退火温度对镁合金和铝合金扩散结合层的影响

来源期刊:中国有色金属学报(英文版)2018年第2期

论文作者:丁云龙 王建刚 赵明 巨东英

文章页码:251 - 258

关键词:退火温度;扩散接合;扩散层;残余应力;拉伸强度

Key words:annealing temperature; diffusion bonding; diffusion layer; residual stress; tensile strength

摘 要:为了研究退火温度对镁合金和铝合金结合层的影响,提高扩散层的性能,采用真空扩散结合的方法焊接镁合金(AZ31B)和铝合金(6061),然后依据热处理理论在电炉中进行退火处理。应用扫描电子显微镜对焊接层的组织进行观察,利用X射线衍射技术测量残余应力,借助EPMA检测元素分布。此外,还分别测量材料的抗拉强度和硬度。结果显示,扩散层随着热处理温度升高而变宽。相比之下,在250 °C退火处理后的试样残余应力值最低,抗拉强度最大。结合实验结果,250 °C是镁合金和铝合金扩散结合件的最适退火温度。

Abstract: To study the effect of annealing temperature on the joints between magnesium and aluminum alloys, and improve the properties of bonding layers, composite plates of magnesium alloy (AZ31B) and aluminum alloy (6061) were welded using the vacuum diffusion bonding method. The composite specimens were continuously annealed in an electrical furnace under the protection of argon gas. The microstructures were then observed using scanning electron microscopy. X-ray diffractometry was used to investigate the residual stresses in the specimens. The elemental distribution was analyzed with an electron probe micro analyzer. The tensile strength and hardness were also measured. Results show that the diffusion layers become wide as the heat treatment temperature increases, and the residual stress of the specimen is at a minimum and tensile strength is the largest when being annealed at 250 °C. Therefore, 250 °C is the most appropriate annealing temperature.

Trans. Nonferrous Met. Soc. China 28(2018) 251-258

Yun-long DING1, Jian-gang WANG2, Ming ZHAO3, Dong-ying JU1,3

1. Department of Material Science and Engineering, Saitama Institute of Technology, Fusaiji 1690, Fukaya, Saitama 369-0293, Japan;

2. Hebei Key Laboratory of Material Near-Net Forming Technology, Hebei University of Science and Technology, Shijiazhuang 050018, China;

3. Department of Materials Science and Engineering, University of Science and Technology Liaoning, Anshan 114051, China

Received 22 December 2016; accepted 21 June 2017

Abstract: To study the effect of annealing temperature on the joints between magnesium and aluminum alloys, and improve the properties of bonding layers, composite plates of magnesium alloy (AZ31B) and aluminum alloy (6061) were welded using the vacuum diffusion bonding method. The composite specimens were continuously annealed in an electrical furnace under the protection of argon gas. The microstructures were then observed using scanning electron microscopy. X-ray diffractometry was used to investigate the residual stresses in the specimens. The elemental distribution was analyzed with an electron probe micro analyzer. The tensile strength and hardness were also measured. Results show that the diffusion layers become wide as the heat treatment temperature increases, and the residual stress of the specimen is at a minimum and tensile strength is the largest when being annealed at 250 °C. Therefore, 250 °C is the most appropriate annealing temperature.

Key words: annealing temperature; diffusion bonding; diffusion layer; residual stress; tensile strength

1 Introduction

With the rapid development of the transportation, aerospace, and defense industries, magnesium alloys have received growing attention due to their low densities, high specific strengths, excellent casting ability, and outstanding vibrational energy absorption [1]. While the use of magnesium alloys allows the weight of components to be reduced, this material is easily corroded. Another group of materials used in a similar role are aluminum alloys, which have attractive mechanical and metallurgical properties including high strength and excellent corrosion resistance [2-5]. It is well-known that both magnesium and aluminum alloys are both widely used in the aerospace, mechanical, electrical, and chemical industries [6-9]. Furthermore, with the growing emphasis on energy economy and environmental concerns, Mg alloys have become a favored choice in the automobile field. If aluminum alloys can be bonded to magnesium alloy and form some kind of composite material, not only would the flexibility and availability of the material be substantially improved, but also the weight and cost would be reduced.

At present, there is much research into this topic. Many welding methods have been used to join Mg alloys and Al alloys. These methods include soldering, electron beam welding, resistance spot welding, explosive welding [10], laser welding, and the vacuum diffusion bonding. However, no matter which technique is used, brittle and hard intermetallic compounds, such as Al3Mg2 and Mg17Al12, form in the joints. This weakens the tensile strength of the joints. As was previously reported elsewhere, the tensile strength of bonded specimens was only 37 MPa [11], despite the Mg/Al alloy being welded with a Zn interlayer [12].

The process of annealing is always applied to plastically deformed metals and alloys in order to soften and restore the ductility and formability of materials [13]. Annealing can transform the structure of crystals and eliminate defects in microstructures, thereby reducing the brittleness and improving the mechanical characteristics of a material. In this work, in order to investigate these effects, annealing treatments were applied at different temperatures. In addition, the microstructures and their properties were investigated. This work represents one of the first attempts to study the effect of annealing temperature on the joints between magnesium and aluminum alloys. Based on the results of this work, the applications of the composite material formed by the diffusion bonding of aluminum alloy and magnesium alloy could be extensive. The composite materials formed by this process will lead to light-weight components, which will in turn lead to decreased depletion of resources and reduced energy usage, which can help mitigate environmental pollution.

2 Experimental

The chemical compositions of AZ31B magnesium alloy and 6061 aluminum alloy are given in Table 1 and Table 2.

Table 1 Composition of AZ31 Mg alloy (mass fraction, %)

Table 2 Composition of Al6061 alloy (mass fraction, %)

The principle impurities present in the alloys are Fe and Ni [14]. These impurities have an adverse effect on the uniformity of microstructures and the distribution of elements. Conversely, the presence of Mn elements can reduce the effect of impurities and refine the grain as well as improve the tensile strength of the diffusion layers. Si can improve the mechanical properties of the alloy at room temperature, and Cu can improve the strength at high temperature. Ca can refine the size of dendrites in Mg17Al12. Additionally, it will form the phase of Al2Ca, which has a very high melting point [15]. Consequently, it can reduce the micro-hardness of the diffusion zone. The element Zn is present firstly for its own solid-solution strengthening and secondly because a small amount of Zn can increase the solubility of Al in Mg, thereby improving the solid solution strengthening effect of Al. Besides, Zn can also reduce the formation of intermetallic compounds [16]. Overall, Zn can reduce micro-hardness and increase the tensile strength of the diffusion layers.

The first step in the experimental procedure was to cut AZ31B magnesium alloy sheets and 6061 aluminum alloy sheets to the dimensions shown in Fig. 1.

Fig. 1 Dimensions of specimen (unit: mm)

The oxide layers on the surface of the substrate were then polished with abrasive papers and the ground samples were wiped with acetone before joining. According to the Mg-Al phase diagram, the joining temperature was chosen as 440 °C. Specimens were successfully joined with a method called vacuum diffusion bonding under the protection of argon gas. After that, in order to refine microstructures and improve the properties of the bonding layers, annealing treatment was carried out. According to the Mg-Al phase graph and previous annealing experience, the samples were annealed using heat treatment temperatures of 200, 250 and 300 °C, and the holding time was 1 h. After heat treatment, samples were cooled to room temperature in an electric furnace.

For the purpose of studying the effect of annealing temperatures on microstructures and the properties of the interfaces, a series of specimens annealed at different conditions were cut across the diffusion zone. The cut sections were then inlaid into resin to facilitate the investigation of microstructures. Using a grinder and abrasive papers (Grit 240, 600, 800, 1200), the samples were ground and polished with a polishing compound.

The microstructures and elemental distribution of the joints were then studied using scanning electron microscopy (SEM) and an electron probe micro analyzer (EPMA). Using a tensile machine, the tensile strength was also investigated. The tensile speed used was 0.008 mm/s. After the measurement, the stress-strain graphs could be obtained. In order to investigate the distribution of residual stress of the specimens annealed at different temperatures, residual stress was measured by X-ray diffraction (XRD), based on the testing principle of residual stress and using X-ray of wavelength λ. Initially, the specimen was irradiated, and a diffraction angle 2θ was obtained which was later used to calculate the slope, M, of 2θ-sin2ψ. Generally, ψ was set to be 0°, 15°, 30° and 45°. This allowed us to obtain the relationship between 2θ and sin2ψ, and thus calculate the residual stress σ using the following equation:

σ=K?△2θ/△sin2ψ=K?M (1)

K is the stress constant of XRD analysis, which can be expressed as

(2)

(2)

where E is the elastic modulus of the material, θ0 is the diffraction angle without stress, and υ is Poisson ratio [17].

For the 6061 Al alloy, 2θ was set to be 140° and the stress constant was -163.32 MPa/(°). When 2θ was set as 155°, the stress constant was -79.14 MPa/(°) at the side of the AZ31 Mg alloy. The tube type was Cr, wavelength was Kα, and the size of collimator was φ0.5 mm. In addition, 2θ values for Mg17Al12 and Al3Mg2 were set to be 150° and 145°, respectively, and the stress constants were -98.97 and -126.22 MPa/(°), respectively. This allowed the results of residual stress to be calculated. Finally, the micro-hardness was measured with a Vickers hardness tester with the load of 10 N.

3 Results and discussion

3.1 Microstructures of joints

Temperature is the most important parameter in the heat treatment process. The microstructures of the bonding interfaces annealed at 200, 250 and 300 °C were therefore observed. The microstructures of the joints are shown in Figs. 2(b-d). Figure 2(a) shows the micro- structures of joints that did not undergo annealing.

The diffusion layers, including layer A, layer B, and layer C, are clearly visible in Fig. 2. Furthermore, as the annealing temperature rises, the width of the diffusion layers increases. This is because the diffusion rate increases with increasing temperatures.

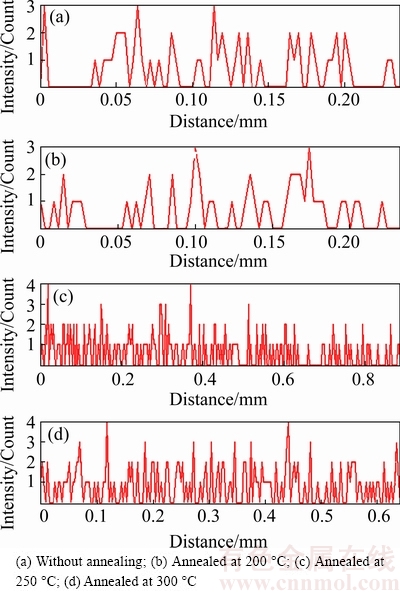

The elemental analysis results are shown in Fig. 3, and the width profiles of the diffusion layers are shown in Fig. 4, which also display the element analysis results from line scanning.

Clearly, the diffusion layers become wide when the heat treatment temperature is increased. The magnesium and aluminum contents vary in layers A, B and C. Specifically, the untreated specimens exhibit a magnesium content of 800-300 counts, and the aluminum content ranges from 50 to 200 counts. The widths of layers A, B and C are 0.017, 0.018 and 0.11 mm, respectively. The widths of layers A, B and C of the specimens heat-treated at 200 °C are approximately 0.022, 0.025 and 0.13 mm, respectively. The magnesium content ranges from 600 to 300 counts across the diffusion layer from the Mg side to the Al side, while the amount of aluminum ranges from 50 counts to 100 counts in the same direction. However, when the sample is treated at 300 °C, the amount of magnesium ranges from approximately 650 to 800 counts, and the aluminum content varies in the range of 50-70 counts.

Fig. 2 SEM micrographs of joints without annealing (a) and with annealing at 200 (b), 250 (c) and 300 °C (d)

Fig. 3 Elemental distribution in joints from surface scanning

Fig. 4 Elemental distribution in joints from line scanning

The thicknesses of layers A, B and C are about 0.06, 0.07 and 0.36 mm, respectively. The results after treating the sample at 250 °C are shown in Fig. 4(c). The width of layer A is about 0.03 mm, and the widths of layers B and C are approximately 0.05 and 0.35 mm, respectively. The magnesium content ranges from 300 to 500 counts, while the aluminum content ranges from 50 to 70 counts. The reason for this variation in the width of the diffusion layers and element abundances is the diversity of annealing temperature. Elemental diffusion rates increase with increasing temperature, and diffusion layer is therefore the widest when the samples are annealed at 300 °C.

3.2 Mechanical properties of joints

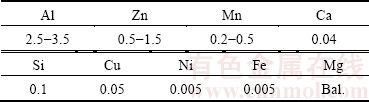

The tensile strength after annealing at different temperatures is shown in the stress-strain graphs in Fig. 5.

Fig. 5 Stress-stain graphs

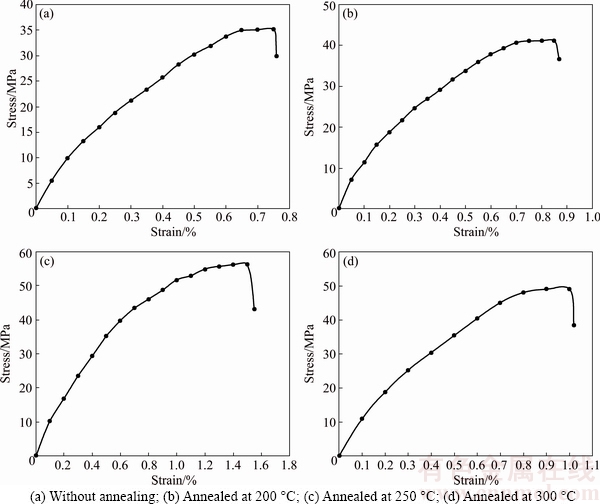

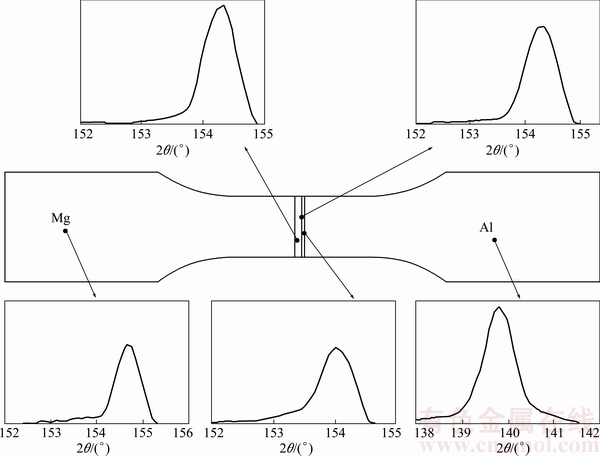

The tensile strength is the highest when the annealing temperature is 250 °C, of about 56 MPa. When the samples are annealed at 200 and 300 °C, the values of tensile strength are approximately 41 and 49 MPa, respectively. Untreated specimens exhibit a tensile strength of 35 MPa. In this work, the application of annealing treatment results in a higher tensile strength. In addition to the stress-strain graphs shown above, the diffraction peak results are shown in Fig. 6 and the residual stresses are shown in Fig. 7.

The diffraction peak of Al emerges when 2θ is near 139°, and the indices of the crystal face are (311). The indices of the crystal face at the diffraction peak of Mg near a 2θ value of 152° [18] are (104). The diffraction peaks of the intermetallic compounds Al3Mg2 and Mg17Al12 occur at 2θ=139.4° and 143°, respectively. The residual stress is a vector, and in this work, it is axially aligned with the specimens. Under a tensile stress, this value will be positive. In contrast, when the stress is compressive, the residual stress will be negative. It can be inferred from Fig. 7 that the residual stress at the interface (marked as 0 in Fig. 7) is tensile, and that of the untreated specimen exhibits a residual stress value of 65 MPa. When the samples undergo heat treatment at 300 and 200 °C, the residual stresses are respectively 51 and 59 MPa. When being treated at 250 °C, the sample exhibits a residual stress of approximately 44 MPa. Thus, the tensile strength of the specimen annealed at 250 °C is the highest, while that of the sample without annealing is the lowest. As the residual stresses are axial tensile stresses, and tensile stress will decrease the tensile strength, higher residual stresses will result in a lower tensile strength. On the contrary, if the residual stresses are compressive, then the higher the stress is, the higher the tensile strength will be. It is apparent that the results of the experiments for tensile strength are in good agreement with the predictions of the residual stress theory.

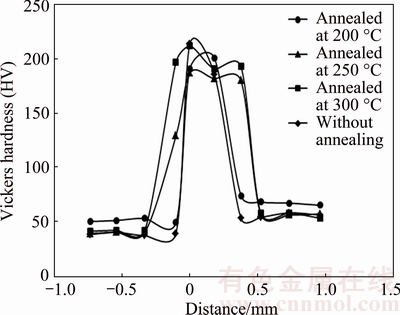

The micro-hardness of the diffusion layers annealed at different temperatures were also investigated in this study, with the load set to be 10 N. The distributions of hardness in the annealed samples are shown in Fig. 8.

The trends in the hardness distributions are broadly similar in that the hardness of the Mg side is higher than that of the Al side, and significantly increases in the diffusion zone. After being annealed at 200 °C, the hardness of the Mg side is HV 69, and HV 51 on the Al side, but is HV 201 in the diffusion bonding region. When the specimen is treated at 250 °C, the hardnesses of the Mg and Al sides are respectively HV 57 and HV 40. The interface has a hardness of HV 187. When the sample undergoes heat treatment at 300 °C, the hardness of the Mg side is HV 58 and is HV 42 in the Al side. The hardness is HV 212 in the bonded zone. When the sample does not undergo annealing, the hardnesses of the Mg and Al sides are respectively HV 55 and HV 39, and the hardness of interface is about HV 214. The hardness in the diffusion layer near the Al substrate is higher than that of the region near the Mg substrate. Thus, the variation in hardness is a result of the intermetallic compounds formed in varying locations in the diffusion zone, and the fundamental factor controlling hardness is the annealing temperature.

Fig. 6 Diffraction peaks from different parts of a bonded specimen

Fig. 7 Residual stress of specimens treated at different temperatures

Fig. 8 Vickers hardness at interfaces annealed at different temperatures

To summarize the results above, it is apparent that 250 °C is the most suitable annealing temperature. The results supporting this conclusion can be explained as follows. From the elemental analysis results presented in Figs. 3 and 4, the content of elements after annealing at 250 °C remains steady. This indicates that the distribution of elements is relatively uniform, and that the microstructure is more uniform. Furthermore, the amount of Zn is relatively steady and more than that under other annealing conditions, as shown in Fig. 9.

Zn has a significant effect on the diffusion zone of Mg alloys and Al alloys. It can reduce the formation of intermetallic compounds of Mg and Al. Even though intermetallic compounds can form, they will precipitate dispersedly, which can produce precipitation strengthening [19]. In other words, the amount of hard and brittle phases in the interface will decrease. This results in more desirable properties than from other annealing conditions. Residual stress is at a minimum, and the tensile strength is the highest.

Fig. 9 Elemental distributions of Zn from line scanning

4 Conclusions

1) It is difficult to obtain high quality bonding strengths between magnesium and aluminum alloy sheets by diffusion bonding alone due to the formation of intermetallic compounds. The application of annealing improves the bonding strength.

2) The width of the diffusion layers increases as the annealing temperature rises, because the diffusion rate becomes faster with increasing temperature.

3) The annealing temperature has a great effect on microstructures and the mechanical behavior of samples. Various results suggest that 250 °C is the most suitable temperature for annealing of the diffusion zone of AZ31B magnesium alloy and 6061 aluminum alloy.

Acknowledgments

This research work has been partially supported by the grant subsidy of the “Nano Project” for Private Universities: 2011-2014 from MEXT, Japan. This study was also supported by the “Advanced Science Research Laboratory” in Saitama Institute of Technology, Japan.

References

[1] LAKSHMINARAYANAN A K, ANNAMALAI V E. Fabrication and performance evaluation of dissimilar magnesium-aluminium alloy multi-seam friction stir clad joints [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 25-35.

[2] SHE Qing-yuan, YAN Hong-ge, CHEN Ji-hua, SU Bin, YU Zhao-hui, CHEN Chao, XIA Wei-jun. Microstructure characteristics and liquation behavior of fiber laser welded joints of Mg-5Zn-1Mn- 0.6Sn alloy sheets [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 812-819.

[3] LIU L M, LIU F. Effect of Ce on micro-structures and properties of Mg/Al butt joint welded by gas tungsten arc with Zn–30Al–xCe filler metal [J]. Science and Technology of Welding and Joining, 2013, 18: 414-420.

[4] LIU Li-ming, LIU Fei, ZHU Mei-li. Study on Mg/Al weld seam based on Zn-Mg-Al ternary alloy [J]. Materials, 2014, 7: 1173-1187.

[5] YAN Y B, ZHANG Z W, SHEN W, WANG J H, ZHANG L K, CHIN B A. Micro-structures and properties of magnesium AZ31B- aluminum 7075 explosively welded composite plate [J]. Materials Science and Engineering A, 2010, 527: 2241-2245.

[6] LI Xiang-rong, LIANG Wei, ZHAO Xing-guo, ZHANG Yan, FU Xiao-peng, LIU Fen-cheng. Bonding of Mg and Al with Mg-Al eutectic alloy and its application in aluminum coating on magnesium [J]. Journal of Alloys and Compounds, 2009, 471: 408-411.

[7] LIU Fei, REN Da-xin, LIU Li-ming. Effect of Al foils interlayer on micro-structures and mechanical properties of Mg-Al butt joints welded by gas tungsten arc welding filling with Zn filler metal [J]. Materials and Design, 2013, 46: 419-425.

[8] ZHU Bo, LIANG Wei, LI Xian-rong. Interfacial micro-structures, bonding strength and fracture of magnesium-aluminum laminated composite plates fabricated by direct hot pressing [J]. Materials Science and Engineering A, 2011, 528: 6584-6588.

[9] SHARMA C, UPADHYAY V, DWIVEDI D K, KUMAR P. Mechanical properties of friction stir welded armor grade Al-Zn-Mg alloy joints [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 493-506.

[10] MA Li, HE Ding-yong, LI Xiao-yan, JIANG Jian-min. Micro- structures and mechanical properties of magnesium alloy AZ31B brazed joint using a Zn-Mg-Al filler metal [J]. J Mater Sci Technol, 2010, 26: 743-746.

[11] SHANG Jing, WANG Ke-hong, ZHOU Qi, ZHANG De-ku, HUANG Jun, GE Jia-qi. Effect of joining temperature on micro-structures and properties of diffusion bonded Mg/Al joints [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1961-1966.

[12] ZHANG Yu, LUO Zhen, LI Yang, LIU Zu-ming, HUANG Zun-yue. Micro-structures characterization and tensile properties of Mg/Al dissimilar joints manufactured by thermo-compensated resistance spot welding with Zn interlayer [J]. Materials and Design, 2015, 75: 166-173.

[13] SUN Hong-fei, CHAO Hong-ying, WANG Er-de. Microstructure stability of cold drawn AZ31 magnesium alloy during annealing process [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(S): s215-s221.

[14] YANG Ming-bo, PAN Fu-sheng, LI Zhong-sheng, ZHANG Jing. Alloying elements and their effects in Mg-Al based elevated temperature magnesium alloys [J]. Materials Review, 2005, 19: 46-49. (in Chinese)

[15] LI Guang-qun, WU Guo-hua, FAN Yu, DING Wen-jiang. Effect of the main alloying elements on microstructure and corrosion resistance of magnesium alloys [J]. Foundry Technology, 2006, 27: 79-83. (in Chinese)

[16] ZHANG Shi-chang, DUAN Han-qiao, CAI Qi-zhou, WEI Bo-kang, LIN Han-tong, CHEN Wei-chen. Effects of the main alloying elements on microstructure and properties of magnesium alloys [J]. Foundry, 2001, 50: 310-315. (in Chinese)

[17] ZHANG Ding-quan, HE Jia-wen. Residual stress analysis by X-ray diffraction and its functions [M]. Xi’an: Xi’an Jiao Tong University, 1999. (in Chinese)

[18] WANG Jian-gang, JU Dong-ying. Study on evolution technology of anisotropic mechanical properties and micro-structures evolution of metal thin plate under complex stress condition [D]. Japan: Saitama Institute of Technology, 2011.

[19] ZHAO L M, ZHANG Z D. Effect of Zn alloy interlayer on interface micro-structures and strength of diffusion-bonded Mg-Al joints [J]. Scripta Materialia, 2008, 58: 283-286.

丁云龙1,王建刚2,赵 明3,巨东英1,3

1. Department of Material Science and Engineering, Saitama Institute of Technology, Fusaiji 1690, Fukaya, Saitama 369-0293, Japan;

2. 河北科技大学 河北省材料近净成形技术重点实验室,石家庄 050018;

3. 辽宁科技大学 材料科学与工程系,鞍山 114051

摘 要:为了研究退火温度对镁合金和铝合金结合层的影响,提高扩散层的性能,采用真空扩散结合的方法焊接镁合金(AZ31B)和铝合金(6061),然后依据热处理理论在电炉中进行退火处理。应用扫描电子显微镜对焊接层的组织进行观察,利用X射线衍射技术测量残余应力,借助EPMA检测元素分布。此外,还分别测量材料的抗拉强度和硬度。结果显示,扩散层随着热处理温度升高而变宽。相比之下,在250 °C退火处理后的试样残余应力值最低,抗拉强度最大。结合实验结果,250 °C是镁合金和铝合金扩散结合件的最适退火温度。

关键词:退火温度;扩散接合;扩散层;残余应力;拉伸强度

(Edited by Bing YANG)

Corresponding author: Dong-ying JU; Tel: +81-48-5856826; Fax: +81-48-5855928; E-mail: dyju@sit.ac.jp

DOI: 10.1016/S1003-6326(18)64658-8