磨矿对矿物表面性质和浮选行为的影响

来源期刊:中国有色金属学报2019年第11期

论文作者:黄子杰 孙伟 高志勇

文章页码:2671 - 2681

关键词:磨矿;表面性质;晶面暴露;晶体结构;浮选

Key words:grinding; surface properties; exposed surfaces; crystal structure; flotation

摘 要:综述了磨矿环境、磨矿介质、外加机械力、磨机类型和助磨剂等磨矿过程中的主要因素对硫化矿和氧化矿颗粒表面性质、矿物浮选行为的影响及机制。结果发现:对于硫化矿,磨矿主要影响颗粒的晶体结构和矿浆电化学性质;对于氧化矿和硅酸盐矿物,磨矿主要影响颗粒晶面暴露程度、反应活性、形状指数及粗糙度等,最终影响矿物的浮选行为。通过对磨矿过程中各种因素的优化,获得具有特定晶体结构、形状参数、特定晶面暴露的矿物颗粒产品,进而实现对矿物浮选及分离行为的精细调控,是未来磨矿研究的重点。

Abstract: The influencing mechanisms of grinding environment, grinding medium, mechanical force, mill types and grinding aids on surface properties and flotation behavior of sulfide and oxidized minerals were systematically reviewed. It was concluded that, for sulfide ores, grinding can mainly affect the crystal structure and pulp electrochemical properties of mineral particles. While for oxidized and silicate minerals, grinding dominantly influences the exposure degree of crystal surfaces, reactivity, shape index and roughness of mineral particles, and ultimately exerts influence on mineral flotation behavior. In the near future, the main researches should be concentrated on coordinated optimization of various factors in grinding process to produce mineral particles with specific crystal structure, shape index and crystal surface exposure which will lead to a precise control of mineral flotation behaviour and hence separation efficiency.

DOI:10.19476/j.ysxb.1004.0609.2019.11.24

黄子杰1, 2, 孙 伟1, 2,高志勇1, 2

(1. 中南大学 资源加工与生物工程学院,长沙 410083;

2. 中南大学 战略含钙矿物资源清洁高效利用湖南省重点实验室,长沙 410083)

摘 要:综述了磨矿环境、磨矿介质、外加机械力、磨机类型和助磨剂等磨矿过程中的主要因素对硫化矿和氧化矿颗粒表面性质、矿物浮选行为的影响及机制。结果发现:对于硫化矿,磨矿主要影响颗粒的晶体结构和矿浆电化学性质;对于氧化矿和硅酸盐矿物,磨矿主要影响颗粒晶面暴露程度、反应活性、形状指数及粗糙度等,最终影响矿物的浮选行为。通过对磨矿过程中各种因素的优化,获得具有特定晶体结构、形状参数、特定晶面暴露的矿物颗粒产品,进而实现对矿物浮选及分离行为的精细调控,是未来磨矿研究的重点。

关键词:磨矿;表面性质;晶面暴露;晶体结构;浮选

文章编号:1004-0609(2019)-11-2671-10 中图分类号:TD921 文献标志码:A

在某些领域,碎磨是对物料进行后续加工的前提,产品的粒度和形状将直接影响后续加工处理的效果。例如,在制药工程领域,碎磨会使药物晶体产生晶格缺陷,并改变其晶体习性,同时沿着附着能较弱、活性更强的表面断裂[1]。在食品领域,通过超微研磨对蛋白质进行表面改性能使蛋白质中生成新的二硫键,从而改变食品蛋白质的结构、空间构象,获得具有特定形状的蛋白质产品[2]。

在矿物加工领域,碎磨的主要目的是为后续分选工艺提供粒度适宜且有用矿物充分单体解离的合适物料[3]。碎磨是选厂能耗和金属材料消耗最大的作业,碎磨效率直接影响选厂的技术经济指标[4]。目前,国家倡导节能减排,对矿物加工领域碎磨作业也提出了更高的要求,即要求碎磨的矿物颗粒产品尽可能在形貌、粒度以及表面性质等方面更利于分选[5]。

磨矿是一个复杂的物理化学过程,磨矿介质、磨矿环境以及入磨物料等因素都会对磨矿产品的表面形状、性质和分选行为产生影响[6]。不同磨矿条件下,产品颗粒形貌及表面性质不同,矿粒与药剂及气泡之间的作用也不同,最终导致选别指标存在差异。因此,磨矿设备及工艺参数的改进与优化,一直是矿物加工领域的研究热点。

本文重点综述了不同磨矿环境、介质形状、介质成分、机械压力、磨机类型及助磨剂等条件下矿物颗粒表面性质及分选行为的差异,并据此总结了磨矿作业对矿物浮选影响的具体表现形式,如矿浆化学性质、颗粒表面性质、颗粒形状参数等,以期通过磨矿条件的改变针对性地调控矿物表面物理化学性质,为实现矿物之间的高效浮选分离提供参考。

1 磨矿过程中影响矿物颗粒表面性质和浮选行为的因素

1.1 磨矿环境

磨矿环境主要包括干磨、湿磨、磨机内气体环境、酸碱性以及浮选药剂添加等,不同磨矿环境下矿物颗粒的表面性质与浮选行为存在差异。

1.1.1 干磨和湿磨

对于绝大多数矿物,干磨或湿磨直接影响矿物颗粒表面的晶格缺陷程度,从而影响矿物表面离子的溶解和反应活性,进而影响矿物的浮选行为。硫化矿多为天然的良好半导体,湿磨时矿物产生的晶格畸变将直接影响磨矿介质与矿物之间的氧化还原反应,在矿物表面形成大量的特殊区域(如氢氧化物、氧化物、硫酸盐的罩盖层区),使其亲水性增强;同时,由于反应消耗了部分溶解氧,导致矿浆中溶解氧含量减少,体系还原性增强,浮选回收率降低[7]。在干磨条件下,虽然矿物颗粒表面同样会产生大量晶格缺陷,但是由于矿物表面未生成亲水性物质,且颗粒表面较粗糙、活性更强,有利于浮选药剂的吸附以及气泡的黏附,因而浮选回收率相比湿磨时高[8]。

对于盐类矿物,干磨时产生的大量结构缺陷使其在溶液中更容易发生溶解,表面亲水性增强[9]。干磨、湿磨还会影响矿物颗粒晶面的暴露程度。锂辉石湿磨产品暴露更多的{110}面,干磨产品暴露更多的{001}面,{110}面反应活性高,与捕收剂作用能力强,因而湿磨产品可浮性更好[10]。

1.1.2 气体环境

磨机内的气体会与磨矿介质或者矿物发生反应,进而影响矿物的表面性质。在实际生产中,磨机内存在氧气,铁介质易与矿物表面发生反应生成氢氧化物沉淀,抑制浮选;而在惰性气体(如氮气)环境下,矿物表面阴极电流较氧气环境下小,矿物电极与铁介质之间的电化学相互作用减弱,可以有效减少铁羟基络合物的生成,有利于浮选[11]。

1.1.3 酸碱性

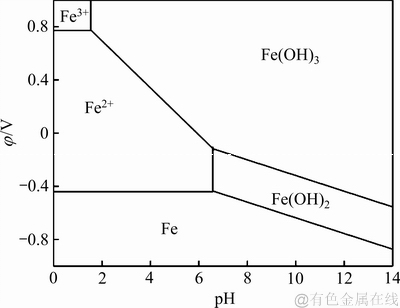

磨机内的酸碱性即pH会影响磨矿介质与矿物颗粒之间的作用,进而影响矿物的浮选行为。硫化矿的可浮性在一定范围内随pH值的增大而提高。但是,在碱性环境下,铁介质与矿物之间存在电化学反应,铁介质的氧化产物Fe3+会与阴极还原反应产生的OH-生成铁的氢氧化物覆盖于硫化矿表面,使其表面亲水性增强(见图1)[12]。因此,合理调控磨机内酸碱性对硫化矿浮选至关重要。

图1 Fe-H2O体系电位与pH值的关系

Fig. 1 Relationship between potential and pH values in Fe-H2O system

1.1.4 浮选药剂添加地点

通常浮选药剂的添加点有两处,即磨机中或浮选槽中。捕收剂的添加点对硫化矿物浮选行为的影响与磨矿介质种类有关。当磨矿介质为钢球时,硫化矿物表面由于吸附部分铁微粒而使表面电位降低,对加入的捕收剂的吸附强度大幅减弱,浮选效果减弱;当磨矿介质为瓷球时,捕收剂加入后矿浆电位上升,矿物颗粒疏水性增强[13-14]。抑制剂如石灰直接加入到磨机中时,由于生成了铁的氢氧化物沉淀,导致矿浆中溶解的Fe2+减少,介质与矿物之间的伽伐尼电偶作用减弱,浮选指标较加入到浮选槽中更好[15]。

1.2 磨矿介质

1.2.1 介质形状

不同形状磨矿介质与矿粒之间的接触方式不同,碎磨机理不同,导致产品颗粒形状指数、表面粗糙度、比表面积等参数存在差异[16-17]。球形介质通常是通过点接触研磨矿石[18],选择性磨矿作用较差,过磨较严重,产品粒级分布较广;而柱形介质与矿物之间主要为线接触,以柱的全长挤压和磨剥矿石[19],磨机中大颗粒未被粉碎之前小颗粒很少有机会受到柱的冲击,过磨程度较轻,产品粒度均匀。

例如,锡矿石细磨时球形介质与矿石之间为点接触,应力过于集中,过粉碎严重;棒形介质单位体积的介质表面积较小,不适于细磨;而双平面短柱形介质能弥补球形与棒形介质的不足,不仅能有效减轻锡矿石的过磨,还可提高合格粒级的利用系数[20]。吴彩斌等[21]提出采用六棱柱状磨矿介质代替传统的球形介质,以控制钨矿产品粒度、泥化程度。CUHADAROGLU等[22]研究发现圆锥柱形介质对硬硼酸钙石的破碎速率较钢球高,对粗颗粒磨矿效果较好,但是随着磨矿时间的增加,球形介质的磨矿产品粒度较圆锥柱形介质更细。

1.2.2 介质成分

磨矿过程中磨矿介质与矿粒不停碰撞,介质成分会对矿物表面性质产生重要影响。采用非铁介质磨矿时,硫化矿物易形成缺金属表面或在表面形成多聚硫,从而增强其疏水性[23]。而铁球作为磨矿介质时,磨矿过程中铁介质及硫化矿自身会形成局部电池,铁介质与硫化矿物之间形成伽伐尼电偶,使体系的还原性增强,不利于捕收剂的吸附[15]。

铁介质磨矿过程中产生的铁离子以及铁的羟基氧化物在硅酸盐矿物表面吸附,矿物表面正电荷增加且ζ电位升高,与阳离子捕收剂的物理吸附作用减弱,浮选受到抑制。呼振锋等[24]研究发现,铁球磨矿下硅酸盐矿物颗粒的浮选回收率高于锆球,主要原因在于部分铁介质磨损固着在矿物表面,提供了更多的阳离子活性位点,有利于捕收剂油酸钠的吸附。

目前,自磨在矿山的应用广泛。传统的金属矿山采用钢球磨矿,可使矿物充分单体解离,但存在成本较高和易产生铁质污染等问题。半自磨产生的顽石硬度较高,表面平整,是较为理想的磨矿介质,而且可避免钢球磨矿大量铁絮状物的产生以及对矿物表面的覆盖。吴彩斌等[25]研究发现,相比传统的钢球,顽石作为磨矿介质时铜硫矿磨矿产品粒度更均匀,过磨程度减轻,有利于改善浮选。

1.3 机械压力

除磨矿介质外,磨矿过程中硫化矿物与介质之间的机械压力也会对硫化矿物电极电位和表面形貌产生影响。机械压力指矿物与介质之间作用力的大小。机械压力越大,矿物外电路电流越小。当磨矿介质为铁球时,介质与矿物之间会形成腐蚀电偶,此时矿物充当阴极,介质充当阳极;机械压力增大,则矿物表面阴极电流减小,体系腐蚀电偶作用增强,药剂吸附作用减弱,浮选受到抑制。当磨矿介质为瓷球时,矿物作为阳极,表面产生阳极电流,发生自身氧化,当机械压力增大时,矿物电极外电路电流减小,体系还原性增强,矿物表面氧化作用减弱,浮选受到抑制[26]。

此外,机械压力还会引起矿物表面形貌的变化。在无机械力作用时,矿物表面平整,形态单一;受到机械力作用时,由于摩擦作用,矿物表面变得不平整。颗粒表面越光滑,疏水性越好,可浮性越好。因此,机械力的存在会对矿物浮选产生不利影响[27]。

1.4 磨机类型

滚筒式球磨机是目前选矿厂应用最广泛的磨机类型之一,具有磨矿效率高、操作简便的优点。但是,其介质施力方式与磨机筒体转速有关,选择性磨矿作用较差,过磨严重。同时,研磨作用易磨去物料的棱边和尖角,磨矿产品颗粒圆形度较高,不利于其与气泡碰撞黏附。

相比于滚筒式球磨机,立式磨机主要是通过挤压剪切作用使物料碎裂,磨辊的压力首先集中于大块物料,随后才是粒度较小的物料,因而选择性磨矿效果较好,产品粒度分布范围较小[28]。

搅拌磨主要用于超细粉碎,磨矿时物料和介质在磨筒内不断地上下、左右相互交换位置,通过介质重力以及介质与物料之间的挤压力将物料粉碎,其产品粒度均匀,磨矿效率高,主要适用于最大粒度小于微米级产品的细磨[29]。

高压辊磨是基于挤满给矿在料柱颗粒层间形成准静压力而使物料粉碎的一种磨矿工艺,广泛应用于金矿中,不仅能减小颗粒尺寸,有效促进目的矿物的解离,而且还能使物料产生更多的微裂纹,为金矿的后续选冶作业创造有利条件[30]。

1.5 助磨剂

在磨矿作业中,能够改变磨矿环境或物料表面物理化学性质的药剂称为助磨剂。助磨剂作用机理,有两种假说。一种是“料浆流变学调节”学说,助磨剂通过调节料浆的流变学性质和颗粒的表面电性,降低矿浆的黏度,促进颗粒之间的分散,从而使矿物颗粒不易在磨矿介质或衬板上团聚。李茂林等[31]研究发现,在高磷鲕状赤铁矿磨矿时,磨机内加入三聚磷酸钠或六偏磷酸钠后,矿浆黏度明显降低,磨机的生产能力大大提高。另一种为“吸附降低硬度”学说。在磨机内,矿物颗粒受到多方向的应力作用,从而形成裂纹发生破裂。加入助磨剂后,助磨剂在矿物表面的吸附可以减少裂纹扩展所需的外应力,阻止新生裂纹的闭合,促进裂纹的扩展,有利于矿物的解离。例如,随着磨矿时间的延长,捕收剂油酸根离子在赤铁矿表面大量吸附,使其表面强度降低,磨矿效率提高;但是,当油酸钠用量较大时,矿浆黏度变大,磨矿介质对矿石的冲击作用减弱,反而产生不利影响[32]。

2 磨矿对矿物颗粒浮选行为的影响机理

硫化矿可浮性与其晶体结构和矿浆物理化学性质密切相关。磨矿时的机械力作用可使矿物产生晶格畸变,表面性质发生改变。矿物晶格畸变程度越高,其化学活性越强,与药剂作用能力越强,可浮性越好。另一方面,磨矿过程中除了存在硫化矿物自身形成的局部电池,还存在磨矿介质与矿物之间的伽伐尼电偶作用,介质发生氧化导致矿浆中溶解氧含量降低,矿浆化学性质发生改变,矿物可浮性变差。

对于氧化矿和硅酸盐矿物,不同磨矿条件下矿物颗粒晶面暴露程度、形状指数及粗糙度等参数存在差异。矿物颗粒的反应活性与其晶面暴露程度有关,高活性晶面暴露比例越大,矿物颗粒与药剂之间的作用能力越强,可浮性越好。此外,颗粒形状指数也会影响矿物颗粒的可浮性,颗粒伸长率越高,与气泡碰撞时越容易突破矿物表面的水化膜,与气泡的黏附概率越高,浮选效果越好。

2.1 硫化矿

2.1.1 晶体结构

磨矿过程中,在机械力作用下硫化矿发生解理,裸露出新鲜表面,表层或次表层会发生不同程度的弹塑性变形,引起多形转变、晶格变形和去晶现象,产生电子-空穴缺陷、色心缺陷和位错等,甚至导致表面基本成分的转变[33]。磨矿过程的机械活化使矿物晶体的晶格参数和Wyckoff参数减小,导致晶体的费米能级升高。黄铁矿在瓷介质磨矿时效果优于铁介质,原因在于瓷介质磨矿时其晶格畸变程度较高,矿物的化学活性较高,与药剂的作用更强[34]。

2.1.2 矿浆物理化学性质

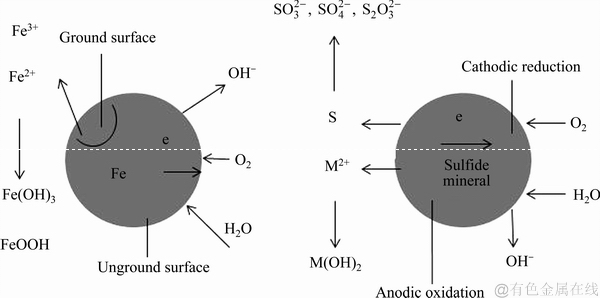

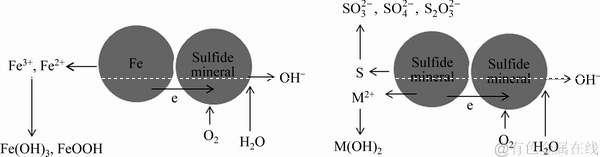

硫化矿的浮选行为主要取决于矿浆物理化学性质和矿物表面性质。矿浆物理化学性质包括矿浆pH、矿浆电位、溶解氧含量和离子浓度等。在磨矿过程中,硫化矿物和介质之间以及矿物与矿物之间相互接触,由于矿物静电位的差别而产生接触电流,从而会发生一系列的电化学反应,电位高的一端发生氧化反应,电位低的一端发生还原反应,在两端生成相应的产物,从而使硫化矿表面性质和可浮性发生改变[35]。研究表明,通过硫化矿/液相界面间的电位调节可以实现对硫化矿亲疏水性的控制。但是,在铁介质等的作用下,磨机内除存在矿物自身所形成的局部电池(见图2),还有磨矿介质与矿物之间的伽伐尼电偶作用(见图3)。

在磨机内,阳极主要发生介质铁的氧化,阴极发生氧的还原;而在硫化矿表面,硫化矿被氧化生成S0或 ,主要反应如下:

,主要反应如下:

Fe →Fe2++2e (1)

Fe2++3H2O→Fe(OH)3+3H++e (2)

MS→M2++S+2e (3)

O2+H2O+2e→2OH- (4)

O2+H2O+2e→2OH- (4)

当采用瓷介质或者玛瑙介质时,体系中主要为矿物自身形成局部电池消耗溶解氧。而当采用铁介质时,还存在铁介质与硫化矿之间的伽伐尼电偶作用,硫化矿总是作为阴极发生氧的还原反应(见式(4)),而铁介质总是作为阳极发生氧化反应(见式(1)),整个过程中消耗的溶解氧更多;Fe2+进一步氧化成Fe3+也将消耗更多的氧,这些因素共同导致矿浆中溶解氧含量的降低。在另一方面,阳极氧化产生的Fe3+易与阴极还原产生的OH-生成铁的氢氧化物,使硫化矿表面亲水性增强[8, 13, 38]。

图2 铁介质与硫化矿物自身形成的局部电池[36-37]

Fig. 2 Model of local cell of iron media and sulfide minerals during grinding[36-37]

图3 铁介质与硫化矿物及不同硫化矿物之间形成的Galvanic电偶示意图[36-37]

Fig. 3 Schematic diagrams of Galvanic interactions occurring between sulfide minerals and grinding media and among different sulfide minerals during grinding[36-37]

2.2 氧化矿和硅酸盐矿物

2.2.1 晶面暴露程度和反应活性

在磨矿过程中,矿物晶体将沿着一定的结晶方向解理,解理面一般平行于层间距较大的面或者阴阳离子电性中和的面,并且沿化学键最弱的方向产生[39]。不同形状的磨矿介质与矿物之间作用方式存在差异,矿物可能沿着不同的方向发生解理或者断裂,导致各晶面暴露程度不同。

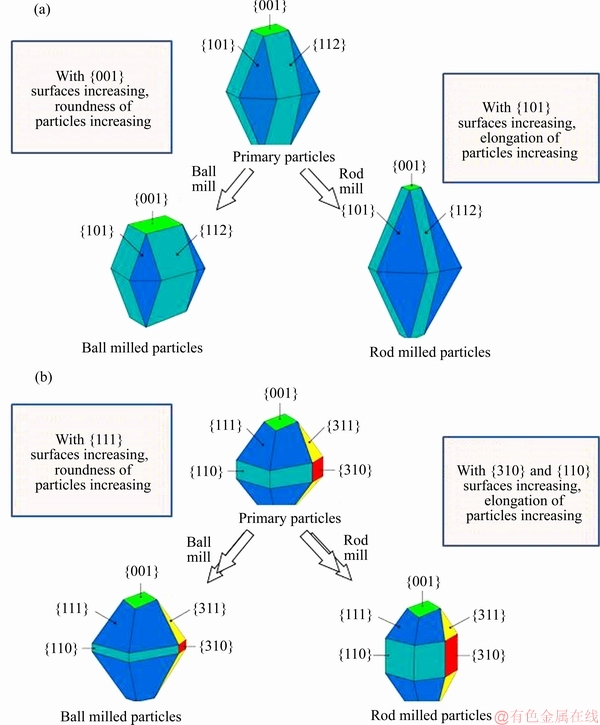

1) 不同形状的磨矿介质作用下同一粒级颗粒的晶面暴露程度和反应活性

高志勇等[18-19]研究了球磨和棒磨对38~74 μm粒级白钨矿和萤石表面性质及可浮性的影响,如图4所示。相比球磨,棒磨产生的白钨矿和萤石颗粒伸长率更大,临界表面张力更小,疏水性更强。白钨矿棒磨产品中暴露更多的{101}晶面,球磨产品中暴露更多的{001}晶面。{101}晶面上每个Ca质点具有3个断裂键,{001}晶面每个Ca具有2个断裂键,因而{101}晶面Ca质点活性更强,与捕收剂分子的作用更强,导致暴露更多{101}面的棒磨产品可浮性更好[39-43]。萤石棒磨产品中暴露更多的{110}和{310}晶面,球磨产品中暴露更多的{111}晶面。{111}晶面上每个Ca质点仅有1个断裂键,而{110}和{310}晶面的Ca分别有2个和4个断裂键,因而{111}面Ca质点反应活性较弱,与捕收剂作用较弱,导致暴露更多{111}面的球磨产品可浮性比棒磨差[18]。

图4 白钨矿(a)和萤石(b)矿物颗粒形状与晶面暴露比例之间的关系

Fig. 4 Relationship between particle morphology and crystal surface exposure degree of scheelite (a) and fluorite (b)

2) 相同形状的磨矿介质作用下不同粒级颗粒的晶面暴露程度和反应活性

徐龙华等[44]研究了不同粒级下长石和锂辉石晶面暴露程度及可浮性的差异。长石{001}面比{010}面具有更多的Al活性位点,油酸钠在{001}面更容易吸附。随着颗粒粒度的增大,长石{010}面逐渐增多,而{001}面逐渐减少,最终导致油酸钠吸附量减少,回收率降低。与长石相反,锂辉石浮选回收率随颗粒粒度的增大而升高。锂辉石粒度越大,锂辉石{110}面暴露比例越高,{001}面暴露越少;{110}面Al质点有两个断裂键,活性更强,更有利于捕收剂的吸附,因而粗粒锂辉石可浮性更好[45]。

3) 相同形状的磨矿介质、不同磨矿环境下颗粒晶面暴露程度和反应活性

朱广丽等[10]研究了干磨、湿磨对锂辉石表面性质及解理情况的影响。锂辉石湿磨产品暴露更多的{110}面,干磨产品暴露更多的{001}面,而{110}面与捕收剂的作用更强,故湿磨时锂辉石可浮性更好。

2.2.2 颗粒形状指数

不同形状的磨矿介质、磨矿方式下矿物解理机制存在差别。自磨主要依靠研磨和磨剥作用使矿石产生裂纹,而球磨和棒磨主要以冲击作用为主[46]。不同形状磨矿介质的施力方式不同,导致产品颗粒的形状参数存在差异。

高志勇等[18-19]研究发现,磨矿产品的形状参数与矿物本身的晶体结构无关,而与其磨矿方式及晶面暴露比例有关。白钨矿棒磨颗粒产品暴露更多的{101}晶面(见图4(a)),因此颗粒伸长率更大,球磨颗粒产品暴露更多{001}晶面,颗粒圆形度更大。萤石棒磨颗粒产品暴露更多的{310}及{110}晶面(见图4(b)),颗粒伸长率更大,球磨颗粒产品暴露更多{111}晶面,颗粒圆形度更大。

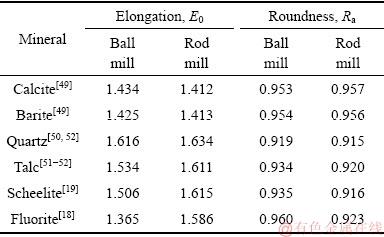

颗粒产品伸长率越高,其形状越不规则,边缘存在的棱边和尖角有利于加速颗粒表面水化层的破裂,从而缩短矿物颗粒与气泡粘附过程中的诱导时间,提高粘附效率[47-48]。与此相反,颗粒产品圆形度越高,则颗粒与气泡之间的黏附力越小,浮选过程中颗粒易从气泡上脱落,选别效率降低。不同磨矿方式下各种常见氧化矿和硅酸盐矿物形状参数见表1[18-19, 49-52]。

2.2.3 粗糙度

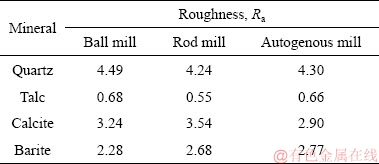

表2所示为几种常见矿物球磨、棒磨和自磨条件下粗糙度的差异。石英和滑石球磨时粗糙度最高,棒磨最低;方解石棒磨时粗糙度最高,自磨最低;而重晶石自磨时粗糙度最高,球磨最低。可见,不同形状磨矿介质作用下,最终产品的粗糙度存在差异。

表1 不同磨矿介质下几种常见矿物的形状参数

Table 1 Shape parameters of several minerals under different grinding media

表2 几种常见矿物不同磨矿方式下表面粗糙度值对比[50-51, 53]

Table 2 Comparison of surface roughness values of several common minerals under different grinding methods[50-51, 53]

颗粒平均粒径直接影响其粗糙度和比表面积,颗粒粒度越小,比表面积和粗糙度越大[54]。比表面积大的颗粒,捕收剂在其表面形成単分子层吸附所需的浓度越高。粗糙度越大,临界表面张力越大,矿物亲水性越强。因此,磨矿过程引起的粗糙度和比表面积的变化将会对矿物浮选产生显著影响。

2.2.4 润湿性和可浮性

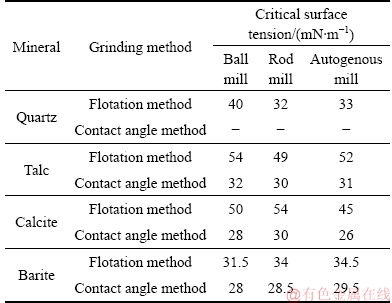

润湿性是矿物可浮性的重要衡量指标,矿物润湿性越强,可浮性越弱。浮选法是矿物亲疏水性的一种间接测量方法,浮选过程中回收率会随着浮选介质表面张力的减小而逐渐下降,当回收率为0时,介质的表面张力即为矿物的临界表面张力,临界表面张力越小,矿物疏水性越好。

表3所示为几种矿物不同磨矿方式下分别采用浮选法和接触角法所测得的临界表面张力值[49-51, 53]。矿物临界表面张力和疏水性与磨矿介质的形状有关。滑石和石英棒磨时临界表面张力总小于球磨,可浮性更好;方解石自磨时临界表面张力小于棒磨和球磨,疏水性更强;而重晶石在球磨下临界表面张力最小,疏水性最强。因此,可根据实际需要,采用合适的磨矿方法以实现矿物之间的有效分离。

表3 几种常见矿物不同磨矿方式下临界表面张力值对比[49-51, 53]

Table 3 Comparison of critical surface tension values of several common minerals under different grinding methods[49-51, 53]

3 结论

1) 磨矿环境、磨机类型、介质形状、成分、助磨剂的添加等因素都会对矿物颗粒表面物理化学性质以及浮选行为产生重要影响,而且对硫化矿和氧化矿具有不同的影响机制。不同磨矿方式下硫化矿的晶体结构和矿浆物理化学性质存在差异。对于氧化矿,磨矿介质形状、磨矿环境对矿物颗粒晶面暴露程度、形状参数、反应活性、粗糙度有显著影响。

2) 浮选的关键在于选择性改变矿物颗粒的亲疏水性。通过磨矿过程中各种因素的优化改变矿物颗粒的形状指数和表面物理化学性质,提高有用矿物高活性晶面的暴露比例,获得具有特定形状、特定晶面暴露的颗粒产品,从而实现矿物浮选分离的精细调控,这都是今后磨矿-浮选-体化需要重点研究的方向。

REFERENCES

[1] ALSUBAIE M, ALJOHANI M, ERXLEBEN A, MCARDLE P. Cocrystal forms of the bcs class iv drug sulfamethoxazole[J]. Crystal Growth & Design, 2018, 18(7): 3902-3912.

[2] 于翠平, 查 越, 吴 凡, 吴 迪, 秦玉婷, 杜 明. 超微粉碎技术对蛋白质理化及功能性质影响的研究进展[J]. 食品安全质量检测学报, 2018, 9(2): 360-365.

YU Cui-ping, CHA Yue, WU Fan, WU Di, QIN Yu-ting, DU Ming. Research progress on the effects of ultra-fine grinding on protein physicochemical and functional properties[J]. Journal of Food Safety and Quality, 2018, 9(2): 360-365.

[3] YAO Wei, LI Mao-lin, ZHANG Ming, CUI Rui, JIANG Hong-qiang, LI Yun, ZHOU Sheng. Effects of grinding media on flotation performance of calcite[J]. Minerals Engineering, 2019, 132: 92-94.

[4] 段希祥. 碎矿与磨矿[M]. 北京: 冶金工业出版社, 2012: 2-5.

DUAN Xi-xiang. Crushing and grinding[M]. Beijing: Metallurgical Industry Press, 2012: 2-5.

[5] 徐秉权. 粉碎新工艺新设备与节能技术[M]. 长沙: 中南工业大学出版社, 1992: 1-4.

XU Bing-quan. New crushing technology, new equipment and energy-saving technology[M]. Changsha: Central South University of Technology Press, 1992: 1-4.

[6] MOOSAKAZEMI F, MOHAMMADI M R T, MOHSENI M, KARAMOOZIAN M, ZAKERI M. Effect of design and operational parameters on particle morphology in ball mills[J]. International Journal of Mineral Processing, 2017, 165: 41-49.

[7] LIU Jiong-tian, HAN Long, CORIN K C, O'CONNOR C T. A study of the effect of grinding environment on the flotation of two copper sulphide ores[J]. Minerals Engineering, 2018, 122: 339-345.

[8] 刘书杰, 何发钰. 磨矿环境对黄铁矿矿浆化学性质及浮选行为影响的研究[J]. 矿冶, 2008, 17(4): 6-10.

LIU Shu-jie, HE Fa-yu. Research on effect of grinding environment on pulp chemical property and flotation behavior of pyrite[J]. Mining And Metallurgy, 2008, 17(4): 6-10.

[9] 呼振峰. 磨矿因素对典型硅酸盐矿物浮选的影响[D]. 北京: 北京科技大学, 2017: 62-70.

HU Zhen-feng. Effects of grinding factors on the flotation behaviors of typical silicates[D]. Beijing: University of Science and Technology Beijing, 2017: 62-70.

[10] ZHU Guang-li, WANG Yu-hua, LIU Xiao-wen, YU Fu-shun, LU Dong-fang. The cleavage and surface properties of wet and dry ground spodumene and their flotation behavior[J]. Applied Surface Science, 2015, 357: 333-339.

[11] 刘玉林. 磨矿对黄铁矿和黄铜矿浮选行为的影响研究[D]. 长沙: 中南大学, 2010: 27-39.

LIU Yu-lin. The research on the effect of grinding on the flotation of pyrite and chalcopyrite[D]. Changsha: Central South University, 2010: 27-39.

[12] XIE Wei-ning, HE Ya-qun, WANG Yu-jie, GE Zhen-zhou, WANG Shuai, WANG Hai-feng. Comparison of flotation behavior of middling coal ground by wet-milling with different media[J]. Particulate Science and Technology, 2017, 35(5): 616-620.

[13] RABIEH A, ALBIJANIC B, EKSTEEN J J. A review of the effects of grinding media and chemical conditions on the flotation of pyrite in refractory gold operations[J]. Minerals Engineering, 2016, 94: 21-28.

[14] PENG Hui-qing, WU Di, ABDELMONEM M. Flotation performances and surface properties of chalcopyrite with xanthate collector added before and after grinding[J]. Results in Physics, 2017, 7: 3567-3573.

[15] BRUCKARD W J, SPARROW G J, WOODCOCK J T. A review of the effects of the grinding environment on the flotation of copper sulphides[J]. International Journal of Mineral Processing, 2011, 93(1): 1-13.

[16] KURSUN H, ULUSOY U. Influence of shape characteristics of talc mineral on the column flotation behavior[J]. International Journal of Mineral Processing, 2006, 78(4): 262-268.

[17] ULUSOY U, KURSUN I. Comparison of different 2D image analysis measurement techniques for the shape of talc particles produced by different media milling[J]. Minerals Engineering, 2011, 24(2): 91-97.

[18] LI Cheng-wei, GAO Zhi-yong. Tune surface physicochemical property of fluorite particles by regulating the exposure degree of crystal surfaces[J]. Minerals Engineering, 2018, 128: 123-132.

[19] LI Cheng-wei, GAO Zhi-yong. Effect of grinding media on the surface property and flotation behavior of scheelite particles[J]. Powder Technology, 2017, 322: 386-392.

[20] 罗春梅, 肖庆飞, 郭永杰, 段希祥. 锡矿石细磨介质形状的选择[J]. 昆明理工大学学报(自然科学版), 2008, 33(1): 1-4.

LUO Chun-mei, XIAO Qin-fei, GUO Yong-jie, DUAN Xi-xiang. Selection on fine grinding media shape of tin ore[J]. Journal of Kunming University of Science and Technology (Science and Technology), 2018, 33(1): 1-4.

[21] 吴彩斌, 周意超, 程长敏, 赵汝全, 石贵明, 杨林峰, 王 琛. 不同接触方式磨矿介质的钨矿磨矿动力学分析[J]. 有色金属工程, 2016, 6(4): 58-62.

WU Cai-bin, ZHOU Yi-chao, CHENG Chang-min, ZHAO Ru-quan, SHI Gui-ming, YANG Lin-feng, WANG Chen. Analysis of different contact ways of grinding media in grinding kinetics in tungsten[J]. Nonferrous Metals Engineering, 2016,6(4): 58-62.

[22] CUHADAROGLU D, SAMANLI S, KIZGUT S. The effect of grinding media shape on the specific rate of breakage[J]. Particle & Particle Systems Characterization, 2010, 25(5/6): 465-473.

[23] CORIN K C, SONG Z G, WIESE J G, O'CONNOR C T. Effect of using different grinding media on the flotation of a base metal sulphide ore[J]. Minerals Engineering, 2018, 126: 24-27.

[24] 呼振峰, 孙传尧. 磨矿介质对典型硅酸盐矿物浮选的影响及机理[J]. 工程科学学报, 2016, 38(9): 1221-1226.

HU Zhen-feng, SUN Chuan-yao. Effects and mechanism of different grinding media on the flotation behaviors of typical silicate minerals[J]. Chinese Journal of Engineering, 2016, 38(9): 1221-1226.

[25] 倪帅男, 吴彩斌, 叶景胜, 何水春, 高李明, 温孝进. 顽石与钢球对某铜矿石的磨矿效果对比[J]. 金属矿山, 2017(9): 87-90.

NI Shuai-nan, WU Cai-bin, YE Jing-sheng, HE Shui-chun, GAO Li-ming, WEN Xiao-jin. Contrast experiment of grinding effect between pebble and steel ball on a copper ore[J]. Metal Mine, 2017(9): 87-90.

[26] 顾帼华, 钟素姣. 方铅矿磨矿体系表面电化学性质及其对浮选的影响[J]. 中南大学学报(自然科学版), 2008, 39(1): 54-58.

GU Guo-hua, ZHONG Su-jiao. Electrochemical properties on surface of galena in grinding system and its influence on flotation[J]. Journal of Central South University(Science and Technology), 2008, 39(1): 54-58.

[27] 胡岳华, 孙 伟, 覃文庆. 方铅矿浮选的机械电化学行为[J]. 中国有色金属学报, 2002, 12(5): 1060-1064.

HU Yue-hua, SUN Wei, QIN Wen-qing. Mechanics- electrochemistry action in PbS flotation[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(5): 1060-1064.

[28] 张育才, 林宗寿, 周惠群, 杜跃兰. 不同粉磨方式矿粉颗粒特性的研究[J]. 武汉理工大学学报, 2008, 30(5): 42-46.

ZHANG Yu-cai, LIN Zong-shou, ZHOU Hui-qun, DU Yue-lan. Research on the particle character of slag micro-powder produced by difference grinding method[J]. Journal of Wuhan University of Technology, 2008, 30(5): 42-46.

[29] LI Jia-jie, HITCH M. Ultra-fine grinding and mechanical activation of mine waste rock using a planetary mill for mineral carbonation[J]. International Journal of Mineral Processing, 2017, 158: 18-26.

[30] 印万忠, 唐 远, 迟晓鹏, 马英强. 高压辊磨机在金矿选冶中的应用[J]. 有色金属(选矿部分), 2016(2): 69-74.

YIN Wan-zhong, TANG Yuan, CHI Xiao-peng, MA Ying-qiang. Application of high pressure grinding rolls in the beneficiation and metallurgy of gold ore[J]. Nonferrous Metals(Mineral Processing Section), 2016(2): 69-74.

[31] 李茂林, 汪 彬, 朱 晔, 杨 鑫. 助磨剂对鄂西高磷鲕状赤铁矿磨矿的影响[J]. 武汉科技大学学报, 2011, 34(2): 93-95.

LI Mao-lin, WANG Bin, ZHU Ye, YANG Xin. Influence of grinding aids on grinding of the high phosphorus oolitic hematite from western Hubei Province[J]. Journal of Wuhan University of Science and Technology, 2011,34(2): 93-95.

[32] 黄业豪, 刘 红, 杨永修, 江 闯, 张 伟, 钱功明. 油酸钠对高磷赤铁矿磨矿过程的影响研究[J]. 中国矿业, 2015, 24(5): 111-114.

HUANG Ye-Hao, LIU Hong, YANG Yong-xiu, JIANG Chuang, ZHANG Wei, QIAN Gong-ming. Effect of sodium oleate on the grinding process of high phosphorus hematite[J]. China Mining Magazine, 2015, 24(5): 111-114.

[33] WANG Xiang-huai, XIE Yen. The effect of grinding media and environment on the surface properties and flotation behaviour of sulfide minerals[J]. Mineral Processing & Extractive Metallurgy Review, 1990, 7(1): 49-79.

[34] 刘书杰, 何发钰, 宋振国. 干式磨矿对黄铁矿表面性质及后续浮选的影响[J]. 有色金属, 2009, 61(4): 109-112.

LIU Shu-jie, HE Fa-yu, SONG Zhen-guo. Effect of dry-grinding on surface property and flotation behavior of pyrite[J]. Nonferrous Metals, 2009, 61(4): 109-112.

[35] 何发钰, 孙传尧, 宋 磊. 磨矿环境对方铅矿和闪锌矿矿浆化学性质的影响[J]. 金属矿山, 2006(8): 30-33.

HE Fa-yu, SUN Chuan-yao, SONG Lei. Study on effect of grinding environment on pulp chemistry of galena and sphalerite[J]. Metal Mine, 2006(8): 30-33.

[36] 冯其明. 硫化矿矿浆体系中的电偶腐蚀及对浮选的影响(Ⅰ): 电偶腐蚀原理及硫化矿矿浆体系中的电偶腐蚀模型[J]. 国外金属矿选矿, 1999(9): 2-4.

FENG Qi-ming. Galvanic corrosion in sulfide ore slurry system and its influence on flotation (Ⅰ): Principle of galvanic corrosion and galvanic corrosion model in sulfide ore slurry system[J]. Metallic Ore Dressing Abroad, 1999(9): 2-4.

[37] 冯其明. 硫化矿矿浆体系中的电偶腐蚀及对浮选的影响(Ⅱ): 电偶腐蚀对磨矿介质损耗及硫化矿物浮选的影响[J]. 国外金属矿选矿, 1999(9): 5-8.

FENG Qi-ming. Galvanic corrosion in sulfide ore slurry system and its influence on flotation (Ⅱ): Effect of galvanic corrosion on grinding medium loss and sulfide mineral flotation[J]. Metallic Ore Dressing Abroad, 1999(9): 5-8.

[38] 王琴琴, 宋永胜, 李文娟. 磨矿介质对黄铜矿磨矿体系矿浆电位的影响[J]. 金属矿山, 2010(3): 113-115.

WANG Qin-qin, SONG Yong-sheng, LI Wen-juan. Effect of different grinding media on the pulp potential during chalcopyrite milling[J]. Metal Mine, 2010(3): 113-115.

[39] GAO Zhi-yong, SUN Wei, HU Yue-hua. Mineral cleavage nature and surface energy: Anisotropic surface broken bonds consideration[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(9): 2930-2937.

[40] 高志勇, 孙 伟, 刘晓文, 胡岳华. 白钨矿和方解石晶面的断裂键差异及其对矿物解理性质和表面性质的影响[J]. 矿物学报, 2010, 30(4): 470-475.

GAO Zhi-yong, SUN Wei, LIU Xiao-wen, HU Yue-hua. Influences on cleavage and surface properties by broken bonds in the surface of scheelite and calcite[J]. Acta Mineralogica Sinica, 2010, 30(4): 470-475.

[41] GAO Zhi-yong, LI Cheng-wei, SUN Wei, HU Yue-hua. Anisotropic surface properties of calcite: A consideration of surface broken bonds[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2017, 520: 53-61.

[42] GAO Zhi-yong, SUN Wei, HU Yue-hua, LIU Xiao-wen. Anisotropic surface broken bond properties and wettability of calcite and fluorite crystals[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(5): 1203-1208.

[43] 高跃升, 高志勇, 孙 伟. 萤石表面性质各向异性研究及进展[J]. 中国有色金属学报, 2016, 26(2): 415-422.

GAO Yue-sheng, GAO Zhi-yong, SUN Wei. A review of anisotropic surface properties of fluorite[J]. The Chinese Joumal of Nonferrous Metals, 2016, 26(2): 415-422.

[44] XU Long-hua, TIAN Jia, WU Hou-qin, DENG Wei, YANG Yao-hui, SUN Wei, GAO Zhi-yong, HU Yue-hua. New insights into the oleate flotation response of feldspar particles of different sizes: Anisotropic adsorption model[J]. Journal of Colloid & Interface Science, 2017, 505: 500.

[45] XU Long-hua, HU Yue-hua, WU Hou-qin, TIAN Jia, LIU Jing, GAO Zhi-yong, WANG Li. Surface crystal chemistry of spodumene with different size fractions and implications for flotation[J]. Separation & Purification Technology, 2016, 169: 33-42.

[46] NEIKOV O D, NABOYCHENKO S S, YEFIMOV N A. Handbook of non-ferrous metal powders[M]. 2nd ed. Oxford: Elsevier, 2019: 65-90.

[47] VAZIRI HASSAS B, CALISKAN H, GUVEN O, KARAKAS F, CINAR M, CELIK M S. Effect of roughness and shape factor on flotation characteristics of glass beads[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2016, 492: 88-99.

[48] VERRELLI D I, BRUCKARD W J, KOH P T L, SCHWARZ M P, FOLLINK B. Particle shape effects in flotation. Part 1: Microscale experimental observations[J]. Minerals Engineering, 2014, 58: 80-89.

[49] ULUSOY U, HICYILMAZ C, YEKELER M. Role of shape properties of calcite and barite particles on apparent hydrophobicity[J]. Chemical Engineering and Processing: Process Intensification, 2004, 43(8): 1047-1053.

[50] ULUSOY U, YEKELER M, HICYILMAZ C. Determination of the shape, morphological and wettability properties of quartz and their correlations[J]. Minerals Engineering, 2003, 16(10): 951-964.

[51] YEKELER M, ULUSOY U, HICYILMAZ C. Effect of particle shape and roughness of talc mineral ground by different mills on the wettability and floatability[J]. Powder Technology, 2004, 140(1): 68-78.

[52] HICYILMAZ C, ULUSOY U, YEKELER M. Effects of the shape properties of talc and quartz particles on the wettability based separation processes[J]. Applied Surface Science, 2004, 233(1): 204-212.

[53] ULUSOY U, YEKELER M. Variation of critical surface tension for wetting of minerals with roughness determined by Surtronic 3+ instrument[J]. International Journal of Mineral Processing, 2004, 74(1): 61-69.

[54] HICYILMAZ C, ULUSOY U, BILGEN S, YEKELER M. Flotation responses to the morphological properties of particles measured with three-dimensional approach[J]. International Journal of Mineral Processing, 2005, 75(3): 229-236.

HUANG Zi-jie1, 2, SUN Wei1, 2, GAO Zhi-yong1, 2

(1. School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Hunan Province for Clean and Efficient Utilization of Strategic Calcium-containing Mineral Resources, Central South University, Changsha 410083, China)

Abstract: The influencing mechanisms of grinding environment, grinding medium, mechanical force, mill types and grinding aids on surface properties and flotation behavior of sulfide and oxidized minerals were systematically reviewed. It was concluded that, for sulfide ores, grinding can mainly affect the crystal structure and pulp electrochemical properties of mineral particles. While for oxidized and silicate minerals, grinding dominantly influences the exposure degree of crystal surfaces, reactivity, shape index and roughness of mineral particles, and ultimately exerts influence on mineral flotation behavior. In the near future, the main researches should be concentrated on coordinated optimization of various factors in grinding process to produce mineral particles with specific crystal structure, shape index and crystal surface exposure which will lead to a precise control of mineral flotation behaviour and hence separation efficiency.

Key words: grinding; surface properties; exposed surfaces; crystal structure; flotation

Foundation item: Projects(51774328, 51404300) supported by National Natural Science Foundation of China; Project (2016YFE0101300) supported by Key Program for International Science and Technology Cooperation Projects of China; Project(2017QNRC001) supported by China Association for Science and Technology; Project(2018JJ2520) supported by the Natural Science Foundation of Hunan Province, China; Project(2018RS3011) supported by the Department of Science and Technology of Hunan Province, China; Project(2017CX007) supported by the Innovation Driven Plan of Central South University, China

Received date: 2018-12-28; Accepted date: 2019-06-20

Corresponding author: GAO Zhi-yong; Tel: +86-731-88876697; E-mail: zhiyong.gao@csu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51774328,51404300);国家国际科技合作计划项目(2016YFE0101300);中国科协青年人才托举工程项目(2017QNRC001);湖南省自然科学基金资助项目(2018JJ2520);湖湘青年英才计划资助项目(2018RS3011);中南大学创新驱动计划项目(2017CX007)

收稿日期:2018-12-28;修订日期:2019-06-20

通信作者:高志勇,教授,博士;电话:0731-88876697;E-mail:zhiyong.gao@csu.edu.cn