DOI:10.11817/j.ysxb.1004.0609.2020-37475

表面状态对DD6镍基单晶合金在950 ℃氧化行为的影响

胡叶兵,朱亚威,程从前,曹铁山,赵 杰

(大连理工大学 材料科学与工程学院,大连 116024)

摘 要:采用X射线衍射、扫描电子显微镜及电子探针等分析手段,研究不同打磨表面状态(180#、400#、1000#砂纸打磨和抛光)下DD6镍基单晶合金在950 ℃的氧化行为。表面状态对合金的氧化速率有重要的影响。随粗糙度增加,表面增重速率逐渐下降。抛光和1000#砂纸打磨的表面具有多层氧化膜结构,氧化膜从外表面向基体分别由NixCo1-xO、Cr-Co-rich、Ta-Cr-rich、Al2O3和无析出相区域组成;而在180#和400#砂纸打磨的表面,氧化膜由单一、连续的Al2O3组成。另外,在抛光和1000#砂纸打磨的表面,氧化动力学呈现两个阶段;而在180#和400#砂纸打磨的表面,并没有观察到氧化动力学转折点的出现。表面变形促进Al由内氧化向外氧化转变。

关键词:镍基单晶合金;氧化;表面状态;氧化膜;动力学;变形

文章编号:1004-0609(2020)-01-0129-11 中图分类号:TG132 文献标志码:A

镍基单晶合金由于其优良的高温力学性能及抗腐蚀性能从而被广泛应用于飞机发动机叶片上[1-2]。现阶段,随着发动机服役温度的逐渐提高,合金氧化行为逐渐成为影响合金服役寿命的关键因素[3-5]。因此,了解合金基体在高温下的氧化机制就显得尤为重要。

近年来,镍基高温合金的氧化行为已经得到了广泛的研究[6-11]。然而,现阶段大部分研究都集中在氧化温度[6-7]、合金成分[8-9]及氧化气氛[10-11]对合金氧化行为的影响,对于表面状态的关注度则不是较高。但已有研究表明,不同的表面状态会对合金氧化行为造成显著的影响[12-16]。有研究发现,表面粗糙度的提高会促进合金中Cr离子的向外扩散,有利于形成保护性氧化膜,使氧化增重速率降低,提高合金的抗氧化性能[12-13]。但也有研究表明,更高的粗糙度会促进Fe离子的向外扩散,从而加速合金的氧化增重,并且增大氧化膜的开裂和剥落倾向[14-16]。可见,对于不同的合金,表面状态对氧化的影响往往有所不同。然而,现阶段关于表面状态对氧化行为影响的研究大多集中在铁基合金中,对Ni-Cr-Al合金的影响的研究还较少。

因此,本文研究了不同表面状态(分别经过180#、400#、1000#砂纸打磨和抛光处理)对DD6镍基单晶合金在950 ℃氧化行为的影响,得到了其氧化增重曲线,用XRD、SEM及EPMA对不同状态下的表面和截面组织进行了表征,并讨论了其氧化机制。

1 实验

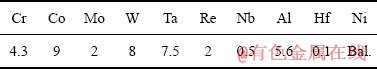

实验采用材料为DD6镍基单晶合金,主要成分如表1所列。合金热处理方式为:(1290 ℃,1 h)+ (1300 ℃,2 h)+(1315 ℃,4 h,AC)+(1120 ℃,4 h,AC)+(870 ℃,32 h,AC)。

将切割好的试样(10 mm×10 mm×2.86 mm)分为四组,其中三组分别用180#、400#和1000#砂纸打磨,另外一组试样用1500#砂纸打磨后用粒度为1.5 μm的抛光膏进行抛光处理。之后将所有试样用无水乙醇超声清洗5 min,干燥后备用。

表1 DD6合金主要元素成分

Table 1 Nominal chemical compositions of DD6 alloy (mass fraction, %)

采用OLS4000型激光共聚焦仪测量试样的粗糙度。在每次氧化实验前,分别测量每个试样的粗糙度,确保相同砂纸打磨下的试样具有基本一致的粗糙度,以避免由于人工打磨程度的不同所造成的实验误差。

静态氧化实验在箱式加热炉中进行,实验温度为950 ℃。采用静态增重法测定合金的氧化增重曲线,将试样累计氧化到200 h。分别在氧化0.5、2、5、10、20、50、100和200 h后取出试样,冷却到室温后在电子天平(精度0.01 mg)上称量,结果取3个试样的测量平均值,绘制氧化增重学曲线。氧化试验后,首先采用岛津XRD-6000型X射线衍射仪分析表面氧化物的物相分析,采用装备有EDS能谱仪的SUPRA55型扫描电镜分析合金表面及截面形貌,并用EPMA-1600型电子探针分析截面元素分布。

2 实验结果

2.1 表面状态

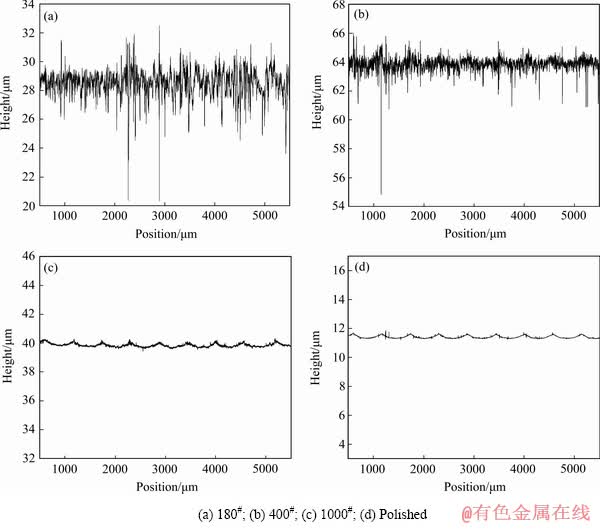

图1所示为合金经不同砂纸打磨和抛光后的表面状态曲线图。其中,经180#、400#和1000#砂纸打磨完的试样粗糙度分别为0.5~0.9 μm、0.2~0.3 μm、0.1~0.2 μm。抛光试样粗糙度在0.05~0.08 μm之间。粗糙度的不同代表了合金不同的表面状态,且随着粗糙度的增加,试样表面凸起与凹陷处的高度差增大,结果如图1所示。

2.2 氧化动力学

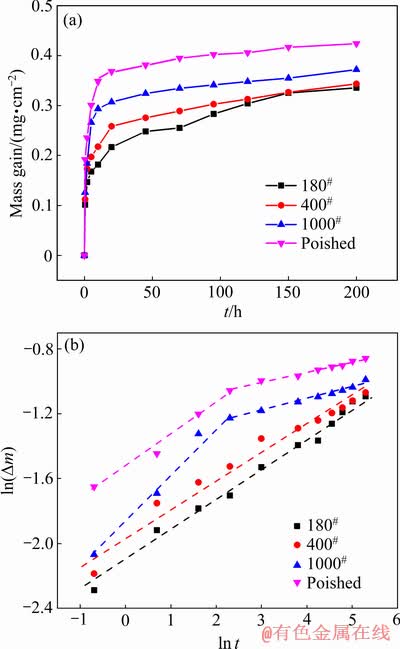

图2所示为不同表面状态合金的氧化增重曲线以及氧化增重与时间的双对数曲线。从图2(a)中可以看到,经180#砂纸打磨后的试样拥有最低的氧化速率,而经抛光处理的的氧化速率最高,即随着表面粗糙度的升高,合金氧化速率降低。

图1 不同SiC砂纸打磨后样品表面状态曲线图

Fig. 1 Curve graphs surface signature after grinding by different SiC papers

一般情况下,合金氧化增重与时间的关系满足幂律关系,可以由下面的公式进行表示:

(1)

(1)

式中: 为单位面积氧化增重;Kp为等温速率常数;t为氧化时间;n为氧化速率指数;C为常数。为了确定n的值,将式(1)等式两边取对数得:

为单位面积氧化增重;Kp为等温速率常数;t为氧化时间;n为氧化速率指数;C为常数。为了确定n的值,将式(1)等式两边取对数得:

(2)

(2)

-

- 曲线的斜率即是氧化速率指数n。从图2(b)中可以看到,对于抛光和1000#砂纸打磨试样,单位面积氧化增重与时间双对数曲线发生了转折,表明氧化速率指数发生了变化,其转折点时间大约为10 h。在转折点之前,即初始氧化阶段,氧化增重快速增加;在转折点之后,氧化过程进入稳态氧化阶段,氧化增重开始变得平缓。而对于180#和400#砂纸打磨试样,则没有明显的转折现象,双对数曲线可拟合为一条直线,这可能表明合金的氧化机制没有发生转变。

曲线的斜率即是氧化速率指数n。从图2(b)中可以看到,对于抛光和1000#砂纸打磨试样,单位面积氧化增重与时间双对数曲线发生了转折,表明氧化速率指数发生了变化,其转折点时间大约为10 h。在转折点之前,即初始氧化阶段,氧化增重快速增加;在转折点之后,氧化过程进入稳态氧化阶段,氧化增重开始变得平缓。而对于180#和400#砂纸打磨试样,则没有明显的转折现象,双对数曲线可拟合为一条直线,这可能表明合金的氧化机制没有发生转变。

图2 950 ℃下不同表面状态合金氧化增重曲线及氧化增重与时间的双对数曲线

Fig. 2 Oxidation kinetics curves of superalloy under different surface signature at 950 ℃(a) and double logarithmic graphs of mass gain and oxidation time with different surface signature at 950 ℃(b)

2.3 XRD物相分析

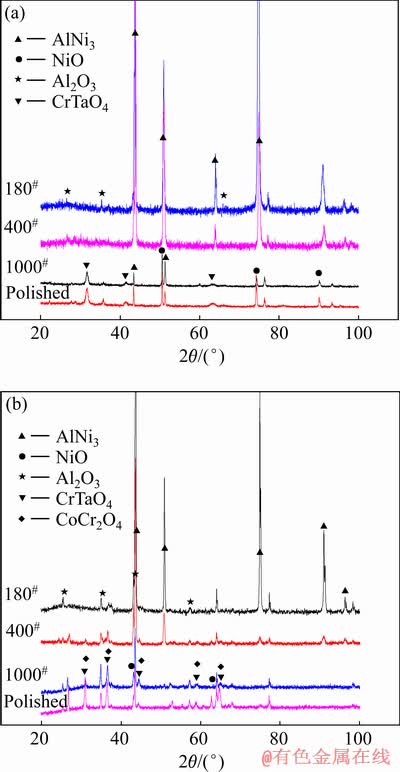

图3所示为不同表面状态合金氧化0.5 h及200 h的XRD物相分析结果。从图3(a)中可以看出,在氧化0.5 h后,即初始氧化阶段,经1000#砂纸打磨和抛光试样的表面氧化产物相类似,都含有较多的NiO及CrTaO4尖晶石相,基体峰相对较弱;而经180#及400#砂纸打磨的试样的基体峰则非常强,表明其氧化膜很薄,氧化产物较少。只有Al2O3峰被检测到,而没有发现NiO和CrTaO4尖晶石相。

图3(b)所示为合金氧化至200 h的XRD结果,相比于0.5 h,此时180#及400#砂纸打磨试样氧化膜中仍只含有Al2O3,但含量显著增加,基体峰强度大幅度下降。1000#砂纸打磨及抛光试样相比于0.5 h生成了更多尖晶石相如CoCr2O4、CrTaO4,而NiO峰强相对有所降低。

综上所述,基体峰的相对强度随着氧化时间的延长而降低,表明氧化膜的厚度逐渐增加。而氧化物的相对强度随着氧化时间的增加而增加,尤其是尖晶石相。

图3 不同表面粗糙度合金氧化0.5 h及200 h的XRD结果

Fig. 3 XRD patterns of superalloy with different surface roughness after oxidation at 950 ℃ for 0.5 h(a) and 200 h(b)

2.4 不同表面状态氧化物形貌及成分

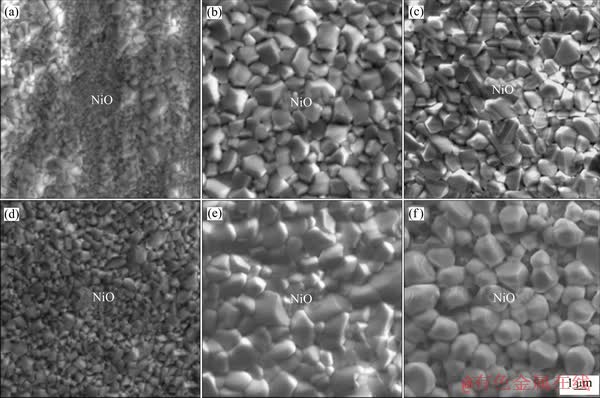

图4所示为合金经1000#砂纸打磨和抛光处理后试样氧化0.5 h、10 h和200 h后的表面相貌。可以看到,在氧化0.5 h后,1000#砂纸打磨及抛光状态下合金表面都是被NiO所覆盖。不同的是,相比于抛光试样,合金在1000#打磨状态下的表面氧化物颗粒较小,主要沿划痕方向呈带状不均匀分布生长,在划痕凸起处,氧化物颗粒直径较大,在划痕凹陷处则较小。在之后的氧化过程中,1000#砂纸打磨及抛光处理试样表面始终被NiO所覆盖,且NiO颗粒尺寸随着氧化时间的增加而增加。

图4 1000#砂纸打磨合金在950 ℃氧化0.5 h、10 h、200 h和抛光处理合金在950 ℃氧化0.5 h、10 h、200 h表面形貌

Fig. 4 Surface morphologies of superalloy after ground to 1000# SiC paper at 950 ℃ for 0.5 h(a), 10 h(b), 200 h(c) and polished for 0.5 h(d), 10 h(e), 200 h(f)

图5 180#砂纸打磨合金在950 ℃氧化0.5 h、10 h、200 h和400#砂纸打磨合金在950 ℃氧化0.5 h、10 h、200 h表面形貌

Fig. 5 Surface morphologies of superalloy after ground to 180# SiC paper at 950 ℃ for 0.5 h(a), 10 h(b), 200 h(c) and 400# for 0.5 h(d), 10 h(e), 200 h(f)

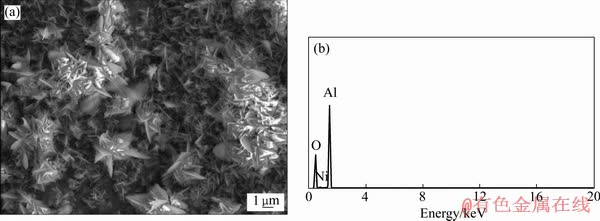

180#及400#砂纸打磨试样氧化0.5 h、10 h和200 h表面相貌如图5所示。合金在180#砂纸打磨状态下氧化0.5 h后,除了少量白色的小颗粒NiO外,还有大面积的黑色复杂氧化物,结合EDS分析和XRD结果可知其主要为Al2O3。相较于1000#和抛光状态下的试样,180#砂纸打磨下的NiO颗粒直径较小,分布也更不均匀。氧化10 h后,此时180#砂纸打磨试样已经看不到白色的小颗粒NiO,取而代之的是大量针状白色氧化物,如图6所示。其成分为59.55O-39.45Al-1Ni,可知其为Al2O3。试样在氧化到200 h后,试样表面全部覆盖为Al2O3。不同于180#砂纸打磨,400#砂纸打磨试样在氧化过程中始终呈现NiO和Al2O3共存的形貌,可见随着粗糙度的增大,表面Al元素含量逐渐增多,Ni元素含量逐渐降低。

2.5 不同表面状态氧化膜相貌及成分分析

图6 180#砂纸打磨试样氧化10 h表面组织形貌及EDS分析

Fig. 6 Oxide morphology(a) and EDS analysis(b) of sample ground to 180# SiC paper after oxidation for 10 h

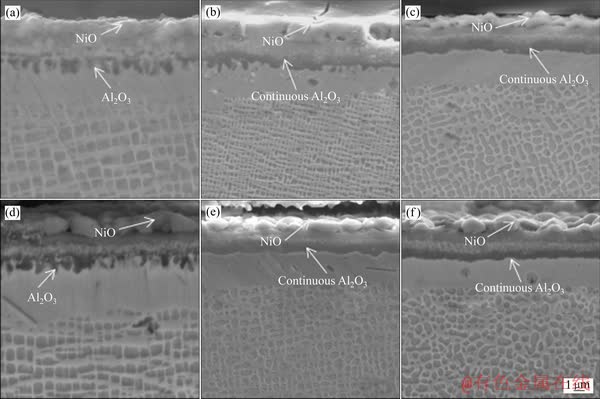

图7 1000#砂纸打磨合金在950 ℃氧化0.5 h、10 h、200 h和抛光处理合金在950 ℃氧化0.5 h、10 h、200 h截面形貌

Fig. 7 SEM images of cross sections of superalloy ground to 1000# SiC paper after oxidation at 950 ℃ for 10 h(a), 100 h(b), 200 h(c) and polished for 10 h(d), 100 h(e), 200 h(f)

图7所示为1000#砂纸打磨和抛光处理合金氧化0.5 h、10 h和200 h截面组织。可以看到,在氧化0.5 h后两种状态合金呈现相似的氧化膜结构,都已经出现了明显的分层结构。结合EDS成分分析及XRD物相结果可知,其氧化膜主要为外层的NiO层,内层的不连续Al2O3层和中间包含CrTaO4及CoCr2O4尖晶石相层。在氧化10 h后,1000#打磨试样及抛光处理试样氧化膜仍呈现明显的三层结构,且内层Al2O3层由不连续变得连续。连续Al2O3层的形成时间与转折点时间相吻合,可以推测连续内Al2O3的形成导致了转折现象的发生。在氧化200 h后,1000#和抛光处理试样氧化膜组织与氧化10 h时相差不大,仍为三层氧化物结构。

与1000#砂纸打磨及抛光试样不同的是,180#砂纸打磨试样氧化膜只有一层,如图8(a)所示。结合EDS分析及XRD结果可知其为Al2O3层,这与合金表面组织相吻合。由于180#砂纸打磨后的划痕较深,氧化膜呈现凸凹不平的形状。NiO颗粒由于分布较少,因此没有在截面中发现。图8(d)所示为400#砂纸打磨试样氧化0.5 h截面形貌,与180#打磨试样类似,氧化膜也为单层的Al2O3。对于180#及400#砂纸打磨试样,合金氧化10 h和200 h后的截面组织与0.5 h时的相似,仍为单层的Al2O3,不同的是氧化膜厚度和无析出相区厚度都有所增加。

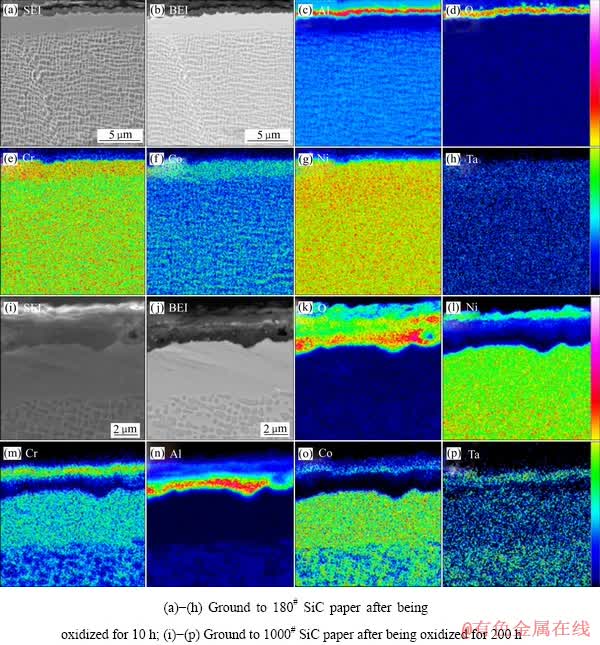

图9所示为400#砂纸打磨合金氧化10 h和1000#砂纸打磨合金氧化200 h的电子探针结果。可以看到,400#砂纸打磨合金氧化层主要富含铝元素和氧元素,证实氧化层为Al2O3,其他金属元素如Cr、Ni、Co和Ta则含量极少,可见连续氧化铝层的形成有效阻止了合金元素的向外扩散。由图9(b)来看,1000#打磨合金氧化200 h的氧化膜外层为富Ni层,内层为富Al层,中间层主要富含Co, Cr和Ta。由于第二相强化相γ′相形成元素Al元素及Ta元素的向外扩散,无析出相区富含Cr和Co元素,而Al及Ta元素较少。

3 讨论

3.1 表面状态对合金氧化动力学的影响

关于粗糙度对合金氧化动力学的影响,现在的研究结果主要分为两种,一种认为表面粗糙度的增加会增大合金的氧化速率,促进氧化反应的进行,如ZHANG[14]的研究结果表明,对于Fe-Cr-Al,粗糙表面会促进合金Fe离子的向外扩散,使表面生成富含Fe的氧化物瘤。在氧化动力学上表现为随着表面粗糙度的升高,氧化速率随之增加;另一种则认为粗糙度的增大会促进保护性氧化膜的形成,从而有利于提高合金的抗氧化性,如GRABKE等[13]的研究发现,粗糙度的增加会促进保护性Cr2O3膜的快速形成,使氧化增重速率下降。之所以出现这种差异,主要在于是否有保护性氧化膜的生成。

图8 180#砂纸打磨合金在950 ℃氧化0.5 h、10 h、200 h和400#砂纸打磨合金在950 ℃氧化0.5 h、10 h、200 h截面组织

Fig. 8 SEM images of cross sections of superalloy ground to 180# SiC paper after oxidation at 950 ℃ for 10 h(a), 100 h(b), 200 h(c) and ground to 400# SiC paper for 10 h(d), 100 h(e), 200 h(f)

图9 180#砂纸打磨合金氧化10 h和1000#砂纸打磨合金氧化200 h截面组织电子探针分析

Fig. 9 Element distribution maps of superalloy with different surface signature

已有研究表明,表面冷加工或者表面粗糙度的增加,将会使近表面区域的位错及缺陷密度大大增加,从而为离子扩散提供了快速扩散通道,使离子向表面的扩散速率大幅升高[17]。此外,粗糙表面的大量缺陷还会使氧化物形核能大大降低,从而增大氧化物形核速度。也有文献发现[14, 18]在对不同粗糙度的TEM观察中发现,经打磨的试样近表面存在大量与表面划痕相平行的位错线,而在抛光试样中位错密度则非常低,

可以推测这些位错线是由砂纸打磨所产生的冷加工导致的。另外,试样表面的高能量位错还会为氧化产物的形成提供更多的形核位置[19]。

由上述实验结果可知,DD6合金180#和400#砂纸打磨试样的氧化产物主要是由氧化铝组成;而经1000#砂纸打磨和抛光试样之后的氧化产物由NiO、Al2O3及复杂的Ni-Cr-Ta等尖晶石相组成。由下述氧化反应的吉布斯自由能[19-20]可知:

2Ni(s)+O2(g)=2NiO(s)

-476980+168.62T (3)

-476980+168.62T (3)

4/5Ta(s)+O2(g)=2/5Ta2O5(s)

-810040+165T (4)

-810040+165T (4)

4/3Cr(s)+O2(g) =2/3Cr2O3(s)

-746840+170.29T (5)

-746840+170.29T (5)

4/3Al(s)+O2(g) =2/3Al2O3(s)

-1120480+214.22T (6)

-1120480+214.22T (6)

各个氧化产物的吉布斯自由能均为负值,且 <

< <

< <

< ,这意味着Al2O3相比于其他氧化物在热力学上是最稳定的。但是由于镍基合金中Al元素的浓度梯度要远远小于镍元素的,因此,在1000#砂纸打磨和抛光试样中,可能由于冷加工硬化层很薄,因此表面状态对合金元素向外扩散的促进作用并不明显,初始阶段氧化反应主要为基体元素Ni与氧离子的反应为主,导致表面氧化物主要为NiO,如图4所示。且由于Al元素不能及时向外扩散,使合金在氧化早期阶段不能形成连续的保护性氧化铝,从而导致初期氧化增重快速增加。相比于1000#砂纸打磨和抛光试样,180#和400#砂纸打磨试样下方存在一定厚度的冷加工硬化区,可以为Al离子的扩散提供快速的短路扩散通道,因此,在氧化早期阶段,有足够多的Al离子和Ni离子竞争与氧离子反应。由于Al离子与氧的亲和力比Ni离子的更大,因此初始阶段氧化反应由Al离子与氧的反应为主,从而使连续氧化铝层快速形成,阻碍了镍离子的向外扩散,从而不能像抛光及1000#砂纸打磨试样那样形成连续的外层NiO层,而只有少量NiO颗粒分布在Al2O3之间,如图5所示。

,这意味着Al2O3相比于其他氧化物在热力学上是最稳定的。但是由于镍基合金中Al元素的浓度梯度要远远小于镍元素的,因此,在1000#砂纸打磨和抛光试样中,可能由于冷加工硬化层很薄,因此表面状态对合金元素向外扩散的促进作用并不明显,初始阶段氧化反应主要为基体元素Ni与氧离子的反应为主,导致表面氧化物主要为NiO,如图4所示。且由于Al元素不能及时向外扩散,使合金在氧化早期阶段不能形成连续的保护性氧化铝,从而导致初期氧化增重快速增加。相比于1000#砂纸打磨和抛光试样,180#和400#砂纸打磨试样下方存在一定厚度的冷加工硬化区,可以为Al离子的扩散提供快速的短路扩散通道,因此,在氧化早期阶段,有足够多的Al离子和Ni离子竞争与氧离子反应。由于Al离子与氧的亲和力比Ni离子的更大,因此初始阶段氧化反应由Al离子与氧的反应为主,从而使连续氧化铝层快速形成,阻碍了镍离子的向外扩散,从而不能像抛光及1000#砂纸打磨试样那样形成连续的外层NiO层,而只有少量NiO颗粒分布在Al2O3之间,如图5所示。

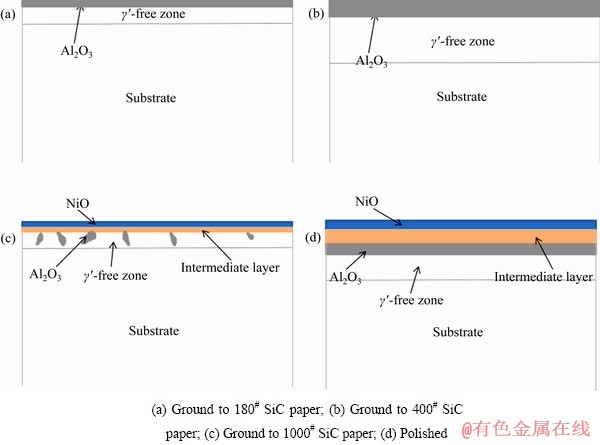

一般认为n-型氧化物如氧化铝,氧化物的生长主要是由阴离子的内扩散与合金/氧化物界面的金属阳离子反应为主的[21];而对于p-型氧化物如氧化镍,氧化物的生长主要是由金属阳离子的外扩散控制生长 的[10]。在氧化0.5 h后,180#和400#砂纸打磨试样在后就已经生成了连续的Al2O3层,因此在氧化早期阶段,180#和400#砂纸打磨试样的氧化反应就由氧离子通过Al2O3层的扩散所控制;而1000#砂纸打磨和抛光试样在氧化0.5 h后主要是由氧化镍和不连续的氧化铝组成,因此在氧化早期阶段,氧化物的生长主要是由镍离子的外扩散所控制。在氧化10 h后,1000#砂纸打磨和抛光处理试样内层短条状Al2O3相互连接,生成了连续的内层Al2O3,从而使合金氧化过程由金属离子及氧离子通过连续氧化铝层的速率所控制,使氧化速率大幅降低,导致了转折点的发生。而180#和400#砂纸打磨试样由于连续Al2O3层始终存在,因此没有转折现象的发生。氧化过程示意图如图10所示。

图10 180#、400#、1000#砂纸打磨及抛光处理后样品的氧化过程示意图

Fig. 10 Schematic diagrams of samples after different oxidation process

3.2 表面状态对合金氧化机制的影响

对于三元或者多元合金,氧化膜的形成往往与合金中各元素的含量有关,已有研究表明[22],Ni-Cr-Al合金通常有三种氧化物形成机制。

1) 当合金中元素Cr和Al 含量较低时,合金生成连续的NiO外氧化层,Al和Cr元素发生内氧化,并且含有NiCr2O4、AlCr2O4等尖晶石相。

2) 当合金中Cr元素含量较高而Al元素含量较低时,合金会生成连续的Cr2O3外层氧化膜,Al元素发生内氧化。

3) 当合金中Al元素的含量较高而Cr元素含量较低时,合金生成连续的外Al2O3保护膜,不发生内氧化。

HUANG等[23]在研究9.2Cr-5.3Al-Ni合金在光滑表面下的等温氧化行为时发现,合金的氧化物生长在枝晶晶符合第三种生长机制,这与文中180#及400#砂纸打磨状态下,氧化物生长机制相似,均是由其他金属阳离子穿过连续Al2O3膜控制的;而在1000#打磨及抛光状态下,合金符合第一种氧化物生长机制,这与AMARO等[24]在研究PWA1484镍基单晶合金的氧化行为机制是相似的。可见,表面状态对合金的氧化生长机制产生了显著的影响。

WANGER[25]在对影响氧化物由内氧化向外氧化转变的因素研究中发现,当氧化产物的体积分数g=f(Vox/Vm)达到临界值g*时,内氧化将会向外氧化转变。WANGER给出了向外氧化转变的临界判据,如下式所示:

>

> (7)

(7)

式中: 是氧在A中的溶解度(摩尔分数);Vm是基体金属或合金的摩尔体积,cm3/mol;Vox是氧化物的摩尔体积;DO是氧在基体中的扩散系数;

是氧在A中的溶解度(摩尔分数);Vm是基体金属或合金的摩尔体积,cm3/mol;Vox是氧化物的摩尔体积;DO是氧在基体中的扩散系数; 是溶质的初始浓度;DB是溶质的外扩散系数;对于Al2O3,系数ν等于2/3。

是溶质的初始浓度;DB是溶质的外扩散系数;对于Al2O3,系数ν等于2/3。

可见,通过增大合金表面的粗糙度,即冷变形处理,可提高溶质的扩散系数,使DB增大,从而降低由内氧化到外氧化的临界浓度,使DD6合金的Al2O3由内氧化转变为外氧化,提高合金抗氧化能力。

4 结论

1) 表面状态对合金的氧化速率有着显著的影响,随着粗糙度增加,氧化速率逐渐下降。

2) 抛光处理与1000#砂纸打磨试样的氧化机制相似,都生成了三层氧化物结构,分别为外层的NiO,内层的Al2O3及中间尖晶石相层,而180#和400#砂纸打磨试样氧化膜主要由单层Al2O3组成。

3) 抛光处理与1000#砂纸打磨试样的氧化增重曲线都发生了转折,转折点为10 h,而180#和400#砂纸打磨试样没有转折现象。抛光处理与1000#砂纸打磨试样在氧化早期生成的Al2O3为不连续状,氧化10 h后Al2O3由不连续变为连续,导致了氧化增重曲线转折现象的发生,而180#和400#砂纸打磨试样在氧化早期就生成了连续Al2O3,因此没有转折现象的发生。

4) 粗糙表面促进了Al2O3由内氧化向外氧化的转变,随着粗糙度增加,合金外氧化物由NiO变为Al2O3。

ReferenceS

[1] TAMARIN Y. Protective coatings for turbine blades[M]. USA: ASM International, 2002.

[2] 黃乾尧, 李役康. 高温合金[M]. 北京: 冶金工业出版社, 2000.

HUANG Qian-yao, LI Yi-kang. Superalloys[M]. Beijing: Metallurgical Industry Press, 2000.

[3] 王 欢, 袁 超, 郭建亭, 秦鹤勇. GH4698合金的疲劳裂纹扩展行为[J]. 中国有色金属学报, 2015, 25(1): 23-29.

WANG Huan, YUAN Chao, GUO Jian-ting, QIN He-yong. Fatigue crack growth behavior of GH4698 alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 23-29.

[4] ZHENG L, ZHANG M, DONG J. Oxidation behavior and mechanism of powder metallurgy Rene95 nickel based superalloy between 800 and 1000 ℃[J]. Applied Surface Science, 2010, 256(24): 7510-7515.

[5] BENSCH M, PREUβNER J, HüTTNER R, OBIGODI G, VIRTANEN S, GABEL J, GLATZEL U. Modelling and analysis of the oxidation influence on creep behaviour of thin-walled structures of the single-crystal nickel-base superalloy Rene N5 at 980 ℃[J]. Acta Materialia, 2010, 58(5): 1607-1617.

[6] PEI H, WEN Z, YUE Z. Long-term oxidation behavior and mechanism of DD6 Ni-based single crystal superalloy at 1050 ℃ and 1100 ℃ in air[J]. Journal of Alloys and Compounds, 2017, 704: 218-226.

[7] LU X, TIAN S, YU X, WANG C. Oxidation behavior of a single-crystal Ni-base superalloy in air at 900 and 1050 ℃[J]. Rare Metals, 2011, 30(1): 439-442.

[8] PARK S J, SEO S M, YOO Y S, JEONG H W, JANG H. Effects of Al and Ta on the high temperature oxidation of Ni-based superalloys[J]. Corrosion Science, 2015, 90: 305-312.

[9] 刘龙飞, 吴树森, 陈 阳, 吕书林. 一种添加微量混合稀土镍基高温合金在950~1150 ℃下的氧化行为[J]. 中国有色金属学报, 2016, 26(4): 1163-1169.

LIU Long-fei, WU Shu-sen, CHEN Yang, Lü Shu-lin, Oxidation behavior of RE-modified nicek-based superalloy between 950 ℃ and 1150 ℃ in air [J]. The Chinese Journal of Nonferrous Metals, 2016, 26(4): 1163-1169.

[10] CHAPOVALOFFJ, ROUILLARD F, WOLSKI K, PIJOLAT M. Kinetics and mechanism of reaction between water vapor, carbon monoxide and a chromia-forming nickel base alloy[J]. Corrosion Science, 2013, 69: 31-42.

[11] ROUILLARD F, CABET C, WOLSKI K, PIJOLAT M. Oxidation of a chromia-forming nickel base alloy at high temperature in mixed diluted CO/H2O atmospheres[J]. Corrosion Science, 2009, 51(4): 752-760.

[12] LEISTIKOW S, WOLF I, GRABKE H J. Effects of cold work on the oxidation behavior and carburization resistance of alloy 800[J]. Materials and Corrosion, 1987, 38(10): 556-562.

[13] GRABKE H J, MULLER-LOREZN E M, STRAUSS S, PIPPEL E, WOLTERSDORF J. Effects of grain size, cold working, and surface finish on the metal-dusting resistance of steels[J]. Oxidation of Metals, 1998, 50(3/4): 241-254.

[14] ZHANG Z G, HOU P Y, GESMUNDO F, NIU Y. Effect of surface roughness on the development of protective Al2O3 on Fe-10Al (at.%) alloys containing 0-10at.% Cr[J]. Applied Surface Science, 2006, 253(2): 881-888.

[15] 董汉君, 张 晖, 何宜柱, 王孝建. 表面处理状态对高铬铸铁轧辊氧化膜生长形态的影响[J]. 金属锻造焊技术, 2009, 38(9): 19-21.

DONG Han-jun, ZHANG Hui, HE Yi-zhu, WANG Xiao-jian. Effects of surface treatment states on oxide growth morphology of high chromiun cast iron roll[J]. Casting Forging Welding, 2009, 38(9): 19-21.

[16] CHAO J, GONZALEZ-CARRASCO J L. The role of the surface roughness on the integrity of thermally generated oxide scales. Application to the Al2O3/MA956 system[J]. Materials Science and Engineering A, 1997, 230(1/2): 39-48.

[17] SUN N, ZHANG L, LI Z, SUN F, DONG X, SHAN A. The effect of surface machining on the high-temperature oxidation of a single crystal Ni-based superalloy[J]. Materials Transactions, 2014, 55(10): 1540-1546.

[18] WANG L, JIANG W G, LI X W, DONG J S, ZHENG W, FENG H, LOU L H. Effect of surface roughness on the oxidation behavior of a directionally solidified Ni-based superalloy at 1100 ℃[J]. Acta Metallurgica Sinica (English Letters), 2015, 28(3): 381-385.

[19] 伯格斯. 金属高温氧化导论[M]. 北京: 高等教育出版社, 2010.

BERGS. Introduction to high temperature oxidation of metals[M]. Beijing: Higher Education Press, 2010.

[20] BARIN I, KNACKE O, KUBASCHEWSKI O. Thermochemical properties of inorganic substrance[M]. Berlin: Springer-Verlag, 1977.

[21] JONES D A. Principles and prevention of corrosion[M]. Upper Saddle River, NJ: Prentice Hall Press, 1996.

[22] GIGGINS C S, PETTIT F S. Oxidation of Ni-Cr-Al alloys between 1000 and 1200 ℃[J]. Journal of the Electrochemical Society, 1971, 118(11): 1782-1790.

[23] HUANG L, SUN X F, GUAN H R, HU Z Q. Oxidation behavior of a single-crystal Ni-base superalloy in air at 900, 1000 and 1100 ℃[J]. Oxidation of Metals, 2006, 65: 207-222.

[24] AMARO R L, ANTOLOVICH S D, RICHARD W N, SINGH P M. High temperature oxidation and γ′ depletion in the single-crystal superalloy PWA1484[J]. Materials at High Temperatures, 2016, 33: 476-488.

[25] WANGER C. Measurement of oxidation rate of metal[J]. J Elect Soc, 1959, 63: 772-790.

Effect of surface signature on oxidation behavior of DD6 alloy at 950 ℃

HU Ye-bing, ZHU Ya-wei, CHENG Cong-qian, CAO Tie-shan, ZHAO Jie

(School of Materials Science and Engineering,Dalian University of Technology, Dalian 116024, China)

Abstract: X-ray diffraction, scanning electron microscopy, and electron microprobe techniques were used to investigate the oxidation behavior of DD6 nickel-based single crystal alloys at 950 ℃ with different surface signature (ground to 180#, 400#, and 1000# and polished). The results show that the surface signature has a significant effect on the oxidation rate of the alloy. The mass gain rate of the specimens gradually decreases as the surface roughness increases. Multi-layers structure is developed on the surface after ground to 1000# and polished. And the oxide film structure, from the top surface to the base metal, is NixCo1-xO, Cr-Co-rich, Ta-Cr-rich, Al2O3 and γ′-free zone. However, the oxide films only consist of a single Al2O3 layer of the alloy after ground to 180# and 400#. In addition, two stages are displayed in the oxidation kinetics of the alloy under the polished and 1000# surface signature, whereas no turning point is observed under the 180# and 400# surface signature. Surface deformation promotes the transformation of Al from internal oxidation to external oxidation. And the morphology of Al2O3 has a significant role on the oxidation kinetics, oxide film evolution and oxidation mechanism.

Key words: nickel-based single alloy; oxidation; surface signature; oxide film; kinetics; deformation

Foundation item: Project(U1610256) supported by National Natural Science Foundation of China; Project (2015AA034402) supported by National High-tech Research and Development Project of China

Received date: 2018-12-07; Accepted date: 2019-03-11

Corresponding author: ZHAO Jie; Tel: +86-411-84709076; E-mail: jiezhao@dlut.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(U1610256);国家高技术研究发展计划资助项目(2015AA034402)

收稿日期:2018-12-07;修订日期:2019-03-11

通信作者:赵 杰,教授,博士;电话:0411-84709076;E-mail:jiezhao@dlut.edu.cn