RRA处理对1973铝合金晶间腐蚀与剥蚀的影响

龚静1,汪明朴1, 2,张茜1,盛晓菲1,杨文超1,李周1, 2

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 教育部有色金属材料科学与工程实验室,湖南 长沙,410083)

摘要:采用维氏硬度、室温拉伸、极化曲线测试和晶间腐蚀、剥落腐蚀试验等方法,并结合金相(OM)和透射电镜(TEM)分析,研究回归再时效(RRA)过程对1973铝合金力学性能及晶间腐蚀和剥落腐蚀的影响。研究结果表明:1973铝合金经不同时效处理后晶间腐蚀和剥落腐蚀趋势相同,耐蚀性能由大到小的RRA工艺顺序为:200 ℃,60 min;180 ℃,60 min;180 ℃,40 min;180 ℃,20 min;T6。RRA 180 ℃处理适量时间可提高1973铝合金的强度和抗晶间腐蚀和剥落腐蚀性能,并且随着回归时间的延长耐蚀性能提高,但强度有所下降。而RRA 200 ℃,60 min处理与180 ℃处理相比,虽然有更好耐蚀性能,但是强度损失太大。因此,1973铝合金经RRA 180 ℃,60 min处理后具有较好的综合性能。

关键词:晶间腐蚀;剥落腐蚀;回归再时效

中图分类号:TG146.21 文献标志码:A 文章编号:1672-7207(2012)07-2520-08

Influence of retrogression and re-aging treatment on intergranular and exfoliation corrosion of 1973 aluminum alloy

GONG Jing1, WANG Ming-pu1, 2, ZHANG Qian1, SHENG Xiao-fei1, YANG Wen-chao1, LI Zhou1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The influence of retrogression and re-aging treatment (RRA) process on mechanical properties and the intergranular and exfoliation corrosion of 1973 aluminum alloy were investigated using hardness measurement, constant tensile properties test, polarization curve measurement, intergranular and exfoliation corrosion tests, optical microscopy (OM) and transmission electron microscopy observation (TEM). The results show that the intergranular corrosion trend is the same as that of exfoliation corrosion after different aging treatments, and the RRA process order of descending corrosion resistance is that: 200 ℃, 60 min; 180 ℃, 60 min; 180 ℃, 40 min; 180 ℃, 20 min; T6. The strength and the resistance of intergranular and exfoliation corrosion of 1973 aluminum alloy can be enhanced with the retrogression and re-aging treatment at 180 ℃. As the retrogression and re-aging treatment at 200 ℃ for 1 h the corrosion resistant of 1973 aluminum alloy increases, however its strength decreases greatly. Retrogression and re-aging at 180 ℃ for 1 h is a suitable processing for 1973 aluminum alloy to have good combination properties.

Key words: intergranular corrosion; exfoliation corrosion; retrogression and re-aging treatment

1973铝合金是一种高性能的超高强Al-Zn-Mg-Cu铝合金,其热轧板材主要用于飞机的机翼整体结构油箱,是制造具有优异综合性能的航空用宽厚板的先进铝合金材料[1]。由于Al-Zn-Mg-Cu铝合金中Zn和Mg的含量较高,Zn/Mg大于2.2时,在合金中形成主要强化相MgZn2相,MgZn2相在合金中的溶解度随温度的降低而急剧下降,具有很强的时效硬化能力,但会导致合金的韧性和抗应力腐蚀性能下降。虽然此系列铝合金在T6态下具有很高的强度,但抗腐蚀性能很差[2-4];通过采用过时效处理如T73,可获得较高的抗应力腐蚀性能,但室温力学性能相对T6态下降幅度较大。成分调整和时效工艺研究一直是改善铝合金综合性能的主要途径。世界各国的材料工作者通过优化合金的成分设计,采用新型成型加工及热处理工艺等,研制开发出多种使用性能更好的高强铝合金[5-7]。但是目前Al-Zn-Mg-Cu系铝合金在产业化应用中普遍以牺牲强度为代价来降低其应力腐蚀敏感性的突出问题,而研究表明[8-10],通过回归再时效(RRA)处理,可以使Al-Zn-Mg-Cu系铝合金在保证T6态强度的同时,提高合金的抗腐蚀性能。为此,本文作者研究了T6峰时效和RRA处理对1973铝合金热轧板材力学性能、晶间腐蚀与剥落腐蚀的影响,并结合微观组织观察对其机理进行分析讨论。

1 实验

实验材料为1973铝合金热轧板材,其化学成分见表1。样品经过470 ℃,1 h固溶处理、淬火后,在不同温度下分别进行峰值时效及RRA处理,其时效制度见表2。时效处理后的样品经砂纸打磨、抛光,以备实验使用。腐蚀实验的试样尺寸(长×宽×高)均为30 mm×20 mm×3 mm,每组3个试样。

样品硬度采用HV-5型小负荷维氏硬度计测试,载荷为20 N。室温拉伸实验在Instron 8032 万能材料力学拉伸机上进行,拉伸速度为2 mm/min,试样沿轧向截取。

晶间腐蚀(IGC)按GB 7998—87标准进行,溶液体系为57 g/L NaCl+10 mL/L H2O2(1.1 g/mL),余量为蒸馏水。试样表面积与溶液体积之比为 10 mm2/mL,实验温度保持在(35±2) ℃,暴露时间为6 h。腐蚀后的试样,用水洗净、吹干,截取其横断面,制成金相试样,在金相显微镜下观察其横截面点蚀和晶间腐蚀情况。

剥落腐蚀按HB 5455—90标准进行,溶液体系为EXCO溶液(4.0 mol/L NaCl+0.5 mol/L KNO3+0.1 mol/L HNO3),溶液体积与试样面积之比为15 mL/cm2,实验温度为(25±3) ℃。分别于腐蚀后12,24和48 h间断观察,拍摄样品腐蚀后表面的宏观形貌,对照HB 5455—90标准对腐蚀试样进行评级。评级代号:N表示未出现腐蚀;P表示点蚀;EA→EB→EC→ED代表剥落腐蚀逐渐加重。

极化曲线测试在电化学工作站IM6ex测试仪器上进行,采用铂电极作为辅助电极,饱和甘汞电极 (SEC)作参比电极,溶液采用EXCO溶液,实验温度保持在25 ℃左右。电位扫描速率是2 mV/s,扫描范围从-1~0 V。

样品的显微组织在Leica DM ILM HC金相显微镜及FEI Tecnai G 220型透射电镜上观察。透射电镜薄片样在MTP-1双喷电解减薄仪上双喷减薄、穿孔,电解液为V(硝酸):V(甲醇)=3:7,温度控制在-25 ℃以下,电压为20 V左右,电流为100 mA左右。

2 实验结果

2.1 硬度和力学性能

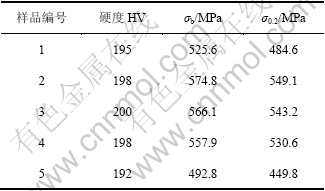

表3所示为不同时效状态下的硬度和拉伸力学性能。由表3可以看出:与T6态相比,经RRA 180 ℃,20 min;RRA 180 ℃,40 min和RRA 180 ℃,60 min处理后,合金的硬度分别提高了1.5%,2.6%和1.5%,抗拉强度分别提高了9.4%,7.7%和6.1%,屈服强度分别提高了13.3%,12.1%和9.5%;而RRA 200 ℃,60 min处理后,硬度、抗拉强度和屈服强度却分别降低了1.5%,6.2%和7.2%。表明RRA 180 ℃处理在一段时间内提高了合金的强硬度,随着回归时间的延长,强度逐渐下降,硬度却相差不大;而RRA 200 ℃,60 min处理,无论与T6态相比还是与RRA 180 ℃,60 min处理相比,都明显降低了合金的强硬度。

表1 1973铝合金板材的化学成分(质量分数)

Table 1 Chemical compositions of 1973 aluminum alloy plate %

表2 1973铝合金时效制度

Table 2 Aging treatment conditions of 1973 aluminum alloy

2.2 晶间腐蚀

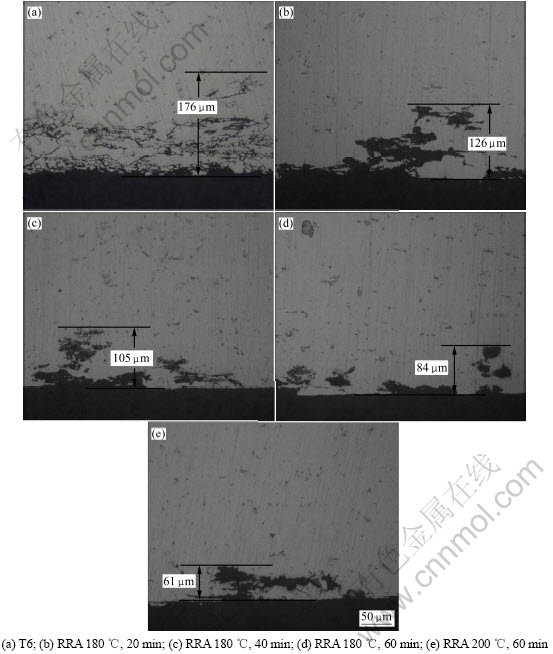

图1所示为不同时效处理后1973铝合金在晶间腐蚀液中浸蚀6 h后的纵截面晶间腐蚀金相组织形 貌。可以看出:T6处理后合金的晶间腐蚀最大深度为176 μm,如图(a)所示;经RRA 180 ℃,20 min;RRA 180 ℃,40 min和RRA 180 ℃,60 min分别处理后,合金的晶间腐蚀最大深度分别降低到126,105和84 μm;而RRA 200 ℃,60 min处理也使合金的晶间腐蚀最大深度降低到61 μm。这表明,与T6处理相比,RRA处理明显提高了合金的抗晶间腐蚀性能;而且在RRA 180 ℃处理一段时间内,合金的抗晶间腐蚀性能随着回归时间的延长而逐渐增加;提高回归温度,可以进一步提高合金的抗晶间腐蚀性能。由此可知:不同时效处理后1973铝合金抗晶间腐蚀性能由小到大的工艺顺序为:T6;RRA 180 ℃,20 min;RRA 180 ℃,40 min;RRA 180 ℃,60 min;RRA 200 ℃,60 min。

表3 不同时效状态下1973铝合金的硬度和拉伸性能

Table 3 Hardness and mechanical properties of 1973 aluminum alloy under different aging treatments

图1 不同时效状态1973铝合金的晶间腐蚀形貌

Fig.1 Intergranular corrosion morphologies of 1973 aluminum alloy under different aging treatments

2.3 剥落腐蚀

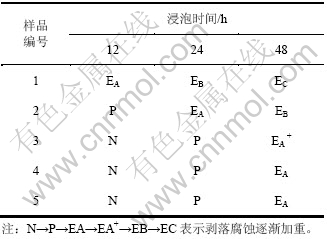

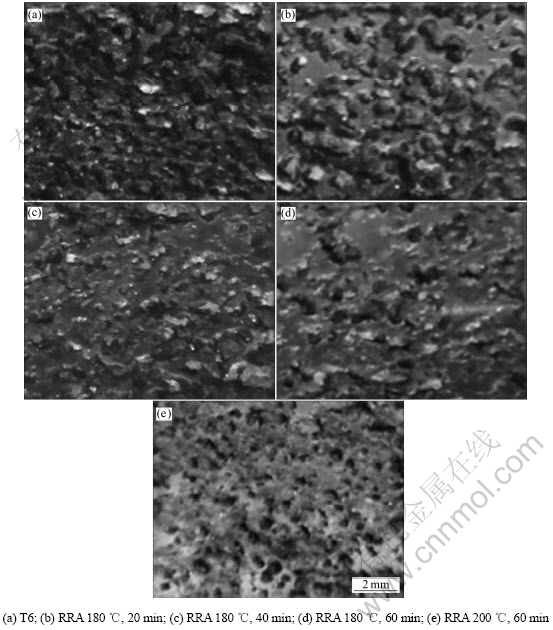

表4和图2所示分别为不同时效处理后1973铝合金在EXCO溶液中浸泡不同时间的剥落腐蚀等级及浸泡48 h后的剥落腐蚀形貌。可以看出:经过12 h浸泡后,3,4和5号样品表面有些褪色,1和2号样品出现鼓泡点蚀,1号样品表面出现了微小的疱疤,裂纹还显示出轻微的分离,说明已开始进入剥蚀阶段;24 h后,所有样品都有不同程度的腐蚀,3,4和5号样品开始出现点蚀,1和2号样品分别发生初等剥蚀和中等剥蚀;48 h后,1号样品已经发生了严重剥蚀,2号样品为中等剥蚀,3,4和5号样品呈现不同程度的初等剥蚀。实验结果表明,RRA处理不同程度地提高了合金的抗剥落腐蚀性能。由此可知:不同时效处理后1973铝合金抗剥落腐蚀性能按由小到大的样品顺序为:1,2,3,4,5号样品。这与前述晶间腐蚀的腐蚀趋势相同。

表4 不同时效状态1973铝合金的剥落腐蚀等级

Table 4 Grade of exfoliation corrosion of 1973 aluminum alloy under different aging treatments

图2 不同时效状态1973铝合金的剥落腐蚀形貌

Fig.2 Exfoliation corrosion morphologies of 1973 aluminum alloy under different aging treatments

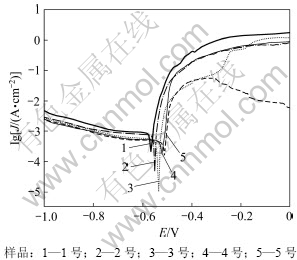

2.4 极化曲线分析

图3所示为1973铝合金不同时效处理状态的在EXCO溶液中的极化曲线,通过Tafel外推法分析极化曲线所测得的电化学腐蚀参数见表5。由图3可以看出:随着回归时间的延长或回归温度的升高,合金的自腐蚀电位正移,自腐蚀电流逐渐减小,说明合金的腐蚀敏感性逐步降低。由表5可知:自腐蚀电位(Ecorr)由小到大的样品顺序为:1,2,3,4,5号;自腐蚀电流(Icorr) 由小到大的样品顺序为:1,2,3,4,5号。自腐蚀电位越正,自腐蚀电流越小,材料的腐蚀速率越小,耐蚀性就越好[11]。这说明RRA处理提高了1973铝合金的耐蚀性能,并且随着回归时间的延长或提高回归温度,合金的耐蚀性都会相应增加。由上分析可知,不同时效处理后1973铝合金抗腐蚀性能由小到大的样品顺序为:1,2,3,4,5号,此结果与晶间腐蚀和剥落腐蚀实验结果相吻合。

图3 1973铝合金不同时效状态的极化曲线

Fig.3 Polarization curves of 1973 aluminum alloy under different aging treatments

表5 1973铝合金不同时效状态的极化曲线腐蚀参数

Table 5 Corrosion parameters of polarization curves of 1973 aluminum alloy under different aging treatments

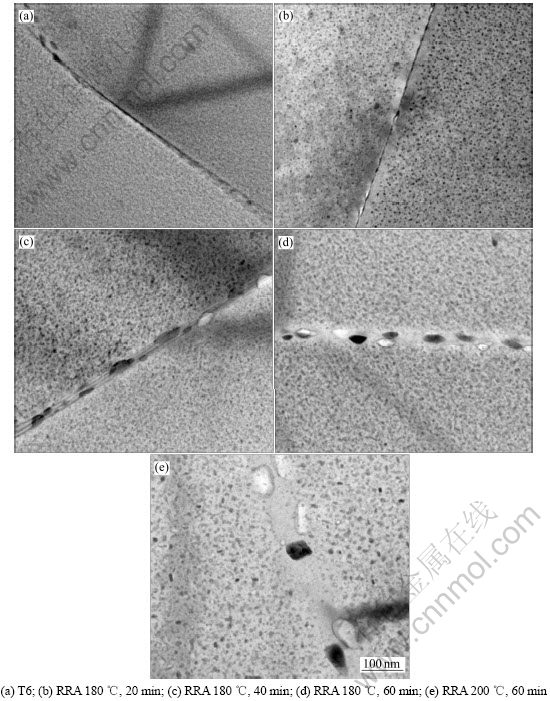

2.5 显微组织观察

图4所示为1973铝合金不同时效状态的TEM像。合金经T6处理后,晶内析出相呈均匀、细小弥散分布,主要为GP区,也可能存在少量η′相;晶界析出相η相细小、连续分布(图4(a))。合金经RRA 180 ℃,20 min处理后(图4(b)),晶内形成与T6态组织类似的均匀弥散的基体析出组织,但较T6态晶内析出相尺寸有所粗化、数量减少、密度下降,主要由η′和η相组成;晶界析出相η相较粗且呈不连续分布,同时在晶界周围形成了明显的无沉淀析出带(PFZ)。RRA 180 ℃,40 min处理后(图4(c)),合金晶内析出相尺寸、PFZ宽度与20 min条件下的PFZ宽度相比相差不大,但晶界处析出相η相变粗、球化。RRA 180 ℃,60 min处理后(图4(d)),合金晶内析出相略有长大,PFZ宽度与20和40 min条件下PFZ宽度相比相差不大,晶界处析出相η相继续变粗、球化且不连续程度明显增加。当提高回归温度至200 ℃时,与RRA 180 ℃,60 min相比,RRA 200 ℃,60 min处理后晶内和晶界析出相粒子尺寸都明显变粗,PFZ明显变宽,晶界析出相进一步球化,晶界析出相的不连续程度也进一步增加(图4(e))。

3 分析与讨论

1973铝合金强度和硬度的变化主要由GP区、η′相、η(MgZn2)相的尺寸、数量和分布所决定。其中GP 区与基体共格,η′相与基体半共格,这两相在合金中起主要的强化作用;η相平衡相与基体非共格,其强化作用较小。

合金经120 ℃,24 h峰时效时效处理后,晶内析出了大量细小弥散的GP区及少量半共格η′(MgZn2)相[12],使得T6处理合金具有很高的强度和硬度,如图4(a)所示。

图4 1973铝合金不同时效状态的TEM像

Fig.4 TEM images of 1973 aluminum alloy under different aging treatments

合金经RRA 180 ℃,20 min处理,在回归处理后未溶解的GP区作为η′相的形核核心,促进η′相形核;同时回归过程中GP区的溶解,增加了基体中的Zn和Mg含量,同样会促进η′相的形核和长大[13],η′相的体积分数逐渐增加。η′相与基体半共格,此时合金以位错绕过机制进行强化;而GP 区与基体共格,合金在T6态主要以位错切割机制进行强化[14];由于η′相以绕过机制引起的强化作用大于GP 区以切割机制的强化作用,表现为合金的强度和硬度上升[12]。但随回归时间延长,RRA 180 ℃在回归处理40 min左右,当η′相的体积分数达到最大时,合金硬度达到峰值;但由于析出相尺寸逐渐粗化,RRA 180 ℃,60 min处理后硬度又下降。由图4(b)~(d)可知:合金分别经RRA 180 ℃,20 min;RRA 180 ℃,40 min和RRA 180 ℃,60 min处理后,晶内粒子平均尺寸相差不是很大,这可能是这3种状态合金硬度相差不大的原因;但晶界平衡相析出状态相差较大,随回归时间延长晶界平衡相逐渐变粗且弥散分布程度不断增加,可能导致了这3种状态合金强度随回归时间延长而降低。

表6 铝固溶体及其析出相的电极电位[17]

Table 6 Electrode potential of aluminum solid solution and precipitates

提高回归温度至200 ℃时,Zn和Mg等溶质原子与空位的扩散速度较快,GP区回溶速率和η′相的析出和长大速率相应加快;由图4(e)也可以看出:RRA 200 ℃,60 min处理后晶内和晶界析出相粒子明显粗化,PFZ变宽,从而导致了合金强度和硬度的明显降低。

铝合金晶间腐蚀主要是电化学腐蚀,是晶界析出相的阳极溶解所致。其原动力是晶界与相邻晶粒之间的电位差,晶界是缺陷、杂质、合金元素富集的地方,析出物与基体或晶界附近贫化区,构成微腐蚀电池,发生沿晶腐蚀,晶间腐蚀便沿着金属或合金的晶粒边界或它的邻近区域进行[15-17]。剥落腐蚀是晶间腐蚀的特殊表现形式,晶界也起着非常重要的作用。热处理使铝合金产生与晶界平行的阳极通道,并目当晶间腐蚀沿着有强烈方向性的扁平晶粒组织进行时,不溶性腐蚀产物(AlCl3或Al(OH)3)的比容均大于基体金属,出现所谓“楔入效应”,撑起上面没有腐蚀的金属,引起分层剥落[18-19]。

合金经T6处理后,晶内基体中的Zn和Mg原子富集,形成大量细小弥散的GP区,其电极电位较负(-1.24~-0.87 V),作阳极(如表6所示);基体A1的电极电位(-0.85 V)较正,作阴极。当合金浸入腐蚀液中,GP区与基体A1之间形成微腐蚀电池,GP区作为阳极优先被溶解。同时晶界平衡相η(MgZn2)相呈链状连续分布,由于η相电极电位(-1.05 V)较负,为阳极相;从而存在一个由晶界阳极性的η相与其边缘铝基体形成的活性腐蚀通道,导致T6处理后合金具有很大的晶间腐蚀及剥落腐蚀敏感性。

合金经180 ℃回归再时效处理后的微观组织如图4(a)~(c)所示。RRA 180 ℃,20 min处理后,相比T6而言,晶内和晶界析出相都有一定得粗化;晶界析出η(MgZn2)相由连续析出向不连续析出转变,晶界η相的不连续分布打断了腐蚀通道,阻碍了电化学腐蚀的进行,降低了晶界腐蚀电流密度;无沉淀析出带PFZ为贫乏固溶体,电位较正,故PFZ的形成降低了基体与晶界间的电位差,降低了电化学腐蚀的驱动力;因此,合金腐蚀敏感性也随之降低。随着回归时间继续延长至40和60 min,晶界上析出相粒子进一步明显粗化,大量非平衡的η′相向平衡的η相转变,η相更加不连续地分布。故RRA 180 ℃,20 min;RRA 180 ℃,40 min和RRA 180 ℃,60 min处理后,η相的不连续分布不仅进一步打断了晶界上的活性腐蚀通道,同时使合金的腐蚀电流密度逐渐减小,腐蚀速率逐渐降低,自腐蚀电位逐渐正移(见表4),导致合金的腐蚀敏感性也随之逐渐降低。合金在RRA 200 ℃,60 min处理后,微观组织如图4(d)所示,晶界析出相的粗化及不连续分布程度进一步增加,PFZ变宽,进一步降低了微电池腐蚀电流密度,使抗腐蚀性能进一步得到提高[20]。经RRA 200 ℃,60 min处理后合金具有最好的抗晶间腐蚀及剥落腐蚀性能,RRA 180 ℃,60 min处理次之,T6处理合金抗腐蚀性能最差。

4 结论

(1) 1973铝合金腐蚀性能主要与晶界析出相η相尺寸、不连续分布程度,PFZ的宽度有关。合金经回归再时效处理后,晶界析出相不连续分布程度的增加及无沉淀析出带PFZ宽度的增大,使合金的抗腐蚀性能不断提高。

(2) 1973铝合金在不同时效处理后晶间腐蚀和剥落腐蚀趋势相同, 耐蚀性能由大到小的RRA工艺顺序为:200 ℃,60 min;180 ℃,60 min;180 ℃,40 min;180 ℃,20 min;T6。

(3) RRA 180 ℃处理一段时间可提高1973铝合金的强度和抗晶间腐蚀和剥落腐蚀性能,并且随着回归时间的延长耐蚀性能越好,但强度有所下降。而RRA 200 ℃,60 min处理与在180 ℃处理相比,虽然有更好耐蚀性能,但是强度大大减小。因此,1973铝合金经RRA 180 ℃,60 min处理后具有较好的综合性能。

参考文献:

[1] 王正安, 汪明朴, 杨文超, 等. 1973铝合金铸态组织及均匀化退火组织研究[J]. 材料工程, 2010(5): 56-63.

WANG Zheng-an, WANG Ming-pu, YANG Wen-chao, et al. Microstructure of as-cast and homogenized 1973 aluminum alloy[J]. Material Engineering, 2010(5): 56-63.

[2] Andreatta F, Terryn H, de Wit J H W. Corrosion behaviour of different tempers of AA7075 aluminum alloy[J]. Electrochimica Acta, 2004, 49(17/18): 2851-2862.

[3] 王洪, 付高峰, 孙继红, 等. 超高强铝合金研究进展[J]. 材料导报, 2006, 20(2): 58-60.

WANG Hong, FU Gao-feng, SUN Ji-hong, et al. Present research and developing trends of ultra high strength aluminum alloys[J]. Materials Review, 2006, 20(2): 58-60.

[4] WANG Feng, XIONG Bai-qing, ZHANG Yon-gan, et al. Effect of heat treatment on the microstructure and mechanical properties of the spray-deposited Al-10.8Zn-2.8Mg-1.9Cu alloy[J]. Materials Science and Engineering A, 2008, 486(1/2): 648-652.

[5] 张新明, 朱航飞, 李国锋, 等. 微量Zr, Er和Y对Al-Zn-Mg-Cu合金铸态组织的影响[J]. 中南大学学报: 自然科学版, 2008, 39(6): 1196-1200.

ZHANG Xin-ming, ZHU Hang-fei, LI Guo-feng, et al. Effects of mini Zr, Er, Y on microstructures of cast Al-Zn-Mg-Cu alloy[J]. Journal of Central South University: Science and Technology, 2008, 39(6): 1196-1200.

[6] 张永安, 王锋, 朱宝宏, 等. 喷射成形Al-10.8Zn-2.8Mg-1.8Cu合金沉淀析出强化行为[J]. 中国有色金属学报, 2006, 16(11): 1845-1849.

ZHANG Yong-an, WANG Feng, ZHU Bao-hong, et al. Microstructural evolution of spray formed Al-l0.8Zn-2.8Mg- 1.8Cu alloy during artificial aging process[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(11): 1845-1849.

[7] LIU Ying-ying, XIA Chang-qing, PENG Xiao-min. Effect of heat treatment on microstructures and mechanical properties of Al-6Zn-2Mg-1.5Cu-0.4Er alloy[J]. Journal of Central South University of Technology, 2010, 17(1): 24-27.

[8] XIAO Yan-ping, PAN Qing-lin, LI Wen-bin, et al. Influence of retrogression and re-aging treatment on corrosion behaviour of an Al-Zn-Mg-Cu alloy[J]. Materials and Design, 2011, 32(4): 2149-2156.

[9] 蔡一鸣, 梁霄鹏, 李慧中, 等. 热处理制度对7039铝合金抗腐蚀性能的影响[J]. 中南大学学报: 自然科学版, 2009, 40(6): 1540-1545.

CAI Yi-ming, LIANG Xiao-peng, LI Hui-zhong, et al. Effect of heat treatment on corrosion resistance of 7039 aluminum alloy[J]. Journal of Central South University: Science and Technology, 2009, 40(6): 1540-1545.

[10] 冯春, 刘志义, 宁爱林, 等. RRA处理对超高强铝合金抗应力腐蚀性能的影响[J]. 中南大学学报: 自然科学版, 2006, 37(6): 1054-1059.

FENG Chun, LIU Zhi-yi, NING Ai-lin, et al. Effect of retrogression and re-aging treatment on stress corrosion cracking resistance of super-high strength aluminum alloy[J]. Journal of Central South University: Science and Technology, 2006, 37(6): 1054-1059.

[11] 孙秋霞. 材料腐蚀与防护[M]. 北京: 冶金工业出版社, 2001: 55-87.

SUN Qiu-xia. Material corrosion and protection[M]. Beijing: Metallurgical Industry Press, 2001: 55-87.

[12] 曾渝, 尹志民, 朱远志, 等. RRA处理对超高强铝合金微观组织与性能的影响[J]. 中国有色金属学报, 2004, 14(7): 1188-1194.

ZENG Yu, YIN Zhi-min, ZHU Yuan-zhi, et al. Effect of RRA on microstructure and properties of new type ultra high strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1188-1194.

[13] FENG Chun, LIU Zhi-yi, NING Ai-lin, et al. Retrogression and re-aging treatment of Al-9.99%Zn-1.72%Cu-2.5%Mg-0.13%Zr aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(5): 1163-1170.

[14] 李志辉, 熊柏青, 张永安, 等. 7B04铝合金的时效沉淀析出及强化行为[J]. 中国有色金属学报, 2007, 17(2): 248-253.

LI Zhi-hui, XIONG Bai-qing, ZHA Yong-an, et al. Ageing precipitation and strengthening behavior of 7B04 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(2): 248-253.

[15] Knight S P, Salagaras M, Trueman A R. The study of intergranular corrosion in aircraft aluminum alloys using X-ray tomography[J]. Corrosion Science, 2011, 53 (2): 727-734.

[16] El-Amoush A S. Intergranular corrosion behavior of the 7075-T6 aluminum alloy under different annealing conditions[J]. Materials Chemistry and Physics, 2011, 126(3): 607-613.

[17] 中国腐蚀与防护学会. 有色金属的耐腐蚀性及其应用[M]. 北京: 化学工业出版社, 1997: 11-21.

Chinese Cankerous and Protection Society. The corrosion resistance of non-ferrous metals and its application[M]. Beijing: Chemical Industry Publisher, 1997: 11-21.

[18] 苏景新, 张昭, 曹发和, 等. 铝合金的晶间腐蚀与剥蚀[J]. 中国腐蚀与防护学报, 2005, 6(3): 181-191.

SU Jing-xin, ZHANG Zhao, CAO Fa-he, et al. Review on the intergranular corrosion and exfoliation corrosion of aluminum alloys[J]. Journal of Chinese Society for Corrosion and Protection, 2005, 6(3): 181-191.

[19] Wloka J, Hack T, Virtanen S. Influence of temper and surface condition on the exfoliation behaviour of high strength Al-Zn-Mg-Cu alloys[J]. Corrosion Science, 2007, 49(3): 1437-1449.

[20] Li J F, Birbilisc N, Li C X, et al. Influence of retrogression temperature and time on themechanical properties and exfoliation corrosion behavior of aluminum alloy AA7150[J]. Materials Characterization, 2009, 60(11): 1334-1341.

(编辑 陈爱华)

收稿日期:2011-09-29;修回日期:2011-11-07

基金项目:国家高技术研究发展计划(“863”计划)项目(2006AA032517);湖南省博士生科研创新项目(CX2010B044)

通信作者:汪明朴(1952-),男,安徽安庆人,教授,博士生导师,从事相变与特种功能材料研究;电话:0731-88830264;E-mail: wangmp@csu.edu.cn