同时定径带处材料流速较高,温度来不及散失,使得焊合面定径带入口处温度最高。模拟结果和Lefstad[31]的结果相吻合,Lefstad发现在相对较低的挤压速度下,热量流向挤压模具,铝材相对较低的温度分布于拐角处。

图7 不同挤压速度下焊合面温度分布

Fig. 7 Simulated temperatures on welding plane along welding chamber height at different extrusion speeds

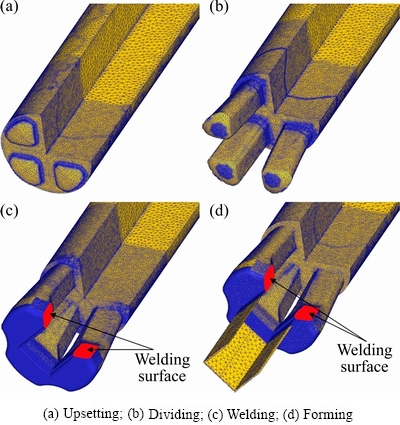

2.4 型材组织

由于不同挤压速度下的温升不一样,导致挤出型材的组织存在一定的差异。图8所示为挤出型材焊缝处显微组织。挤出型材均发生了明显的完全动态再结晶(挤压前均匀化组织粗大且不均匀,晶粒大小约为198 μm,见图2)。图8(a)所示为挤压速度为3 mm/s下焊缝处组织,可以看出,在大晶粒(晶粒尺寸约为80~90 μm)晶界处有很多小的晶粒,晶粒尺寸约为5~10 μm,晶粒呈等轴状。图8(b)所示为挤压速度为7 mm/s下焊缝处组织,晶粒组织逐渐均匀化,晶粒尺寸约为70~100 μm。随着挤压速度的增加,晶粒更加均匀,且呈等轴晶状。这因为随着挤压速度的升高,材料在变形区停留的时间减小,再结晶晶粒来不及长大,而挤压速度增大带来更大的储存能,使材料有足够的能量发生再结晶[7, 32]。当挤压速度达到11 mm/s时,挤压温升促使再结晶晶粒长大的因素取得主导,使得挤压速度为11 mm/s时的晶粒比挤压速度为9 mm/s时的略大,如图8(c)和图8(d)所示。

图8 不同挤压速度下挤出型材横截面光学显微组织

Fig. 8 Optical microstructures of cross-section of as-extruded 6063 alloy at different ram speeds

3 焊合质量判定准则及验证

3.1 焊合质量判定准则

多孔分流模挤压过程中焊缝是固态焊合过程,在焊合面会形成纵向焊缝,纵向焊缝质量是评价空心型材质量的一个重要指标,然而,焊缝质量很难定量表达。通常,焊合室局部应力和温度以及材料通过焊合室的时间将会影响焊缝的强度和韧性[33-35]。

DONATI等[18]考虑死区等因素对焊合质量的影响,把节点速度作为校正因子提出了K准则。K是焊合面焊合压力与材料有效应力比值对焊合路径的积分值:

(2)

(2)

式中:p为焊合压力;σ为材料有效应力;l为焊合路径,开始于分流桥的底部,结束于模具出口。

在实际中,为了便于计算,K值可以表示为

(3)

(3)

焊合路径可以有效且方便地识别,有利于对焊合质量定量地评估。

3.2 分析与验证

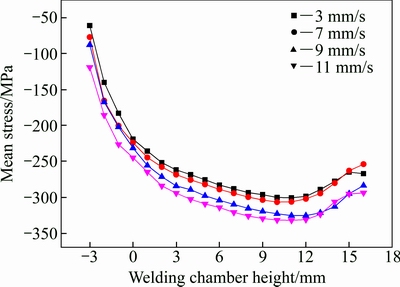

图9所示为焊合面平均圧力分布图,从A→B,焊合面平均应力从焊合室的顶部到焊合室的底部逐渐增大,在焊合室高度为14 mm处达到最大。焊合室底部平均应力降低是由于随着型材通过定径带的流出应力得到一定程度的释放。随着挤压杆速度的增加,平均应力也随着增大,有利于材料的焊合。挤压杆速度从3到11 mm/s,焊合面的平均应力增大11%。在多数情况下,高的挤压杆速度引起高的应变速率,从而引起高的焊合压力。但高的挤压速度也带来了高的温升,如图7所示,使得材料变形抗力降低,材料的软化效应增强。

图9 焊合面平均应力分布

Fig. 9 Simulated mean stress distribution on welding plane along welding height at different extrusion speeds

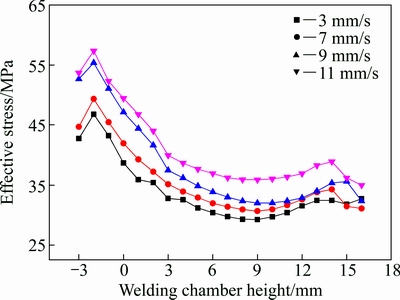

由前所述,温度对焊合质量的影响是通过对坯料屈服行为的影响来施加的,材料的屈服行为可以由有效应力来表示。图10所示为焊合面沿着焊合室高度方向有效应力分布图。从图10中可以看出,从A到B有效应力先增大后降低后又缓慢上升,这是温度、应变和应变速率综合作用的结果[36]。挤压速度从3 mm/s到11 mm/s,最大有效应力从46 MPa增加到59 MPa,增幅明显。

图10 不同挤压速度下焊合面有效应力分布

Fig. 10 Simulated effective stress distribution on welding plane along welding height at different extrusion speeds

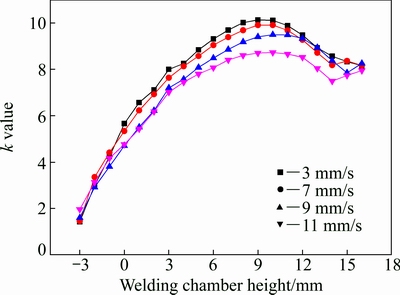

图11所示为焊合面焊合压力与材料有效应力比值k的分布图,k值越大材料的焊合性能越好。从图中可以看出焊合室k值从焊合室底部到顶部先逐渐升高,在焊合室高度为10 mm位置达到最大,后缓慢降低,最后保持平稳。k最大值和最小值分别出现在焊合室高度为10 mm位置和定径带入口,这是因为在定径带入口,随着材料的流出焊合面焊合压力降低,如图8。而材料有效应力随着定径带处材料应变速率升高而增大,如图10。随着挤压速度的增加k值出现了平缓的下降,和VALBERG[37]以及DONATI等[18]的实验结果相一致,高的挤压速度将带来不良的焊合质量。这是由于在挤压过程中挤压速度升高,材料的应变速率增大,有效应力增大,当挤压速度由3 mm/s增加到11 mm/s时,材料的有效应力增大了28%。而挤压速度升高,挤压力增大,使得焊合面焊合压力增大,当挤压速度由3 mm/s增加到11 mm/s时,焊合面焊合压力增大了11%,明显低于材料有效应力的增大幅度。使得焊合面焊合压力与材料有效应力比值随着挤压速度的升高而逐渐降低,焊合质量下降。同时,增加挤压速度会缩短焊合面金属材料的接触时间,降低了焊合面的焊合效果。膨胀实验结果如图12所示,随着挤压速度的增大,最大载荷位移逐渐降低,与k值预测结果相吻合。

图11 不同挤压速度下焊合面k值分布

Fig. 11 Simulated k values distribution on welding plane along welding height at different extrusion speeds

图12 膨胀测试结果

Fig. 12 Maximum displacement at different extrusion speeds

4 结论

1) 挤压力随着金属流入分流孔、焊合室而逐渐增大,当金属到达定径带处时达到峰值,峰值应力后由于材料与挤压筒之间的摩擦力降低、动态再结晶和温升软化效应使挤压力减小。

2) 随着挤压速度的增大,焊合面温度逐渐升高,焊合压力和焊合面材料有效应力增大,而焊合压力与材料有效应力比值降低。

3) 挤出型材晶粒组织呈等轴晶组织,发生了明显的完全再结晶,随着挤压速度的增加,晶粒组织更加均匀。当挤压速度为11 mm/s时,由于型材温升增大,型材再结晶晶粒出现了明显的长大。

4) 随着挤压速度的增大,试样在膨胀实验后的最大变形量逐渐减少,这与k值随着挤压速度的增加而缓慢下降,使得焊合面焊合强度逐渐减弱相吻合,验证了所建立的k值模型的准确性。

REFERENCES

[1] KOFFLER C, ROHED-BRANDENBURGER K. On the calculation of fuel savings through lightweight design in automotive life cycle assessments[J]. The International Journal of Life Cycle Assessment, 2010, 15(1): 128-135.

[2] MAYYAS A T, QATTAWI A, MAYYAS A R, OMAR M. Quantifiable measures of sustainability: A case study of materials selection foreco-lightweight auto-bodies[J]. Journal of Cleaner Production, 2013, 40(3): 177-189.

[3] 王 冠, 刘志文, 徐从昌, 李落星. 诱导孔对铝合金薄壁梁轴向压缩变形行为的影响[J]. 中国有色金属学报, 2016, 26(3): 494-506.

WANG Guan, LIU Zhi-wen, XU Cong-chang, LI Luo-xing. Effect of cut-outs on axial collapse behaviors of aluminum with thin-walled structure[J]. The Chinese Journal of Nonferrous Metals Society, 2016, 26(3): 494-506.

[4] GUO L G, DANG L, YANG H, ZHANG J, ZHENG W D. Identification of processing window for extrusion of large thick-walled Inconel 625 alloy pipes using response surface methodology[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(7): 1902-1911.

[5] MEHTEDI M E, SPIGARELLI S, GABRIELLI F, DONATI L. Comparison study of constitutive models in predicting the hot deformation behavior of AA6060 and AA6063 aluminum alloys[J]. Materials Today Proceedings, 2015, 2(10): 4732-4739.

[6] JI X K, ZHANG H, LUO S, JIANG F L, FU D F. Microstructures and properties of Al-Mg-SI alloy overhead conductor by horizontal continuous casting and continuous extrusion forming process[J]. Materials Science and Engineering A, 2016, 649(1): 128-134.

[7] FANG H Z, LI R X, CHEN R R, YU B Y, QU Y Q, XUN S W, LI R D. Microstructure and mechanical properties of Al-6Zn-2.5Mg-1.8Cu alloy prepared by squeeze casting and solid hot extrusion[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(7): 2130-2136.

[8] JO H H, LEE S K, JUNG C S, KIM B M. A non-steady state FE analysis of Al tubes hot extrusion by a porthole die[J]. Journal of Materials Processing Technology, 2006, 173(2): 223-231.

[9] YU J Q, ZHAO G Q, ZHANG C S, CHEN L. Dynamic evolution of grain structure and micro-text along a welding path of aluminum alloy profiles extruded by porthole dies[J]. Materials Science and Engineering A, 2017, 682: 679-690.

[10] SHI L, YANG H, GUO L G, DANG L, ZHANG J. Large-scale manufacturing of aluminum alloy plate extruded from subsize billet by new porthole-equal channel angular processing technique[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(5): 1521-1530.

[11] 侯文荣, 张志豪, 谢建新, 马青梅, 盖洪涛. 基于质点逆向追踪的铝合金空心型材横断面温度的不均匀性[J]. 中国有色金属学报, 2015, 25(7): 1798-1807.

HOU Wen-rong, ZHANG Zhi-hao, XIE Jian-xin, MA Qing-mei, GAI Hong-tao. Temperature inhomogeneity on cross section of Al alloy hollow profile based on reverse point tracking method[J]. The Chinese Journal of Nonferrous Metals Society, 2015, 25(7): 1798-1807.

[12] GAGLIARDI F, CITREA T, AMBROGIO G, FILICE L. Influence of the process setup on the microstructure and mechanical properties evolution in porthole die extrusion[J]. Materials and Design, 2014, 60(8): 274-281.

[13] LI L, ZHANG H, ZHOU J, DUSZCZYK J, LI G Y, ZHANG Z H. Numerical and experimental study on the extrusion through a porthole die to produce a hollow magnesium profile with longitudinal weld seams[J]. Materials and Design, 2007, 29(6): 1190-1198.

[14] GAGLIARDI F, CITREA T, AMBROGIO G, FILICE L. Influence of the process setup on the microstructure and mechanical properties evolution in porthole die extrusion[J]. Materials and Design, 2014, 60(8): 274-281.

[15] den BAKKER A J, WERKHOVEN R J, SILLEKENS W H, KATGERMAN L. The origin of weld seam defects related to metal flow in the hot extrusion of aluminum alloys EN AW-6060 and EN AW-6082[J]. Journal of Materials Processing Technology 2014, 214(11): 2349-2358.

[16] GAGLIARDI F, ALFARO I, AMBROGIO G, FILICE L, CUETO E. NEM-FEM comparison on porthole die extrusion of AA-6082[J]. Journal of Mechanical Science and Technology, 2013, 27(4): 1089-1095.

[17] MAHMOODKHANI Y, WELLS M A, PARSON N, POOLE W J. Numerical modelling of the material flow during extrusion of aluminum alloys and transverse weld formation[J]. Journal of Materials Processing Technology, 2014, 214(3): 688-700.

[18] DONATI L, TOMESANI L. The prediction of seam welds quality in aluminum extrusion[J]. Journal of Materials Processing Technology, 2004, 153(22): 366-373.

[19] 侯文荣, 张志豪, 谢建新, 陈蕴博. 铝合金空心型材分流模挤压成形全过程温度场的数值模拟[J]. 中国有色金属学报, 2013, 23(10): 2769-2778.

HOU Wen-rong, ZHANG Zhi-hao, XIE Jian-xin, CHEN Yun-bo. Numerical simulation of temperature field during whole extrusion processor of aluminum hollow profile with porthole die extrusion forming[J]. The Chinese Journal of Nonferrous Metals Society, 2013, 23(10): 2769-2778.

[20] LIU G, ZHOU J, DUSZCZK J. FE analysis of metal flow and weld seam formation in a porthole die during the extrusion of a magnesium alloy into a square tube and the effect of ram speed on weld strength[J]. Journal of Materials Processing Technology, 2008, 200(1/3): 185-198.

[21] JO HH, JEONG C S, LEE S K, KIM B M. Determination of welding pressure in the non-steady-state porthole die extrusion of improved Al7003 hollow section tubes[J]. Journal of Materials Processing Technology, 2003, 139(1): 428-433.

[22] DONATI L, TOMESANI L, MINAK G. Characterization of seam weld quality in AA6082 extruded profiles[J]. Journal of Materials Processing Technology, 2007, 191(1): 127-131.

[23] BAKKER A J, KATGERMAN L, ZWAAG S D. Analysis of the structure and resulting mechanical properties of aluminium extrusions containing a charge weld interface[J]. Journal of Materials Processing Technology, 2016, 229: 9-21.

[24] YU J Q, ZHAO G Q, CHEN L. Analysis of longitudinal weld seam defects and investigation of solid-state bonding criteria in porthole die extrusion process of aluminum alloy profiles[J]. Journal of Materials Processing Technology, 2016, 237: 31-47.

[25] LU X, ZHANG C S, ZHAO G Q, GUAN Y J, CHEN L, GAO A J. State-of-the-art of extrusion welding and proposal of a method to evaluate quantitatively welding quality during three-dimensional extrusion process[J]. Materials and Design, 2016, 89: 737-748.

[26] FAN X H, TANG D, FANG W L, LI D Y, PENG Y H. Microstructure development and texture evolution of aluminum multi-port extrusion tube during the porthole die extrusion[J]. Materials Characterization, 2016, 118: 468-480.

[27] ZECHNER J, MOHANTY G, FRANTZ C, CEBECI H, PHILIPPE L, MICHLER J. Mechanical properties and interface toughness of metal filled nanoporous anodic aluminum oxide coatings on aluminum[J]. Surface and Coatings Technology, 2014, 260(15): 246-250.

[28] 黄东男, 张志豪, 李静媛, 谢建新. 焊合室深度及焊合角对方形管分流双孔挤压成形质量的影响[J]. 中国有色金属学报, 2010, 20(5): 954-960.

HUANG Dong-nan, ZHANG Zhi-hao, LI Jing-yuan, XIE Jian-xin. Influences of welding chamber depth and welding angle on forming quality of extrusion of square tube by porthole die[J]. The Chinese Journal of Nonferrous Metals Society, 2010, 20(5): 954-960.

[29] DICK C P, KORKOLIS Y P. Anisotropy of thin-walled tubes by a new method of combined tension and shear loading[J]. International Journal of Plasticity, 2015, 71: 87-112.

[30] ZHANG C S, ZHAO G Q, CHEN Z R, CHEN H, KOU F J. Effect of extrusion stem speed on extrusion process for a hollow aluminum profile[J]. Materials Science and Engineering B, 2012, 177(19): 1691-1997.

[31] LEFSTAD M. Metallurgical speed limitation during the extrusion of AlMgSi-alloys[D]. Norway: University of Trondheim, 1993.

[32] 杨胜利, 沈 健, 闫晓东, 李锡武, 孙宝庆, 毛柏平. 基于Al-Cu-Li合金流变行为的动态再结晶动力学与形核机制[J]. 中国有色金属学报, 2016,26(2): 365-374.

YANG Sheng-li, SHEN Jian, YAN Xiao-dong, LI Xi-wu, SUN Bao-qing, MAO Bai-ping. Dynamic recrystallization kinetics and nucleation mechanism of Al-Cu-Li alloy based on flow behavior[J]. The Chinese Journal of Nonferrous Metals Society, 2016, 26(2): 365-374.

[33] CERETTI E, FRATINI L, GAGLIARDI F, GIARDINI C. A new approach to study material bonding in extrusion porthole dies[J]. Manufacturing Technology, 2009, 58(1): 259-262.

[34] COOPER D R, ALLWOOD J M. Influence of diffusion mechanisms in aluminum solid-state welding processes[J]. Procedia Engineering, 2014, 81: 2147-2152.

[35] YU J Q, ZHAO G Q, CHEN L. Investigation of interface evolution, microstructure and mechanical properties of solid-state bonding seams in hot extrusion process of aluminum alloy profiles[J]. Journal of Materials Processing Technology, 2016, 230: 153-166.

[36] 刘新华, 晏玉平, 谢建新. 应变速率对藕状多孔镁垂直于气孔方向压缩变形行为与力学性能的影响[J]. 中国有色金属学报, 2016, 26(4): 747-757.

LIU Xin-hua, YAN Yu-ping, XIE Jian-xin. Effect of strain rate on compressive deformation behaviors and mechanical properties of lotus-type porous magnesium in direction vertical to pores[J]. The Chinese Journal of Nonferrous Metals Society, 2016, 26(4): 747-757.

[37] VALBERG H. Extrusion welding in aluminum extrusion[J]. International Journal of Materials and Product Technology, 2002, 17(7): 497-556.

LI Shi-kang1, 2, LI Luo-xing1, 2, LIU Zhi-wen1, 2, WANG Guan3

(1. State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University, Changsha 410082, China;

2. College of Mechanical and Vehicle Engineering, Hunan University, Changsha 410082, China;

3. College of Mechanical Engineering, Ningxia University, Yinchuan 750021, China)

Abstract: The evolution of extrusion pressure, temperature, welding pressure and effective stress of 6063 aluminum alloy were investigated under different extrusion pressures through building up three-dimensional FE simulation during porthole extrusion, and their effect on the quality of the weld seams were evaluated. The evaluation welding quality model was established and its accuracy was verified by expanding tests. FE simulation results reveal that the extrusion pressure increases with the metal flowing into the inlet ports, welding chamber and die bearing. Over the pressure peak, the extrusion pressure decreases continuously. As ram speed increasing, the temperatures, the mean stresses and the effective stresses on the welding plane in the welding chamber increase. k value shows downward trend with the ram speed increasing. Expanding tests confirm that the extrusion at higher ram speed leads to a bad bonding at the longitudinal weld seams, which corresponds to the k value.

Key words: aluminum alloy; extrusion; porthole die; weld; finite element analysis

Foundation item: Project(U1664252) supported by the State Key Projects of National Natural Science Foundation of China; Project (2016YFB0101700) supported by Major Program of National Natural Science Foundation of China; Project(51475156) supported by the National Natural Science Foundation of China; Project(51605234) supported by the National Natural Science Foundation for Young Scientists of China; Project(31515007) supported by Opening Foundation of State Key Laboratory of Advanced Design and Manufacture for Vehicle Body, China

Received date: 2016-07-26; Accepted date: 2017-03-24

Corresponding author: LI Luo-xing; Tel: +86-731-88821571; E-mail: luoxing _li@yahoo.com

(编辑 李艳红)

基金项目:国家自然科学基金重点资助项目(U1664252);国家重点研发计划项目(2016YFB0101700);国家自然科学基金面上资助项目(51475156);国家自然科学基金青年基金资助项目(51605234);湖南大学汽车车身先进设计制造国家重点实验室开放基金资助项目(31515007)

收稿日期:2016-07-26;修订日期:2017-03-24

通信作者:李落星,教授,博士;电话:0731-88821571;E-mail:luoxing _li@yahoo.com