基于少齿数的非对称渐开线齿轮主动设计

田兴,李威

(北京科技大学 机械工程学院,北京,100083)

摘要:为了提高齿轮的传动能力,研究少齿非对称渐开线直齿轮的设计方法。采用齿条刀具的切向变位,设计非对称双圆角齿条刀具,推导包括变位的非对称齿轮全齿廓直角坐标方程和无侧隙啮合条件。分析非对称渐开线少齿数齿轮的根切现象,求解不同齿数的齿轮根切点压力角。采用基于少齿数的非对称渐开线直齿轮主动设计方法计算不同齿数齿轮副啮合的参数以及所能达到的最大传动重合度。研究结果表明:采用主动设计方法,齿轮能达到最大的传动重合度;当小齿轮齿数为4时,大齿轮的最小齿数为7。

关键词:切向变位;少齿数;主动设计;根切

中图分类号:TH132 文献标志码:A 文章编号:1672-7207(2013)03-0955-08

Direct Design for asymmetric involute gear based on small teeth

TIAN Xing, LI Wei

(School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: In order to improve the gear capacity, asymmetric involute gear based on small teeth was discussed. Tangential modification with rack cutter was used, asymmetric rack cutter with double radii was designed, and total tooth profile equations with modification and no lateral clearance meshing for the asymmetric gear were derived. Undercut phenomenon for asymmetric involute gear with small number of teeth was analyzed. The pressure angle at undercut point with different numbers of teeth was solved. Using the direct design method for asymmetric involute gear with small number of teeth, the gearing mesh parameters and the maximum contact ratio were calculated. The results show that the maximum contact ratio can be obtained using the direct design method. The minimum number of gear tooth is 7 when the pinion teeth number is 4.

Key words: tangential modification; small number of teeth; direct design; undercutting

传统的标准齿轮设计虽然在齿轮的互换性和刀具低库存方面有很大优势[1-3],但是随着齿轮传动向高速和高效率方向发展(如航空航天领域和汽车行业),标准齿轮在接触和弯曲应力、齿面润滑等方面表现出来的缺点愈加明显[4-6]。为了满足用户日益苛刻的订制需求,齿轮的主动设计方法应运而生。本文主动设计方法主要针对少齿数非对称渐开线直齿圆柱齿轮进行研究。非对称齿轮由Yoerkie等[6-8]提出,肖望强等[9-10]对此种齿形进行了研究。在非对称齿轮的基础上,唐进元等[11-14]对少齿数齿轮副啮合情况进行了理论分析。由于少齿数的非对称渐开线直齿轮涉及根切情况,它的结构比普通非对称渐开线齿轮的结构复杂,目前国内对该齿形的研究很少。本文作者在变位的基础上,对齿条刀具、全齿廓方程和根切现象进行分析,对适用于单向传动的齿轮潜在设计思想和基于少齿数的非对称齿轮的主动设计方法进行研究,并运用ANSYS参数化设计语言(APDL)实现了齿轮的参数化建模。

1 齿轮的变位

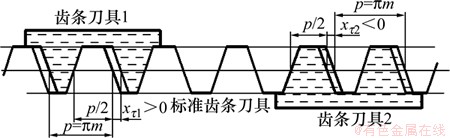

在设计渐开线啮合齿轮时,通过改变齿轮的几何尺寸来提高齿轮的性能,其中大都采取了径向变位。径向变位的主动轮1和从动轮2的径向变位系数分别为x1和x2。不同齿数的主动轮和从动轮啮合的封闭图的边界条件决定了x1和x2的范围。在径向变位的同时,采用切向变位可以使传统的齿轮封闭图区域扩大, 增加轮齿强度和防止齿顶变尖,尤其适用于少齿数齿轮的设计。齿条刀具的切向变位如图1所示,其中: 为切向变位系数,规定齿条刀具齿宽减小方向为切向正变位;m为模数。

为切向变位系数,规定齿条刀具齿宽减小方向为切向正变位;m为模数。

图1 标准齿条刀具的切向变位

Fig.1 Basic rack cutter with tangential modification

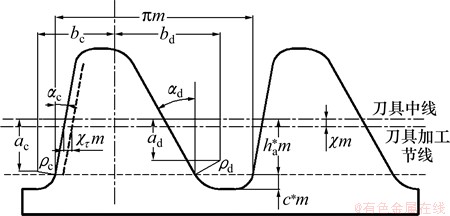

2 非对称齿条刀具的齿形方程

图2所示为非对称双圆角齿条刀具的齿廓示意图。基本齿廓由双圆角和直线组成。齿条刀具斜直线切出非对称齿轮的渐开线部分,圆角切出非对称齿轮的齿根过渡曲线部分,圆角顶端直线切出非对称齿轮的齿根圆部分。

图2 非对称双圆角齿条刀具

Fig.2 Asymmetric rack cutter with double radii

经过简单几何推导,可以得到如下几何关系式:

(1)

(1)

(2)

(2)

(3)

(3)

式中: 和

和 分别为非工作侧和工作侧齿形角;

分别为非工作侧和工作侧齿形角; 和

和 分别为非工作侧和工作侧圆角。

分别为非工作侧和工作侧圆角。

3 非对称渐开线直齿齿廓方程推导

3.1 渐开线齿廓方程的建立

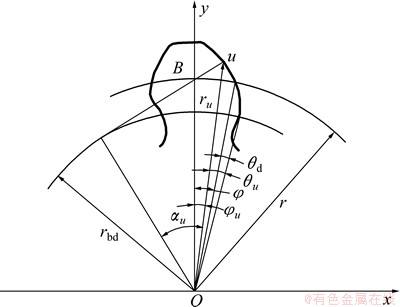

非对称渐开线齿廓是由2个不同直径的基圆展成的渐开线组成。以齿轮基圆圆心O为坐标系原点,以非对称齿轮轮齿的分度圆中心点B与点O的连线作为纵坐标y,建立如图3所示的直角坐标系。

图3 渐开线齿廓直角坐标图

Fig.3 Involute profile coordinate system

在非对称渐开线工作侧齿廓上任取一点u(x, y),可以推导出非对称齿轮工作侧渐开线齿廓方程为:

(4)

(4)

式中:inv为渐开线函数, ;

;  ;

; 为工作侧渐开线齿廓起始点的压力角;

为工作侧渐开线齿廓起始点的压力角; 为工作侧齿顶圆的压力角,

为工作侧齿顶圆的压力角,

在非对称渐开线非工作侧齿廓上任取1点v(x, y),可以推导出非对称齿轮非工作侧渐开线齿廓方程为

(5)

(5)

式中, 。

。 为非工作侧渐开线齿廓起始点的压力角,

为非工作侧渐开线齿廓起始点的压力角, 为非工作侧齿顶圆的压力角。

为非工作侧齿顶圆的压力角。

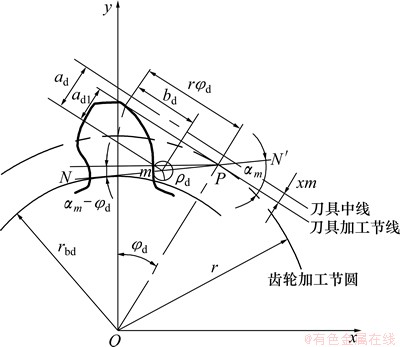

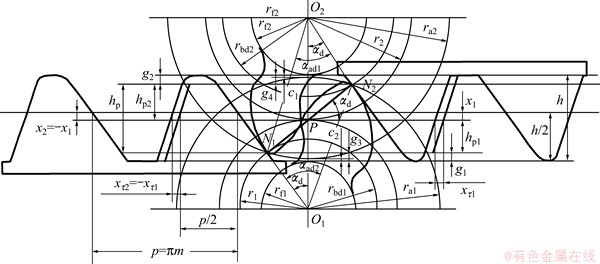

3.2 齿根过渡曲线方程的建立

如图4所示,点P为齿条刀具的加工节线与齿轮的加工节圆的交点,即节点。直线NN′是齿条刀具齿顶圆角与齿根过渡曲线接触点的公法线。在工作侧齿根过渡曲线上任取一点m(x, y),推导出延伸渐开线等距曲线参数方程为

(6)

(6)

图4 过渡曲线直角坐标图

Fig.4 Coordinate system of transition curve

式中: ,

, 90°。

90°。

在非工作侧齿根过渡曲线上任取1点n(x, y),推导出延伸渐开线等距曲线参数方程为

(7)

(7)

式中: ,

, 90°。

90°。

4 非对称渐开线齿轮无侧隙啮合条件

当一对非对称渐开线齿轮啮合时,为了保证两齿轮的分度圆做无滑动的纯滚动,齿轮1分度圆槽宽应等于齿轮2分度圆的齿厚,非对称齿轮无侧隙啮合的方程为

(8)

(8)

5 齿轮的根切

在应用范成法加工齿轮时,受到齿数的限制,当齿数少到一定程度的时候即发生根切,这对于在某些需要减少齿数的场合是极其不利的。限制根切的条件为[15-16]

(9)

(9)

根切会导致齿轮齿根厚度减小和重合度降低。但是,在设计非对称少齿数齿轮时,根切现象不可避免。因此,限制非对称齿轮工作侧根切而让非工作侧根切产生根切的方案势在必行。

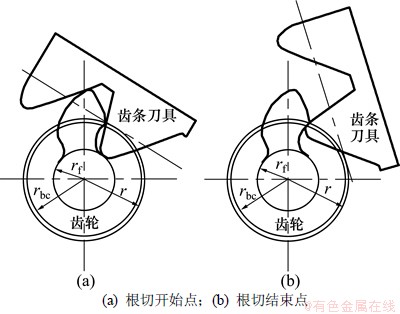

当齿轮齿数很少,而非工作侧压力角也较小时,非对称齿轮非工作齿侧必然发生根切,根切过程如图5所示。在图5(a)中,齿条刀具的圆角齿顶部分开始加工非对称齿轮非工作侧的过渡曲线;加工至图5(b)状态时,齿轮过渡曲线已完成非工作侧过渡曲线的加工。若渐开线齿廓曲线和齿根过渡曲线的交点为k,那么点k即为根切点。联立渐开线参数方程(5)和过渡曲线参数方程(7),令

图5 根切过程示意图

Fig.5 Undercut process schemes

(10)

(10)

根据方程组(10)可以解出 和

和 。此时,

。此时, 就是点k处的渐开线齿廓的压力角。由于此方程组是

就是点k处的渐开线齿廓的压力角。由于此方程组是 和

和 的复杂函数,需要利用数学计算软件MATLAB来解决非线性方程组的求解问题。

的复杂函数,需要利用数学计算软件MATLAB来解决非线性方程组的求解问题。

以模数m=10、齿顶高系数 、切向变位系数xt=0、顶隙系数c*=0.1、工作侧压力角

、切向变位系数xt=0、顶隙系数c*=0.1、工作侧压力角 和非工作侧压力角

和非工作侧压力角 为例,计算不同的x和z的情况下根切点压力角

为例,计算不同的x和z的情况下根切点压力角 。

。

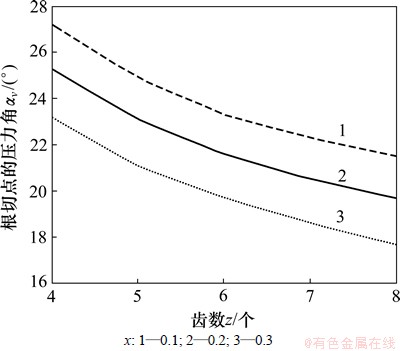

用MATLAB的曲线拟合功能,绘制出齿数z与根切点压力角 的关系,如图6所示。

的关系,如图6所示。

图6 齿数z与根切点压力角 的关系曲线

的关系曲线

Fig.6 Relation curve with number of teeth and pressure angle at undercut Point

从图6可以看出:随着齿数z和径向变位系数x的增加,根切点的压力角 逐渐减小,这说明根切的程度越来越弱;当齿数增大到一定值时,根切现象消失。

逐渐减小,这说明根切的程度越来越弱;当齿数增大到一定值时,根切现象消失。

6 齿轮的潜在设计方法

由于非对称齿轮主要用于单向传动,因此,主要研究工作侧齿廓的啮合情况。传统理论方法设计齿轮时,实际啮合线要比理论啮合线短。此时非对称齿轮在传动方向上的重合度计算公式为

(11)

(11)

当齿轮副齿数减少时,传动重合度很有可能小于1,因此,齿轮设计的重点是尽可能延长实际啮合线。基于潜在设计方法的渐开线啮合如图7所示。当实际啮合线与理论啮合线相等,重合度到达理论上的最大值时,啮合线开始于点N1,结束于点N2。齿顶圆ra1和齿顶圆ra2分别过啮合线的结束点N2和起始点N1。于是,非对称齿轮在传动方向上的重合度计算公式为

(12)

(12)

本文采用等变位齿轮传动,变位系数之和X1+X2=0, 。此时,非对称齿条刀具的齿形角等于非对称齿轮的压力角。

。此时,非对称齿条刀具的齿形角等于非对称齿轮的压力角。

为了确定图7中齿轮的参数,预先选取啮合的一对齿轮的齿数z1和z2,模数m以及齿轮的潜在重合度 (

( ≥1),根据式(12),计算非对称齿轮工作侧的压力角

≥1),根据式(12),计算非对称齿轮工作侧的压力角 :

:

(13)

(13)

然后,根据图7可以得到齿顶圆压力角为

(14)

(14)

以节点P为界点,齿条刀具斜直线部分高度为:

(15)

(15)

根据式(15),非对称齿条刀具斜直线部分高度之和为:

(16)

(16)

非对称齿条刀具圆角高度为

(17)

(17)

非对称齿条刀具齿全高为

(18)

(18)

非对称齿轮的径向变位系数为

(19)

(19)

非对称齿轮齿顶圆的齿顶厚为

(20)

(20)

为了保证轮齿不被折断,通常

;i=1, 2 (21)

;i=1, 2 (21)

当sa1=sa2时,可求得切向变位均衡系数 为:

为:

(22)

(22)

图7 基于潜在设计方法的渐开线啮合

Fig.7 Involute meshing based on Potential method

7 少齿数非对称渐开线直齿轮的主动设计和建模

对于少齿数双压力角非对称渐开线圆柱直齿齿轮的设计,需要确定以下参数:模数m、齿数z、齿顶高系数 、非工作侧压力角

、非工作侧压力角 、工作侧压力角

、工作侧压力角 、径向变位系数x,切向变位系数

、径向变位系数x,切向变位系数 、顶隙系数c*。

、顶隙系数c*。

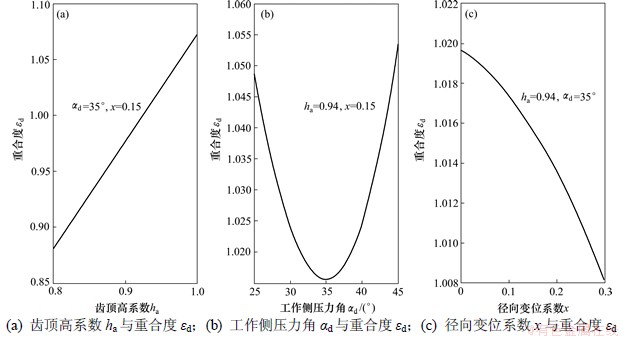

图8所示为非对称齿轮的重合度 与齿顶高系数

与齿顶高系数 、工作侧的压力角

、工作侧的压力角 、径向变位系数x的关系。从图8可以看出:径向变位系数x对重合度

、径向变位系数x的关系。从图8可以看出:径向变位系数x对重合度 影响最小;其次是工作侧压力角

影响最小;其次是工作侧压力角 ;齿顶高系数

;齿顶高系数 对重合度

对重合度 影响最大。随着

影响最大。随着 的增大,非对称齿轮的重合度

的增大,非对称齿轮的重合度 显著增大。因此,在满足不根切和齿顶厚合格的情况下,应尽可能增大

显著增大。因此,在满足不根切和齿顶厚合格的情况下,应尽可能增大 。

。

在设计齿轮时,模数m、齿数z和非工作侧压力角 可以预先确定,其余的参数通过以下步骤确定:

可以预先确定,其余的参数通过以下步骤确定:

步骤1:确定径向变位系数x。由于本文采取等高变位,因此,取 。根据式(13),(14)和(19),可以得到径向变位系数x:

。根据式(13),(14)和(19),可以得到径向变位系数x:

(23)

(23)

步骤2:齿顶高系数 和工作侧压力角

和工作侧压力角 的确定。将确定的径向变位系数x代入式(9),初取齿顶高系数

的确定。将确定的径向变位系数x代入式(9),初取齿顶高系数 ,算出符合不根切条件的工作侧压力角

,算出符合不根切条件的工作侧压力角 的最大值。然后代入式(12),计算出实际重合度。若重合度小于1,则可以适当增加工作侧压力角

的最大值。然后代入式(12),计算出实际重合度。若重合度小于1,则可以适当增加工作侧压力角 ,代入式(9)得到相应的

,代入式(9)得到相应的 ,再代入式(12)验算重合度是否大于1。若满足条件,则用齿顶厚条件(21)验算齿顶厚是否满足条件;若不满足齿顶厚条件,则适当减小工作侧压力角

,再代入式(12)验算重合度是否大于1。若满足条件,则用齿顶厚条件(21)验算齿顶厚是否满足条件;若不满足齿顶厚条件,则适当减小工作侧压力角 后,再代入式(9),得到相应的

后,再代入式(9),得到相应的 ,验算重合度

,验算重合度 和齿顶厚sa,直到满足条件为止。

和齿顶厚sa,直到满足条件为止。

图8 重合度εd与相关参数的关系

Fig.8 Relationship between contact ratio εd and related parameters

步骤3:切向变位系数 的确定。将确定的参数x,

的确定。将确定的参数x, 和

和 代入式(22)即可得到切向变位系数

代入式(22)即可得到切向变位系数 。

。

步骤4:顶隙系数c*的确定。为了保证齿条刀具为双圆角,必须满足下面的顶隙系数的条件:

(24)

(24)

由于齿条刀具1采取的是切向正变位,齿条刀具2采取的是切向负变位,显然, <

< ,因此,满足

,因此,满足 <

< 即可。

即可。

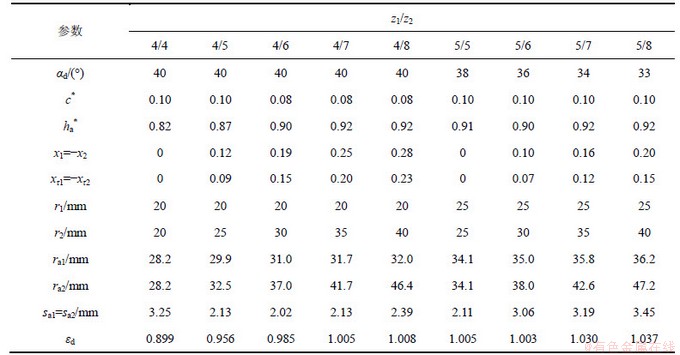

运用主动设计方法,分别计算了不同齿数的各齿轮副(z2/z1≥1)啮合参数以及最大传动重合度,结果见表1。

从表1可以看出:当z1确定时,随着z2的增加,齿轮的径向变位系数x1和切向变位系数 会相应的增大,非对称齿轮的重合度也会逐渐增大。当z1=4时,要满足非对称齿轮重合度

会相应的增大,非对称齿轮的重合度也会逐渐增大。当z1=4时,要满足非对称齿轮重合度 ≥1的条件,z2的最小齿数为7。当z1≥5时,只要z2/z1≥1,非对称齿轮重合度

≥1的条件,z2的最小齿数为7。当z1≥5时,只要z2/z1≥1,非对称齿轮重合度 ≥1恒成立。

≥1恒成立。

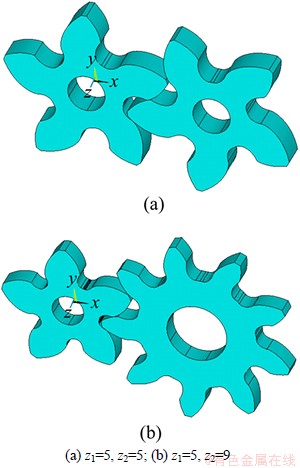

采用ANSYS对齿轮进行参数化建模。首先,根据已知参数生成一个轮齿端面,然后经过旋转复制生成一个完整的齿轮,最后拉伸生成一个完整的齿轮实体。基于APDL语言的参数化建模技术,实现了渐开线圆柱齿轮几何模型的参数化设计。图9所示为不同齿数的齿轮副啮合情况。

表1 齿轮副啮合参数

Table 1 Gear meshing parameters

图9 齿轮副啮合建模

Fig.9 Gear meshing modeling

8 结论

(1) 在齿轮设计过程中,采用切向变位,可以增加轮齿强度和防止齿顶变尖,尤其适用于少齿数齿轮的设计。

(2) 推导了包括变位的非对称齿轮全齿廓直角坐标方程和无侧隙啮合条件,通过联立渐开线参数方程和过渡曲线参数方程,解出根切点压力角的具体数值,解释了齿轮根切程度的趋势。

(3) 运用主动设计方法,计算不同齿数的齿轮副啮合的参数以及齿轮副啮合所能达到的最大传动重合度。当z1=4时,要满足非对称齿轮重合度εd≥1的条件,z2的最小齿数为7;当z1≥5时,只要z2/z1≥1,非对称齿轮重合度εd≥1恒成立。

参考文献:

[1] Kapelevich A. Synthesis of asymmetric involute gearing[J]. Sov Mach Sci, 1987, 8(1): 554-561.

[2] Kapelevich A. Geometry and design of involute spur gears with asymmetric teeth[J]. Mechanism and Machine Theory, 2000, 35(1): 117-130.

[3] Kapelevich A. Direct gear design for spur and helical gears[J]. Gear Technology, 2002, 19(3): 29-35.

[4] Kapelevich A. Application of gears with asymmetric teeth in turboprop engine gearbox[J]. Gear Technology, 2008, 25(1): 60-65.

[5] Kapelevich A, Shekhtman Y. Tooth fillet profile optimization for gears with symmetric and asymmetric teeth[J]. Gear Technology, 2009, 26(7): 73-79.

[6] Yoerkie C. Acoustic vibration characteristics of high contract ration planetary gears[C]//Chory A G. 40th Annual Forum Proceedings. Moskow: Alexandria, 1984: 19-20.

[7] Kumar V, Muni D, Muthuveerappar G. Optimization of asymmetric spur gear drives to improve the bending load capacity[J]. Mechanism and Machine Theory, 2008, 43(7): 829-858.

[8] 黄中华, 张晓建, 周玉军. 渐开线齿轮啮合碰撞力仿真[J]. 中南大学学报: 自然科学版, 2011, 42(2): 379-383.

HUANG Zhonghua, ZHANG Xiaojian, ZHOU Yujun. Simulation of contact force of involute gear meshing[J]. Journal of Central South University: Science and Technology, 2011, 42(2): 379-383.

[9] 肖望强, 李威, 李梅. 双压力角非对称齿廓齿轮齿根弯曲应力的有限元分析[J]. 北京科技大学学报, 2006, 28(6): 570.

XIAO Wangqiang, LI Wei, LI Mei. Finite element analysis of the tooth root bending stress of an unsymmetric gear with double pressure angles[J]. J Univ Sci Technol Beijing, 2006, 28(6): 570.

[10] Litvin F, Fuentes A. Gear geometry and applied theory[M]. Cambridge University Press, 2004: 125-127.

[11] 唐进元, 刘艳萍, 周长江, 等. 基于APDL与高级语言的齿轮有限元建模方法[J]. 机械传动, 2007, 31(3): 21-23.

TANG Jinyuan, LIU Yanping, ZHOU Changjiang, et al. Gear finite element modeling method based on APDL and high-level language[J]. Mechanical Transmission, 2007, 31(3): 21-23.

[12] Arnaudov K, Dimitrov I, Iordanov P. Machine elements[M]. Sofia: Technika, 1980: 542-543.

[13] Alipiev O. Generalized dependencies of the tooth width of involute gears with profile and tangential asymmetry[J]. Mechanics of Machines, 2007, 15(3): 70-74.

[14] Alipiev O. Geometric calculation of involute spur gears defined with generalized basic rack[J]. Theory of Mechanisms and Machines, 2008, 12(2): 60-70.

[15] Alipiev O. Geometric design of involute spur gear drives with symmetric and asymmetric teeth using the Realized Potential Method[J]. Mechanism and Machine Theory, 2011, 46(1): 10-32.

[16] Costopoulos T. Reduction of gear fillet stresses by using one-sided involute asymmetric teeth[J]. Mechanism and Machine Theory, 2009, 44(8): 1524-1534.

(编辑 赵俊)

收稿日期:2012-02-20;修回日期:2012-05-25

基金项目:国家自然科学基金资助项目(51275035);冶金研究基金资助项目(YJ2010-007)

通信作者:田兴(1986-),男,湖南常德人,博士研究生,从事机械设计及控制与制造技术的研究;电话:13466756883;E-mail: beikejixietianxing@163.com