Cu-Nb合金薄膜的微观结构与辐照损伤

来源期刊:稀有金属2021年第3期

论文作者:于开元 李彦 孙祎帆 张干 张展瑄

文章页码:372 - 377

关键词:Cu-Nb合金;薄膜;辐照损伤;非晶;

摘 要:采用真空磁控溅射共溅法制备了CuxNb100-x(x=15,25,35,50,65,75,85,%,原子分数)7种成分的合金薄膜,采用氦(He)离子注入手段对合金薄膜进行室温辐照改性,利用X射线衍射仪(XRD)、透射电子显微镜(TEM)和纳米压痕仪研究了辐照前后合金薄膜的微观形貌、相组成与力学特性。结果显示:当Cu含量≤25%或≥75%时,合金薄膜由单一晶体相构成,晶粒形貌为等轴晶,尺寸约为100 nm,前者晶界处有Cu富集,后者晶界处有Nb富集;经He离子辐照后,He泡均匀分布于晶粒内,未见明显偏聚;辐照后样品的纳米压痕硬度显著高于未辐照样品,呈现辐照硬化。当Cu含量为35%~65%时,合金薄膜由晶体与非晶双相构成,其中晶体相为颗粒状,尺寸为10~20 nm,均匀分布于非晶基体中;经He离子辐照后,He泡主要分布于晶体/非晶界面处,晶体或非晶相内部的He泡难以分辨;辐照后样品的纳米压痕硬度低于未辐照样品,呈现辐照软化。

稀有金属 2021,45(03),372-377 DOI:10.13373/j.cnki.cjrm.XY20110004

于开元 李彦 孙祎帆 张干 张展瑄

中国石油大学(北京)新能源与材料学院

采用真空磁控溅射共溅法制备了CuxNb100-x(x=15,25,35,50,65,75,85,%,原子分数)7种成分的合金薄膜,采用氦(He)离子注入手段对合金薄膜进行室温辐照改性,利用X射线衍射仪(XRD)、透射电子显微镜(TEM)和纳米压痕仪研究了辐照前后合金薄膜的微观形貌、相组成与力学特性。结果显示:当Cu含量≤25%或≥75%时,合金薄膜由单一晶体相构成,晶粒形貌为等轴晶,尺寸约为100 nm,前者晶界处有Cu富集,后者晶界处有Nb富集;经He离子辐照后,He泡均匀分布于晶粒内,未见明显偏聚;辐照后样品的纳米压痕硬度显著高于未辐照样品,呈现辐照硬化。当Cu含量为35%~65%时,合金薄膜由晶体与非晶双相构成,其中晶体相为颗粒状,尺寸为10~20 nm,均匀分布于非晶基体中;经He离子辐照后,He泡主要分布于晶体/非晶界面处,晶体或非晶相内部的He泡难以分辨;辐照后样品的纳米压痕硬度低于未辐照样品,呈现辐照软化。

中图分类号: TL34;TG146.11;TB383.2

作者简介:于开元(1983-),男,山东威海人,博士,副教授,研究方向:纳米金属材料,电话:010-89739243,E-mail:kyyu@cup.edu.cn;

收稿日期:2020-11-06

基金:国家自然科学基金项目(51501225)资助;

Yu Kaiyuan Li Yan Sun Yifan Zhang Gan Zhang Zhanxuan

College of New Energy and Materials,China University of Petroleum-Beijing

Abstract:

Understanding the microstructural response of metals and alloys to the radiation of particles,such as electrons,neutrons,protons and ions,is vital for the service extension of the existed nuclear materials and the development of new radiation-tolerant structural materials for the next generation nuclear energy. It has been shown for decades that the interfaces in metals and alloys are effective in capturing and sinking the radiation-induced point defects and defect clusters,leading to enhanced radiation tolerance. In this study,we have obtained abundant crystal/amorphous interfaces in Cu-Nb alloy thin films,which were later on subject to He ion irradiation. The microstructure and indentation hardness of the pristine and irradiated specimens have been studied and compared. Seven CuxNb100-x(x=15,25,35,50,65,75,85(%,atom fraction))thin film specimens were deposited on oxidized single crystal silicon(100)substrates using magnetron co-sputtering technique at room temperature. The as-deposited thin film specimens were irradiated by 100 keV He ions to the dose of 6×1020 m-2 at room temperature in a vacuum chamber. X-ray diffraction(XRD)results showed that the Cu-Nb thin films were composed of single crystalline phase when the Cu content was ≤25% or ≥75%,as indicated by the exclusive Cu or Nb peaks. Transmission electron microscopy(TEM)images revealed that the grains were equiaxed and the average grain size was about 100 nm. Nb-rich or Cu-rich regions were observed at the grain boundaries owing to the high intermixing enthalpy between Cu and Nb. When the Cu content ranged from 35% to 65%,the Cu-Nb thin films were composed of both crystalline and amorphous phases.The crystalline phase was in the form of particles,which embedded uniformly in the amorphous matrix. All of the dual phase specimens showed a wide peak between Cu(111)and Nb(110)in the XRD pattern. The wide peak moved towards Cu(111)with the increasing of Cu content and vice versa. After He irradiation,the He bubbles were observed to reside uniformly within the equiaxed grains of the single phase specimens,showing no preferential distribution. As for the dual phase specimens,the He bubbles however distributed primarily at the crystalline/amorphous interfaces. It was suggested that the preferential distribution of the He bubble might be related to the high energy state of crystalline/amorphous interfaces as well as the unlimited sinking effect of the amorphous phase.An additional possible reason was that the partial crystallization of the amorphous phase might have led to local volume contraction,giving rise to the negative pressure at the interfaces and hence the concentration of He atoms. It was noteworthy that we had not observed complete inhibition of the nucleation of the He bubbles,in contrast to the Cu-Nb multilayers. This is likely due to the bias absorption of interstitials and vacancies at the interfaces. Another possible explanation was that the interfaces density was not sufficiently high such that the critical concentration of He atoms could be reached and the He bubble nucleation occurred. Last,nanoindentation results showed that significant radiation induced hardening for Cu-Nb thin film specimens in which the Cu content was ≤25% or ≥75%.The indentation hardness of these specimens increased by 0.1~0.8 GPa after He ion irradiation. Such hardening behavior could be interpreted using the Taylor hardening model,i.e. the hardening originated from the pinning of dislocations by the He bubbles. In contrast,radiation induced softening was observed in specimens with Cu content ranging from 35% to 65%. This was possibly attributed to radiation induced crystallization,which decreased the volume fraction of the amorphous phase(the hard phase)and hence reduced the average hardness of the specimen.

Keyword:

Cu-Nb alloy; thin film; radiation damage; amorphous;

Received: 2020-11-06

核反应堆中,金属材料在高通量粒子轰击下产生高浓度辐照缺陷,导致肿胀、硬化和脆化,对材料安全持久服役提出挑战

几十年前,人们已认知材料中的界面可有效吸收缺陷并减缓辐照损伤

与大多研究关注的晶体/晶体界面不同,晶体/非晶界面没有位错结构,且因非晶相原子堆垛密度较小而具备更大过剩体积,故缺陷累积行为与规律可能不同。本文制备了内含晶体/非晶界面的Cu-Nb合金薄膜,表征了其微观形貌与晶体结构,研究了其经He离子辐照后的缺陷分布特点与硬度演变规律,有助于加深人们对晶体/非晶合金辐照损伤特性的理解。

1 实验

1.1 合金薄膜制备

利用K.J.Lesker真空磁控溅射设备共溅制备Cu-Nb合金薄膜。Cu,Nb靶材纯度均为99.99%(原子分数),基片采用表层为Si O2的Si(100)。溅射前本底真空度为6×10-6Pa,通入氩气后分压保持为0.5 Pa,溅射温度为室温。采用直流电源,通过改变靶电源功率(50~500 W)控制Cu,Nb溅射速率,从而调控薄膜成分。最终获得样品的薄膜厚度为600~700 nm。

1.2 辐照实验

采用美国TAMU加速器实验室的150 k V离子加速器在室温下进行He离子注入,本底真空度为1×10-5Pa。He离子动能为100 ke V,注入剂量为6×1020m-2。辐照过程中,样品温升不超过50℃。

1.3 微观与力学测试

采用Oxford型X射线能谱分析仪(EDS)测定样品成分。采用Brukers D8型X射线衍射仪(XRD)进行相结构分析。采用FEI Tecnai F20场发射透射电镜(TEM)对辐照前后的样品进行微观形貌表征。采用Gatan离子减薄仪进行双侧减薄制备TEM样品。采用Keysight G200型纳米压痕仪进行硬度测试,压入过程中选用连续刚度法(CSM),最大压入深度为200 nm,应变速率范围为0.01~0.20 s-1。

2 结果与讨论

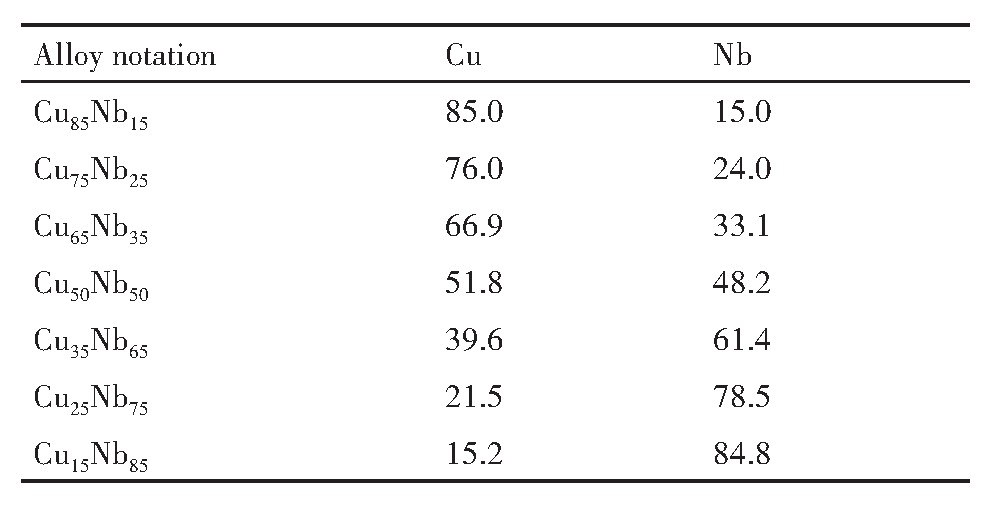

EDS面扫结果表明样品的Cu,Nb含量与合金名义成分比较接近,故下文将采用名义成分(即CuxNb100-x的形式)命名、描述各样品(表1)。XRD结果(图1)显示,Cu85Nb15与Cu75Nb25样品主要呈现Cu(111)衍射峰,说明薄膜具有强(111)取向,其晶体结构接近纯Cu的面心立方结构。与之不同,Cu15Nb85与Cu25Nb75样品则呈现Nb(110)衍射峰,说明薄膜具有强(110)取向,其晶体结构接近纯Nb的体心立方结构。简言之,Cu-Nb合金中两元素含量差别较大时(Cu≤25%或≥75%),样品由单一晶体相构成,其晶体结构由含量较多的元素决定。相比之下,Cu65Nb35,Cu50Nb50和Cu35Nb65这3种样品的XRD谱线中,均出现了非晶峰。随Cu含量减少非晶峰向Nb(110)方向移动,且Cu(111)峰强度减弱。当Cu含量为50%时,非晶峰近乎介于Cu(111)峰与Nb(110)峰中间。当Cu含量为25%时,Cu(111)峰完全消失,非晶峰出现在接近于Nb(110)的位置。这表明Cu-Nb合金中两元素含量差别较小时(35%≤Cu≤65%),样品由晶体、非晶两相构成。非晶相形成的原因为:Cu,Nb混合焓高(2000 J·mol-1)

表1 Cu-Nb合金薄膜的元素含量(%,原子分数) 下载原图

Table 1 Elemental concentration of Cu-Nb thin films(%,atom fraction)

图1 Cu-Nb合金薄膜的XRD图谱

Fig.1 XRD patterns of Cu-Nb thin films

图2展示了Cu-Nb合金薄膜的微观形貌。透射电镜(TEM)明场像照片(图2(a))显示,Cu85Nb15由尺寸约为100 nm等轴晶组成,图2(a)插图的扫描透射电镜(STEM)照片以及成分线扫的结果表明Nb富集于晶界处——与明场像中的黑色区域形貌和分布规律吻合。类似地,Cu15Nb85也由尺寸约为100 nm等轴晶组成(图2(b)),插图的STEM照片以及成分线扫的结果显示了富Cu区在晶界处的分布。相比之下,Cu65Nb35形貌显著不同(图2(c)),该样品由非晶基体与分布于基体内的晶体颗粒构成,晶体颗粒尺寸为10~20 nm,选区电子衍射花样(SAD)可见非晶环与微弱衍射斑点。图2(d)中的高分辨TEM照片进一步证实了晶体/非晶双相的存在,并标明了相界面。Cu50Nb50(图2(e))和Cu35Nb65(图2(f))两样品的微观形貌与Cu65Nb35类似。上述TEM结果与XRD结果一致,证实通过共溅的方法可获得内含晶体/非晶界面的Cu-Nb合金薄膜。

图2 Cu-Nb合金薄膜的TEM照片

Fig.2 TEM images of Cu-Nb thin films

(a)Cu85Nb15;(b)Cu15Nb85;(c,d)Cu65Nb35;(e)Cu50Nb50;(f)Cu35Nb65

为探究上述样品的辐照损伤,采用能量为100ke V的He离子进行注入实验。图3为基于KinchPeach方法的SRIM软件模拟结果

经He离子辐照后样品的微观形貌如图4所示。对于不存在晶体/非晶界面的Cu85Nb15(图4(a))与Cu15Nb85(图4(b))样品,He泡主要呈均匀弥散分布,未见He泡在晶界处明显偏聚。前者He泡密度(单位体积He泡数量)约为8×1023m-3(TEM样品厚度取100 nm),后者He泡密度约为2×1022m-3,这可能源于Nb原子离位能(60 e V)本征高于Cu原子离位能(30 e V)

图3 动能为100 ke V,剂量为6×1020m-2的He离子辐照Cu50Nb50合金的SRIM模拟结果

Fig.3 SRIM simulation results of Cu50Nb50irradiated by 100ke V He ions to the dose of 6×1020m-2

图4 He离子辐照后Cu-Nb合金薄膜的TEM照片

Fig.4 TEM images of He irradiated Cu-Nb

(a)Cu85Nb15;(b)Cu15Nb85;(c)Cu65Nb35;(d)Cu35Nb65

值得注意的是,尽管非晶相理论上有无限的缺陷容纳能力

图5为辐照前后Cu-Nb合金薄膜样品的纳米压痕硬度对比。结果显示,Cu85Nb15与Cu15Nb85等不含晶体/非晶界面(或少量晶体/非晶界面)的合金样品辐照后压痕硬度提高约0.1~0.8 GPa。根据Taylor硬化模型

图5 He离子辐照前后Cu-Nb合金薄膜的纳米压痕硬度

Fig.5 Indentation hardness of Cu-Nb thin films before and af-ter He ion irradiation

3结论

1.利用磁控溅射共溅法,调控改变Cu,Nb元素的相对含量,可获得由单一晶体相组成或由晶体/非晶双相组成的Cu-Nb合金薄膜。

2.经He离子辐照后,单一晶体相合金中的He泡均匀分布于晶粒内,而晶体/非晶合金的He泡主要分布于晶体/非晶界面。

3. 经He离子辐照后,单一晶体相合金中产生辐照硬化,而晶体/非晶合金呈现辐照软化。

参考文献

[1] Zinkle S J,Was G S.Materials challenges in nuclear energy[J].Acta Materialia,2013,61(3):735.

[4] Ackland G.Controlling radiation damage[J].Science,2010,327(5973):1587.