文章编号:1004-0609(2016)-04-0766-07

时效温度对镍铝青铜合金的硬质相演变的影响

李振亚,杨丽景,许 赪,冒守栋,宋振纶

(中国科学院 宁波材料技术与工程研究所 中国科学院海洋新材料与应用技术重点实验室

浙江省海洋材料与防护技术重点实验室,宁波 315201)

摘 要:采用自行熔炼牌号为ZQAl10-4-4的镍铝青铜合金(Cu-10%Al-4.7%Ni-3.5%Fe-0.8%Mn),采用SEM、XRD、EDS、DSC、内耗测试、硬度测试、摩擦性能测试等分析手段,研究时效温度对合金中硬质相的演变规律以及合金力学性能的影响。结果表明:在450 ℃以上时效时,合金的硬质马氏体转变为较软的α相基体,并随着时效温度的升高而导致弥散分布的K相聚集长大,使合金的硬度降低、摩擦磨损量增加。合金在420~450 ℃这一时效温度区间,具有最佳显微硬度(约420 HV)和较好的耐磨性能。

关键词:镍铝青铜;时效;力学性能;耐磨性能

中图分类号:TG166.2 文献标志码:A

镍铝青铜是以铜铝二元合金为基体,添加铁、镍、锰等合金元素熔炼而成的复杂铝青铜,具有高强度、高硬度、高耐磨、高耐蚀以及良好的加工性能[1-3],广泛应用于舰船螺旋桨、阀门以及水下紧固件等方面[4]。镍铝青铜在铁、镍含量较高时,会出现复杂的K相。K相属于金属间化合物,按照成分、形状以及分布来区别主要分为4类,其中KI、KII、KIV都是富铁相,以Fe3Al为基体;KIII相为富镍相,以NiAl为基体。K相对合金成分、热处理工艺与加工工艺很敏感,而另一方面K相的分布方式与形态大小对合金的力学性能影响很大[5-8]。近年来,国内外学者对镍铝青铜的研究主要集中在成分优化、热加工和热处理以及等通道挤压等非常规手段来提高其力学性能和耐磨性能[9-12]。林高用等[5]研究了固溶时效对QAl9-4-3组织性能的影响,提出了固溶温度的升高或时效温度的降低,原β相区的马氏体特征越明显;李文生等[13]研究了新型高铝青铜Cu-14Al+X的热处理强化提出了合金在920 ℃固溶处理及580 ℃时效处理后具有优良的综合力学性能; 等[14]研究了时效处理对Cu-Al-Fe系合金的滑动摩擦性能的影响。但是由于镍铝青铜的复杂组织状态,对镍铝青铜在固溶时效中组织和性能的演变规律认识较少。因此,本文作者采用成分简单、自行熔炼牌号为ZQAl10-4-4的镍铝青铜,对合金在固溶和时效过程中硬质相的演变规律进行考察和分析,尤其是时效温度对合金中硬质相的析出规律以及合金性能的影响,为镍铝青铜的热处理工艺制定提供有力的支撑。

等[14]研究了时效处理对Cu-Al-Fe系合金的滑动摩擦性能的影响。但是由于镍铝青铜的复杂组织状态,对镍铝青铜在固溶时效中组织和性能的演变规律认识较少。因此,本文作者采用成分简单、自行熔炼牌号为ZQAl10-4-4的镍铝青铜,对合金在固溶和时效过程中硬质相的演变规律进行考察和分析,尤其是时效温度对合金中硬质相的析出规律以及合金性能的影响,为镍铝青铜的热处理工艺制定提供有力的支撑。

1 实验

1.1 实验材料

实验材料为实验室自行熔炼[15]的ZQAl10-4-4牌号合金,其主要化学成分如表1所列。分别采用电解铜、纯铝、纯镍、铁丝、纯锰片为原料,利用高频感应炉在石墨坩埚中熔炼上述铜合金,浇铸于事先预热至100 ℃的方形槽石墨模具中,在空气中冷却,经线切割获得8 mm×8 mm×10 mm的样品。

表1 ZQAl10-4-4牌号合金化学成分(质量分数,%)

Table 1 Chemical composition of ZQAl10-4-4 alloy (mass fraction, %)

为研究镍铝青铜固溶时效组织的变化规律,将试样在900 ℃和950 ℃下保温2 h后水冷,并将950 ℃固溶2 h后的试样进行时效处理,时效温度分别为300、420、450、480、510、600和700 ℃,保温时间均为2 h,空冷。热处理试验在S62-3-10型电阻炉中进行,采用AI-708P型仪器进行控温。

1.2 组织与性能测试

试样经打磨抛光后,用FeCl3酒精溶液进行刻蚀,采用FEI Quanta FEG 250型场发射扫描电子显微镜观察显微组织并进行能谱分析,采用D8 Advance型X射线衍射仪确定物相组织。由于材料原因,精细的物相组织由显微组织及其能谱分析、XRD结果结合文献分析进行确定。采用由中科院固体物理所研发的多功能力学仪进行内耗分析,采用NETZSCH 404C型高温差示式扫描量热仪分析固溶和时效态样品的DSC曲线。通过UMT型摩擦磨损试验机测试样品的摩擦因数和磨损性能,摩擦方式为往复式摩擦,距离为5 mm,摩擦副选用直径为3 mm的GCr15钢球,载荷为5 N,频率为2 Hz,摩擦时间为20 min,磨损量运用表面轮廓仪测得的磨痕的5个不同部位扫描磨槽的截面,取5个不同部位的截面积分,再乘以距离获得样品体积磨损量。采用MVS-1000D1型显微硬度仪测定不同组织的显微硬度,载荷为4.9 N。每个样品取5个不同的地方测量,取平均值。

2 结果与分析

2.1 固溶态合金组织结构

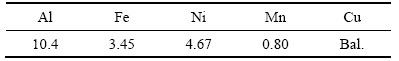

图1(a)所示为ZQAl10-4-4合金在950 ℃下固溶2 h、随炉冷却后的组织形貌。图1(b)所示为该合金950℃下固溶2 h、水冷后的组织形貌。图1(c)所示为该合金900 ℃下固溶2 h、水冷后的组织形貌。可以看到,950 ℃下固溶后炉冷的组织主要为α+β′+K相,其中K相是析出相KI、KII、KIII和KIV的总称。文献[9, 16]报道KI、KII和KIV都是富铁相,以Fe3Al为基体,KIII为富镍相,以NiAl为基体。KI一般呈玫瑰花瓣状或者块状,尺寸较大;KII多呈球状、尺寸较KI的小;KIII相呈片层状,分布于α相与β相界面处;KIV相为细小颗粒状的富铁相。根据能谱分析和XRD结果,参照文献报道的K相的析出位置与形态大小[9, 16],在图1中标定K相为:分布在α和β′相上的球形颗粒状的KII相、分布于α与β′相晶界处的片层状的KIII相和分布于α相内的球形颗粒状的KIV相,其中KII相与KIV相形态相似,但KII相的尺寸较大。在固溶后炉冷的组织中没有发现明显的KI相,这可能由于合金中铁含量低于镍含量导致[9, 16]。JAHANAFROOZ等[16]报道了成分为Cu-10%Al-5%Ni-5%Fe的镍铝青铜合金的组织演变,提出当合金中铁元素含量较高于镍元素含量时,出现KI相,反之则不出现KI相。这个结果与本研究结果一致。在950 ℃下固溶后水冷的合金组织主要为β′+K相,其中β′相为β相在共析反应β→α+KIII中受抑制而转变成的马氏体[17],在图1(b)中呈针状。而淬火态组织中的K相主要有弥散分布的球状的KII相与弥散分布的更加细小球状的KIV相。从图1(c)中可以看出,900 ℃固溶水冷的合金组织基体上分布着未完全固溶的白色细条状α相组织及细小颗粒状K相组织。

图1 ZQAl10-4-4固溶后炉冷和水冷状态下组织形貌

Fig. 1 Microstructures of ZQA110-4-4 alloy subjected to different solution treatments and cooling

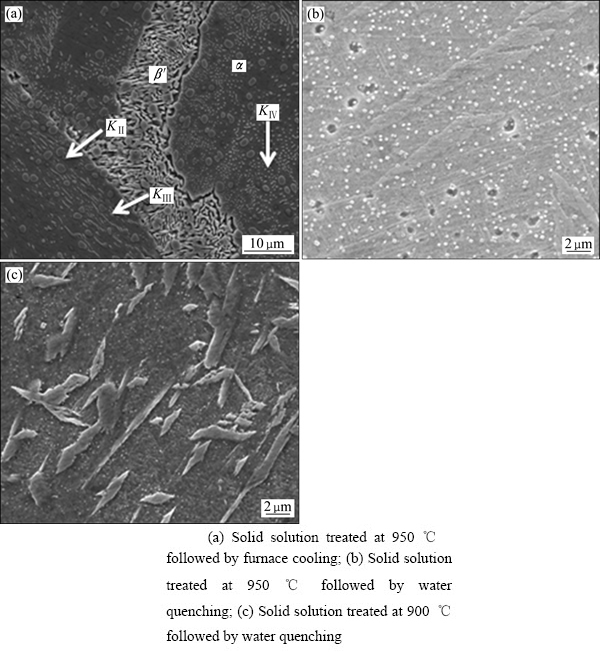

为更好地确认合金组织结构,采用XRD分析了图1所示3种组织的相结构,结果如图2所示。结果表明:合金在900 ℃下未形成完全的α→β转化,故900 ℃水冷组织中存在着α相的衍射峰。而冷却时高温区的β相因水淬的冷却速度很快,经非扩散型相变转变为马氏体相β′相。合金在950 ℃固溶过程中α→β转化完全,在水冷的过程中转变为β′相,而在炉冷的过程中由于冷速足够慢,有足够的时间发生扩散相变转化为α相。在图1中的大量析出相K相在图2中未能看到明显的谱线,这主要是由于一方面组织中K相组织的尺寸很小,在纳米级别,峰值低,而合金中主要存在的Cu相峰和Cu3Al相的峰非常明显,对比下来导致K相的峰在XRD谱中很难分辨;另一方面由于K相的衍射峰被合金中Cu3Al相的峰所覆盖,造成无法标定。

图2 3种热处理状态下合金的XRD谱

Fig. 2 XRD patterns of alloys under three different heat treatments

2.2 时效温度对合金组织结构的影响

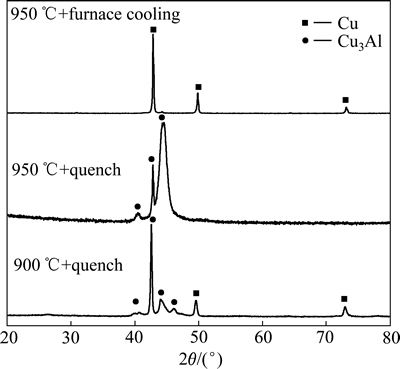

图3所示为合金在不同时效温度热处理后的组织形貌。可以看出,当时效温度低于450 ℃时,时效后的组织由β′和K相组成,针状马氏体随着时效温度的提高有所粗化。当时效温度达到480 ℃时,合金的针状马氏体形态已不明显,合金组织主要为共析组织α相和K相组织[13],其中K相组织呈弥散分布且形态开始发生改变。时效温度提高到600 ℃时,K相的形态变的不规则,有聚集趋势,呈椭球状或水滴状。当时效温度达到700 ℃时,合金中有明显的α相组织,同时出现片层状KIII相,表明时效过程中马氏体转变基本完全,然后在冷却的过程中发生了β→α+KIII的共析相变。此外,KII相在α相晶间析出,但是与淬火态的KII相比较,K相发生粗化,且有聚集长大的现象。

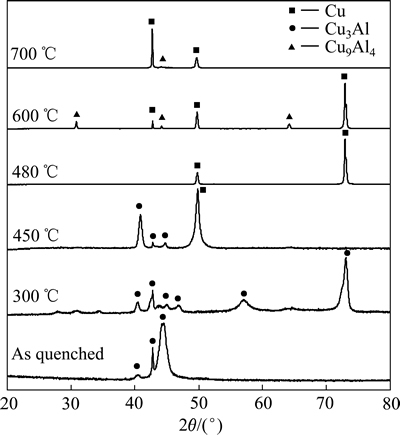

为了认识在不同时效温度下合金的相结构,对图3所示的样品进行XRD扫描相分析,其结果如图4所示。可以看到,在时效温度低于450 ℃时,合金的相组成和淬火后一致,为马氏体相;当时效温度为450 ℃时,合金中开始出现部分的α相;当时效温度高于450 ℃时,β′相基本消失,合金主相为α相。在时效温度为600 ℃时,XRD结果显示合金中存在部分以Cu9Al4为基体γ2相。

图5所示为950 ℃淬火态样品恒定功率下所测得的典型内耗曲线。可以看出,淬火态样品的内耗值在升温至400℃时出现一个先下降再上升的过程,而第二、三次重复试验的内耗曲线没有这个峰谷现象,而且不同频率所测得的内耗曲线变化趋势基本一致。这说明淬火态样品在升温至400 ℃时经历了一个相变,在相变过程中淬火态样品中的针状马氏体发生转变,生成α相。而在后续第二、三次的重复试验中,由于内耗试验加热温度最高为640 ℃,低于α相的固溶温度,因此没有明显的相变发生。综合图5内耗曲线分析拟合,马氏体转变发生在温度400~550 ℃之间。

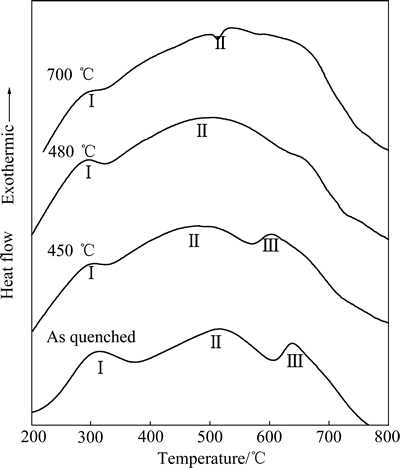

为了研究不同时效温度对合金组织演变的影响,研究了不同时效温度下热处理的样品从室温加热到900℃的DSC曲线,如图6所示。可以看到淬火态样品DSC曲线有3个放热峰,峰值分别出现在320 ℃、520 ℃、640 ℃附近。由于DSC曲线测试过程中加热速度较快,DSC曲线上峰值温度较实际相变温度有所滞后。结合SEM和XRD结果综合分析可以得到:样品在升温的过程中,第1个放热峰代表的是K相的析出,固溶处理过程中来不及析出的K相在随后的升温过程中继续析出(Ⅰ);随着温度的升高,当达到马氏体转变的温度,此时马氏体开始转变,即β′相的分解(Ⅱ);当温度继续升高,β相发生共析转变β→ α+KIII(Ⅲ)。当样品经450 ℃时效后,其DSC曲线与淬火态相似,表明时效温度尚未进入马氏体相变温度区域。时效温度升至480 ℃时,合金的DSC曲线第3个峰基本消失,表明480℃时效后的样品在升温过程中没有发生共析转变β→α+KIII,这与SEM和XRD所观察到的无β′相一致。当时效温度为700 ℃时,DSC曲线较为平缓,无明显峰值,表明700 ℃时效后样品中无残余马氏体相,K相也基本析出完全。可以看到450 ℃时效后的DSC曲线的后两个放热峰温度较低于淬火后的,这是因为样品在450 ℃时效过程中马氏体获得了较多的激活能,而此时马氏体只有少量分解,使得在后续DSC测试升温过程中合金中马氏体的分解更容易发生,综合导致450 ℃时效后的DSC曲线的放热峰偏左。

2.3 时效温度对力学性能的影响

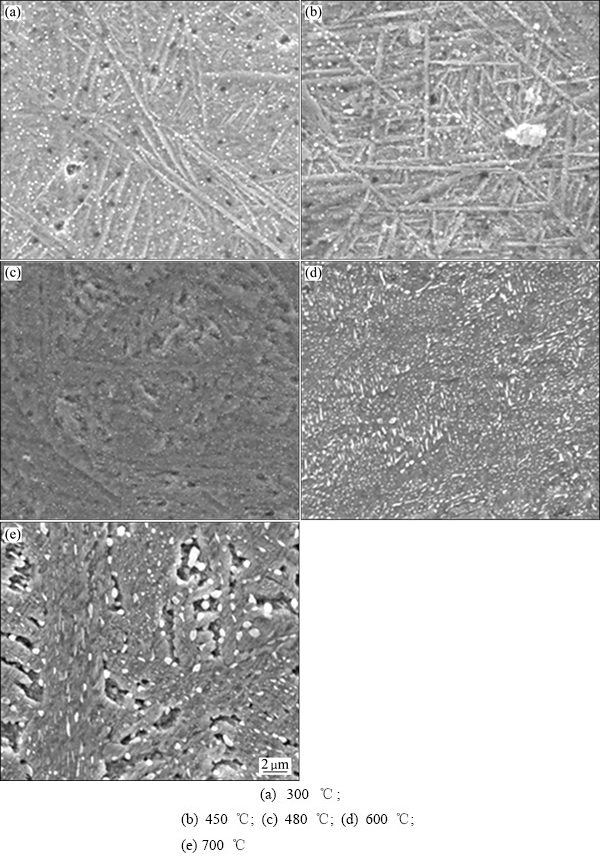

图7所示为合金在不同时效温度下时效后所测得的显微硬度值和摩擦磨损量,淬火态合金的力学性能也列在图7中作对比。可以看出,不同的时效温度对显微硬度与摩擦磨损量影响很大。其中显微硬度随着时效温度的升高先提高后降低,在420~450 ℃区间显微硬度最大,约405~420 HV,而合金的磨损量在时效温度低于450 ℃时基本不变,之后随着时效温度的升高先增加后减少。

图3 ZQAl10-4-4合金不同时效温度处理2 h后空冷组织SEM像

Fig. 3 SEM images of ZQAl10-4-4 alloy after aging treatment at different temperatures

图4 ZQAl10-4-4合金在不同时效温度热处理后的XRD谱

Fig. 4 XRD patterns of ZQAl10-4-4 alloy after aging treatment at different temperatures

图5 ZQAl10-4-4合金950 ℃固溶+水冷后组织的内耗曲线

Fig. 5 Internal friction curve of ZQAl10-4-4 alloy after quenching at 950 ℃

决定合金ZQAl10-4-4的硬度的主要有基体的硬度、合金元素的固溶强化以及析出相K相的析出强化。当时效温度低于马氏体转变温度450 ℃时,合金的基体为马氏体组织,本身具有很高的硬度,且在时效过程中K相持续析出,弥散分布于基体组织上,对合金整体有弥散强化作用,导致合金的硬度进一步增加。当时效温度高于马氏体转变温度时,硬质马氏体转变为α相软基体,同时随着时效温度的增加,K相虽然也有析出,但是也会出现聚集长大的现象,从而减弱K相的弥散强化作用,尤其是片层状KIII相对合金的力学性能有一定的恶化作用,进一步降低合金的硬度。

图6 ZQAl10-4-4合金不同热处理状态样品DSC曲线

Fig. 6 DSC curves of ZQAl10-4-4 samples under different heat treatments

图7 ZQAl10-4-4合金不同热处理状态下的显微硬度值和摩擦磨损量

Fig. 7 Microhardness and wear loss of ZQA110-4-4 alloy under different heat treatments

合金的耐磨性的关键影响因素之一是硬度,但是耐磨性还与基体硬度、析出相分布和形态有关。随着时效温度的升高至480 ℃以上时,合金的马氏体开始向软质α相转变,因此大大增加了磨损量。而时效温度升高至510 ℃以上时,马氏体转变基本完成,因此,磨损量的增加趋势减弱。

总而言之,合金在420~450 ℃这一时效温度区间,具有最佳显微硬度和较好的耐磨性能。

3 结论

1) ZQAl10-4-4镍铝青铜合金(Cu-10%Al- 4.7%Ni-3.5%Fe-0.8%Mn)在950 ℃固溶形成β固溶体和弥散分布的K相,在随后的时效过程中,在450 ℃附近发生马氏体转变,在700 ℃左右发生共析转变β→α+KIII。

2) 时效温度对合金的K相形态与分布有显著影响,时效温度高于480 ℃时,K相开始集聚、长大,其弥散分布呈现不均匀现象,至700 ℃,形成层状KIII相。

3) 时效温度对合金ZQAl10-4-4的力学性能影响很大,当时效温度低于450 ℃时,合金的维氏硬度增加,耐磨性能基本不变;当时效温度高于450 ℃时合金的维氏硬度有一个突变,且低于淬火后组织维氏硬度,耐磨性能变差。本研究中合金在420~450 ℃这一时效温度区间,具有最佳显微硬度和较好的耐磨性能。

REFERENCES

[1] CULPAN E A, ROSE G. Microstructural characterization of cast nickel aluminium bronze[J]. Journal of Materials Science, 1978, 13(8): 1647-1657.

[2] CULPAN E A, ROSE G. Corrosion behaviour of cast nickel aluminium bronze in sea water[J]. British Corrosion Journal, 1979, 14(3): 160-166.

[3] 徐建林, 王智平. 铝青铜合金的研究与应用进展[J]. 有色金属, 2004, 56(4): 51-54.

XU Jian-lin, WANG Zhi-ping. Research and application situation of aluminum bronze[J]. Nonferrous Metal, 2004, 56(4): 51-54.

[4] 宋德军, 胡光远, 卢 海, 胡伟民. 镍铝青铜合金的应用与研究现状[J]. 材料导报, 2007, 21: 450-459.

SONG De-jun, HU Guang-yuan, LU Hai, HU Wei-min. Surevy of progress on the research and practice of nickel-aluminum braze[J]. Materials Review, 2007, 21: 450-459.

[5] 林高用, 王 莉, 许秀芝, 曾菊花. 固溶时效对QAl9-4-3铝青铜组织和性能的影响[J]. 中国有色金属学报, 2013, 23(3): 679-686.

LIN Gao-yong, WANG Li, XU Xiu-zhi, ZENG Ju-hua. Effect of solution and aging treatment on microstructure and properties of QAl9-4-3 aluminum bronze[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 679-686.

[6] LIN Gao-yong, LEI Yu-xia, ZENG Ju-hua, Li Han, XU Xiu-zhi. A comparative study on effects of special casting processes on microstructural development in Cu-10Al-4Fe-4Ni alloy[J]. Journal of Materials Research, 2013, 28(20): 2874-2880.

[7] NI Ding-rui, XUE Peng, WANG Dong, XIAO Bo-lü, MA Zong-yi. Inhomogeneous microstructure and mechanical properties of friction stir processed NiAl bronze[J]. Materials Science and Engineering A, 2009, 524(1): 119-128.

[8]  J, LANG K H, BAUMEISTER G, SCHULZE V. Microstructure and mechanical properties of micro tensile specimens made of CuAl10Ni5Fe4 produced by micro casting[J]. Microsystem Technologies, 2011, 17(2): 301-311.

J, LANG K H, BAUMEISTER G, SCHULZE V. Microstructure and mechanical properties of micro tensile specimens made of CuAl10Ni5Fe4 produced by micro casting[J]. Microsystem Technologies, 2011, 17(2): 301-311.

[9] ANANTAPONG J, UTHAISANGSUK V, SURANUNTCHAI S, MANONUKUL A. Effect of hot working on microstructure evolution of as-cast nickel aluminum bronze alloy[J]. Materials & Design, 2014, 60: 233-243.

[10] BARR C J, MCDONALD D T, XIA K. Significantly enhanced tensile strength and ductility in nickel aluminium bronze by equal channel angular pressing and subsequent heat treatment[J]. Journal of Materials Science, 2013, 48(13): 4749-4757.

[11] McDONALD D T, BARR C J, XIA K. Effect of equal channel angular pressing on lamellar microstructures in nickel aluminum bronze[J]. Metallurgical and Materials Transactions A, 2013, 44(12): 5556-5566.

[12] NI Ding-rui, XUE Peng, MA Zong-yi. Effect of multiple-pass friction stir processing overlapping on microstructure and mechanical properties of as-cast NiAl bronze[J]. Metallurgical and Materials Transactions A, 2011, 42(8): 2125-2135.

[13] 李文生, 路 阳, 袁利华, 王智平, 金玉花. 新型铝青铜Cu-14Al-X的热处理强化[J]. 金属热处理, 2006, 31(8): 71-75.

LI Wen-sheng, LU Yang, YUAN Li-hua, WANG Zhi-ping, JIN Yu-hua. Heat treatment strengthening of a novel aluminum bronze Cu-14Al-X[J]. Heat Treatment of Metals, 2006, 31(8): 71-75.

[14]  M, ALTUNPAK Y. The effect of aging heat treatment on the sliding wear behaviour of Cu-Al-Fe alloys[J]. Materials & Design, 2009, 30(3): 878-884.

M, ALTUNPAK Y. The effect of aging heat treatment on the sliding wear behaviour of Cu-Al-Fe alloys[J]. Materials & Design, 2009, 30(3): 878-884.

[15] LI Wen-sheng, LU Yang, WANG Zhi-ping, YUAN Li-hua, JIN Yu-hua. Preparation, mechanical properties and wear behaviours of novel aluminum bronze for dies[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(3): 607-612.

[16] JAHANAFROOZ A, HASAN F, LORIMER G W, RIDLEY N. Microstructural development in complex nickel-aluminum bronzes[J]. Metallurgical Transactions A, 1983, 14(10): 1951-1956.

[17] 金云学, 都春燕, 王 磊. 镍铝青铜组织在热处理过程中的演变规律[J]. 特种铸造及有色合金, 2014, 34(9): 1004-1008.

JIN Yun-xue, DU Chun-yan, WANG Lei. Microstructural evolution of nickel-aluminum bronze during heat treatment process[J]. Special Casting & Nonferrous Alloys, 2014, 34(9): 1004-1008.

Effect of aging temperature on hard phase evolution of nickel aluminum bronze

LI Zhen-ya, YANG Li-jing, XU Cheng, MAO Shou-dong, SONG Zhen-lun

(Key Laboratory of Marine Materials and Related Technologies, Zhejiang Key Laboratory of Marine Materials and Protective Technologies, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo 315201, China)

Abstract: ZQAl10-4-4 nickel aluminum bronze (Cu-10%Al-4.7%Ni-3.5%Fe-0.8%Mn) was prepared. The effect of aging temperature on the hard phase evolution and mechanical properties of the alloy was investigated by SEM, XRD, EDS, DSC, internal friction, microhardness and wear tests. The results show that the alloy exhibits a phase transformation of hard martensite into soft α phase when aging above 450 ℃, and shows significant aggregation and growth of evenly-distributed K phases with the increasing of aging temperature. In the meantime, the alloy exhibits a decreasing microhardness and increasing wear with increasing the aging temperature. A maximum microhardness value of about 420 HV and good wear resistance are achieved when the alloy is aged at temperatures of 420-450 ℃.

Key words: nickel aluminum bronze; aging; mechanical property; wear resistance

Foundation item: Project(2013B10046) supported by the Major Project of Industrial Technology Innovation and Industralization Achievement of Ninbo, China

Received date: 2015-04-19; Accepted date: 2015-12-14

Corresponding author: SONG Zhen-lun; Tel: +86-13867853975; E-mail: songzhenlun@nimte.ac.cn

(编辑 王 超)

基金项目:宁波市产业技术创新及成果产业化重大项目(2013B10046)

收稿日期:2015-04-19;修订日期:2015-12-14

通信作者:宋振纶,研究员,博士;电话:13867853975;E-mail: songzhenlun@nimte.ac.cn