Preparation of spray deposited aluminum alloy sheets via novel rolling technique

ZHANG Hao(张昊), CHEN Zhen-hua(陈振华), YAN Hong-ge(严红革),

CHEN Ding(陈鼎), LI Wei(李微)

College of Materials Science and Engineering, Hunan University, Changsha 410082, China

Received 15 July 2007; accepted 10 September 2007

Abstract: A novel ceramic rolling technique was developed to improve the formability of spray deposited porous aluminum alloy sheets, in which the sheet preform was canned and ceramic particulates were adopted as the medium for transferring pressure to make a homogenous hydrostatic stress field. The fractional thickness deformation, fractional longitudinal elongation, and fractional lateral spreading were calculated from the dimensions of samples before and after ceramic rolling. The results show that the flowing of metals in the longitudinal and transverse directions can be restrained during rolling. So ceramic rolling can effectively improve the density of the spray deposited performs. When the thickness reduction ratio is up to about 60%, the full density preforms can be obtained. The effect of the kinds of ceramic particulates, including Al2O3, SiO2 and graphite on the densification behavior of the preforms during rolling was investigated. The results imply that the Al2O3 particles with the size of about 74 μm are most effective.

Key words: aluminum alloy; ceramic rolling; spray deposition; densifying

1 Introduction

As an advanced material preparation technology, spray deposition has been widely used to produce alloys and metal matrix composites[1-3]. In principle, the spray deposited preforms usually exhibit limited mechanical properties due to the porosity and a lack of sound metallurgical bond between the particles[4]. Higher performance can be achieved by further densification and deformation. However, comparing with the fully dense materials, the deformation of spray deposited preforms is very complicated and difficult because of the existence of porosity and oxidation film on the surface of the deposited particles.

Densification of porous metal preforms by hot working requires shearing the pores so that they collapse and the porosity is eliminated[5]. Unlike the densification of porous metal by close-die forge or extrusion via a high hydrostatic stress field, densification of porous metal during rolling occurs under a generalized stress field having both hydrostatic and deviatoric components.

The application of such a stress field on porous materials causes flattening of pores and brings about rapid densification by collapsing the pores at a faster rate. Rolling processing is an effective fabrication process for obtaining a fully-density product from a spray deposited porous preform. However, elongation and spreading in longitudinal and transverse directions easily lead to surface and side cracks during rolling when the as-deposited particles lack sound metallurgical bonds.

In the case of hot rolling of a fully dense material, since the bulk volume maintains constant, a decrease in thickness results in the increase in length and spreading in width. However, in the case of porous materials, volume changes take place during rolling and the longitudinal and transverse flow are significantly lower than that of a fully dense material when given the same amount of thickness deformation[6].

During the past decades, many advanced techniques such as cyclic pressing and pseudo-HIP were developed, which were verified to be effective in powder pressing[7-9]. To date, however, there has been little attempt to improve the formability of spray deposited porous preforms. In the present study, a novel rolling technique was developed. The flow and densification behaviors of preforms during rolling process were examined.

2 Experimental

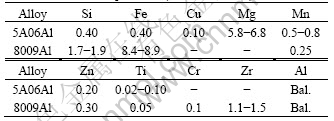

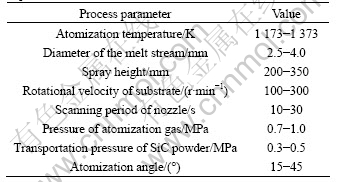

The spray deposited materials 5A06Al and 8009Al/SiCp were served as the raw material, and the compositions are given in Table 1. SiC particles with a volume fraction of 15% and mean size of about 10 μm were selected as the reinforcement phase. And these alloys were prepared by a multilayer spray deposition technique developed by the authors. The processing parameters of the spray deposition experiments are given in Table 2. The initial relative density of the 5A06Al and 8009Al/SiCp were about 72% and 76%, respectively. A schematic diagram of the multilayer spray deposition equipment is shown in Fig.1.

Table 1 Material compositions (mass fraction,%)

Table 2 Process parameters of multi-layer spray deposition experiment

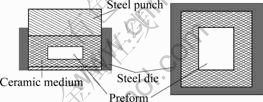

The preforms of 5A06Al and 8009Al/SiCp with the dimensions of 30 mm×30 mm×8 mm were selected to study the densification behavior during the ceramic rolling. The schematic diagrams are shown in Fig.2. The dimensions of punch were 95 mm×95 mm×20 mm. The Al2O3, SiO2 and graphite particles with the size of about 74 μm were used as the pressure transmission medium during rolling. The hot rolling was performed on a two-high mill with rolls of 360 mm in diameter and 600 mm in length. The nominal rolling speed was 0.43 m/s. The preforms were preheated for 1 h before rolling and reheated for 30 min between each pass in a furnace operated at 733 K.

The mechanical properties of the composite were examined by means of tensile testing at a tensile velocity of 0.5 mm/min at room temperature. The tensile fracture structures of preforms were characterized by scanning electron microscopy (JSM-6700F).

Fig.1 Schematic diagram of multilayer spray deposition device for cylindrical billets preparation

Fig.2 Schematic illustration of ceramic rolling

All the procedure was repeated, an average of four to five measurements was taken for each parameter.

3 Results and discussion

3.1 Deformation characteristics and density evolution during rolling

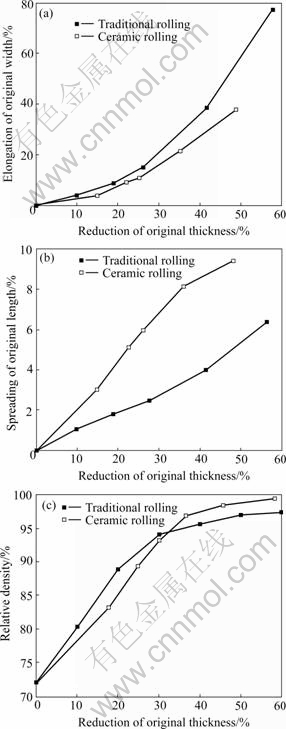

The deformation behaviors of 5A06Al alloy preform were reflected by the developing of elongation, spreading measure and relative density with thickness reduction during the ceramic rolling and traditional rolling processes, as indicated in Fig.3. When the Al2O3 particles are concerned, it can be found that, in comparison with the traditional rolling, the ceramic- rolled samples exhibit distinctly higher spreading measure. It can be easily explained that the ceramic particles could reduce the friction which operate on preform, so the resisting force of metal flow caused by friction decreases obviously. Both samples show similar elongation and density when the thickness reduction ratio is less than 30%. By contrast, a remarkable lower elongation is attained for the ceramic-rolled samples and densification increase with increasing thickness reduction ratio. In the primary stage of ceramic rolling process, the ceramic particles is loosening, the effect of rejection for metal flow is less. As rolling proceeded, the ceramic particles are compacted and serve the function of rejection of metal flow and densification. The deformation and densification of 8009Al/SiCp are similar to those of the 5A06Al alloy samples.

Fig.3 Effect of thickness reduction on elongation (a), spreading (b) and relative density (c) of porous material

During traditional rolling, transversal cracks usually occur on the surface of preform when the thickness reduction is up to 26.5%. But in the processing of ceramic rolling, no cracks appear while the thickness reduction is 60%. When the thickness reduction is up to 47.5%, the sample can be directly rolled by traditional rolling process without cracks.

3.2 Microstructure evolution and mechanical property

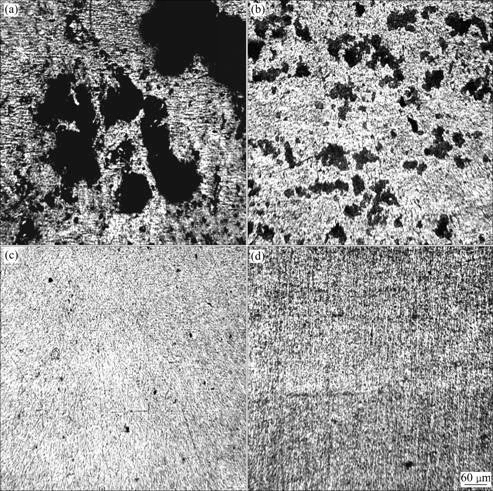

The microstructure evolution of the 5A06Al alloy sample during ceramic rolling is shown in Fig.4. There are many pores with various sizes distributed irregularly in the spray deposited alloy preform. As ceramic rolling proceeds, large pores in some local regions collapse into numerous smaller pores (Fig.4(b)). When the thickness reduction is 43.5%, the pores have almost vanished (Fig.4(c)), and due to the plasticity deformation, streaky structure appear when the thickness reduction is 60% (Fig.4(d)).

The room-temperature mechanical properties of 8009Al/SiCp preforms processed by ceramic rolling and traditional rolling are given in Table 3.

Table 3 Room temperature mechanical properties of 8009Al/ SiCp

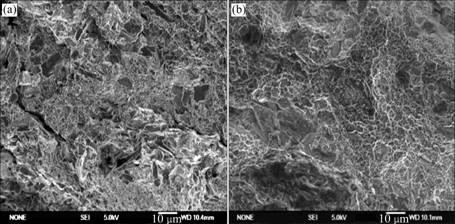

It can be found that, the tensile strength and elongation increase with the increasing of thickness reduction. It can be explained that, as the rolling proceeds, the pores decrease and density augment, the metallurgical bond between the particles can be obtained. As seen from Fig.5, when the thickness reduction is 25%, there are pores in the fractographs and the bond between the SiC particles and matrix is feebleness (Fig.5(a)). No pores can be found and the fracture surface presents dimple structure, as shown in Fig.5(b).

3.3 Effect of kinds of ceramic particles

In order to investigate the effect of different kinds of ceramic particles on densification behavior, Al2O3, SiO2 and graphite particles with the size of about 74 μm were adopted. Fig.6 shows the densification behaviors of 8009Al/SiCp spray deposited preforms during ceramic rolling with various ceramic particulates.

Fig.4 Evolution of microstructures with different thickness reduction during ceramic rolling: (a) 0; (b) 20%; (c) 43.5%; (d) 60%

Fig.5 Tensile fracture structures of 8009Al/SiCp with different thickness reduction during ceramic rolling: (a) 25%; (b) 50%

It is obviously that the Al2O3 particles have the best effect of densification, which is consistent with the experimental result. The compressing and densification are difficult for ceramic particles, so in the process of ceramic rolling, the Al2O3 particles can transfer the rolling pressure to preform effectively[10]. There are two reasons about the importance of the original hardness of ceramic particles. One is that the hardness of ceramic particles would affect the pressure distribution in die cavity, if the hardness is small, the interacting of particles would cause the plastic flow of particles under the impressed pressure, leading to inhomogeneous distribu tion of pressure. And the other is that the plastic flow of ceramic particles can influence the deformation of preform and cause distortion of preform and densification incomplete.

Fig.6 Effect of thickness reduction and ceramic particles on relative density of 8009Al/SiCp performs

4 Conclusions

1) The novel rolling technique, ceramic rolling, can effectively densify the spray deposition preforms and avoid cracks which usually occur during the traditional rolling processing.

2) The microstructure and mechanical property of spray deposited materials can be improved by ceramic rolling processing.

3) Al2O3 particles are more proper to serve as the rolling medium than SiO2 and graphite particles.

Acknowledgement

The authors would like to thank CHEN Gang, SUN You-ping and HE Yi-qiang for preparation of the porous preforms. We would also like to thank LI Jian-jian and WU Heng for their careful preparation of the compression workpieces.

References

[1] BERGMANN D, FRITSCHING U. Sequential thermal modelling of the spray-forming process [J]. International Journal of Thermal Sciences, 2004, 43: 403-415.

[2] LAVERNIA E J, GRANT N J. Spray deposition of metals: A review [J]. Material Science and Engineering A, 1988, 98: 381-394.

[3] SKINNER D J, BYE R L, RAYBOULD D, BROWN A M. Dispersion strengthened Al-Fe-V-Si alloys [J]. Scripta Metallurgica, 1986, 20(6): 867-872.

[4] KIM H S. Densification mechanisms during hot isostatic pressing of stainless steel powder compacts [J]. Journal of Materials Processing Technology, 2002, 123(2): 319-322.

[5] BHARGAVA S, DUBE R K. Changes in the longitudinal flow and apparent plastic Poisson’s ratio of a porous metal strip during hot densification rolling [J]. Metall Trans A, 1988, 19(5): 1205-1211.

[6] CHEN Z H, ZHAN M Y, XIA W J. Putting on the squeeze to improve porous metal density [J]. Metal Powder Report, 2004, 59(9): 40-47.

[7] TANG F, HAGIWARA M, SCHOENUNG J M. Formation of coarse-grained inter-particle regions during hot isostatic pressing of nanocrystalline powder [J]. Scripta Materialia, 2005, 53(6): 619-624.

[8] PALM M, PREUHS J, SAUTHOFF G. Production scale processing of a new intermetallic NiAl-Ta-Cr alloy for high-temperature application (Part II): Powder metallurgical production of bolts by hot isostatic pressing [J]. Journal of Materials Processing Technology, 2003, 136(3): 114-119.

[9] WEGMANN G, GERLING R, SCHIMANSKY F P. Temperature induced porosity in hot isostatically pressed gamma titanium aluminide alloy powders [J]. Acta Materialia, 2003, 51(3): 741-752.

[10] KUHN H A, FERGUSON B L, SIMITH O D. Pseudo-HIP using conventional presses [J]. Metal Powder Report, 1983, 38(6): 321-323.

Foundation item: Project(06FJ3041) supported by Science and Technology Bureau of Hunan Province, China

Corresponding author: CHEN Zhen-hua; Tel/Fax: +86-731-8821648; E-mail: zhanghao0122@21cn.com

(Edited by YUAN Sai-qian)