NiFe2O4/Cu金属陶瓷与金属的磷酸盐黏接特性

张雷,陈孜,李志友,周科朝,李超

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:采用磷酸铝铬为胶黏剂,NiFe2O4陶瓷粉与Cu-Ag合金粉为填充料,CuO为固化剂,对NiFe2O4/Cu金属陶瓷与45#钢的黏接特性进行研究。通过测试黏接接头强度、分析黏接界面和黏接层的显微结构和物相组成等研究胶黏剂浓度和处理工艺对黏接接头室温和高温黏接性能的影响。实验结果表明,于120 ℃固化和1 000 ℃热处理后的黏接界面结合紧密,于120 ℃固化后的室温拉剪强度达53.88 MPa,于1 000 ℃热处理后的室温拉剪强度为25.43 MPa;700 ℃时试样拉剪强度达29.25 MPa,800 ℃时接头的拉剪强度降为6.54 MPa;胶黏剂的软化及熔化是导致800 ℃时接头高温黏接强度降低的一个主要原因,同时,高温下磷酸盐分解物的挥发及其物相反应导致黏接层疏松、多孔。

关键词:磷酸铝铬胶黏剂;黏接强度;黏接界面;黏接层

中图分类号:TG496 文献标志码:A 文章编号:1672-7207(2010)06-2149-07

Phosphate bonding characteristic of NiFe2O4/Cu cermet and metal

ZHANG Lei, CHEN Zi, LI Zhi-you, ZHOU Ke-chao, LI Chao

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: An adhesive bonding technology of NiFe2O4/Cu cermet and 45# steel was investigated using aluminum chromium phosphate as binder, CuO as curing agents and NiFe2O4 ceramic powder and Cu-Ag powder as fillers. Strength of bonded joint, microstructure of bonding interface and phase composition of the adhesive layers were characterized. The effects of binders and process on room-temperature and high temperature bonding performance were studied. The results show that the consistence of binders and treatment technologies are critical to adhesion performance of bonded joint at room-temperature and high temperature. Bonding interface combines closely after curing at 120 ℃ and heat treatment at 1 000 ℃. After curing at 120 ℃, the room temperature tensile shearing strength is 53.88 MPa. Tensile shearing strengths of bonded joint are 25.43 MPa after heat treatment at 1 000 ℃, 29.25 MPa at 700 ℃ and 6.54 MPa at 800 ℃, respectively. Softening and melting of binders behavior at 800 ℃ is responsible for the decrease in strength of bonded joint. Volatile of decomposition products and phase reaction also cause porous adhesive layer which weakens the strength.

Key words: aluminium chromium phosphate binder; bonding strength; bonding interface; adhesive layer

陶瓷与金属的连接是工程应用需要解决的关键技术之一。陶瓷材料与金属间的物相性能差异、两者间较差的界面润湿性,使得采用铆接、螺接、焊接等传统连接方式均难实现有效可靠连接[1-5]。现代黏接工艺是一项新工艺、新技术,它能部分代替焊接、铆接和螺接工艺,将金属和陶瓷材料牢固地连接在一起,并且可以达到较高的强度要求[6]。黏接具有固化速度快、使用温度范围广、工艺简单、价格低廉和成型性能好等优点[7]。研究结果表明:采用磷酸盐胶黏剂黏接金属和陶瓷时,可获得较理想的室温黏接强度[8-10],套接拉剪强度达18 MPa以上,平面搭接拉剪强度为 2 MPa左右。Gao等[11]采用以CePO4和ZrO2为主要成分的胶黏剂黏接25%CePO4/ZrO2和ZrO2陶瓷,对CePO4与(CePO4+ZrO2)的质量比对黏接强度和接头微观结构的影响,并测得当CePO4与(CePO4+ZrO2)的质量比为0.5时,其黏接强度达414 MPa。在调配被黏接物间的线膨胀系数、弹性模量等物性差异、大幅度降低热应力的同时,合理使用填充料,还能起到提高接头黏接强度的作用。在氧化铜-磷酸无机胶中加入适当导电组元,可改善其导电性能,而且连接结构经高温处理后仍具有较好的黏结强度和密封性能,可满足具有导电性能要求的陶瓷材料的连接应用需求[12]。韩敏等[13-14]用新型耐高温DT5012无机胶黏剂连接了高纯α-Al2O3和20#钢,所得连接结构室温拉剪强度达24.45 MPa,550 ℃时拉剪强度达19.75 MPa,700 ℃时拉剪强度达21.75 MPa。NiFe2O4基金属陶瓷是具有广阔应用前景的铝电解惰性阳极材料,但其与金属导杆连接困难及连接导电性差等问题限制了该材料的铝电解应用[15]。本文作者针对铝电解用NiFe2O4基金属陶瓷的上述需求,采用磷酸铝铬胶黏剂[16],以NiFe2O4陶瓷粉、Cu-Ag合金作填充料,CuO粉为固化剂进行NiFe2O4基金属陶瓷与45#钢的套接黏接研究,探索胶黏剂浓度、处理工艺对黏接结构室温、高温拉伸剪切强度的影响,并重点分析金属陶瓷(NiFe2O4/Cu)-黏接层界面结合特征。

1 实验方法

实验用磷酸铝铬胶黏剂为H3PO4,Al(OH)3,CrO3,H2BO3、柠檬酸和水经160 ℃合成的产物。填充料为NiFe2O4陶瓷粉和Cu-Ag合金粉按质量比1?1的混合物。固化剂为粒径≤75 μm的CuO粉。黏接结构的制备过程为:首先将磷酸铝铬胶黏剂、填充料和固化剂按比例混合均匀,将配制好的黏结剂均匀涂布于金属陶瓷和45#钢金属试样被黏接表面,黏接后进行固化处理,固化过程分为3个阶段:(1) 于室温下放置2~ 3 h;(2) 于60 ℃保温4~6 h;(3) 于120 ℃保温12 h。部分试样固化后于1 000 ℃保温处理2 h。

采用Instron3369力学试验机,按GB/T 7124—2008标准测试黏接结构的套接拉伸剪切强度,拉伸速率为1 mm/min;高温拉剪强度测试温度为500,600,700和800 ℃。采用DIL 402C/1/4/7G热膨胀仪测试固化剂CuO与含水量(质量分数)为15%的磷酸铝铬胶黏剂混合制备的柱状试样的高温结构变化情况,升温速率为5 ℃/min。采用Rigaku D-Max/2550VB+型X线衍射仪分析黏接层的物相组成。采用JSM-6490Lv扫描电子显微镜观察黏接界面结合状态及黏接层断面形貌。

2 结果与讨论

2.1 黏接层的物相结构分析

磷酸盐胶黏剂主要是由Al(H2PO4)3,H2O和H3PO4组成的酸性混合液,主要成分为Al(H2PO4)3,其为Al(OH)3与H3PO4的反应产物,见式(1)。胶黏剂中的Al(H2PO4)3和未反应完的H3PO4与固化剂CuO在固化过程中反应生成CuHPO4·H2O和AlPO4,见式(2)[17]和(3)[18-19]。

3H3PO4+Al(OH)3→Al(H2PO4)3+3H2O (1)

Al(H2PO4)3+2CuO→2CuHPO4·H2O+ AlPO4 (2)

H3PO4+CuO→CuHPO4·H2O (3)

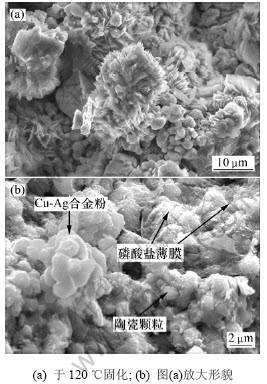

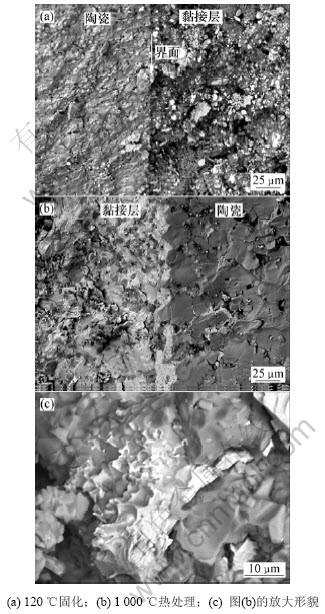

图1所示为黏接层于120 ℃固化后内部断面形貌。从图1(a)可以观察到晶花状的物质,经能谱分析证明为CuHPO4·H2O物相,它以晶态存在,在黏接层内部形成一个呈星芒状彼此穿插连续分布的结构,主要通过离子键和氢键把Cu2+和水分子等结合在一起,具有一定的硬度和固结能力[20]。从图2(b)可观察到较暗的颗粒为陶瓷颗粒,其粒径为2~5 μm,较亮的颗粒为Cu-Ag合金颗粒,这些颗粒表面均匀地包覆一层磷酸盐薄膜,形成了陶瓷颗粒和金属颗粒之间的黏接纽带。

图1 黏接层于120 ℃固化后内部的SEM形貌

Fig.1 SEM micrographs of adhesive layer after curing at 120 ℃

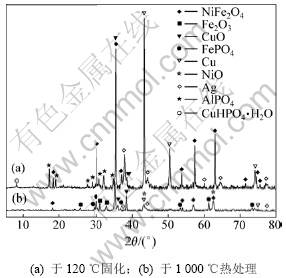

图2所示为黏接层经120 ℃固化和1 000 ℃热处理后的X线衍射图。图2表明:黏接层于120 ℃固化后主要物相为NiFe2O4,Cu,Ag,CuO,CuHPO4·H2O和少量的AlPO4,黏接层于1 000 ℃热处理后主要物相为NiFe2O4,Cu,Ag,CuO,NiO,Fe2O3和FePO4。说明在120 ℃固化过程中,胶黏剂与固化剂CuO反应只生成了CuHPO4·H2O和AlPO4 2种物相(见反应式(2)和(3))。由于CuHPO4·H2O是热不稳定相,当温度高于300 ℃时,会分解为晶态Cu3(PO4)2[21],同时在黏接层/金属界面上,由于Fe的电位高于Cu的电位,在金属表面易发生置换反应生成Fe2O3,如式(4)所示。此外,在高温条件下,磷酸盐会分解产生P2O5,其与Fe2O3 反应生成FePO4,如式(5)。因此,经1 000 ℃热处理后,固化反应产物CuHPO4·H2O基本反应完全。XRD分析结果也表明,黏接层经高温热处理后,无CuHPO4·H2O及AlPO4物相存在。

2Fe+3CuO→ Fe2O3+3Cu (4)

P2O5+Fe2O3→ 2FePO4 (5)

图2 黏接层于120 ℃固化和1 000 ℃热处理后的XRD谱

Fig.2 XRD patterns of adhesive layer after curing at 120 ℃ and heat treatment at 1 000 ℃

2.2 黏接接头的力学性能

2.2.1 黏接接头室温强度

表1所示为采用不同含水量黏接胶黏剂所得接头经120 ℃固化和1 000 ℃热处理后的室温拉剪强度。从表1可以发现:黏接接头的室温拉剪强度随着胶黏剂含水量增大而降低;黏结剂固化后,其接头黏接强度的形成取决于H3PO4,Al(H2PO4)3与CuO反应形成CuHPO4·H2O胶结产物的量和分布状态,在产物分布均匀的情况下,胶黏剂含水量越高,即Al(H2PO4)3和H3PO4含量越小,固化时形成CuHPO4·H2O的量越少,接头的拉剪强度越低;同时,胶黏剂含水量越高,而接头在固化时由于水气蒸发所形成的孔隙越多,对接头黏接强度的负面影响也越多。

为考查接头在高温环境处理后的残余黏接强 度,实验测试了套接黏接接头经1 000 ℃热处理后的室温拉剪强度(见表1)。结果表明:于1 000 ℃热处理后接头的室温拉剪强度仍能保持于120 ℃固化后的45%~48%的强度。

表1 不同含水量黏接胶黏剂所得接头经120 ℃固化和1 000 ℃热处理后的室温拉剪强度

Table 1 Tensile shearing strength at room temperature for bonded joints with different binder consistences after curing at 120 ℃and heat treatment at 1 000 ℃

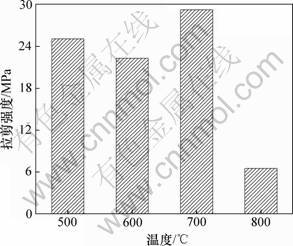

2.2.2 黏接接头高温强度

采用含水量为15%的磷酸铝铬胶黏剂制备了套接高温拉剪强度测试试样,经120 ℃固化后分别进行500,600,700和800 ℃高温拉剪强度测试。黏接接头高温拉剪强度如图3所示。结果表明:当温度低于700 ℃时,接头依然能够保持较大的拉剪强度;700 ℃时,试样拉剪强度达29.25 MPa,但800 ℃时,试样的拉剪强度急剧下降,拉剪强度为6.54 MPa。

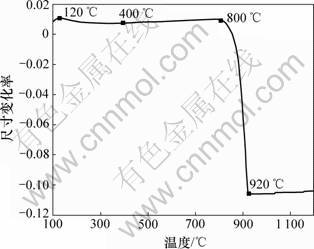

用固化剂CuO与含水量为15%的磷酸铝铬胶黏剂混合制备柱状试样,试样经120 ℃固化后,在热膨胀测试仪上测试了样品的尺寸变化情况,测试结果见图4。图4表明:试样在整个测试的温度范围内尺寸发生了较为明显的变化,在120~400 ℃内,试样缓慢收缩;在400~800 ℃,试样尺寸缓慢增加,线膨胀率较小;当温度高于800 ℃时,线膨胀率急剧降低为负值。根据文献[20],YW1型氧化铜磷酸盐无机胶黏剂在725 ℃开始软化,在950 ℃开始熔化,结合图4所示的测试结果,可以判断本文所制备的磷酸铝铬胶黏剂[16]体系的软化温度为800 ℃,熔化温度为920 ℃。因此,固化剂CuO与磷酸盐胶黏剂反应产物的软化及熔化是导致温度高于800 ℃后试样拉剪强度降低的一个主要原因。

图3 黏接接头高温段拉剪强度

Fig.3 Tensile shearing strength at high temperatures for bonded joints

图4 CuO与胶黏剂柱状试样于120 ℃固化后的尺寸变化率与温度的关系

Fig.4 Relationship between dimensional change percentage of gluing tetragonal prism specimen of CuO curing with binder at 120 ℃ and temperature

2.3 黏接层的显微组织分析

图5所示为于120 ℃固化和1 000 ℃热处理后的金属陶瓷-黏接层界面断面形貌。从图5可见:于 120 ℃固化后的金属陶瓷-黏接层界面结合紧密,主要受益于金属陶瓷颗粒表面微孔和凹凸结构,对糊状的黏接剂的吸附作用[22];于1 000 ℃热处理后金属陶瓷与黏接层结合紧密,界面清晰,由于热处理过程中金属陶瓷晶粒发生了不同程度的长大,使得界面上的陶瓷颗粒参差不齐,呈现锯齿状边界,与黏接层达到很好的机械嵌合作用,在一定程度上增大了黏接面积,改善了界面结合状态。图5(c)所示为图5(b)所示的黏接层中局部放大形貌,可观察到黏接层中部分金属相表面出现了韧窝结构,说明黏接层中的Cu-Ag合金金属相在断裂过程中承受了一定的拉应力。

图5 于120 ℃固化和1 000 ℃热处理后的金属陶瓷-黏接层界面断面形貌

Fig.5 Cross-section of interface of cermet-adhesive layer after curing at 120 ℃ and heat treatment at 1 000 ℃

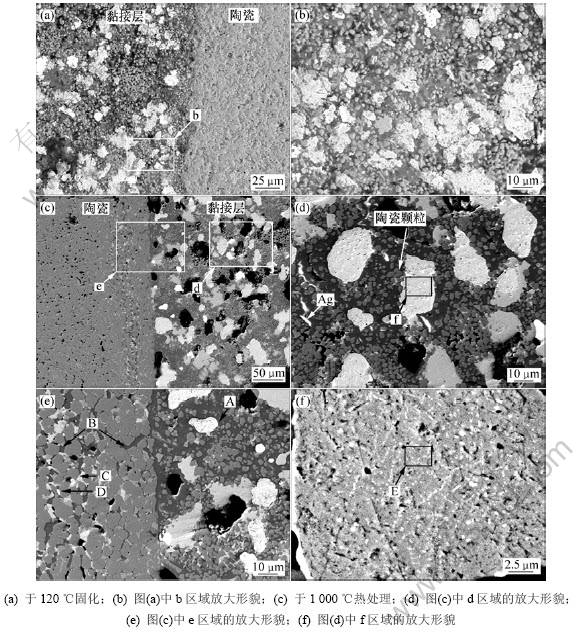

图6所示为金属陶瓷-黏接层界面抛光后的显微形貌。

图6 于120 ℃固化和1 000 ℃热处理后的金属陶瓷-黏接层界面SEM形貌

Fig.6 SEM images of interface of cermet-adhesive layer after curing at 120 ℃ and heat treatment at 1 000 ℃

从图6可见:经120 ℃固化后的金属陶瓷-黏接层界面曲折模糊且致密;在黏接层中可观察到3种物相,即均匀分布的、灰色点状的陶瓷颗粒,亮灰色的金属相及分布于两者间糊状的黏结相(见图6(b))。黏接结构经1 000 ℃热处理后,界面平直且清晰,其中黏接层为多孔结构,黏接层中的孔隙呈不规则分布。放大的黏接层细部(见图6(d))表明:这些孔隙主要为黏接层中磷酸盐反应产物结晶水的脱除及高温下的物相反应所致,Cu-Ag合金相也在高温处理过程中由弥散状迁移聚集呈块状分布。在图6(c)中可观察到在黏接界面靠近金属陶瓷一侧存在一层厚度为25 μm左右的扩散层和较多的细小孔隙,表明热处理过程中黏接层中的黏结剂及金属相通过金属陶瓷中的孔隙结构扩散进入金属陶瓷基体。图6(e)进一步展示了扩散层与黏接层的界面结合状态,扩散效果清晰可辨。

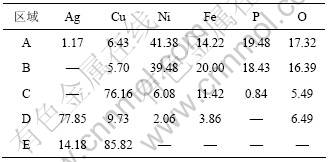

采用能谱对图6(e)和6(f)中A~E等区域进行了半定量元素分析,结果(摩尔分数)见表2。可见:A区的主要成分为FePO4,Fe2O3和NiO,及少量金属Cu和Ag;B区与A区成分大致相同,主要为磷酸盐黏结剂和Fe2O3的反应产物;C区和D区的主要元素分别为Cu和Ag,黏接层中的部分Cu-Ag合金在高温下扩散进入金属陶瓷基体。图6(f)中的E区主要为Ag和Cu 2种元素,即该区为黏接层中的金属相。在高温下Ag和Cu形成固溶体,在降温过程中,Ag会沿Cu相的晶界或晶内缺陷处析出[23],因而出现了Ag以点状、条状分布的状态。

表2 A~E区域的能谱分析结果

Table 2 Results of energy spectrum analysis of A-E regions %

上述分析结果表明:在采用磷酸铝铬胶黏剂黏接连接金属陶瓷时,黏接层中的黏结剂及金属相向金属陶瓷一侧发生了较为明显的扩散,扩散现象的发生在改善两者界面结合状态的同时,也对提高界面的结合强度起到一定的促进作用;另一方面,于1 000 ℃热处理后,黏接层因磷酸盐分解物的挥发及其与Fe2O3的反应导致黏接性能下降,同时产生的大尺寸孔隙导致黏接层疏松多孔,黏接强度降低。

3 结论

(1) 连接结构的黏接强度随胶黏剂浓度的增大而提高,用含水量为15%的磷酸铝铬胶黏剂黏接金属陶瓷与金属时,于120 ℃固化后的室温拉剪强度可达53.88 MPa,于1 000 ℃热处理后的室温拉剪强度达25.43 MPa。

(2) CuO与磷酸盐胶黏剂反应产物的软化及熔化是导致800 ℃以后试样拉剪强度降低的一个主要原因。同时,高温下磷酸盐分解物的挥发及其与Fe2O3反应导致黏接性能下降,产生的大尺寸孔隙也对黏接强度产生一定的负面影响。

(3) 金属陶瓷基体与黏接层界面结合紧密,过渡层平滑。在高温下,黏接层中的黏结剂及金属组元向金属陶瓷一侧的扩散现象,该现象对金属陶瓷基体与黏接层界面结合强度的提高起到了促进作用。

参考文献:

[1] 李卓然, 樊建新, 冯吉才, 等. 氧化铝陶瓷与金属连接的研究现状[J]. 宇航材料工艺, 2008(4): 6-10.

LI Zhuo-ran, FAN Jian-xin, FENG Ji-cai. Progress in joining of alumina ceramics to metal[J]. Aerospace Material & Technology, 2008(4): 6-10.

[2] Vegter R H, den Ouden G. Diffusion bonding of zirconium to silicon nitride using nickel interlayer[J]. Journal of Material Science, 1998, 33(18): 4525-4530.

[3] Iseki T, Kameda T, Marayama T. Interfacial reaction between SiC and aluminum during joining[J]. Journal of Science, 1984, 19(l): 692-698.

[4] 邢世凯, 屈玲玲, 王静, 等. 工程陶瓷材料及其与金属连接工艺的研究进展[J]. 陶瓷, 2003(6): 9-12.

XING Shi-kai, QU Ling-ling, WANG Jing, et al. Engineering ceramic materials and ceramic-metal bonding technology[J]. Ceramics, 2003(6): 9-12.

[5] Treheux D, Lourdin P, Mbongo B, et al. Metal-ceramic solid state bonding: Mechanisms and mechanics[J]. Scripta Metallurgical at Materialia, 1994, 31(8): 1055-1060.

[6] 熊腊森. 黏接技术问答[M]. 北京: 机械工业出版社, 2005: 10.

XIONG La-sen. Question and answer of adhesion technology[M]. Beijing: Mechanical Industry Press, 2005: 10.

[7] 杨伟群, 李树杰. 陶瓷-金属的连接工艺[J]. 航空工程与维修, 1998(1): 17-19.

YANG Wei-qun, LI Shu-jie. Joining technology for ceramic and metal[J]. Aviation Engineering & Maintenance, 1998(1): 17-19.

[8] 刘志甫, 徐晓伟, 李玉萍, 等. 用无机胶黏接金属和陶瓷[J]. 北京科技大学学报, 1999, 21(5): 476-478.

LIU Zhi-pu, XU Xiao-wei, LI Yu-ping, et al. Joining metals to ceramics with inorganic adhesive bonding[J]. Journal of University of Science and Technology Beijing, 1999, 21(5): 476-478.

[9] 郑举功, 陈泉水, 杨婷, 等. 氧化铜-磷酸盐无机胶黏剂的制备工艺研究[J]. 东华理工学院学报, 2006, 29(1): 84-87.

ZHENG Ju-gong, CHEN Quan-shui, YANG Ting, et al. Study on the preparation technics of copper oxide-phosphate inorganic adhesive[J]. Journal of East China Institute of Technology, 2006, 29(1): 84-87.

[10] 李冰, 王超, 陈泽明, 等. 中温固化磷酸盐基耐高温胶黏剂的研制[J]. 化学与黏合, 2008, 30(3): 15-16.

LI Bing, WANG Chao, CHEN Ze-ming, et al. Study on preparing high temperature resistant phosphate adhesive cured at moderate temperature[J]. Chemistry and Adhesion, 2008, 30(3): 15-16.

[11] GAO Hai, LIU Jia-chen, DU Hai-yan, et al. Effects of adhesive composition on bond strength of green joined CePO4-ZrO2 ceramics[J]. Scripta Materialia, 2003, 49(6): 512-520.

[12] 田永奎, 张星, 彭有根, 等. 用于金属-陶瓷黏接的无机导电胶[J]. 华北工学院学报, 1998, 19(1): 62-63.

TIAN Yong-gui, ZHANG Xing, PENG You-gen. The inorganic electrical conductive sticker for gluing metal ceramics[J]. Journal of North China Institute of Technology, 1998, 19(1): 62-63.

[13] 韩敏, 陶文亮, 艾浩, 等. α-Al2O3陶瓷膜管与金属黏接强度的实验研究[J]. 黏接, 2007, 28(4): 32-35.

HAN Min, TAO Wen-liang, AI Hao, et al. Study on bonding strength of α-Al2O3 ceramic membrane tube to 20# steel[J]. Adhesion in China, 2007, 28(4): 32-35.

[14] 韩敏, 陶文亮, 田星, 等. α-Al2O3陶瓷膜管与金属黏接试样机械特性及显微结构的实验研究[J]. 材料导报, 2008, 22(8): 146-149.

HAN Min, TAO Wen-liang, TIAN Xing, et al. Investigation on mechanical characteristic and microstructure of α-Al2O3 ceramic membrane tube and metal bonding samples[J]. Materials Review, 2008, 22(8): 146-149.

[15] 张雷. 铝电解用NiFe2O4/M金属陶瓷惰性阳极材料制备与性能研究[D]. 长沙: 中南大学粉末冶金国家重点实验室, 2006: 14-17.

ZHANG Lei. The preparation and properties of NiFe2O4/M based cermet inert anode for primary aluminum smelting[D]. Changsha: Central South University. State Key Laboratory of Powder Metallurgy, 2006: 14-17.

[16] 张雷, 周科朝, 李志友, 等. 铝电解陶瓷基惰性阳极与金属导杆连接结构及其制备方法: 中国, 200810031871.4[P]. 2008-07-24.

ZHANG Lei, ZHOU Ke-chao, LI Zhi-you, et al. The preparation method and connecting structure of ceramic-based inert anodes in aluminum to metal guide rod: China, 200810031871.4[P]. 2008-07-24.

[17] Finch T, Sharp J H. Chemical reactions between magnesium and aluminum orthophosphate to form magnesia-phosphate cements[J]. Journal Material Science, 1989, 24: 4379-4386.

[18] Wagh A S, Jeong S Y. Chemically bonded phosphate ceramics: I, A dissolution model of formation[J]. Journal of the American Ceramic Society, 2003, 86(11): 1838-1844.

[19] 张玉龙, 李长德. 金属用胶黏剂[M]. 北京: 中国石化出版社, 2004: 390.

ZHANG Yu-long, LI Chang-de. Adhesive for metal[M]. Beijing: China Petrochemical Press, 2004: 390.

[20] 贺孝先, 孙争光, 晏成栋. 无机胶黏剂[M]. 昆明: 化学工业出版社, 2003: 62-68.

HE Xiao-xian, SUN Zheng-guang, YAN Cheng-dong. Inorganic adhesive[M]. Kunming: Chemical Industry Press, 2003: 62-68.

[21] 汤旭相, 李瑞安. 氧化铜及其与磷酸反应产物的研究[J]. 黏接, 1985, 6(2): 1-4.

TANG Xu-xiang, LI Rui-an. Studies on copper oxide and the reactants reacted it with phosphoric acid[J]. Adhesion in China, 1985, 6(2): 1-4.

[22] 殷立新, 徐修成. 胶黏基础与胶黏剂[M]. 武汉: 华中科技大学出版社, 2004: 6.

YIN Li-xin, XU Xiu-cheng. Adhesive base and adhesive[M]. Wuhan: Huazhong University of Science and Technology Press, 2004: 6.

[23] 郭庚辰. 液相烧结粉末冶金材料[M]. 北京: 化学工业出版社, 2002: 215.

GUO Geng-chen. Liquid-phase sintering powder metallurgy material[M]. Beijing: Chemical Industry Press, 2002: 215.

(编辑 赵俊)

收稿日期:2010-01-06;修回日期:2010-04-15

基金项目:国家高技术研究发展计划项目(2008AA030501);国家重点基础研究发展规划资助项目(2005CB623703)

通信作者:张雷(1975-),男,辽宁锦州人,博士,从事粉末冶金先进陶瓷材料研究;电话:0731-88836264;E-mail: zhanglei@mail.csu.edu.cn