文章编号:1004-0609(2015)-09-2565-10

不同破碎方式下磨矿技术效率

刘 磊1, 2 曹进成1, 2, 3,吕 良1, 2, 3,郭珍旭1, 2,岳铁兵1, 2

(1. 中国地质科学院 郑州矿产综合利用研究所,郑州 450006;

2. 国土资源部多金属矿评价与综合利用重点实验室,郑州 450006;

3. 东北大学 资源与土木工程学院,沈阳 110089)

摘 要:对高压辊磨机(HPGR)产品和圆锥破碎机(CC)产品的磨矿技术效率进行对比研究,评价不同破碎方式后的磨矿效果。相对于圆锥产品,辊压产品个别粒级分布的“双峰”特征更加明显,平均粒度较小,分布更加不均匀。辊压产品所需要的磨矿时间短、可磨性好。对于粒径小于2.0 mm全粒级给矿和粒径小于0.5 mm给矿,辊压产品的磨矿技术效率低,降低的幅度随着磨矿细度的增加而降低直至两者的磨矿技术效率相当;对于粒径在0.5~2.0 mm范围给矿,辊压产品的磨矿技术效率与圆锥产品的相当甚至略高。基于此,提出一种高压辊磨机超细碎-分级磨矿新工艺,该工艺既可大幅降低一段磨机的入磨量,又可提高磨矿技术效率,减弱整体磨矿过程中的过粉碎。

关键词:高压辊磨机;圆锥破碎机;磨矿技术效率;超细碎-分级磨矿

中图分类号:TD451 文献标志码:A

Grinding technical efficiencies in various comminution modes

LIU Lei1, 2, CAO Jin-cheng1, 2, 3,  Liang1, 2, 3, GUO Zhen-xu1, 2, YUE Tie-bing1, 2

Liang1, 2, 3, GUO Zhen-xu1, 2, YUE Tie-bing1, 2

(1. Zhengzhou Institute of Multipurpose Utilization of Mineral Resources,

Chinese Academy of Geological Sciences, Zhengzhou 450006, China;

2. Key Laboratory for Polymetallic Ores' Evaluation and Utilization,

Ministry of Land and Resources, Zhengzhou 450006, China;

3. College of Resources & Civil Engineering, Northeastern University, Shenyang 110089, China)

Abstract: In consideration of overgrinding in grinding process, the grinding technical efficiency (Et) of comminuted hematite products using a high-pressure grinding roller (HPGR) and a conventional cone crusher (CC) were comparatively studied. Compared with CC products, individual size distributions (ISDs) in HPGR product show a more significant “double-peak” characteristic. The results show that HPGR products are finer and have a wider full-size distribution because of the greater proportion of fines. HPGR products need a shorter grinding time and have a lower relative grindability. HPGR products have a lower Et at a decreasing rate than the CC product for feeds of <2.0 mm and <0.5mm size fractions, and then show a slightly higher Et for the feed of 0.5-2.0 mm size fraction. Based on the above research, a new process of ultra-crushing in HPGR – classified grinding is advanced. The new comminuting process is adopted to reduce ores tonnage into first stage ball mill significantly, improve grinding efficient and weaken overgrinding in the whole grinding process.

Key words: high-pressure grinding roller; cone crusher; grinding technical efficiency; ultra-crushing-classified grinding

选矿过程中,粉磨的能耗占到整个选厂能耗的60%~70%,实现选厂的多碎少磨及以碎代磨是降低选厂能耗的有效途径。高压辊磨机是基于料层粉碎原理设计的一种超细碎矿岩破碎设备,由于具有单位破碎能耗和钢耗低、处理能力大、占地面积少、设备作业率高等特点,在冶金矿产行业逐渐得到广泛的应用[1-3]。高压辊磨机有两个压辊:一个为定辊,一个为可以前后小幅度水平移动的动辊,压力则通过高压油缸加载到动辊两端的轴承座上。高压辊磨机工作时的比压力(液压系统提供的总压力作用于压辊侧视方向投影面积时所产生的压强)范围为3~9 N/mm2,但在工作间隙内的尖峰负荷能够达到几百甚至上千兆帕压力[4-6]。

料层粉碎方式并不发生由于颗粒摩擦或细粒团聚而引起的能量损失,能耗较传统粉碎技术的降低约30%~50%,磨损也明显减少[7]。高压辊磨机对磨矿机给料预先粉碎后,能够降低矿石的磨矿功指数,减小磨矿介质尺寸,提高磨矿效率[8]。依据高压辊磨机的特点,在矿石、水泥粉碎方面目前常采用以下几种工艺[9-10]:开路工艺、边料循环闭路工艺和筛分全闭路工艺。

本文作者前期的研究发现,高压辊磨机粉碎产品内部结构疏松,裂纹数量多,而常规破碎机粉碎产品结构致密,裂纹数量少。同一粒级下的BET比表面积测试结果显示,与常规破碎机产品相比,辊压产品的比表面积更大,裂纹空隙更多,其产品的磨矿特性和分选特性得到一定的提高[11-13]。侯英等[14]对西藏墨竹工卡邦铺钼铜矿进行了高压辊磨和传统破碎试验对比,并对两种粉碎产品进行磨矿动力学研究,试验结果表明高压辊磨产品的磨矿磨矿速度较快。矿石经高压辊磨机粉碎后有利于后续磨矿,但对磨矿产品技术效率方面的评价未见详细报道。基于此,本文作者在实验室条件下,对辊压产品(HPGR)和圆锥产品(CC)进行磨矿试验研究,研究不同破碎方式对磨矿技术效率的影响,并提出一种高压辊磨机超细碎-分级磨矿新工艺,研究结果对高压辊磨机在超细碎应用方面具有一定的指导意义。

1 实验

试验选用的高压辊磨机为CLM-25-10,压辊直径为250 mm,压辊宽度为100 mm,参照前期试验结果[15],辊面比压力(SCF)选取4.4 N/mm2(HPGR4.4)和5.2 N/mm2(HPGR5.2),辊面速度为0.18 m/s,工作辊隙为4~7 mm。试验选用的圆锥破碎机的型号为GYP-300。试验样品为鞍山式赤铁矿,有用矿物主要是赤铁矿,含有少量磁铁矿,Fet品位为27.02%;脉石矿物主要为石英,SiO2含量为57.64%(质量分数)。原矿d80为18.5 mm。矿石的松散密度为2.142×103 kg/m3,矿石水分含量小于0.5%(质量分数)。

原矿经过高压辊磨机和圆锥破碎机全闭路破碎后(控制筛孔的尺寸为2 mm)进行不同磨矿时间的批次磨矿磨矿试验。磨矿机型号为XMB-70A型三辊四筒磨机,筒体尺寸为d140 mm×160 mm,磨球介质质量为3.75 kg,磨机转速为310 r/min。每次试验时,磨矿给矿为300 g,磨矿含量为65%(质量分数)。每个磨矿产品筛分分析后进行粒度分布拟合。

2 结果与分析

2.1 破碎产品粒度分布

在控制筛孔尺寸2 mm的条件下,高压辊磨机和圆锥破碎机全闭路产品的个别粒级分布如图1所示。

图1 不同破碎方式下产品个别粒级分布

Fig. 1 Individual size distributions of product in different crushing modes

从图1可以看出,两种破碎产品的个别粒级分布均存在“双峰”特征,分别出现在粒径<0.18 mm和0.5~1.6 mm两个粒级范围内。圆锥产品粒径在0.5~1.6 mm范围内的 “峰”尖锐,该粒级的个别产率为53.04%,而粒径<0.18 mm的“峰”相对平缓,该粒级的个别产率为24.38%;辊压产品 “双峰”特征明显,细粒级含量更高,在辊面比压力为5.2 N/mm2的条件下,粒径<0.18 mm的个别产率为38.43%,粒径在0.5~1.6 mm范围内个别产率为41.65%。

平均粒度(Dw)能够反映物料粒度的平均大小,偏差系数(Kd)用来表明物料的均匀程度,两者的计算公式如式(1)和(2)所示[16]:

(1)

(1)

(2)

(2)

式中:Dw为加权平均粒度,mm;Kd为偏差系数,Kd越大,产品粒度分布越不均匀;di为个别粒级算术平均粒度,mm;ri为个别粒级产率,%。

不同破碎方式下产品平均粒度和偏差系数如表1所列。与圆锥产品相比,辊压产品的平均粒度(Dw)小,但偏差系数明显增大,尤其在辊面比压力为5.2 N/mm2的条件下。这表明在相同的控制粒度下,辊压产品粒度细,但其粒度分布更加不均匀。

表1 不同破碎方式下的产品平均粒度(Dw)和偏差系数(Kd)

Table 1 Dw and Kd of different crushing products

2.2 磨矿产品技术效率

磨矿是将物料磨到某一指定粒度x的过程,在磨矿过程中同时还应该指定某一过粉碎粒度y,粒度介于x与y之间的粒度才能称为合格粒级。磨矿技术效率(Et)评价的是合格粒级的效率[16],定义为粒度x的磨矿效率减去过粉碎粒度y的磨矿效率,其表达式如式(3)所示:

(3)

(3)

式中:γ1为给矿中小于粒度x的产率,%;γ2为给矿中小于粒度y的产率,%;γ为磨矿产品中小于粒度x的产率,%;γ3为磨矿产品中小于粒度y的产率,%。

当不发生磨矿作用时,γ=γ1及γ3=γ2, Et=0;当全部磨到过粉碎时,γ=γ3=100,Et=0。因此,Et能从技术上评价磨矿过程的好坏,Et越高越好。

分别对辊压产品和圆锥产品进行不同磨矿时间的批次磨矿磨矿试验,不同粒度给矿下磨矿产品的粒度分布如图2~10所示。根据磨矿试验结果和粒度特征方程可以模拟出不同磨矿时间下的粒度分布方程。粒度特征方程选择R-R方程[17]如式(4)所示:

(4)

(4)

式中:R为粒度大于x的正累计产率,%;x为颗粒粒度或筛孔宽;b为与产物粒度相关的参数;n为与物料性质有关的参数。

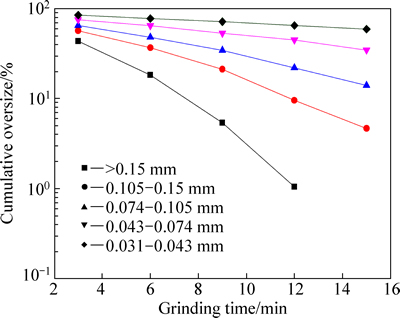

图2 粒径小于2.0 mm圆锥产品的磨矿曲线

Fig. 2 Grinding curves of CC products with size less than 2.0 mm

图3 粒径小于2.0 mm辊压产品的磨矿曲线(4.4 N/mm2)

Fig. 3 Grinding curves of HPGR products with size less than 2.0 mm in SCF of 4.4 N/mm2

图4 粒径小于2.0 mm辊压产品的磨矿曲线(5.2 N/mm2)

Fig. 4 Grinding curves of HPGR products with size less than 2.0 mm in SCF of 5.2 N/mm2

图5 粒径在0.5~2.0 mm范围内圆锥破碎产品的磨矿曲线

Fig. 5 Grinding curves of CC products with size in range of 0.5-2.0 mm

图6 粒径在0.5~2.0 mm范围内辊压产品的磨矿曲线(4.4 N/mm2)

Fig. 6 Grinding curves of HPGR products with size in range of 0.5-2.0 mm in SCF of 4.4 N/mm2

图7 粒径在0.5~2.0 mm范围内辊压产品的磨矿曲线(5.2 N/mm2)

Fig. 7 Grinding curves of HPGR products with size in range of 0.5-2.0 mm in SCF of 5.2 N/mm2

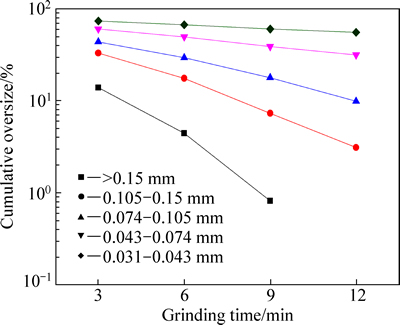

图8 粒径小于0.5 mm圆锥产品的磨矿曲线

Fig. 8 Grinding curves of CC products with size less than 0.5 mm

图9 粒径小于0.5 mm辊压产品的磨矿曲线(4.4 N/mm2)

Fig. 9 Grinding curves of HPGR products with size less than 0.5 mm in SCF of 4.4 N/mm2

图10 粒径小于0.5 mm辊压产品的磨矿曲线(5.2 N/mm2)

Fig. 10 Grinding curves s of HPGR products with size less than 0.5 mm in SCF of 5.2 N/mm2

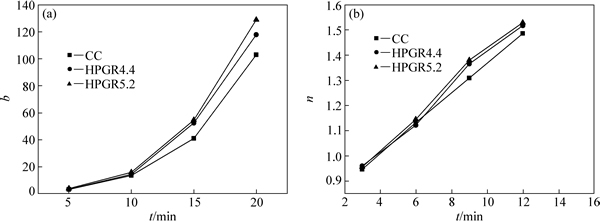

按照式(4)可以求出不同破碎方式下参数b和n随时间t的变化曲线,如图11~13所示。从图11中可以看出,对于粒径<2.0 mm的全粒级给矿,曲线b=f(t)和n=f(t)呈抛物线。而对于粒径在0.5~2.0 mm范围(见图12)和粒径<0.5 mm(见图13)的给矿,曲线b=f(t)呈抛物线,曲线n=f(t)近似线性。

因此,

(5)

(5)

(6)

(6)

将式(5)和(6)代入式(4)后得到式(7):

(7)

(7)

式中:a0、a1、a2、c0、c1、c2均为常数,对于粒径在0.5~2.0 mm范围和粒径<0.5 mm的给矿,c2=0。对式(7)各参数进行拟合求值,结果如表3所列。

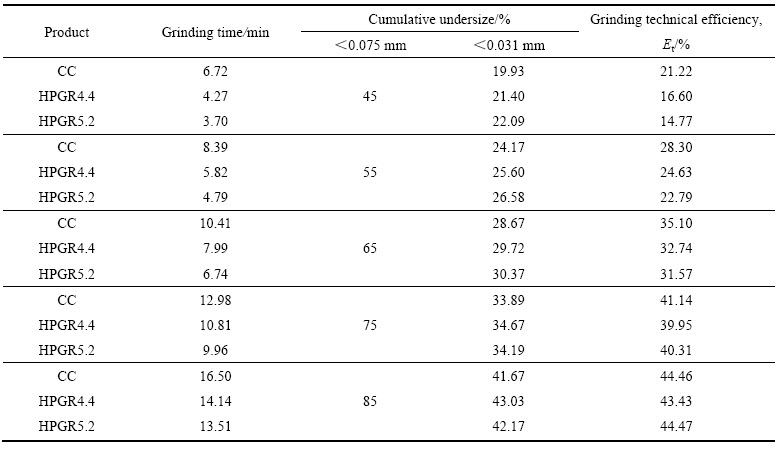

通过表3中粒度方程的参数可以求出磨矿产品的粒度分布随时间的变化情况,进而计算出在不同破碎方式下同一磨矿细度的磨矿时间和磨矿技术效率如表

4~表6所列。本次研究设定过粉碎粒度为0.031 mm。

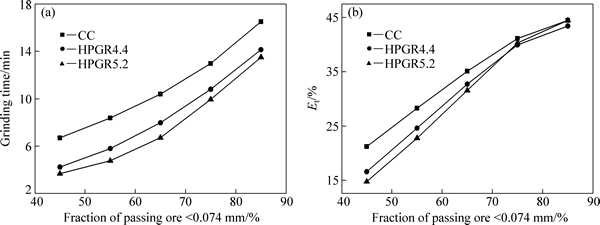

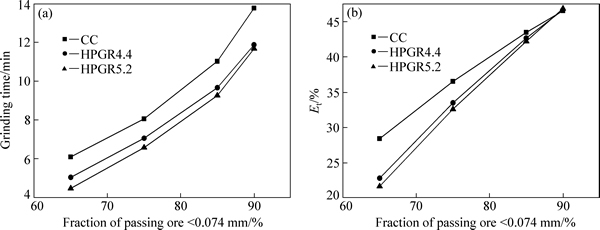

从图14可以看出,对于粒径<2.0 mm全粒级给矿,当磨矿磨矿至同一细度时,辊压产品所需要的磨矿时间明显低于圆锥产品的所需时间,时间缩短的幅度在2.17~3.67 min不等,这表明辊压产品的相对可磨度低、可磨性好、磨矿速度快。

随着磨矿细度的增加,磨矿技术效率提高,当磨矿细度增加到粒径<0.074 mm含量75%后,磨矿技术效率的变化趋于平缓。相对于圆锥产品而言,辊压产品的磨矿技术效率要低,但是降低的幅度随着磨矿细度的增加而降低,由6.45%降至0.83%。当磨矿细度增加到粒径<0.074 mm含量为75%后两者的磨矿技术效率相当。这表明对于粒径<2.0 mm全粒级给矿,辊压产品在粗磨条件下的合格中间粒级效率较低,存在一定的过粉碎现象,磨矿效果较差,但这种劣势会随着磨矿细度的增加而逐渐减弱,到达一定程度后而消失。

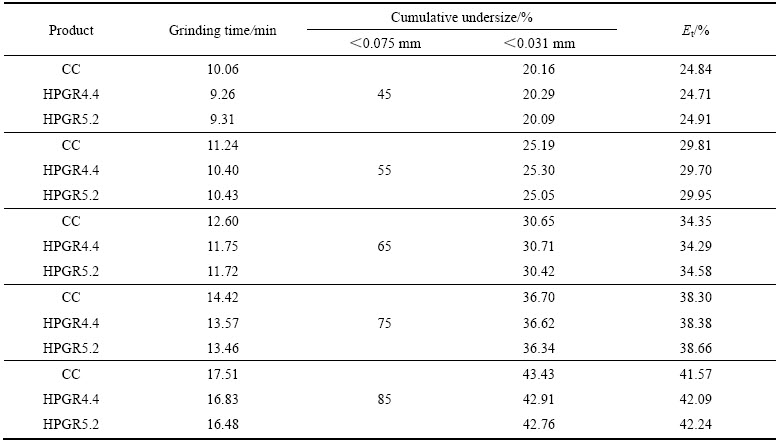

从图15可以看出,对于粒径在0.5~2.0 mm范围给矿,当磨矿磨矿至同一细度时,辊压产品所需要的磨矿时间同样低于圆锥产品的所需时间,时间缩短的幅度在0.80~1.03 min之间,明显低于粒径<2.0 mm全粒级给矿的幅度。磨矿技术效率同样随着磨矿细度的增加而增大。与粒径<2.0 mm全粒级给矿不同的是,辊压产品的磨矿技术效率与圆锥产品的相当甚至略高。显然,对于粒径在0.5~2.0 mm范围给矿,辊压产品的磨矿时间短、磨矿技术效率高、磨矿效果更好。

图11 粒径小于2.0 mm的全粒级给矿下参数b和n随时间的变化曲线

Fig. 11 Variation curves of b (a) and n (b) with grinding time for feed with size less than 2.0 mm

图12 粒径在0.5~2.0 mm范围内给矿下参数b和n随时间的变化曲线

Fig. 12 Variation curves of b (a) and n (b) with grinding time for feed with size in range of 0.5-2.0 mm

图13 粒径小于0.5 mm的给矿下参数b和n随时间的变化曲线

Fig. 13 Variation curves of b (a) and n (b) with grinding time for feed with size less than 0.5 mm

表3 不同破碎方式下式(7)的参数

Table 3 Parameters of Eq. (7) for different crushing products

表4 粒径小于2.0 mm全粒级给矿下不同磨矿细度下的磨矿技术效率(Et)

Table 4 Grinding technical efficiency Et at different grinding finenesses for feed with size less than 2.0 mm

表5 粒径在0.5~2.0 mm范围给矿下不同磨矿细度下的磨矿技术效率

Table 5 Grinding efficiency Et at different grinding finenesses for feed with size in range of 0.5-2.0 mm

表6 粒径小于0.5 mm粒级给矿下不同磨矿细度下的磨矿技术效率

Table 6 Et at different grinding finenesses for feed with size less than 0.5 mm

从图16可以看出,对于粒径<0.5 mm给矿,当磨矿磨矿至同一细度时,辊压产品所需要的磨矿时间明显低于圆锥产品的所需时间,时间缩短的幅度在1.00~2.09 min不等。粒径<0.5 mm给矿的磨矿技术效率变化规律与粒径<2.0 mm全粒级给矿的一致。辊压产品的磨矿技术效率较低,但是降低的幅度随着磨矿细度的增加而降低,当磨矿细度增加到粒径<0.074 mm含量90%后两者的磨矿技术效率相当。结合辊压产品的粒度分布特征(见图1),可以推断出,粒径<2.0 mm全粒级产品在粗磨条件下磨矿技术效率低的原因是由于独特的破碎方式使得辊压产品细粒级含量高,这部分细粒级产品的可磨性好,在磨矿粉碎过程中容易过粉碎。

图14 粒径小于2.0 mm全粒级给矿下磨矿时间和磨矿技术效率随细度的变化曲线

Fig. 14 Variation curves of grinding time (a) and Et (b) with grinding fineness for feed with size less than 2.0 mm

图15 粒径在0.5~2.0 mm范围给矿下磨矿时间和磨矿技术效率随细度的变化曲线

Fig. 15 Variation curves of grinding time (a) and Et (b) with grinding fineness for feed with size in range of 0.5-2.0 mm

图16 粒径小于0.5 mm粒级给矿下磨矿时间和磨矿技术效率随细度的变化曲线

Fig. 16 Variation curves of grinding time (a) and Et (b) with grinding fineness for feed with size less than 0.5 mm

磨矿机的碎磨作用是钢球之间的点接触,在随机性点打击的情况下发生“贯穿破碎”作用。“贯穿破碎”作用缺乏选择性, 更容易沿着裂纹处发生,破碎产物不是不同种类矿物粒子的单体解离,而是岩矿颗粒粒度的机械减小,其粉碎结果一方面产生许多连生体,另一方面又造成严重的过粉碎。如上所述,与圆锥产品相比,由于独特的破碎方式,辊压产品的内部裂纹发育充分,细粒级含量高,物料的机械强度(抗破碎强度)降低。在磨矿初期,辊压产品细粒级部分发生随机性“贯穿破碎”的概率会大大提高,更容易造成过粉碎;而到磨矿中后期,辊压产品内部裂纹在磨矿作用下形成了新的断裂面,新生颗粒内部结构致密,与圆锥产品相比,过粉碎已不再显著。该部分机理研究将在后续文章中详细阐述。

2.3 矿石高压辊磨机超细碎-分级磨矿新工艺的提出

基于高压辊磨机全粒级产品粒度特性和磨矿特性,本文作者提出一种高压辊磨超细碎-分级磨矿新工艺。原矿采用高压辊磨机进行全闭路超细粉碎,闭路控制筛孔的尺寸为3~5 mm[9],对嵌布粒度较细的矿石需要进行两段磨矿磨矿时,可以对辊压产品预先分级出细粒级产品(适宜的分级粒级为粒径<0.5 mm),该细粒级产品可以跳过一段磨矿直接进入二段磨矿得到粒径<0.074 mm含量在90%左右的产品,而粗粒级产品仍需两段磨矿,其原则流程如图17所示。这种高压辊磨机超细碎-分级磨矿新工艺,既可以大量的降低一段磨机的入磨量(进入一段磨机的入磨量可降低40%~50%),又可以缩短磨矿时间、提高磨矿技术效率从而减弱整体磨矿过程中的过粉碎(尤其在一段粗磨下)。该工艺也适用于多段磨矿工艺。

图17 高压辊磨机超细碎-分级磨矿新工艺流程图

Fig. 17 New process flowsheet of ultra-crushing-classified grinding

3 结论

1) 在控制粒度为2.0 mm的全闭路破碎条件下,破碎产品的个别粒级分布呈现出“双峰”的特征,“双峰”分别出现在粒径<0.18 mm和0.5~1.6 mm两个粒级范围内。辊压产品的“双峰”特征明显,而圆锥产品中粒径<0.18 mm 的“峰”相对平缓,粒径在0.5~1.6 mm范围内的“峰”更加尖锐。“双峰”特征使得辊压产品的平均粒度小,分布更加不均匀。

2) 考虑到磨矿过程中的过粉碎,通过磨矿技术效率来评价不同破碎方式的磨矿效果,过粉碎粒度设定为0.031 mm。当磨矿磨矿至同一细度时,辊压产品所需要的磨矿时间明显低于圆锥产品的所需时间,表明辊压产品的相对可磨度低,可磨性好。相对于圆锥产品而言,对于粒径<2.0 mm全粒级给矿和粒径<0.5 mm粒径给矿,辊压产品的磨矿技术效率要低,但是降低的幅度随着磨矿细度的增加而降低,当磨矿细度增加到某一程度后两者的磨矿技术效率相当。在粗磨条件下,辊压产品的磨矿在粉碎产品中合格的中间粒级产品的效率较低,过粉碎现象更严重,磨矿效果较差,但这种劣势会随着磨矿细度的增加而逐渐减弱,到达一定程度后而消失。而对于粒径在0.5~2.0 mm范围给矿,辊压产品的磨矿技术效率与圆锥产品的相当甚至略高,但辊压产品所需的磨矿时间更短,辊压产品的磨矿效果更好。

3) 基于辊压产品的粒度分布特征和磨矿特性,提出一种高压辊磨超细碎-分级磨矿新工艺,该工艺也适用于两段或多段磨矿工艺。原矿采用高压辊磨机进行全闭路超细粉碎,闭路控制筛孔的尺寸为3~5 mm,对辊压产品预先分级出细粒级产品(分级粒级为粒径<0.5 mm),该细粒级产品可以跳过一段磨矿直接进入二段磨矿得到粒径<0.074 mm含量在90%左右的产品,而粗粒级产品仍需两段磨矿磨矿。该工艺既可以大量地降低一段磨机的入磨量(进入一段磨机的入磨量可降低40%~50%),又可以缩短磨矿时间、提高磨矿技术效率,减弱整体磨矿过程中的过粉碎(尤其在一段粗磨下)。

REFERENCES

[1] NORGATE T E, WELLER K R. Selection and operation of high pressure grinding rolls circuits for minimum energy consumption[J]. Minerals Engineering, 1994, 7(10): 1253-1267.

[2] FUERSTENAU D W, KAPUR P C. Newer energy-efficient approach to particle production by comminution[J]. Powder Technology, 1995, 82(1): 51-57.

[3] 高 航, 方存光, 杨晓明, 徐小荷. 高压辊磨技术的发展及其在选矿业的应用前景[J]. 中国有色金属学报, 1998, 8(S2): s623-s626.

GAO Hang, FANG Cun-guang, YANG Xiao-ming, XU Xiao-he. Development of HPGR technology and the application prospect in the mineral processing[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(S2): s623-s626.

[4] MAXTON D, MORLEY C, BEARMAN R. A quantification of the benefits of high pressure rolls crushing in an operating environment[J]. Minerals Engineering, 2003, 16(9): 827-838.

[5] LIM W I L, WELLER K R. Some benefits of using studded surfaces in high pressure grinding rolls[J]. Minerals Engineering, 1999, 12(2): 187-203.

[6] DANIEL M J, MORRELL S. HPGR model verification and scale-up[J]. Minerals Engineering, 2004, 17(11/12): 1149-1161.

[7] AYDOGAN A, ERGUN L, BENZER H. High pressure grinding rolls (HPGR) applications in the cement industry[J]. Minerals Engineering, 2006, 19(2): 130-139.

[8] FUERSTENAU D W, LUTCH J J. The effect of ball size on the energy efficiency of hybrid high-pressure roll mill/ball mill grinding[J]. Powder Technology, 1999, 105(1): 199-204.

[9] van der MEER F P, GRUENDKEN A. Flowsheet considerations for optimal use of high pressure grinding rolls[J]. Minerals Engineering, 2010, 9(23): 663-669.

[10] 袁致涛, 刘 磊, 严 洋, 韩跃新. 高压辊磨机粉碎贫赤铁矿产品粒度特性[J]. 东北大学学报(自然科学版), 2011, 32(6): 875-878.

YUAN Zhi-tao, LIU Lei, YAN Yang, HAN Yue-xin. Product size characteristics of low grade hematite in high pressure grinding roll[J]. Journal of Northeastern University (Natural Science), 2011, 32 (6): 875-878.

[11] HAN Yue-xin, LIU Lei, YUAN Zhi-tao. Comparison of low-grade hematite product characteristics in a high pressure grinding roller and jaw crusher[J]. Mineral & Metallurgical Processing, 2012, 29 (2): 75-80.

[12] 刘 磊, 曹进成, 郭珍旭, 岳铁兵, 吕 良. 不同破碎方式下贫赤铁矿石分选特性对比研究[J]. 矿山机械, 2014, 42(7): 110-115.

LIU Lei, CAO Jin-cheng, GUO Zhen-xun, YUE Tie-bing,  Liang. Comparative study on separation characteristics of lean hematite in various comminution modes[J]. Mining & Processing Equipment, 2014, 42(7): 110-115.

Liang. Comparative study on separation characteristics of lean hematite in various comminution modes[J]. Mining & Processing Equipment, 2014, 42(7): 110-115.

[13] LIU Lei, TAN Qi, YUE Tie-bing, GUO Zhen-xue. Pre-concentration of ultrafine crushed hematite ores[J]. Separation Science and Technology, 2014, 49(9): 144-1448.

[14] 侯 英, 丁亚卓, 印万忠, 姚 金. 磨矿动力学参数对磨矿速度的影响[J]. 东北大学学报(自然科学版), 2013, 34(5): 708-711.

HOU Ying, DING Ya-zhuo, YIN Wan-zhong, YAO Jin. Influence of grinding kinetics parameters on grinding speed[J]. Journal of Northeastern University (Natural Science), 2013, 34(5): 708-711.

[15] LIU Lei, HAN Yue-xin, YUAN Zhi-tao. Crushed product characteristics of low-grade hematite in high-pressure grinding roller[J]. Advanced Materials Research, 2011, 158(1): 35-41.

[16] 段希祥. 碎矿与磨矿[M]. 3版. 北京: 冶金工业出版社, 2013, 16: 135-136.

DUAN Xi-xiang. Crushing and grinding[M]. 3nd ed. Beijing: Metallurgical Industry Press, 2013, 16: 135-136.

[17] WILLS B A, NAPIER T J. Mineral processing technology[M]. Queensland: Elsevier Science & Technology Books, 2006: 96-97.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51304175)

收稿日期:2014-12-09;修订日期:2015-04-25

通信作者:刘 磊,副研究员,博士;电话:0371-68632152;E-mail:liulei_9910@163.com