DOI: 10.11817/j.issn.1672-7207.2017.05.005

基于RSM的铝合金大锻件局部加载成形质量控制

王梦寒1,马鹏程1,周峻峰1,吴道祥1,曾庆华2

(1. 重庆大学 材料科学与工程学院,重庆,400044

2. 西南铝业(集团)有限责任公司 锻造厂,重庆,401326)

摘要:为解决局部加载条件下铝合金大型锻件成形过程中微观组织不均匀与过渡区筋部充填不满的问题,借助于响应面法(RSM)与数值模拟相结合的策略对锻件局部加载成形工艺进行研究。以锻件微观组织均匀性和填充性作为质量评价目标,建立坯料温度、压力机速度、上模斜角角度、道次与质量指标之间的关系模型,并得到合理的工艺参数:坯料温度为440 ℃,压力机速度为10 mm/s,上模斜角角度为158°,3道次成形,各道次压下量分别为20,20和5 mm,将得到的工艺参数进行再模拟并应用于生产试制。对生产试制得到的锻件的典型截面进行组织观察。研究结果表明:模拟和实际生产的锻件微观组织均匀,分布规律一致,且锻件均充填完整,所提出的策略能有效对大型锻件局部加载成形宏、微观质量进行控制。

关键词:铝合金大锻件;局部加载;微观组织;填充性;响应面法

中图分类号:TG316 文献标志码:A 文章编号:1672-7207(2017)05-1155-07

Control of local loading forming quality for aluminum alloy heavy forging based on RSM

WANG Menghan1, MA Pengcheng1, ZHOU Junfeng1, WU Daoxiang1, ZENG Qinghua2

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. Forging Branch, Southwest Aluminum (Group) Co. Ltd., Chongqing 401326, China)

Abstract: The strategy of combining response surface method with FEM was proposed to solve the problems under filling and micro-structural uniformity of 7050 aluminum alloy heavy forging, which was formed in the process of local loading. A response surface model was established, with the micro-structural uniformity and filling capacity as its evaluation objectives, and billet temperature, press velocity, angle of up die and parameter for passes were selected as the design variables of that model. Then the reasonable process parameters were obtained: billet temperature, press velocity and angle of up die are 440 ℃, 10 mm/s and 158°, respectively. The number of passes is three, the amount of each pass was 20, 20 and 5 mm. The parameters obtained above were applied in simulation and practical manufacture. The results show that not only the microstructure of forging obtained by simulation and manufacturer is uniform but also the distribution law of microstructure is consistent. The capacity of filling is good too. The quality of the microstructure and macrostructure of heavy forging can be effectively managed by the strategy proposed.

Key words: aluminum alloy heavy forging; local loading; microstructure; filing capacity; response surface method

铝合金大型锻件在航空、航天领域应用日趋广泛。利用传统的锻造方法因现有设备吨位不足而无法成形该类锻件[1-2]。局部加载工艺的出现为此类锻件的成形提供了一种可能得新思路。局部加载成形时坯料只在某个局部区域发生变形,通过不断变换加载区域以实现对大型、复杂、整体锻件的成形,能有效降低成形载荷,改变材料的应力状态进而提升材料的塑性成形能力[3]。但局部加载成形过程中变形区、未变形区、过渡区交替存在,工艺较复杂,影响参数较多[4]。不当的局部加载参数设置以及加载方式往往导致高筋部位充填不满,各区域之间晶粒粒度分布不均匀等缺陷。同时,局部加载时特殊的变形方式(变形的不同时性),使得先变形区域温度较高以至发生空烧,导致晶粒粒度分布不均匀,这使得锻件各加载区和过渡区的力学性能存在较大差异。为此,国内外学者针对局部加载成形工艺开展了相关研究。孙志超等[5-6]通过局部加载方式对 TA15 钛合金H形构件成形过程进行分析,得出过渡区宽度、加载道次以及温度等对最终锻件组织的影响规律,并就某大型复杂构件建立了局部加载有限元模型,模拟分析了成形参数与过渡区成形和微观组织演变的规律。ZHANG等[7]研究了圆角半径以及拔模斜度对局部加载成形的影响。樊晓光[8]通过TA15钛合金热模拟压缩试验获得了该合金多道次热变形行为和组织演变机制,系统研究了变形过程中温度、变形速度以及形变量对合金初生相体积分数、晶粒粒度等的影响规律。而局部加载是多工步、多参数、多场耦合作用下的高度非线性复杂物理过程,上述在实际成形过程中对某单一因素或目标进行的研究与控制往往不能满足航空大型锻件宏、微观质量的要求。本文作者以某T型截面7050铝合金大型锻件为例,为控制其局部加载宏、微观质量提出了将响应面代理模型、试验设计和有限元相结合的综合解决方案,通过建立以充填性、微观组织均匀性为质量评价指标,以坯料温度、压力机速度、上模斜角角度、道次等工艺参数为响应变量的关系模型,对相应工艺参数进行系统多目标优化,并对采用优化后的工艺参数生产的实际锻件进行微观组织检测。

1 局部加载成形工艺概述

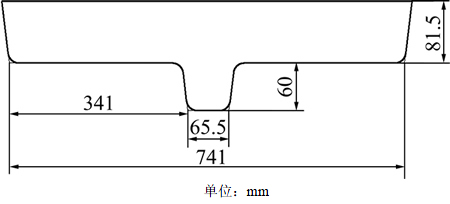

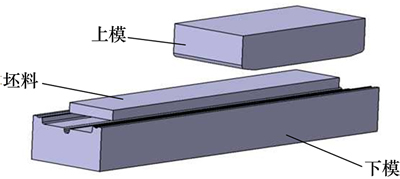

锻件截面为T型,是某型号飞机重要结构件之一,属典型高筋宽腹板件,T型截面尺寸如图1所示。图2所示为该T型构件局部加载成形的三维模型。

整个局部加载过程分3段进行,在总的压下量恒定的情况下,道次数目由各道次实际压下量分配决定。一次成形下搭接区的金属的充填性能差,晶粒粗大,微观组织均匀性差;随着加载道次的增加,过渡区筋部的充填深度增加,平均晶粒粒度减小,因此,主要研究多道次条件下对其成形过程的影响规律。在整个实际生产过程中,第1道次分3段由一端依次压向另一端,下一道次坯料与上模具的相对运动轨迹呈“品”字型,即下一道次的压制,上模中心大致对准上一道次2段过渡区的位置。上模具相对于坯料一次进给量为1 300 mm,各道次均从一端模压至另一端。且整个过程要求1火次或2火次成形。坯料长×宽×高为600 mm×135 mm×3 700 mm,总的压下量为45 mm,即从135 mm压至90 mm。合格的锻件其筋部须充填完整,各变形区晶粒粒度分布均匀。

图1 T型截面尺寸

Fig. 1 Section of forging

图2 三维模型

Fig. 2 3D model

2 局部加载成形工艺优化

响应面法是一种数学与统计相结合的方法,为数据处理及分析的有效方式,通过在设计变量范围内进行试验、建模、数据分析与最优化等过程对所关注的响应值进行优化。预测模型通常有一阶和二阶2种,对于4因素试验,为保证结果的准确性,应尽可能选择高阶模型设计准则[9],即

(1)

(1)

式中:m为第j个设计变量;y为目标响应值; 为变量xi的线性效应;

为变量xi的线性效应; 为xi与xj之间的交互作用效应;

为xi与xj之间的交互作用效应; 为xi的二次效应;

为xi的二次效应; 为误差项。式(1)中各系数可通过回归分析确定[10]。

为误差项。式(1)中各系数可通过回归分析确定[10]。

2.1 优化目标选择

微观组织尤其是晶粒粒度在很大程度上决定着锻件的力学性能,晶粒均匀程度亦对性能有着重要影响,混晶越严重,其冲击韧性和抗疲劳寿命越低。在一定压下量下,过渡区金属由于其属于自由变形区,材料的聚集、填充相比于其他区域更加困难,更易出现充填不满。因此,在研究此加载成形过程时选择微观组织均匀性和过渡区填充性能为评价指标。

2.1.1 微观组织均匀性

局部加载成形后的锻件组织均匀即为先后成形的各段微观组织间差异控制在一定合理范围之内,微观

组织均匀性评价函数如下:

(2)

(2)

(3)

(3)

(4)

(4)

式中:n和n1分别为原始坯料网格总数、成形后被搭接区分开的区域网格数; 为所划分网格的体积;V为对应锻件的体积;

为所划分网格的体积;V为对应锻件的体积; 和

和 为对应区域每个网格晶粒粒度;Dave和

为对应区域每个网格晶粒粒度;Dave和 分别为最终锻件的平均晶粒粒度和2个过渡区之间晶粒平均尺寸。

分别为最终锻件的平均晶粒粒度和2个过渡区之间晶粒平均尺寸。

2.1.2 筋部充填性

充填不满通常发生在筋部,因此选取锻件筋部剖面与对应的理想锻件间的面积差异作为衡量锻件填充性能的评价指标,其目标函数如下:

(5)

(5)

式中:η为锻件充填性能目标函数;N为单元总数;Ai为锻件筋部剖面上第i个单格中实际锻件区域的面积。为简化模型,将2个优化目标线性加权和法后转化为单目标问题予以研究,分别对优化目标函数进行量纲归一化处理,得到的线性加权后的目标函数如下:

(6)

(6)

式中: 和

和 为加权系数,描述目标函数的重要程度,

为加权系数,描述目标函数的重要程度, ;总目标

;总目标 越小,则锻件的微观组织均匀性与充填质量越好。

越小,则锻件的微观组织均匀性与充填质量越好。

鉴于此大锻件水平投影面积较大、筋部较高,材料在流动时的摩擦阻力大,极大地影响了筋部金属的充填性;同时,微观组织均匀性与晶粒粒度也是决定锻件力学性能的重要因素,且前期的研究发现该锻件填充性与组织均匀性之间存在一定正相关性,即筋部填充情况较好的区域往往晶粒更加细小,由此加权系数各取0.5[11]。

2.2 试验设计

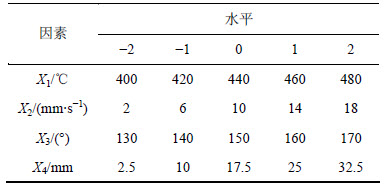

应变速率、变形温度、道次对变形金属动态再结晶过程有着重要影响[12-13]。前一道次的变形历史影响着后续道次变形,各道次压下量也直接决定成形后微观组织状态[14],在设计中首次压下量通常选取较大值,此次优化过程取20 mm。过渡区金属的流动与其倾斜角有直接联系,不同的倾斜角金属的充填深度和变形程度不同,从而影响过渡区金属宏观变形和微观组织。分步压制时在坯料表面会形成“台阶”,斜角的设计主要考虑台阶处金属变形的稳定性,过小易产生金属折叠,设计中通常为130°~170°。在研究该局部加载成形工艺影响因素时,考虑的工艺参数有坯料初始温度X1、压力机工作速度X2、模具倾斜角参数X3、道次压下量X4以及变形次数。变形道次与单次压下量有关,在考虑变形次数对成形的影响时,取第1道次的压下量为20 mm,X4为第2道次压下量,则下一道次的压下量为(45-20-X4) mm。选取合理的参数变动范围,借助试验设计方法,构造有限元分析样本点试验矩阵,以减小响应面模型多项式拟合时的噪音和改善设计空间表述。综上所述,变量的选择和因素水平如表1所示。

表1 各因子水平中心复合设计

Table 1 Central composite design of each factors’ levels

2.3 数值模拟

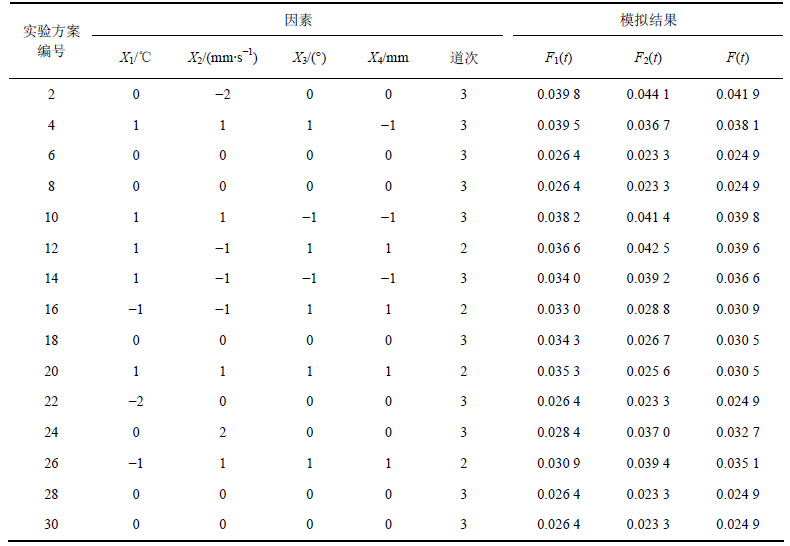

坯料为7050铝合金,材料的流动应力与应变速率、变形温度和应变的关系为 ,相关数据取自文献[15]。在锻件成形模拟分析中,模具温度设为380 ℃,坯料与模具以及空气间的热传导系数设为11 W/(m2·℃),坯料与模具间的摩擦因数取0.3,平均增量步长为0.5 mm.采用4因素5水平的中心复合试验设计。试验实施方案和部分试验结果如表2所示。

,相关数据取自文献[15]。在锻件成形模拟分析中,模具温度设为380 ℃,坯料与模具以及空气间的热传导系数设为11 W/(m2·℃),坯料与模具间的摩擦因数取0.3,平均增量步长为0.5 mm.采用4因素5水平的中心复合试验设计。试验实施方案和部分试验结果如表2所示。

2.4 响应面模型

对表2数据进行回归分析,将得到的系数代入式(1),得到相应回归模型为

(7)

(7)

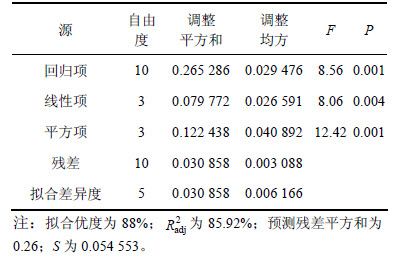

式(7)为数值方程,各变量的单位见表1。为验证所建立响应面模型是否能有效反映响应值与设计变量间的对应规律,应用方差分析对回归模型以及模型中的线性项、平方项及交叉项进行显著性分析,并得出回归模型的可靠性评价指标S,R2和 ,见表3。由表3可以看出:该模型P均小于0.05(a=0.05),由此说明建立的二阶模型显著。通常R2和

,见表3。由表3可以看出:该模型P均小于0.05(a=0.05),由此说明建立的二阶模型显著。通常R2和 越大且其值越接近,则s越小,回归模型的拟合程度越好。从表3可以看出:所得到的回归模型的拟合程度达到88%,说明该模型的预测精度较高。通过上述分析,说明该模型可以较精确地描述目标值y与设计变量X1,X2,X3和X4之间的响应。

越大且其值越接近,则s越小,回归模型的拟合程度越好。从表3可以看出:所得到的回归模型的拟合程度达到88%,说明该模型的预测精度较高。通过上述分析,说明该模型可以较精确地描述目标值y与设计变量X1,X2,X3和X4之间的响应。

2.5 优化结果分析与结论

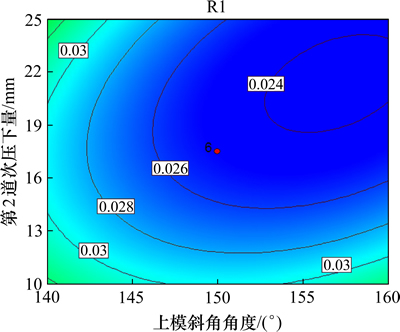

通过对回归模型中线性项、平方项、交叉项的显著性分析,得到设计变量对总的目标响应值的影响显著性从高到低依次为变形道次、上模斜角角度、温度、变形速度。变形道次和上模斜角角度的交互项对响应值的影响最大,具体影响规律见图3。从图3可以看出:当x1=0,x2=0时,响应值随着上模斜角角度和第2道次分配量的增加而减小,当角度为158°时响应值降到0.024以下,响应值有明显的最小值。综合响应面,结合实际生产条件和工艺参数允许范围,通过MATLAB软件求出可行设计空间中响应面模型的最小值即为响应参数的最优解。最佳工艺选择3道次成形,对应参数组合如下:坯料温度为440 ℃,压力机速度为10 mm/s,上模斜角角度为158°,3道次成形下各道次分配量分别20,20和5 mm,即在此参数下可以获得筋部填充良好、组织较均匀的锻件。

表2 部分实验方案及实验结果

Table 2 A portion of test program and results

表3 回归分析结果

Table 3 Result of regression analysis

图3 响应值等高线图

Fig. 3 Contour images of response values

3 试验验证

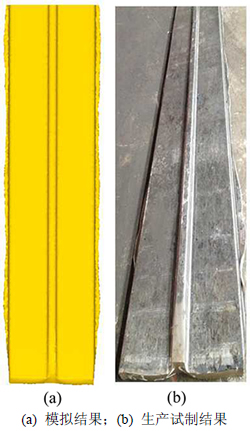

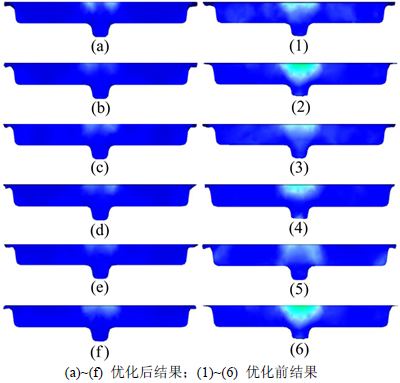

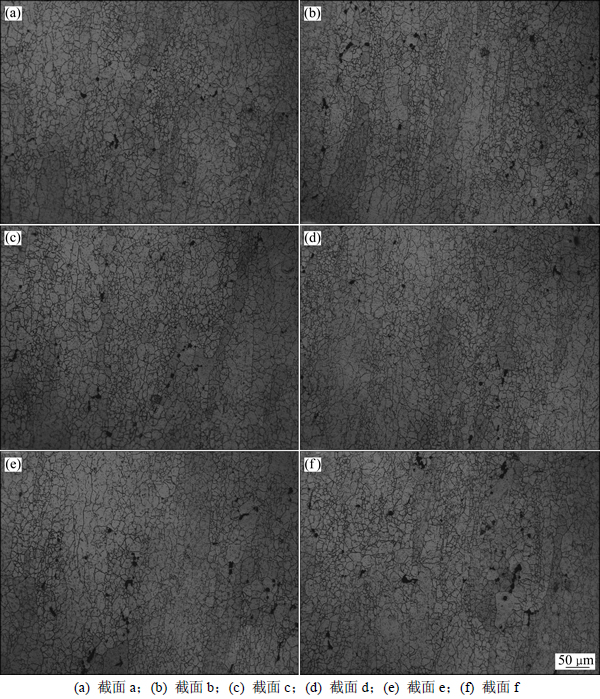

采用得到的工艺参数对该大锻件进行有限元模拟。过渡区筋部的填充情况是锻件成形宏观质量的重要评价指标之一。图4(a)和(b)所示分别为模拟结果与实际生产的锻件照片。由图4可见:锻件过渡区筋部充填完整,模拟结果和实际生产结果非常符合。图5所示为优化前后锻件各典型截面平均晶粒粒度分布情况,典型截面位于两过渡区之间。由图5可以看出:优化后的晶粒分布更加均匀,晶粒更加细小(颜色越接近深色,晶粒越细小)。经测定,整体大平面翘曲变形程度小于标准的3%,锻件总体宏观质量合格。对成形后的锻件进行固溶(470 ℃,1 h,水冷)+时效处理(120 ℃,24 h)。沿着典型截面对锻件进行剖切、取样后光学显微观察。由于筋部区域晶粒易出现粗大现象,所有采样点均位于筋部中心位置。金相观察结果见图6。对图6中的金相组织按照GB/T 24177—2009“金属双重晶粒度表征与测定方法”对其进行晶粒度分析与统计[16],得出其实际平均晶粒粒度。表4所示为模拟和实际测得的平均晶粒粒度。晶粒的均匀性取决于各截面处平均晶粒粒度的波动情况。按照最佳工艺条件下的对比情况,根据GB/T 24177—2009“金属双重晶粒度表征与测定方法”对其进行晶粒度分析与统计[16],得出其实际平均晶粒粒度。

从表4可以看出:模拟得到平均晶粒粒度和实际晶粒粒度显示筋部晶粒均较小,且趋势较一致,模拟优化结果的准确性得到验证。锻件端部脱离模具的趋势较大,其筋部变形量较小,动态再结晶程度比其他筋部区域低。

图4 模拟结果及实际生产的锻件对比

Fig. 4 Comparison of forging between simulation and actual production

图5 优化前后锻件截面平均晶粒粒度

Fig. 5 Average grain size of section of forging in simulation and actual production

图6 金相观测结果

Fig. 6 Metallographic phases of speculation

表4 模拟和实际平均晶粒粒度统计

Table 4 Statistics of average grain size in practice and simulation

4 结论

1) 将响应面法引入大型锻件局部加载成形过程中,通过以有限元方法和响应面法相结合的方法建立了以改善锻件微观组织质量和充填性能为目标,以坯料温度、压力机速度、上模斜角角度、道次表征量为设计变量的二阶响应模型,以88%以上的精度描述了各设计变量和目标响应值的显著性和影响规律。

2) 通过将工艺条件进行参数化表征,利用响应面法有机地与工艺参数结合并纳入锻件成形优化过程中,考虑了工艺及其对应的工艺参数对成形过程的协同影响效应,得到各参数影响的显著性规律,并最终获得了最佳的工艺及其工艺参数组合:采用3道次成形工艺,道次分配量分别为20,20和5 mm,坯料温度为440 ℃,压力机速度为10 mm/s,上模斜角角度为158°。并可为同类锻件的生产提供参考。

3) 再模拟和生产试制验证了得到的工艺参数,金相观察结果与模拟结果规律一致,生产试制锻件宏观和微观质量合格,可对局部加载复杂成形过程中锻件的质量进行控制。

参考文献:

[1] 杨平, 单德彬, 高双胜, 等. 筋板类锻件等温精密成形技术研究[J]. 锻压技术, 2006, 31(3): 55-58.

YANG Ping, SHAN Debin, GAO Shuangsheng, et al. Research on isothermal precision technology of rib-web forging parts[J]. Forging & Stamping Technology, 2006, 31(3): 55-58.

[2] 高双胜. 筋板类构件局部加载等温精密模锻工艺的研究[D]. 哈尔滨: 哈尔滨工业大学材料科学与工程学院, 2003: 10.

GAO Shuangsheng. Research on isothermal local loading precision technology of rib-web forging parts[D]. Harbin: Harbin Institute of Technology. College of Materials Science and Engineering, 2003: 10.

[3] ZHANG S H, WANG Z R, WANG Z T, et al. Some new features in the development of metal forming technology[J]. Journal of Materials Processing Technology, 2004, 151(1/2/3): 39-47.

[4] 杨合, 孙志超, 詹梅, 等. 局部加载控制不均匀变形与精确塑性成形研究进展[J]. 塑性工程学报, 2008, 2(15): 6-14.

YANG He, SUN Zhichao, ZHAN Mei, et al. Advances in control of unequal deformation by locally loading and theories related to precision plastic forming[J]. Journal of Plasticity Engineering, 2008, 2(15): 6-14.

[5] 孙志超, 杨合, 李志燕. TA15 合金 H 型构件等温局部加载成形工艺研究[J]. 稀有金属材料与工程, 2009, 38(11): 1904-1909.

SUN Zhichao, YANG He, LI Zhiyan, et al. Research of isothermal local loading on H-shaped component of TA15 alloy [J]. Rare Metal Materials and Engineering, 2009, 38(11): 1904-1909.

[6] 李志燕, 杨合, 孙志超. TA15合金大型复杂构件等温局部加载过渡区宏微观变形研究[J]. 稀有金属材料与工程, 2008, 37(9): 1516-1521.

LI Zhiyan, YANG He, SUN Zhichao, et al. Macro and micro deformation research on translation area of isothermal local loading of heavy component of TA 15 alloy[J]. Rare Metal Materials and Engineering, 2008, 37(9): 1516-1521.

[7] ZHANG Dawei, YANG He. Metal flow characteristics of local loading forming process for rib-web component with unequal- thickness billet[J]. International Journal of Advanced Manufacturing Technology, 2013, 68(9): 1949-1965.

[8] 樊晓光. 钛合金复杂大件等温局部加载成形组织演变研究[D]. 西安: 西北工业大学材料学院, 2013: 23-60.

FAN Xiaoguang. Structure evolution research of isothermal local loading of heavy component of titanium alloy[D]. Xi’an: Northwestern Polytechnical University. School of Materials Science and Engineering, 2013: 23-60.

[9] 刘佳, 张宏, 石岩. 基于Design-Expert V7设计的不锈钢激光非熔透搭接焊工艺优化研究[J]. 机械工程学报, 2011, 47(16): 52-60.

LIU Jia, ZHANG Hong, SHI Yan. Technology optimization research of laser nonpenetration lap welding of stainless steel based on design-expert V7[J]. Journal of Mechanical Engineering, 2011, 47(16): 52-60.

[10] MONTGOMERY D C. Design and analysis of experiments[M]. 5th. New York: John Wiley, 2001: 427-430.

[11] 申丽娟, 杨军, 赵宇. 基于方差传递模型的飞机蒙皮拉行工艺稳健设计[J]. 机械工程, 2011, 47(1): 145-151.

SHEN Lijuan, YANG Jun, ZHAO Yu.Robust design of aircraft skin stretch forming process based on transmitted variance model[J]. China Mechanical Engineering, 2011, 47(1): 145-151.

[12] 李周兵, 沈健, 闫亮明, 等. 应变速率对7055铝合金显微组织和力学性能的影响[J]. 稀有金属, 2009, 34(5): 643-647.

LI Zhoubing, SHEN Jian, YAN Liangming, et al. Influence of hot process strain rate on microstructures and tensile properties of 7055 aluminum alloy[J]. Chinese Journal of Rare Metals, 2009, 34(5): 643-647.

[13] 杨勇彪, 张治民, 王强. 变形次数及温度对7A04铝合金微观组织及力学性能影响的研究[J]. 热加工工艺, 2013, 42(15): 130-133.

YANG Yongbiao, ZHANG Zhimin, WANG Qiang. Influence of temperature and deformation times on microstructure and mechanical properties of 7A04 aluminum alloy[J]. Hot Working Technology, 2013: 42(15): 130-133.

[14] 张亚萍, 靳丽, 董杰, 等. 道次压下量和退火工艺对Mg-Zn-Ce-Zr合金微观组织及力学性能的影响[J]. 中国有色金属学报, 2012, 22(11): 2985-2991.

ZHANG Yaping, JIN Li, DONG Jie, et al. Effects of per-pass reduction and annealing treatment on microstructures and mechanical properties of Mg-Zn-Ce-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 2985-2991.

[15] 王梦寒, 黄龙, 王瑞, 等. 基于响应面法的铝合金筋板类锻件工艺参数多目标优化[J]. 材料科学与工艺, 2014, 22(1): 123-128.

WANG Menghan, HUANG Long, WANG Rui, et al. Multi-objective optimization of process parameters by RSM for aluminum-alloy rib-web forgings[J]. Materials Science & Technology, 2014, 22(1): 123-128.

[16] 杨亮, 董建新, 何智勇, 等. 基于组织均匀性的690合金管冷轧及退火工艺优化[J] . 北京科技大学学报, 2012,34(4): 410-416.

YANG Liang, DONG Jianxin, HE Zhiyong, et al. Optimization design of cold rolling and annealing process for 690 alloy tubes based on microstructure uniformity[J]. Journal of University of Science and Technology Beijing, 2012, 34(4): 410-416.

(编辑 陈爱华)

收稿日期:2016-07-22;修回日期:2016-09-13

基金项目(Foundation item):中央高校基本科研业务费资助项目(CDJZR14130006);科技部重大专项(2012ZX04010-081) (Project(CDJZR14130006) supported by the Fundamental Research Funds for the Central Universities; Project(2012ZX04010-081) supported by Major Specific Item of Science & Technology Ministry)

通信作者:王梦寒,副教授,博士,从事金属塑性成形工艺及模具CAD/CAE/CAM研究;E-mail: cquwmh@163.com