DOI: 10.11817/j.ysxb.1004.0609.2020-37561

基于模糊综合评判的复合胶凝材料开发及料浆配比优化

温震江1, 2,高 谦1, 2,王永定3,杨晓炳1, 2

(1. 北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京 100083;

2. 北京科技大学 土木与资源工程学院,北京 100083;

3. 金川集团股份有限公司,金昌 737100)

摘 要:针对矿山采用水泥胶凝材料充填成本较高的问题,利用当地矿渣和粉煤灰等固废资源开发低成本胶凝材料,并基于矿山现有的充填系统对料浆配比进行优化,在满足矿山要求的前提下,以期达到最大经济效益。首先,对试验材料进行物化分析;其次,采用正交试验、极差分析等方法进行复合胶凝材料配比优化试验,确定优化配比为粉煤灰10%、熟料8%、脱硫石膏14%、矿渣微粉68%,并利用XRD和SEM等手段来探究复合胶凝材料的水化产物及其微观结构,进一步揭示其水化机理;最后,在此基础上利用该胶凝材料进行充填料浆配比试验,并以7 d强度、28 d强度、泌水率、塌落度和充填成本为指标基于多目标模糊综合评判法进行料浆配比优化。结果表明:以采用复合胶凝材料、尾砂和戈壁集料配比1:1、胶砂比1:6、质量分数78%为最优配比,并以此配比进行验证试验,得到相应的7 d强度、28 d强度、泌水率和塌落度分别为1.76 MPa、4.82 MPa、5.98%和23.2 cm。充填体强度、料浆稳定性和料浆流动性均满足矿山要求,并且充填成本为103元/m3,较原来195元/m3的充填成本降低了47%。

关键词:充填采矿法;矿渣;粉煤灰;胶凝材料;模糊综合评判;配比优化

文章编号:1004-0609(2020)-03-0698-10 中图分类号:TD853;X751 文献标志码:A

近年来,随着社会经济的高速发展,人们对矿产资源的需求量逐年上升,资源开采逐步向深地发展,地压越来越大,加之国家对环境保护以及安全生产要求的提高,对矿山开采活动产生的废石、尾砂等固体废弃物加收环保税;而在诸多采矿方法中,充填法不仅可以提高固体废弃物的综合利用率,减少占地和污染,而且充填体可以支持采空区避免塌陷,有利于控制采场地压,这些优点使得充填采矿法被广泛应用[1-4]。充填材料的选择和配比,尤其是胶凝材料的选择不仅影响充填效果,而且对充填成本起决定性作用[5-6]。目前,对于充填材料的选择、配比及优化、新型胶凝材料的开发、充填效果影响因素等方面国内外均进行了大量研究,其中DJURDJEVAC等[7]基于试验法研究了充填工艺及物料配比对充填体强度的影响;FALL等[8]基于满意度函数对充填料进行配比优化;张钦礼等[9]、刘志祥等[10]、周科平[11]分别采用BP神经网络和灰色理论来优化充填料配比;对于新型胶凝材料的开发,杨志强等[12]利用金川水淬镍渣等废弃物开发胶凝材料;李茂辉 等[13]、LEE等[14]、肖柏林等[15]分别利用粉煤灰、磷石膏开发复合胶凝材料;除此之外,ALDHAFEERI等[16]研究了温度对充填体强度发展的影响;邓代强等[17]研究了胶凝材料掺量对充填体强度的影响;刘志祥等[18]基于分形理论研究骨料级配对充填体强度的影响;曹帅等[19]、李雅图等[20]研究了充填体在不同条件下的力学特性。本文在前期大量探索性试验的基础上,结合前人研究成果,首先利用冶金工业废渣开发新型胶凝材料,然后利用开发的胶凝材料进行充填料浆配比研究,并基于多目标模糊优选决策模型对充填料浆配比进行优化,以此得到在满足矿山对于流动性和强度要求的前提下,充填成本最低的充填材料配比方案。

1 多目标模糊优选决策模型

模糊优选决策是指决策要素(如目标、属性、备选方案等)含有模糊性的决策[21],其是基于模糊数学建立优化模型用于解决那些很难用经典优化模型求解的决策问题。对于多目标决策模型,通过m个指标对n个方案进行综合评判,则有m×n的目标特征值矩阵X[22-23]。

对于方案j可以用向量xj来表示m个指标的特征值,则

为了消除评价指标不同量纲的影响,对目标特征值矩阵按照式(1)~(3)不同类型进行归一化处理,得到目标相对优属度矩阵R[24-25]:

越大越优型:

(1)

(1)

适度中间型:

(2)

(2)

越小越优型:

(3)

(3)

式中:rij表示方案j第i个指标归一化处理之后的目标特征值;yi第i指标的理想值;i=1, 2, …, m;j=1, 2, …, n。

并根据加权距优欧式距离与加权距劣欧式距离平方之和为最小的原则得到其相对优属度,如式(4)所 示[21-22],然后通过比较相对优属度大小,从中选取相对优属度最大的方案。

(4)

(4)

式中:wi表示第i个评判指标权重。

2 复合胶凝材料配比试验

2.1 试验材料

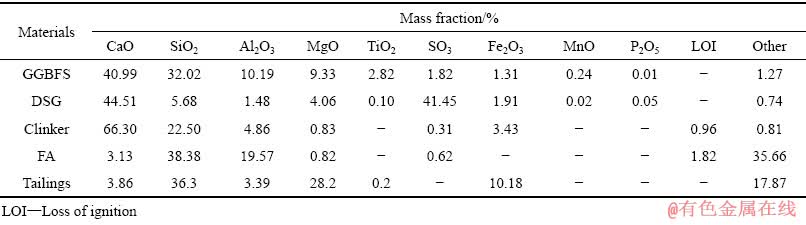

表1 试验材料化学成分分析结果

Table 1 Analysis results of chemical components of test materials

图1 尾砂和戈壁集料粒径特征分布曲线

Fig. 1 Characteristics distribution curves of particle size of tailings and Gobi aggregates

试验采用矿渣微粉(GGBFS)、脱硫石膏(DSG)、熟料(Clinker)、粉煤灰(FA)、尾砂(Tailings)和水,其中矿渣微粉和脱硫石膏为钢铁厂生产的工业副产品,细度(45 μm筛余)分别为5.57%和15.35%;熟料则是购于当地的水泥厂经过粉磨细度达到10.11%;粉煤灰取自南湖热电厂,对其进行X射线荧光光谱实验(XRF)分析,结果如表1所示;尾砂取自新疆某矿,粒径分布如图1(a)所示,可以计算出其特征粒径d10、d30、d60和d90分别为15.22、27.38、76.78和148.27 μm,其粒径大于75 μm的颗粒含量占41.12%,属于较粗的尾砂;戈壁集料粒径分布如图1(b)所示,特征粒径d10、d30、d60和d90分别为19.2、387.9、1676.5和6288.4 μm,75 μm以下细颗粒含量仅为14.5%,粒径较粗,与尾砂配合使用有利于提高充填体强度。

根据表1矿渣微粉XRF分析结果可以计算得出其碱性系数M0=1.192>1,属于碱性矿渣,质量系数K=1.724>1.6,活性指数Ma=0.318>0.3,属于较高活性矿渣,其微观形态如图2所示,主要由不规则的块状颗粒组成,块状体颗粒尺寸差异较大,块状颗粒上面附着细微小颗粒,主要为玻璃相物质,是矿渣胶凝活性的主要物质。综上所述该矿渣属于具有较高活性的碱性矿渣,可以用于开发新型充填胶凝材料。

2.2 试验方案

根据前期大量探索性试验,针对固体废弃物开发新型胶凝材料,配方试验方案如下:粉煤灰含量固定10%,以熟料8%~12%、脱硫石膏10%~14%设计两因素三水平的正交试验,在胶砂比1:4,质量浓度70%条件下浇筑成70.7 mm×70.7 mm×70.7 mm的标准试块,并在温度(20±1) ℃和湿度大于95%的养护条件下养护至相应龄期测试其强度。

图2 矿渣微粉的微观形貌

Fig. 2 Microscopic morphologies of GGBFS

2.3 试验结果及分析

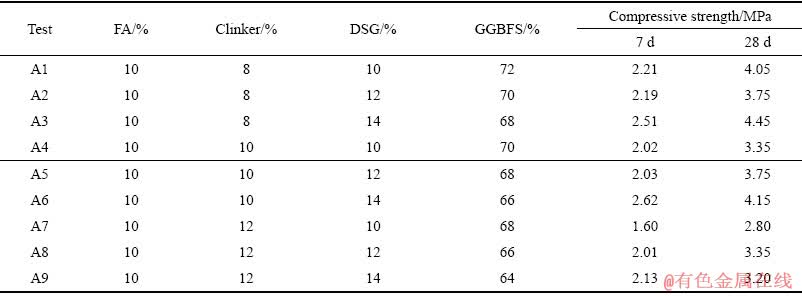

具体试验方案及结果如表2所示,然后对其进行极差分析,极差分析结果如表3所示。

由表2~3可知,矿渣基复合胶凝材料充填体强度正交试验充填体7 d强度均大于1.5 MPa,28 d强度均大于2.5 MPa。极差分析结果表明,7 d强度的矿渣胶凝材料中熟料含量8%和10%的收敛率仅相差0.08,而28 d强度相差0.33。由此可知,水泥熟料增加或减小2%,可以提高充填体后期强度;胶结体7 d和28 d强度的脱硫石膏12%与14%两水平的收敛率差值分别为0.34和0.31。由此可见,增大脱硫石膏掺量7 d和28 d强度均能提高;根据胶结充填体强度试验及极差分析结果可知,复合胶凝材料优化配方为粉煤灰10%、熟料8%、脱硫石膏14%、矿渣微粉68%,经过试验验证满足矿山要求,并将其确定为后续充填材料配比优化试验的胶凝材料。

表2 复合胶凝材料充填体强度正交试验结果

Table 2 Orthogonal test results of strength of composite cementitious material filling body

表3 复合胶凝材料充填体强度正交试验极差分析结果

Table 3 Range analysis results of orthogonal test on strength of composite cementitious material filling body

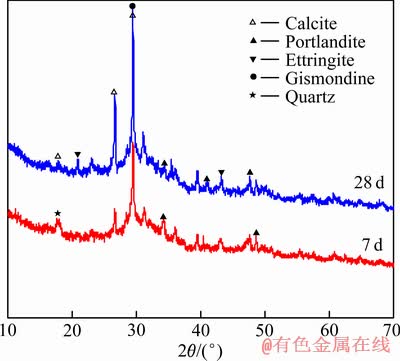

2.4 复合胶凝材料水化机理分析

为了进一步探究复合胶凝材料的水化产物及其微观结构,采用SEM和XRD等方法研究其水化机理,按照国标GB/T 346—2001制备净浆试块,标准养护至相应龄期之后立即用乙醇浸泡使其停止水化反应,烘干后研磨制样。利用XRD获得复合胶凝材料不同龄期水化产物物相,如图3所示。由图3可以看出,矿渣-粉煤灰胶凝材料胶凝硬化体系中有很多非晶态物质存在,其水化产物主要包含氢氧钙石、方解石和斜方钙沸石,除此之外,还观察到存在一定量的钙矾石和石英衍射峰;随着水化反应的进行,矿渣的分散作用促进了水化反应,并且矿渣的二次反应加速了Ca2+的消耗,方解石、斜方钙沸石的衍射峰逐渐增强,钙矾石的衍射峰有也有一定程度的增强,进一步促进了充填体抗压强度的提高。

图3 复合胶凝材料水化产物XRD谱

Fig. 3 XRD patterns of hydration products of composite cementitious material

并且利用SEM得到复合胶凝材料不同龄期的微观组织,如图4所示,其中图4(a)和(b)分别为7 d和28 d的SEM像。由图4可知,随着养护龄期的增加,水化反应不断进行,粉煤灰和矿渣的活性逐渐被激发,更多地参与到水化反应中。由图4(a)看出,水化7 d能够看到少量针棒状物质生成;由图4(b)可知,随着水化反应的进行,28 d时钙沸石和钙矾石不断生成,含量逐渐增加,结构变得更加致密,胶凝材料抗压强度随之增大。

图4 复合胶凝材料净浆水化产物的SEM像

Fig. 4 SEM images of hydration products of composite cementitious material

3 充填料浆配比优化试验

通过矿渣基胶凝材料充填体强度试验与优化决策,获得了满足矿山要求的充填胶凝材料。为了更好地在矿山应用,针对矿山现有的充填系统对充填料浆配比进行优化,在提高充填效果的同时降低成本,以期获得最大的经济效益和环保效益。

3.1 试验方案

根据矿山现有的充填系统进行充填料浆配比试验,具体试验方案如下:

1) 骨料,采用尾砂与戈壁集料按照1:1配制成的混合骨料;

2) 胶凝材料,采用粉煤灰10%、水泥熟料8%、脱硫石膏14%和矿渣微粉68%配比,并粉磨成细度不大于5%的矿渣基胶凝材料;

3) 胶砂比(CSR),采用1:4、1:6和1:8 3种胶砂比;

4) 质量浓度(MC),采用74%、76%和78% 3种浓度。

3.2 试验结果与分析

3.2.1 试验结果

按照上述试方案进行充填料浆配比试验,试验结果如表4所示。

表4 混合骨料充填料浆配比试验结果

Table 4 Test results of mixing aggregate filling slurry

3.2.2 试验结果分析

根据表4试验结果分析胶砂比和浓度对各项指标的影响,如图5~8所示。当胶砂比为1:4时,戈壁砂-尾砂混合骨料胶结充填体7 d平均抗压强度为3.02 MPa,28 d平均抗压强度为6.21 MPa,均满足矿山对充填体强度要求。由图5和6可知,随着胶砂比减小,胶结充填体强度的降低速率在增大。当胶砂比降低到1:6时,胶结体7 d强度仅为1.47 MPa,由此降低了51%;胶结体28 d强度降低到3.66 MPa,降低了41%。由图7可知,充填料浆泌水率(BR)随着料浆浓度的增大而降低,就胶砂比1:4而言,料浆浓度从74%增加大78%,泌水率降低了40%;料浆泌水率随着胶砂比的增大而降低,就浓度74%而言,胶砂比从1:8增大到1:4,泌水率降低了9.2%。由图8可知,充填料浆塌落度(Slump)随着料浆浓度的增大而减小,当胶砂比1:4时,浓度从74%增大到78%,塌落度减小了5.75%;胶砂比对屈服应力的影响,就浓度78%而言,当胶砂比从1:4减小到1:8,塌落度增大了7.51%。

图5 胶结充填体7 d强度与料浆浓度的关系

Fig. 5 Relationship between 7 d strength of cemented filling and slurry concentration

图6 胶结充填体28 d强度与料浆浓度的关系

Fig. 6 Relationship between 28 d strength of cemented filling and slurry concentration

图7 充填料浆泌水率与浓度的关系

Fig.7 Relationship between bleeding rate and concentration of filling slurry

图8 充填料浆塌落度与浓度的关系

Fig. 8 Relationship between slump and concentration of filling slurry

3.3 充填料浆配比优化

采矿活动要综合考虑经济效益,在保证充填质量的前提下,尽可能降低充填成本,矿山充填除了要考虑充填体强度、料浆稳定性和流变性外,还要考虑充填成本等因素,因此,优化充填料浆配比方案实质是一个多因素多目标优化问题,可以利用模糊优选决策理论进行综合评判优化,全面反映料浆配比情况,更有效地选择最佳配比方案。

根据矿山对于7 d和28 d强度要求:R7 d≥1.5 MPa,R28 d≥2.5 MPa,结合表4中的料浆配比试验结果可知,有6组料浆配比方案的7 d强度大于1.5 MPa,28 d强度大于2.5 MPa,可以满足矿山要求。把这6组配比方案作为备选方案,并将7 d强度、28 d强度、料浆泌水率、料浆塌落度和充填成本作为评判指标,对6组充填料浆配比方案进行优化,备选方案每个指标的取值如表5所示,其中7 d和28 d强度属于越大越优型;根据FALL等[26-27]研究表明泌水率合理范围为5%~20%,结合试验结果的范围,可将其看作越小越优型;塌落度合理范围为15~30 cm,并将理想值定为18 cm,根据试验结果可将其看作越小越优型;而充填成本属于越小越优型,其按照单位体积充填体所需各物料价格计算所得。对于多目标模糊综合评判指标的权重w对于料浆配比优化结果影响显著,采用层次分析法,结合工程实际情况[27],确定充填体7 d强度w1、28 d强度w2、泌水率w3、塌落度w4和充填成本w5的权重分别为0.15、0.15、0.05、0.1和0.55。

表5 充填料浆配比方案目标特征值

Table 5 Eigen value of filling slurry ratio schemes

根据表3得到目标特征值矩阵X如下:

其中7 d和28 d强度属于越大越优型,充填成本属于越小越优型,泌水率和塌落度根据试验结果也可看作越小越优型,据此由式(1)~(3)对目标特征值进行归一化处理得到目标相对优属度矩阵R:

各指标权重向量w=[0.15 0.15 0.05 0.1 0.55 ]T,据此根据式(4)计算各个方案的相对优属度,结果为uj=[0.1304 0.1423 0.1597 0.8403 0.8554 0.8889]。

根据计算结果可知:方案6相对优属度为0.8889,即采用复合胶凝材料,胶砂比1:6,质量浓度78%的条件下相对优属度最大,可将其看作综合评判最优的方案。并以此配比进行验证试验,如图9所示,试验过程限于篇幅不再赘述,得到相应的7 d强度、28 d强度、泌水率和塌落度分别为1.76 MPa、4.82 MPa、5.98%和23.2 cm,充填体强度、料浆稳定性和料浆流动性均满足矿山要求。

图9 泌水率和塌落度验证测试

Fig. 9 Verification tests of bleeding rate and slump

4 结论

1) 利用X射线荧光光谱实验(XRF)分析试验材料化学组成,主要试验材料矿渣微粉的碱性系数M0= 1.192>1,属于碱性矿渣,质量系数K=1.724>1.6,活性指数Ma=0.318>0.3,属于较高活性矿渣;可以用于开发新型充填胶凝材料。

2) 针对固废资源进行复合胶凝材料配比试验,根据正交试验及极差分析结果获得复合胶凝材料优化配方为粉煤灰10%、熟料8%、脱硫石膏14%、矿渣微粉68%,并经过试验验证满足矿山对充填体强度的要求。

3) 由不同龄期微观组织的SEM像可知,随着养护龄期的增加,水化反应不断进行,粉煤灰和矿渣的活性逐渐被激发,更多地参与到水化反应中,水化7 d能够看到少量针棒状物质生成,28 d时钙沸石和钙矾石不断生成,含量逐渐增加,结构变得更加致密,胶凝材料抗压强度随之增大。

4) 针对现有的充填系统进行充填料浆配比试验,并以7 d强度、28 d强度、泌水率、塌落度以及单位充填成本为指标,利用多目标模糊综合评判法进行优化,获得综合评判最优的充填料浆配比方案,即采用复合胶凝材料,胶砂比1:6,质量浓度78%,并以此配比进行验证试验,得到相应的7 d强度、28 d强度、泌水率和塌落度分别为1.76 MPa、4.82 MPa、5.98%和23.2 cm,充填体强度、料浆稳定性和料浆流动性均满足矿山要求。

REFERENCES

[1] 古德生. 对中国矿业可持续发展问题的思考[J]. 世界采矿快报, 1997, 13(2): 3-5.

GU De-sheng. Thoughts on sustainable development of mining industry in China[J]. World Mining Express, 1997, 13(2): 3-5.

[2] 王新民, 赵建文, 张钦礼, 吴 鹏. 露天转地下最佳开采模式[J]. 中南大学学报(自然科学版), 2012, 43(4): 1434-1439.

WANG Xin-min, ZHAO Jian-wen, ZHANG Qin-li, WU Peng. Optimal mining model of transition from open-pit to underground mining[J]. Journal of Central South University, 2012, 43(4): 1434-1439.

[3] 李夕兵, 周 健, 王少锋, 刘 冰. 深部固体资源开采评述与探索[J]. 中国有色金属学报, 2017, 27(6): 1236-1262.

LI Xi-bing, ZHOU Jian, WANG Shao-feng, LIU Bing. Review and practice of deep mining for solid mineral resources[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(6): 1236-1262.

[4] 李夕兵, 刘 冰, 姚金蕊, 石 英, 李地元, 杜绍伦, 何忠国. 全磷废料绿色充填理论与实践[J]. 中国有色金属学报, 2018, 28(9): 1845-1865.

LI Xi-bing, LIU Bing, YAO Jin-xin, SHI Ying, LI Di-yuan, DU Shao-lun, HE Zhong-guo. Theory and practice of green mine backfill with whole phosphate waste[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(9): 1845-1865.

[5] 付自国, 乔登攀, 郭忠林, 谢锦程, 黄 飞, 王佳信. 基于RSM-BBD的废石-风砂胶结体配合比与强度试验研究[J]. 煤炭学报, 2018, 43(3): 694-703.

FU Zi-guo, QIAO Deng-pan, GUO Zhong-lin, XIE Jin-cheng, HUANG Fei, WANG Jia-xin. Experimental research on mixture proportion and strength of cemented hydraulic fill with waste rock[J]. Journal of China Coal Society, 2018, 43(3): 694-703.

[6] 由 希, 任凤玉, 何荣兴, 丁航行. 阶段空场嗣后充填胶结充填体抗压强度研究[J]. 采矿与安全工程学报, 2017, 34(1): 163-169.

YOU Xi, REN Feng-yu, HE Rong-xing, DING Hang-xing. Research on compressive strength of cemented filling body in subsequent filling at the stage of open stope[J]. Journal of Mining & Safety Engineering, 2017, 34(1): 163-169.

[7] DJURDJEVAC L, IGNJATOVIC D, LJUBOJEV M, MTROVIC M. Change the uniaxial compressive strength of paste backfill depending on change the parameters[J]. Mining & Metallurgy Engineering Bor, 2016(1): 17-24.

[8] FALL M, BENZAAZOUA M, SAA E G. Mix proportioning of underground cemented tailings backfill[J]. Tunnelling & Underground Space Technology, 2008, 23(1): 80-90.

[9] 张钦礼, 李谢平, 杨 伟. 基于BP网络的某矿山充填料配比优化[J]. 中南大学学报(自然科学版), 2013, 44(7): 2867-2874.

ZHANG Qin-li, LI Xie-ping, YANG Wei. Optimization of filling slurry ratio in a mine based on back-propagation neural network[J]. Journal of Central South University (Science and Technology), 2013, 44(7): 2867-2874.

[10] 刘志祥, 龚永超, 李夕兵. 基于分形理论和BP神经网络的充填料性能研究[J]. 黄金科学技术, 2017, 25(2): 38-44.

LIU Zhi-xiang, GONG Yong-chao, LI Xi-bing. Study on the backfilling material properties based on fractal theory and BP neural network[J]. Gold Science and Technology, 2017, 25(2): 38-44.

[11] 周科平. 充填体粒径分布对其强度影响的灰色关联分 析[J]. 矿业研究与开发, 1995, 15(4): 32-35.

ZHOU Ke-ping. A gray correlativity analysis of influence of particle size distribution of filling body strength[J]. Mining Research and Development, 1995, 15(4): 32-35.

[12] 杨志强, 高 谦, 王永前, 倪 文, 陈得信. 利用金川水淬镍渣尾砂开发新型充填胶凝剂试验研究[J]. 岩土工程学报, 2014, 36(8): 1498-1505.

YANG Zhi-qiang, GAO Qian, WANG Yong-qian, NI Wen, CHEN De-xin. Experimental study on new filling cementing material using water-hardening nickel slag tailings of Jinchuan Mine[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(8): 1498-1505.

[13] 李茂辉, 杨志强, 王有团, 高 谦. 粉煤灰复合胶凝材料充填体强度与水化机理研究[J]. 中国矿业大学学报, 2015, 44(4): 650-655.

LI Mao-hui, YANG Zhi-qiang, WANG You-tuan, GAO Qian. Experiment study of compressive strength and mechanical property of filling body for fly ash composite cementitious materials[J]. Journal of China University of Mining & Technology, 2015, 44(4): 650-655.

[14] LEE N K, LEE H K. Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature[J]. Construction & Building Materials, 2013, 47(5): 1201-1209.

[15] 肖柏林, 杨志强, 高 谦. 金川矿山磷石膏基新型充填胶凝材料的研制[J]. 矿业研究与开发, 2015(1): 21-24.

XIAO Bo-lin, YANG Zhi-qiang, GAO Qian. Development of new filling cementitous material of phosphogypsum in Jinchuan Mine[J]. Mining Research and Development, 2015(1): 21-24.

[16] ALDHAFEERI Z, FALL M, POKHAREL M, POURAMINI Z. Temperature dependence of the reactivity of cemented paste backfill[J]. Applied Geochemistry, 2016, 72(9): 10-19.

[17] 邓代强, 姚中亮, 朱永建, 汪令辉. 胶结充填体强度预测及水泥消耗量反演计算[J]. 中国矿业大学学报, 2013, 42(1): 39-44.

DENG Dai-qiang, YAO Zhong-liang, ZHU Yong-jian, WANG Ling-hui. Forecasting cemented backfill strength: Back calculation of cement dosage[J]. Journal of China University of Mining & Technology, 2013, 42(1): 39-44.

[18] 刘志祥, 李夕兵. 尾砂分形级配与胶结强度的知识库研 究[J]. 岩石力学与工程学报, 2005,25(10): 1789-1793.

LIU Zhi-xiang, LI Xi-bing. Study on fractal gradation of tailings and knowledge bank of its cementing strength[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 25(10): 1789-1793.

[19] 曹 帅, 宋卫东, 薛改利, 王 洋, 朱鹏瑞. 考虑分层特性的尾砂胶结充填体强度折减试验研究[J]. 岩土力学, 2015, 36(10): 2869-2876.

CAO Shuai, SONG Wei-dong, XUE Gai-li, WANG Yang, ZHU Peng-rui. Tests of strength reduction of cemented tailings filling considering layering character[J]. Rock and Soil Mechanics, 2015, 36(10): 2869-2876.

[20] 李雅阁, 金龙哲, 谭 昊, 王 浩. 胶结充填体力学特性的加载速率效应试验[J]. 哈尔滨工业大学学报, 2016, 48(9): 49-53.

LI Ya-ge, JIN Long-zhe, TAN Hao, WANG Hao. Experiment of loading rate effect on mechanical characteristics of cemented filling body[J]. Journal of Harbin Institute of Technology, 2016, 48(9): 49-53.

[21] 吴开信. 多目标模糊优选决策模型及其在资源分配中的应用[D]. 成都: 西南交通大学, 2007.

WU Kai-xin. The model of fuzzy optimal selection among multi-objectives and its application for the allocation of the resources[D]. Chengdu: Southwest Jiaotong University, 2007.

[22] 张丽娟, 何捷聪, 陈 逸, 关裕彤. 广州某淤泥地基固化改良试验及优化配比研究[J]. 地下空间与工程学报, 2017, 13(2): 344-347, 369.

ZHANG Li-juan, HE Jie-cong, CHEN Yi, GUAN Yu-tong. Research on mud foundation solidification improvement experiment and optimal additive portion of a project in Guangzhou[J]. Chinese Journal of Underground Space and Engineering, 2017, 13(2): 344-347, 369.

[23] 朱丽萍, 张虎元, 谭 煜, 袁 微, 刘 平. 基于模糊综合评判的膨润土-砂最优配比计算[J]. 兰州大学学报(自然科学版), 2018, 54(3): 310-316.

ZHU Li-ping, ZHANG Hu-yuan, TAN Yu, YUAN Wei, LIU Ping. Determination of the optimal bentonite-sand ratio based on fuzzy integrated evaluation[J]. Journal of Lanzhou University(Natural Sciences Edition), 2018, 54(3): 310-316.

[24] 高 峰, 王巧莉, 彭先艳, 艾凯明. 基于指标满意度的充填配比正交优化试验[J]. 福州大学学报(自然科学版), 2015, 43(3): 422-427.

GAO Feng, WANG Qiao-li, PENG Xian-yan, AI Kai-ming. Orthogonal optimization test of backfill mix ratio based on index satisfaction[J]. Journal of Fuzhou University(Natural Science Edition), 2015, 43(3): 422-427.

[25] 鞠萍华, 黄广全, 肖莉明, 冉 琰, 姚梦生. 多目标模糊综合评价的装配序列优选方法[J]. 哈尔滨工业大学学报, 2018, 50(7): 154-163.

JU Ping-hua, HUANG Guang-quan, XIAO Li-ming, RAN Yan, YAO Meng-sheng. Optimization method of assembly sequence based on multi-objective fuzzy comprehensive evaluation[J]. Journal of Harbin Institute of Technology, 2018, 50(7): 154-163.

[26] FALL M, BENZAAZOUA M, SAA E G. Mix proportioning of underground cemented tailings backfill[J]. Tunnelling & Underground Space Technology, 2008, 23(1): 70-80.

[27] 吴 浩, 赵国彦, 陈 英. 多目标条件下矿山充填材料配比优化实验[J]. 哈尔滨工业大学学报, 2017, 49(11): 101-108.

WU Hao, ZHAO Guo-yan, CHEN Ying. Multi-objective optimization for mix proportioning of mine filling materials[J]. Journal of Harbin Institute of Technology, 2017, 49(11): 101-108.

Development of composite cementitious material and optimization of slurry proportion based on fuzzy comprehensive evaluation

WEN Zhen-jiang1, 2, GAO Qian1, 2, WANG Yong-ding3, YANG Xiao-bing1, 2

(1. Key Laboratory of High Efficient Mining and Safety of Metal Mine, Ministry of Education, University of Science and Technology Beijing, Beijing 100083, China;

2. School of Civil and Resource Engineering, University of Science and Technology Beijing, Beijing 100083, China;

3. Jinchuan Group Co., Ltd., Jinchang 737100, China)

Abstract: In view of the high cost of cement cementing materials in mines, the low-cost cementitious materials were developed by using local solid waste resources, such as slag and fly ash; and the filling slurry ratio was optimized based on the existing filling system of the mines, so as to achieve maximum economic benefits on the premise of meeting the requirements of mines. Firstly, the physical and chemical analysis of the test material was carried out. Secondly, the orthogonal test and range analysis were used to optimize the proportion of composite cementitious material, and the optimized ratio was determined to be 10% fly ash(FA) , 8% clinker, 14% desulfurization gypsum(DSG)and 68% ground granulated blast furnace slag (GGBFS). The hydration products and microstructure of composite cementitious material were explored by means of XRD and SEM, and its hydration mechanism was further revealed. Finally, based on this, the cementitious material was used to carry out the filling slurry ratio experiment, and the slurry ratio was optimized based on multi-objective fuzzy comprehensive evaluation method with 7 d strength, 28 d strength, bleeding rate(BR), slump and filling cost as indicators. The results show that, when the composite cementitious material is used, the ratio of tailings to Gobi aggregate is 1:1, the cement-sand ratio (CSR) is 1:6 and the mass concentration(MC) is 78% as the optimum proportion; and the verification test is carried out with this ratio, and the corresponding 7 d strength, 28 d strength, bleeding rate and slum pare 1.76 MPa, 4.82 MPa, 5.98% and 23.2 cm, respectively, which meet the requirements of the mine, and the filling cost is 103 yuan/m3, which is 47% lower than the original filling cost of 195 yuan/m3.

Key words: filling mining method; slag; fly ash; composite cementitious materials; fuzzy comprehensive evaluation; proportion optimization

Foundation item: Project(2017YFC0602903) supported by the National Basic Research Development Program of China

Received date: 2019-04-03; Accepted date: 2019-06-24

Corresponding author: GAO Qian; Tel: +86-18600173341; E-mail: gaoqian@ces.ustb.edu.cn

(编辑 李艳红)

基金项目:国家重点研究发展计划重点专项(2017YFC0602903)

收稿日期:2019-04-03;修订日期:2019-06-24

通信作者:高 谦,教授,博士;电话:18600173341 ;E-mail:gaoqian@ces.ustb.edu.cn