文章编号:1004-0609(2008)11-1977-06

AZ31镁合金热变形本构方程

王忠堂1,张士宏2,齐广霞1, 王 芳1,李艳娟1

(1. 沈阳理工大学 材料科学与工程学院,沈阳 110168;

2. 中国科学院 金属研究所,沈阳 110016)

摘 要:在温度为250~350 ℃、应变速率为0.01~1.0 /s、最大变形程度为50%条件下对AZ31镁合金的高温流动应力变化规律进行热模拟实验研究。对双曲正弦模型的Arrhenius本构方程进行简化,与原模型相比,简化后的计算模型的计算结果相对误差小于4.2%。根据热模拟实验数据,确定AZ31镁合金高温变形本构关系模型,该本构关系模型的相对计算误差小于13%。实验确定的AZ31镁合金本构关系模型的适用温度范围为250~350 ℃,应变速率范围为0.01~1.0 /s。

关键词:AZ31镁合金;本构关系;流动应力;热变形

中图分类号:TG 146.22 文献标识码:A

Constitutive equation of thermal deformation for

AZ31 magnesium alloy

WANG Zhong-tang1, ZHANG Shi-hong2, QI Guang-xia1, WANG Fang1, LI Yan-juan1

(1. School of Materials Science and Engineering, Shenyang Ligong University, Shenyang 110168, China;

2. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The changing rules of flow stress at high temperatures for AZ31 magnesium alloy were studied by thermal simulation experiment, at temperature ranging from 250 to 350 ℃, strain-rate from 0.01 to 1.0 /s, and the deformation degree of 50%. Arrhenius equation was simplified. Compared with the original model, the errors of this simplified model are less than 4.2%. According to the data of thermal simulation experiment, the model showing the constitutive thermal deformation for relationship of AZ31 magnesium alloy was determined. The relative errors between the calculation results by the model and experiment results are less than 13%. The suitable conditions of this model for AZ31 magnesium alloy are that the temperature ranges in 250?350 ℃, and the strain rate 0.01?1.0 /s.

Key words: AZ31 magnesium alloy; constitutive relationship; flow stress; thermal deformation

镁合金是实用结构金属中最轻的材料,具有良好的耐磨性、热传导性、屏蔽效应、尺寸稳定性、高导热性、高阻尼性、易于回收和色泽鲜艳美观等物理性能,因此,关于镁合金材料的开发利用是目前世界上的重要研究方向之一。

流动应力与变形温度、应变速率和应变等之间的关系,可表述为 。式中σ为流变应力,

。式中σ为流变应力, 为等效应变,

为等效应变, 为等效应变速率,T为变形温度。YARITA等[1]采用平面压缩实验,获得AZ31镁合金板材在20~250 ℃时的应力—应变关系,分析了平面压缩实验中润滑对应变的影响,并采用弹塑性有限元法分析了塑性变形行为。窗体底部

为等效应变速率,T为变形温度。YARITA等[1]采用平面压缩实验,获得AZ31镁合金板材在20~250 ℃时的应力—应变关系,分析了平面压缩实验中润滑对应变的影响,并采用弹塑性有限元法分析了塑性变形行为。窗体底部

TAKUDA等[2]研究了AZ31镁合金温成形时的流动应力与应变关系,分析了温度和应变速率对流动应力与应变关系的影响规律,建立了基于加工硬化指数n、应变速率指数m和应力指数K以及温度的流动应力与应变关系模型,即 ,

, ,

, ,m = f2(T)。CARL等[3]研究了AZ31镁合金在75~200 ℃, 应变速率0.001~2 500 /s时的应力与应变关系,研究发现在当应变速率在0.001~2 500 /s范围内,应变速率对屈服应力及流动应力的影响最小。HAO等[4]根据Gleeble 3500热模拟实验数据,分析了铸态AZ31镁合金的应力与应变关系。ABU-FARHA等[5]研究了AZ31在73~ 932 °F、应变速率为0.000 01~0.03 /s条件下的应力—应变变化规律,并确定了应变速率敏感系数,认为在一定的温度范围和应变速率范围内,AZ31具有超塑性效应。BEER等[6]研究了AZ31镁合金在300~450 ℃范围内,应变速率0.001~1.0 /s的条件下,流动应力和微观组织的演变规律。AZ31镁合金在发生动态再结晶时,当应变值为0.5时,初始晶粒尺寸细化1倍;当应变达到2时,平均晶粒尺寸从22.5 μm 降低到 7.3 μm。KOIKE等[7]研究了AZ31镁合金轧制板材在室温到523 K(250 ℃)时的晶界滑移规律,在423 K时的晶界滑移能量为80 kJ/mol。MCQUEEN等[8]研究了温度在180~450 ℃,应变速率在0.01~1.0 /s时,镁合金的热延展性和强度,以及发生动态再结晶的条件,分析了AZ31镁合金挤压板材的应力应变变化规律。GUO等[9]研究了Mg-Al-Zn合金在高温时的流动应力变化规律,AZ31镁合金在350 ℃时的激活能为112 kJ/mol,AZ80镁合金在350 ℃时的激活能为220 kJ/mol。WATANABE等[10]研究发现,当晶粒尺寸为130 μm、温度为648 K以及应变速率为0.000 03 /s时,AZ31镁合金的伸长率达到196%。黄光胜等[11]提出一种AZ31镁合金高温本构方程的计算模型,并考虑了动态回复流变应力和稳态动态再结晶流变应力,计算过程涉及十多个公式,计算模型复杂。本文作者建立的模型结构简单,可以满足计算精度的AZ31镁合金热变形本构关系。

,m = f2(T)。CARL等[3]研究了AZ31镁合金在75~200 ℃, 应变速率0.001~2 500 /s时的应力与应变关系,研究发现在当应变速率在0.001~2 500 /s范围内,应变速率对屈服应力及流动应力的影响最小。HAO等[4]根据Gleeble 3500热模拟实验数据,分析了铸态AZ31镁合金的应力与应变关系。ABU-FARHA等[5]研究了AZ31在73~ 932 °F、应变速率为0.000 01~0.03 /s条件下的应力—应变变化规律,并确定了应变速率敏感系数,认为在一定的温度范围和应变速率范围内,AZ31具有超塑性效应。BEER等[6]研究了AZ31镁合金在300~450 ℃范围内,应变速率0.001~1.0 /s的条件下,流动应力和微观组织的演变规律。AZ31镁合金在发生动态再结晶时,当应变值为0.5时,初始晶粒尺寸细化1倍;当应变达到2时,平均晶粒尺寸从22.5 μm 降低到 7.3 μm。KOIKE等[7]研究了AZ31镁合金轧制板材在室温到523 K(250 ℃)时的晶界滑移规律,在423 K时的晶界滑移能量为80 kJ/mol。MCQUEEN等[8]研究了温度在180~450 ℃,应变速率在0.01~1.0 /s时,镁合金的热延展性和强度,以及发生动态再结晶的条件,分析了AZ31镁合金挤压板材的应力应变变化规律。GUO等[9]研究了Mg-Al-Zn合金在高温时的流动应力变化规律,AZ31镁合金在350 ℃时的激活能为112 kJ/mol,AZ80镁合金在350 ℃时的激活能为220 kJ/mol。WATANABE等[10]研究发现,当晶粒尺寸为130 μm、温度为648 K以及应变速率为0.000 03 /s时,AZ31镁合金的伸长率达到196%。黄光胜等[11]提出一种AZ31镁合金高温本构方程的计算模型,并考虑了动态回复流变应力和稳态动态再结晶流变应力,计算过程涉及十多个公式,计算模型复杂。本文作者建立的模型结构简单,可以满足计算精度的AZ31镁合金热变形本构关系。

材料本构关系模型是塑性变形过程数值模拟和模具设计不可缺少的基础理论,材料本构关系模型的计算精度和形式直接影响计算结果和计算速度[12?14]。目前文献上看,关于镁合金材料热变形应力与应变的定性分析的研究论文很多,但关于镁合金材料热变形本构关系模型的研究报道并不多,文献提出的本构关系模型还存在不足,或者形式复杂,引用时不方便或影响计算速度等。本研究的目的就是建立结构简单并可以满足计算精度的AZ31镁合金热变形本构关系模型。建立准确的材料热变形本构关系模型对于分析材料变形特征、成形性能和优化塑性成形工艺及模具设计有着重要意义[15?16]。

1 实验

将原棒材加工成d12 mm×15 mm圆柱形试样,在Gleeble1500热模拟实验机上进行等应变速率压缩实验。试样采用快速感应加热,加热速度10 ℃/s,保温3 min,使试样内部的温度均匀;加热过程中,抽真空防止合金被氧化。实验温度为250,300和350 ℃,应变速率为0.01,0.1和1 /s,变形程度均为50%。为减小摩擦,试样两端面采用石磨垫片润滑。整个实验过程中,通过实验机的微机处理系统自动采集实验数据,对实验数据进行处理后得到试样的应力—应变曲线。

2 流动应力—应变曲线

图1所示为不同温度和应变速率时的应力—应变关系。从图1可知,起始部分曲线的斜率随变形温度的升高而降低,且随变形量的增大,曲线上升缓慢,达到一定应变后,曲线开始缓慢下降,之后呈水平状态。这表明在变形的初始阶段,处于微应变阶段,加工硬化占主导,镁合金仅发生部分的动态回复和再结晶,加工硬化作用远大于软化作用,从而引起应力值的急剧上升。随着变形的进行,曲线上升缓慢,达到一定应变值后,呈下降趋势,说明动态再结晶的发生增加了软化作用,使流变应力下降,随变形的进一步进行流变应力达到稳定水平线[17]。

图1 不同条件下AZ31镁合金的真应力—应变曲线

Fig.1 Curves of true stress—strain for AZ31 Mg alloy under different conditions: (a) 250 ℃; (b) 350 ℃; (c) Strain-rate 0.01 /s; (d) Strain-rate 1.0 /s

3 本构方程的建立

由于材料在塑性加工过程中的动态响应是材料内部组织演化过程引起的硬化和软化过程综合作用的结果,故本构关系是高度非线性的,不存在普遍适用的构造方法。通常依据Arrhenius型方程对实验数据采用数理统计的方法建立本构关系。

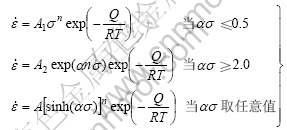

金属的高温变形是一个热激活过程,其变形温 度、应变速率对流变应力的影响可用Arrhenius方程表示[18?19]:

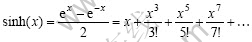

对于双曲正弦模型 ,经过Thaler展开后得到:

,经过Thaler展开后得到:

当x≤0.5时,忽略三次项以上的项,则 ,其相对误差小于4.2%;当x≥2.0时,忽略

,其相对误差小于4.2%;当x≥2.0时,忽略 项,则

项,则 ,其相对误差小于1.9%。因此,Arrhenius方程中的双曲正弦函数可以简化成线性函数或指数函数形式,简化结果见式(2)和(3)。

,其相对误差小于1.9%。因此,Arrhenius方程中的双曲正弦函数可以简化成线性函数或指数函数形式,简化结果见式(2)和(3)。

当温度不变时,Q、R、T和A均为常数,根据式(2)和(3)可以确定n和 值,即:

值,即:

在温度变化的条件下,Q随温度的变化而变化,R、 、n和A均为常数,根据式(4)可以得到Q和A的计算式:

、n和A均为常数,根据式(4)可以得到Q和A的计算式:

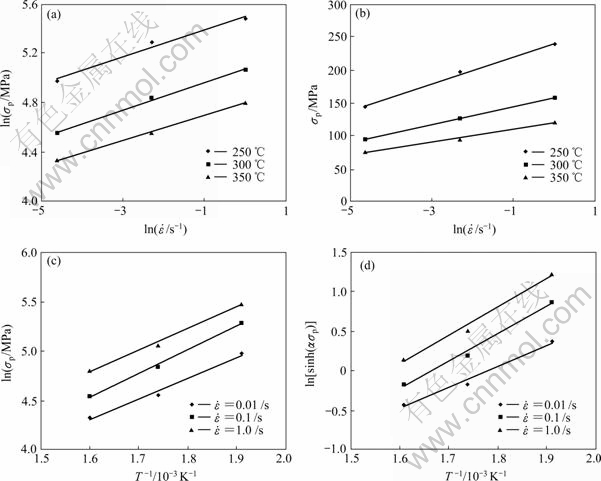

式中 n和 由式(2)和(3)确定。本文计算时,流变应力

由式(2)和(3)确定。本文计算时,流变应力 取峰值应力

取峰值应力 。根据实验数据

。根据实验数据 ,

, 和T的值,绘制

和T的值,绘制 —

— 、

、 —

— 和

和 —1/T曲线,结果如图2所示。根据图2的实验结果,得到

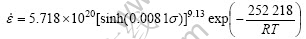

—1/T曲线,结果如图2所示。根据图2的实验结果,得到 、n、Q和A的值,即n=9.13,

、n、Q和A的值,即n=9.13, =0.008 1,Q=252 218 (J/mol),A=5.718×1020,A1=19.286,A2=9.009×1017。

=0.008 1,Q=252 218 (J/mol),A=5.718×1020,A1=19.286,A2=9.009×1017。

图2 不同条件下峰值应力与应变速率和温度的关系

Fig.2 Curves of peak stress vs strain-rate and temperature under different conditions: (a)  —

— ; (b)

; (b)  —

— ; (c)

; (c)  —T ?1; (d)

—T ?1; (d)  —T ?1

—T ?1

将上述参数代入式(4)中,即可得到AZ31 镁合金的本构关系模型,见式(9)。建立的本构模型计算值与实验所得的数据进行比较,如图3所示。对计算结果与实验结果进行误差分析表明,所建立的本构关系模型的计算结果与实验结果之间的相对误差小于13%。本文确定的AZ31镁合金本构关系模型的适用温度范围为250~350 ℃,应变速率范围为0.01~1.0 /s。

图3 不同条件下模型计算结果与实验结果比较

Fig.3 Comparisons of calculated results by model with experimented ones under different conditions: (a) Strain rate 0.1 /s; (b) Strain rate 1.0 /s; (c) 523 K; (d) 623 K

4 结论

1) 对双曲正弦模型的Arrhenius本构方程经过简化,得到:

当 ≤0.5时,简化模型计算结果的相对误差小于4.2%;当

≤0.5时,简化模型计算结果的相对误差小于4.2%;当 ≥2.0时,简化模型计算结果的相对误差小于1.9%。

≥2.0时,简化模型计算结果的相对误差小于1.9%。

2) 利用回归的方法确定了变形激活能Q为252 kJ/mol,应力指数n为9.13,得到AZ31镁合金热变形本构方程:

3) 确定的本构关系模型的计算结果与实验值之间的相对误差小于13%,本构关系模型的适用温度范围为250~350 ℃,应变速率范围为0.01~1.0 /s。

REFERENCES

[1] IKUO Y, TAKASHI N, TSUYOSHI H. Stress and strain behaviors of Mg alloy AZ31 in plane strain compression[J]. Solid Mechanics and Material Engineering, 2006, 48(4): 299?304.

[2] TAKUDA H, MORISHITA T, KINOSHITA T, SHIRAKAWA N. Modelling of formula for flow stress of a magnesium alloy AZ31 sheet at elevated temperatures[J]. Journal of Materials Processing Technology, 2005, 164/165: 1258?1262.

[3] CARL M, KORZEKWA C, CERRETA ELLEN, LOPEZ F. A comparison of the mechanical response high purity magnesium and AZ31 magnesium alloy[J]. Journal of The Minerals Metals & Materials Society (JOM), 2004, 56(11): 31?32.

[4] HAI H, MAIJER M, WELLS A. Prediction and measurement of residual strains in a DC cast AZ31 magnesium billet[J]. Journal of the Minerals Metals & Materials Society( JOM), 2004, 56(11): 136.

[5] ABU-FARHA FADI K, KHRAISHEH MARWAN K. Deformation characteristics of AZ31 Magnesium alloy under various forming temperatures and strain rates[J]. Journal of the Minerals Metals & Materials Society( JOM), 2004, 56(11): 287.

[6] BEER A G, BARNETT M R. The hot working flow stress and microstructure in magnesium AZ31[C]//Magnesium Technology 2002 Conference of TMS Annual Meeting, Seattle, WA: Minerals, Metals and Materials Society, 2002: 193?198.

[7] KOIKE J, OHYAMA R, KOBAYASHI T, SUZUKI M.  Grain-boundary sliding in AZ31 magnesium alloys at room temperature to 523 K[J]. Materials Transactions, 2003, 44(4): 445?451.

Grain-boundary sliding in AZ31 magnesium alloys at room temperature to 523 K[J]. Materials Transactions, 2003, 44(4): 445?451.

[8] MCQUEEN H J, MYSHLAEV M, SAUERBORN M, MWEMBELA A. Flow stress microstructures and modeling in hot extrusion of magnesium alloys[C]//Magnesium Technology 2000 Conference of TMS Annual Meeting. Nashville, TN: Minerals, Metals and Materials Society, 2000: 355?362.

[9] GUO Qiang, YAN Hong-ge, CHEN Zhen-hua. Flow stress of Mg-Al-Zn alloys during hot compression deformation at elevated temperatures[J]. Journal of Hunan University Natural Sciences, 2006, 33(3): 75?79.

[10] WATANABE H, TSUTSUI H, MUKAI T, KOHZU M. Deformation mechanism in a coarse-grained Mg-Al-Zn alloy at elevated temperatures[J]. International Journal of Plasticity, 2001,17(3): 387?397.

[11] 黄光胜, 汪凌云, 黄光杰. AZ31镁合金高温本构方程[J]. 金属成形工艺, 2004, 22(2): 42?44.

HUANG Guang-sheng, WANG Ling-yun, HUANG Guang-jie. Constitutive equation of AZ31 magnesium alloy for high temperature[J]. Metal Forming Technology, 2004, 22(2): 42?44.

[12] 张文玉, 刘先兰. 异步轧制AZ31镁合金板材室温冲压性能研究[J]. 塑性工程学报, 2007, 14(4): 6?9.

ZHANG Wen-yu, LIU Xian-lan. Research on drawability of AZ31 magnesium alloy sheet processed by differential speed rolling at room temperature[J]. Journal of Plasticity Engineering, 2007, 14(4): 6?9.

[13] 黄光胜, 徐 伟, 黄光杰, 刘天模. 镁合金板材冲压性能与冲压工艺研究进展[J]. 材料导报, 2006,20(11): 73?77.

HUANG Guang-sheng, XU Wei, HUANG Guang-jie, LIU Tian-mo. The development of stamping properties and stamping technology of magnesium alloy sheet[J]. Materials Review, 2006, 20(11): 73?77.

[14] 于彦东, 李彩霞. 镁合金AZ31B板材热拉深成形工艺参数优化[J]. 中国有色金属学报, 2006, 16(5): 786?790.

YU Yan-dong, LI Cai-xia. Optimization of processing parameters for magnesium alloy AZ31B sheets in thermal deep-drawing process[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(5): 786?790.

[15] 苌群峰, 李大永, 彭颖红, 曾小勤. AZ31镁合金板材温热冲压数值模拟与实验研究[J]. 中国有色金属学报, 2006, 16(4): 580?584.

CHANG Qun-feng, LI Da-yong, PENG Ying-hong, ZENG Xiao-qin. Numerical simulation and experimental study of warm deep drawing of AZ31 magnesium alloy sheet[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(4): 580?584.

[16] 刘祖岩, 刘 刚, 梁书锦. AZ31镁合金应力—应变关系的测定与四维描述[J]. 稀有金属材料与工程, 2007, 36(3): 304?308.

LIU Zu-yan, LIU Gang, LIANG Shu-jin. Measurement of the stress—strain relationship of AZ31 magnesium alloy and its four-dimensional description[J]. Rare Metal Materials and Engineering, 2007, 36(3): 304?308.

[17] 汪凌云, 黄光胜, 范永革, 黄光杰. 变形AZ31镁合金的晶粒细化[J]. 中国有色金属学报, 2003, 13(3): 594?599.

WANG Ling-yun, HUANG Guang-sheng, FAN Yong-ge, HUANG Guang-jie. Grain refinement of wrought AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(3): 594?599.

[18] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation[J]. ACTA Metallurgica, 1966, 14: 1136?1138.

[19] DANIEL J, WHITTENBERGER. The influence of grain size and composition on slow plastic flow in FeAl between 1 100 and 1 400 K[J]. Mater Sci Eng A, 1986, 77: 103?113.

基金项目:国家自然科学基金资助项目(50775211)

收稿日期:2008-03-04;修订日期:2008-08-25

通讯作者:王忠堂,教授,博士;电话:024-24686019;E-mail: ztwang@imr.ac.cn

(编辑 龙怀中)