文章编号:1004-0609(2012)06-1536-10

熔体处理在制备Mg-9Zn-2Al镁合金半固态浆料中的作用

李 春1,李元东1,马 颖1, 2,陈体军1, 2,武慧慧1,李艳磊1

(1. 兰州理工大学 甘肃省有色金属新材料省部共建国家重点实验室,兰州 730050;

2. 兰州理工大学 有色金属合金及加工教育部重点实验室,兰州 730050)

摘 要:采用自孕育法制备新型Mg-9Zn-2Al高锌镁合金半固态浆料,研究孕育剂加入量为5%(质量分数)、导流器角度为45°时熔体处理温度对Mg-9Zn-2Al镁合金组织的影响。对孕育剂加入熔体后的熔化状况进行分析,并从原子团簇角度探讨熔体处理温度对一次孕育的作用机理。结果表明:熔体处理温度过高或过低时,组织平均晶粒尺寸较大;在695~710 ℃范围内,晶粒平均尺寸较小,约为47.5~48.8 μm。根据所推导出的孕育剂在导流器入口处的温度表达式,可以确定自孕育法铸造的最佳熔体处理温度,提出用固相率fS描述自孕育剂的熔化状况。

关键词:Mg-9Zn-2Al镁合金;半固态浆料;熔体处理;自孕育法;原子团簇

中图分类号:TG146.2 文献标志码:A

Role of melt processing in preparation of Mg-9Zn-2Al magnesium alloy semi-solid slurry

LI Chun1, LI Yuan-dong1, MA Ying1, 2, CHEN Ti-jun1, 2, WU Hui-hui1, LI Yan-lei1

(1. State Key Laboratory of Gansu Advanced Non-ferrous Metal Materials,

Lanzhou University of Technology, Lanzhou 730050, China;

2. Key Laboratory of Non-ferrous Metal Alloys and Processing, Ministry of Education,

Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: A noval high zinc-content Mg-9Zn-2Al magnesium alloy semi-solid slurry was prepared by self-inoculation method(SIM). The effect of melt treatment temperature on the microstructure was investigated when the addition of self-inoculants is 5% (mass fraction) and the angle of fluid director is 45°. The melting state of the inoculants was analyzed. Furthermore, the mechanism of the primary inoculation was discussed from the standpoint of atomic cluster. The results show that the average grain size increases when the melt temperature is excessively low or high. In temperature range of 695-710 ℃, the average grain size is smaller, about 47.5-48.8 μm. In SIM casting, a proper melt treatment temperature can be determined by the derived formula, which is the temperature of the inoculants in the entrance of fluid director. Meanwhile, the solid phase ratio fS is put forward to describe the case of inoculants’ melting.

Key words: Mg-9Zn-2Al magnesium alloy; semi-solid slurry; melt treatment; self-inoculation method (SIM); atomic cluster

铸造镁合金的成形工艺主要包括高压铸造、砂型铸造、金属型铸造、低压铸造和熔模铸造等[1]。但是,这些传统的铸造方法很难形成复杂形状的大型零件,而且所加工的铸件中存在大量的缩松、缩孔和气孔等缺陷,不易进行后期的热处理和表面处理[2]。然而,自从19世纪70年代,FLEMINGS等[3]提出半固态成形技术以来,为传统铸造中所存在的技术难题开辟了一条新的途径。至此,国内外众多学者致力于半固态成形技术的研究,开发出连续流变转化技术(Continuous rheo-conversion process, CRP)[4]、冷却斜板法[5]、近液相线铸造[6]、新流变铸造(New rheo-casting, NRC)[7]、固-液混合[8]、双螺旋机械搅拌[9]等一系列高效制备半固态组织的铸造工艺。总体来说,根据球形/近球形晶粒的来源可以将现有的浆料制备工艺分成两大类,即树枝晶破碎球化技术和控制形核抑制树枝晶生长技术。对于枝晶破碎球化,FLEMINGS[3]认为,半固态金属组织是在枝晶生成后,再发生枝晶臂折断、破碎、球化而形成的。而控制形核与抑制树枝晶生长技术的核心是通过控制金属熔体的热力学条件,使合金凝固初期局部激冷,抑制晶粒呈树枝状生长,在熔体中形成大量的自由晶,从而直接获得球形/近球形的初生固相[10]。

本文作者采用自孕育法制备浆料。自孕育法[11] (Self-inoculation method,SIM法)就是指将两个一定成分、质量、温度的合金母液-固相(或液相、半固态)、半固态-半固态(或固相)混合,再经过一定角度的导流器,利用两个合金液(体)的不同性质,如温度、表面张力和组织等,在混合后使得合金液中瞬间形成大量晶核(一次自孕育),同时通过导流器产生紊流,促进晶粒增殖、加强自孕育效果(二次自孕育)、抑制晶粒长大,获得具有非枝晶初生固相的固-液混合浆料,然后进行各种后续热加工,如流变成形或触变成形。李元东等[12-14]和XING等[15]以商用AM60镁合金为目标合金,研究浇注温度、自孕育剂和导流器对合金组织的影响,结果表明:合理的熔体处理温度、孕育剂加入量、导流器长度和角度对非枝晶组织的形成起重要作用。在此基础上,本文作者针对一种新型的Mg-9Zn-2Al镁合金,研究熔体处理在制备半固态浆料的过程中温度对自孕育剂熔化状况的影响,并从原子团簇的角度探讨熔体处理对孕育形核的作用机理,进而分析其对坯料组织的影响。

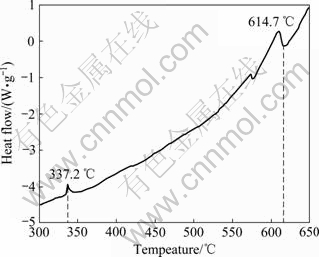

1 实验

实验合金选用自行开发的Mg-9Zn-2Al新型镁合金。采用纯度为99.99%的Mg、Zn、Al,并以纯度为99.9%的氩气作保护,在井式坩埚电阻炉中熔炼并浇铸而成。在NETZSCH STA449C综合热分析仪上对坯料进行差示扫描量热分析(DSC),DSC升温曲线如图1所示,确定坯料的液相线温度为614.7 ℃,共晶温度为337.2 ℃。该合金的结晶区间较宽,有利于浆料固相率的控制和操作。根据合金的液相线温度,选取熔体处理温度分别为665、680、695、710和725 ℃。但实验过程中在665 ℃浇注时,由于温度过低,合金液在未流入模具之前就已经凝固。

图1 Mg-9Zn-2Al镁合金的DSC曲线

Fig. 1 DSC curve of Mg-9Zn-2Al magnesium alloy

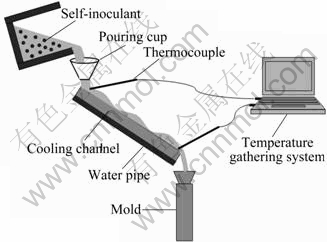

自孕育法工艺路线如图2所示。将纯Mg锭料放入井式坩埚电阻炉中熔炼,待合金全部熔化且温度达到680 ℃时,同时加入已配好的纯Zn和纯Al,待其全部熔化后,开始测温。熔体温度达到710~730 ℃后,用1%~1.5%(质量分数)C2Cl6进行精炼除气,调整金属液温度为700 ℃左右时浇注成d 15 mm×150 mm的棒料,然后加工成5 mm×5 mm×5 mm金属块做孕育剂。同前面的熔炼工艺,在一定的熔体处理温度(665、680、695、710,725 ℃)下,以尺寸5 mm×5 mm×5 mm、加入5%(质量分数)孕育剂加入到Mg-9Zn-2Al镁合金熔体中,并采用十六通道的温度采集器测量熔体在导流器上的入口和出口温度。熔体经双流股混合导流器,一部分浇注成d 15 mm×150 mm的棒料,另一部分直接进行水淬。

图2 自孕育法浇注过程示意图

Fig. 2 Schematic diagram of self-inoculation method

为了使得晶界清晰化,测其晶粒尺寸,将浇注成的棒料锯成d 15 mm×15 mm的试样进行T6处理。通过比较,确定最佳的T6处理工艺:固溶温度为330 ℃,固溶时间为12 h,时效温度为175 ℃,时效时间为16 h。之后采用MEF-3光学显微镜观察其组织和形貌,并用Image Pro软件测定其晶粒尺寸与分布。

2 实验结果

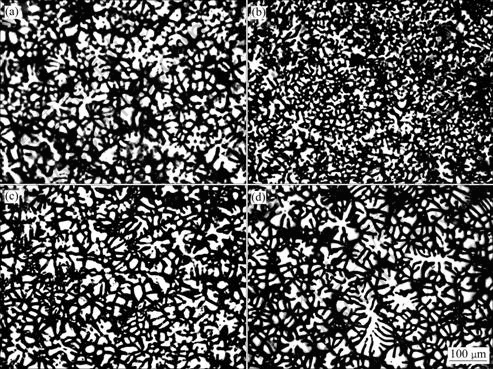

2.1 熔体处理过程中Mg-9Zn-2Al镁合金的水淬组织

图3所示为不同熔体处理温度下半固态浆料的水淬组织。由图3可以看出:熔体处理温度较低时,组织中初生相的尺寸较大,随温度升高,初生相尺寸逐渐减小,近球状的初生相数量增多。然而,温度过高时,由于合金熔体的出口温度高于液相线温度,浆料自由晶数量少,组织主要由液相直接激冷形成发达的枝晶组成。

2.2 熔体处理过程中Mg-9Zn-2Al镁合金的铸态及T6处理组织

图4所示为Mg-9Zn-2Al镁合金的铸态及T6处理组织。图4(a)~(e)所示为传统铸造和不同熔体处理温度下自孕育法铸造的铸态组织,图4(f)~(j)所示为对应的经T6处理后的组织。

由图4(a)可以看出,传统铸造工艺下浇注的坯料组织由发达的树枝晶组成,并伴随有明显的二次枝晶臂。而在自孕育工艺下,凝固组织中枝晶数量显著减少,取而代之的是一些球状和不发达的枝晶,其形貌随着熔体处理温度的变化而变化。由图4(b)可以看出,组织中有较粗大的块状晶存在,同时还存在大量的蔷薇状晶和一些细小的枝晶。随着熔体处理温度的升高,如图4(c)、(d)所示,组织中有大量的块状初生相存在,枝晶明显减少,而且组织变得细小均匀。随着温度的进一步升高,如图4(e)所示,组织中出现了发达的枝晶,且组织变得粗大、不均匀。

为了测定晶粒尺寸分布,对铸态组织进行了T6处理,处理结果如图4(f)~(j)所示。并用Image-Pro Plus5.0软件,采用等面积圆直径表征晶粒的大小,测得不同熔体处理温度下的晶粒尺寸分布,如图5所示。

图5(a)所示为传统铸造工艺下晶粒尺寸的分布状况。由图5(a)可以看出,晶粒尺寸分布很不均匀,超过100 μm的晶粒数量较大。在自孕育法铸造工艺下,晶粒细小而且分布较均匀。由图5(b)可以看出,熔体处理温度为680 ℃时,晶粒尺寸主要分布在40~60 μm,随着熔体处理温度的升高,晶粒尺寸变大,平均晶粒尺寸主要分布在20~60 μm之间(见图5(b),(c)),当温度达725 ℃时,晶粒尺寸进一步增大,主要分布在40~80 μm之间(见图5(d))。

图3 半固态浆料的水淬组织

Fig. 3 Microstructures of semi-solid slurry after water quenching at different temperatures: (a) 680 ℃; (b) 695 ℃; (c) 710 ℃; (d) 725 ℃

图4 传统铸造和不同熔体处理温度下的铸态和T6处理组织

Fig. 4 Microstructures of as-cast((a)-(e)) and T6 treatment((f)-(j)) samples at traditional casting and different melt treatment temperatures: (a), (f) Traditionally cast at 695 ℃; (b), (g) 680 ℃; (c), (h) 695 ℃; (d), (i) 710 ℃; (e), (j) 725 ℃

图5 传统铸造和不同熔体处理温度下自孕育浇铸坯料的晶粒尺寸分布

Fig. 5 Grain size distributions of Mg-9Zn-2Al magnesium alloy produced by self-inoculation method and traditional casting at different melt treatment temperatures: (a) Traditionally cast at 695 ℃; (b) 680 ℃; (c) 695 ℃; (d) 710 ℃; (e) 725 ℃

图6所示为不同熔体处理温度条件下坯料的平均晶粒尺寸。由图6可以看出:在传统铸造工艺下,坯料的晶粒尺寸较大,达到88 μm;而在自孕育工艺 下,随着熔体处理温度的升高,晶粒尺寸先减小后增大。当熔体处理温度为695 ℃时,晶粒尺寸最小,为47.5 μm。

3 分析与讨论

自孕育法制备半固态浆料过程中,不同的熔体处理温度或过热度在合金凝固过程中起到关键性作用,它不仅影响孕育剂的熔化状况,而且还影响着液态金属中原子团簇的尺寸、数量及分布,最终影响着坯料的晶粒尺寸及分布。

图6 传统铸造和不同熔体处理温度下自孕育浇注坯料的平均晶粒尺寸

Fig. 6 Average grain sizes of Mg-9Zn-2Al magnesium alloy samples produced by traditional casting at 695 ℃ and self- inoculation method at different melt treatment temperatures

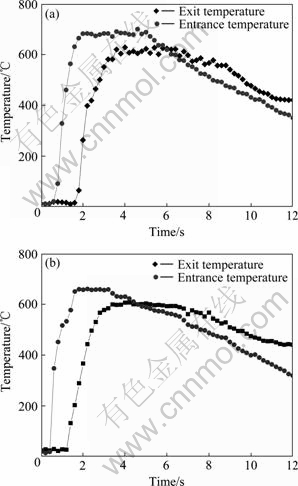

3.1 熔体处理温度对自孕育剂熔化状况的影响

为了研究加入孕育剂及经过导流器前后熔体的温度变化情况,采用十六通道的温度采集器对熔体在导流器上的入口和出口温度进行了采集,如图7所示。由图7(a)可以看出:当合金熔体温度为725 ℃,加入5%的孕育剂后,合金熔体温度下降,在导流器入口处温度为680 ℃左右,出口温度为620 ℃,高于Mg-9Zn-2Al镁合金的液相线温度(614.7 ℃),为全液态;当合金熔体温度为695 ℃,加入5%孕育剂后,合金熔体的温度迅速降至659 ℃左右,经导流器,出口温度降至607 ℃,低于液相线温度,为半固态(见图4(b))。

根据所测得的合金熔体的温度变化曲线,计算出不同熔体处理温度下,孕育剂加入前后母熔体的温度变化情况,结果如表1所列。其中,tm为熔体处理温度;ti、to分别为导流器入口和出口温度;?T为孕育剂加入前后母熔体的温度差,K;?T1为导流器入口处与出口处的温度差,K。

加入孕育剂前后,熔体与孕育剂之间发生热量交换,引起母熔体温度的降低。母熔体损失的热量等于孕育剂吸收的热量和熔体与空气对流散失的热量,即

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

式中:Q2为加入孕育剂前后母熔体损失的热量;Q1为孕育剂吸热使其熔化的热量;Q为母熔体与空气对流散失的热量;mi、mm分别为孕育剂、熔体的质量;cp为合金的比热容;x为孕育剂加入量;T为加入母熔体的孕育剂在导流器入口处的温度;Tr为室温;fS为固相率;L为潜热;?T为孕育剂加入后母熔体的实测温度降。

图7 合金熔体在浇注过程中温度变化曲线

Fig.7 Temperature variation curves of alloy melt during pouring: (a) 725 ℃; (b) 695 ℃

表1 熔体处理前后温度变化

Table 1 Contrast of temperature variation before and after melt treatment processing

实验中,作如下假定:

1) 此试验在绝热的坩埚内进行,且熔体在室外停留的时间很短,即Q可忽略不计;

2) 熔体散失的热量全部被孕育剂吸收。

因此,式(1)可以简化为

Q2=Q1 (5)

采用阶梯函数法,对温度和固相率之间的关系进行处理可得:

(6)

(6)

将式(2)、(3)、(4)、(6)代入式(5)可得:

(7)

(7)

其中:

;

;

式中:TS 为固相线温度;TL为液相线温度。

由式(7)可以看出:

1) 孕育剂在导流器入口处的温度T与母熔体的温度降?T成线性关系,并随?T的增大而增大;

2) 若确定了母熔体和孕育剂在导流器入口处的温度,则可以确定合金自孕育法铸造的最佳熔体处理温度;

3) 若测得孕育剂加入后母熔体的温度降,则可以判断出孕育剂的熔化状况。

利用式(7),计算不同熔体处理温度下,Mg-9Zn-2Al镁合金中孕育剂的熔化状况。表2所列为Mg-9Zn-2Al镁合金热力学计算的相关数据。具体计算方法如下:将所测得的不同熔体处理温度下孕育剂的温度降?T代入式(7),计算出不同熔体处理温度下,孕育剂在导流器入口处的温度T,再将T代入式(6)计算出孕育剂熔化后的固相相率fS,计算结果如表3所示。

fS值反映孕育剂的熔化状况,同时也影响孕育剂加入后熔体的存在状态、内部结构和热力学状态。当fS远大于0时,孕育剂只有少量熔化;当fS大于0但在其附近时,孕育剂已基本熔化;当fS小于0时,孕剂已完全熔化。LI等[16]研究认为:熔体处理参数不当会出现“夹生”残留现象,而已熔化树枝晶附近的液相中枝晶熔化“残片”的存在为合金自身物质细化提供了“籽晶”。从表3可以看出,当熔体处理温度为665 ℃时,母熔体的温度降至637 ℃,而所加入孕育剂的温度仅为456.6 ℃,在此温度下,孕育剂的固相率fS高达56.97%,这说明孕育剂仅有不到一半被熔化,整个熔体的温度场处于极不均匀的状态,所以最终导致低温浇注时组织粗大且不均匀; 当熔体处理温度在695~710 ℃时, 所加孕育剂的固相率fS降至10.34%~21.87%,说明所加孕育剂已基本熔化,可能存在一些高熔质点相未被熔化,或存在少量孕育剂没有完全融化,而是处于半固态状态;当熔体处理温度为725 ℃时,孕育剂全部熔化后的温度为651 ℃,已超过其熔点温度,此时,所加孕育剂的固相率为-13.08%,说明所加的孕育剂已经全部熔化,加入的孕育剂没有起到一次孕育的效果(见图3(d)和图4(e)、(j)),而只是降低的熔体的浇注温度,相当于低温浇注。

表2 Mg-9Zn-2Al镁合金热力学计算相关数据

Table 2 Relative data used in thermodynamic calculation of Mg-9Zn-2Al magnesium alloy

表3 不同熔体处理温度下自孕育剂熔化状况计算结果

Table 3 Calculative results of case of self-inoculant melting at different treatment temperature

3.2 孕育剂加入量对自孕育剂熔化状况的影响

图8所示为不同孕育剂加入量下母熔体温度场的变化情况。从图8可以看出,在没有加入孕育剂时,短暂的时间(5 s)内,母熔体的温度变化不大,而加入孕育剂后,母熔体的温度变化较大,且随着孕育剂加入量的增多,降温越明显,且降温速度也越快。具体变化状况与应用式(7)的计算结果如表4所列。

表4中所列为熔体处理温度为695 ℃、不同孕育剂加入量时的热力学计算结果。由表4可以看出,在同一温度下,孕育剂的加入量对一次孕育的效果影响很大。孕育剂加入量较少(3%)时,其状况与熔体处理温度为725 ℃、孕育剂加入量为5%时的孕育剂熔化状况类似;当孕育剂加入量较多(7%)时,其状况与熔体处理温度为665 ℃、孕育剂加入量为5%时的孕育剂熔化状况类似。

图8 不同孕育剂加入量下熔体温度场的变化

Fig. 8 Variations of temperature field on different mass fraction of self-inoculants

表4 不同孕育剂加入量下的热力学计算结果

Table 4 Results of thermodynamic calculation on different addition of self-inoculants

综上所述,孕育剂熔化的速率与熔体处理温度有关,熔体处理温度越高,孕育剂熔化的速率越大;反之,孕育剂熔化速率越小。如果延长孕育剂熔化的时间,那么最终孕育剂将会全部熔化,但不能发挥一次孕育剂的有效作用。熔体处理温度影响着孕育剂加入量的多少,孕育剂加入量较多时,熔体处理温度应升 高,反之,熔体处理温度应降低。孕育剂的熔化过程有以下几种情况:1) 所加入的孕育剂仍有残留;2) 所加入的孕育剂没有完全熔化,而是处于半固态状态;3) 孕育剂中的高熔质点相没有熔化;4) 孕育剂完全熔化。

3.3 熔体处理对熔体形核的影响

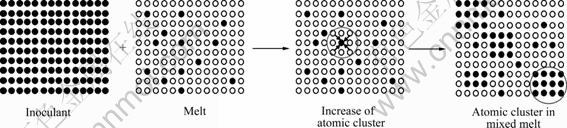

李元东等[12]的前期研究认为,在自孕育法制备半固态浆料的过程中,孕育剂加入后,在母熔体中瞬间形成了一些过冷区,促进了其一次形核。根据液态金属结构假说[17],金属熔体是由具有一定大小的原子团簇和金属原子共同组成的。该原子团簇能够保持一定尺寸和结构的稳定性,与温度相关。一定温度下,某一大小的团簇数量占优,当温度降低,团簇结构和尺寸的变化如图9所示[18]。

在孕育剂加入量一定的情况下,不同的熔体处理温度对熔体中所形成的原子团簇的数量及大小的影响是不同的。熔体结构的变化如图10所示。固态的孕育剂具有长程有序的原子结构,液态熔体是短程有序的原子结构,而且存在一些高熔质点相(如图中黑点所示)。加入孕育剂后,熔体中将存在一些较小的过冷区,将会促使高熔质点相周围的原子与其成键,使得原子团簇的幻数增大。团簇越多,相同凝固条件下的临界晶核的“准晶胚”越多,凝固组织越细小;相反,则凝固组织粗化。

熔体处理温度影响着熔体中所形成的原子团簇及数量。当熔体处理温度较低时,一方面,由于原子与高熔质点相结合形成较大的原子团簇;另一方面,由于孕育剂本身没有完全熔化而形成大量较大的原子团簇,所以在极冷凝固过程中,组织较大且不均匀(见图3(a)和图4(b))。当熔体温度较高时,一方面,自孕育剂完全熔化,而不能形成大量的原子团簇;另一方面,熔体中的高熔质点相较少,降低了原子向其堆积成核的几率。而当熔体温度在695 ℃附近时,两个因素对原子团簇的形成共同起到有效的作用,原子团簇的幻数不会过大,而且均匀地分布于熔体之中(见3(b)和图4(c))。

图9 原子团簇结构随尺寸的演变[18]

Fig. 9 Evolution of structure of atomic cluster during size change[18]

图10 自孕育剂、母熔体及混合熔体的结构示意图

Fig. 10 Schematic diagrams of structure of self-inoculants, self-melt and mixed melt

4 结论

1) 较传统铸造,自孕育法铸造使得晶粒显著细化,当孕育剂加入量为5%,导流器角度为45°时,熔体处理温度对组织形貌的影响较大,温度过高或过低时,组织平均尺寸较大。在695~710 ℃范围内,晶粒平均尺寸较小,约为47.5 μm。

2) 加入母熔体的孕育剂在导流器入口处的温度表达式为T=k?T+b,通过此式可以确定合金自孕育法铸造的最佳熔体处理温度。

3) 提出用固相率fS表征孕育剂的熔化状况,当fS远大于0时,孕育剂只有少量熔化,此时母熔体处于极不均匀状态;当fS大于0但在其附近时,孕育剂已基本熔化,可能存在少量高熔质点相作为形核的衬底;当fS小于0时,孕育剂已完全熔化,所加的孕育剂未达到一次孕育的效果。

4) 熔体处理在制备Mg-9Zn-2Al镁合金半固态浆料的过程中,熔体处理参数影响着熔体中原子团簇的形成和分布,最终影响晶粒尺寸及分布。

REFERENCES

[1] 王建军, 王智民. 铸造镁合金成形工艺与发展趋势[J]. 中国铸造装备与技术, 2005(5): 4-8.

WANG Jian-jun, WANG Zhi-min. Present status and development trend on forming process of cast magnesium alloy[J]. China Foundry Machinery & Technology, 2005(5): 4-8.

[2] Van HANFTEN W M, KOOL W H, KATGERMAN L. Hot tearing studies in AA5182[J]. Journal of Materials Engineering and Performance, 2002, 11(5): 537-543.

[3] FLEMINGS M C. Behavior of metal alloys in the semi-solid state[J]. Metal Trans, 1991, 22B(3): 269-293.

[4] PAN Q Y, FINDON M, APELIAN D. The continuous rheoconversion process (CRP): A novel SSM approach[C]// Proceedings of the 8th International Conference on Semi-Solid Processing of Alloys and Composites. Limassol: North American Die Casting Association, 2004.

[5] HAGA T, SUZUKI S. Casting of aluminum alloy ingots for thixoforming using a cooling slope[J]. Journal of Materials Processing Technology, 2001, 118(1): 169-172.

[6] 董 杰, 路贵民, 任栖锋, 崔建忠. 液相线铸造法非枝晶半固态组织形成机理探讨[J]. 金属学报, 2002, 38(2): 203-207.

DONG Jie, LU Gui-min, REN Qi-feng, CUI Jian-zhong. Discussion on the formation mechanism of non-dendritic semisolid microstructures during liquidus casting[J]. Acta Metallurgica Sinica, 2002, 38(2): 203-207.

[7] KAUFMANN H, MUNDI A, POTZINGER R, UGGOWITZER P J, ISHIBASHI N. An update on the new rheo-casting- development work for Al-and Mg-alloys[J]. Die Casting Engineer, 2002, 29(4): 16-19.

[8] 陈振华, 陈 鼎, 严红革, 陈吉华. 固液混合铸造的研究[J]. 湖南大学学报: 自然科学版, 2002, 29(4): 20-26.

CHEN Zhen-hua, CHEN Ding, YAN Hong-ge, CHEN Ji-hua. The mixed solid-liquid casting technology[J]. Journal of Hunan University: Natural Sciences Edition, 2002, 29(4): 20-26.

[9] FAN Z. Development of the rheo-diecasting process for magnesium alloys[J]. Mater Sci Eng A, 2005, 413/414: 72-78.

[10] 郭洪民. 半固态铝合金流变成形工艺与理论研究[D]. 南昌: 南昌大学, 2007.

GUO Hong-min. Investigation on technique and theory of rheoforming for semi-solid aluminum alloys[D]. Nanchang: Nanchang University, 2007.

[11] 李元东, 杨 建, 马 颖. 自孕育半固态制浆技术的研究[J]. 特种铸造及有色合金, 2010, 30(3): 227-230.

LI Yuan-dong, YANG Jian, MA Ying. Self-inoculation method for preparation of semi-solid slurry[J]. Special Casting & Nonferrous Alloys, 2010, 30(3): 227-230.

[12] 李元东,杨建,马颖, 曲俊峰,张鹏.浇注温度对自孕育铸造法制备 AM60 镁合金半固态浆料的影响(Ⅰ)[J]. 中国有色金属学报, 2010, 20(6): 1046-1052.

LI Yuan-dong, YANG Jian, MA Ying, QU Jun-feng, ZHANG Peng. Effect of pouring temperature on AM60 Mg alloy semi-solid slurry prepared by self-inoculation method(Ⅰ)[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1046-1052.

[13] 李元东, 杨 建, 马 颖, 曲俊峰, 张 鹏. 自孕育剂参数对自孕育铸造法制备AM60镁合金半固态浆料的影响(Ⅱ)[J]. 中国有色金属学报, 2010, 20(11): 2178-2186.

LI Yuan-dong, YANG Jian, MA Ying, QU Jun-feng, ZHANG Peng. Effect of inoculant parameters on Mg alloy semisolid slurry prepared by self-inoculation method(Ⅱ)[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2178-2186.

[14] 李元东, 邢 博, 马 颖, 郝 远. 导流器对自孕育铸造法制备AM60镁合金半固态浆料的影响(Ⅲ)[J]. 中国有色金属学报, 2012, 22(1): 22-32.

LI Yuan-dong, XING Bo, MA Ying, HAO Yuan. Effect of cooling channel on AM60 Mg alloy semisolid slurry prepared by self-inoculation method(Ⅲ)[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 22-32.

[15] XING Bo, LI Yuan-dong, MA Ying, CHEN Ti-jun, HAO Yuan. Research on microstructure of partial remelting of AM60 alloy billet prepared with self-inoculation method[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(9): 1622-1629.

[16] LI Yuan-dong, QU Jun-feng, XING Bo, MA Ying, CHEN Ti-jun. Role of self-inoculants in solidification process of AZ91D magnesium alloy[C]//2011 International Conference on Remote Sensing Environment and Transportation Engineering. Nanjing, 2011: 6287-6290.

[17] 王建中. 电脉冲孕育处理技术与液态金属团簇结构假说的研究[D]. 北京: 北京科技大学, 1998.

WANG Jian-zhong. The research of treating technology with electro-pulse modification and the hypothesis of liquid metal cluster structure[D]. Beijing: University of Science & Technology Beijing, 1998.

[18] 王广厚. 团簇物理学[M]. 上海: 上海科学技术出版社, 2003.

WANG Guang-hou. Cluster physics[M]. Shanghai: Shanghai Scientific & Technical Publishers, 2003.

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划前期预研项目(2010CB635106);国家自然科学基金资助项目(50964010)

收稿日期:2011-07-04;修订日期:2011-11-10

通信作者:李元东,教授,博士;电话:0931-2976795;E-mail: liyd_lut@163.com