顶板诱导崩落技术及其在大厂铜坑92号矿体的应用

张世超,周科平,胡建华,苏家红,古德生

(中南大学 资源与安全工程学院,湖南 长沙,410083)

摘 要:为解决大型贫矿床传统方法开采过程中存在的资源整体回收率低、后期地压控制难等问题,研究采用连续采矿—顶板诱导崩落综合技术,其空区处理与后期地压控制关键是顶板诱导崩落技术。针对华锡大厂铜坑矿92号矿体的工程地质条件,进行连续采矿顶板诱导崩落的工业试验,基于理论与工程类比相结合的方法,确定合理顶板爆破诱导崩落的参数、实施方案、安全控制措施,分析爆破诱导崩落的工程实际应用情况。试验结果表明:采用预裂爆破与诱导崩顶爆破的方法,通过对顶板的诱导崩落处理,成功地在下方采空区形成了厚度为17.8 m左右的岩石缓冲垫层,有效地降低顶板冒落带来的冲击气浪危害;在预裂孔间产生明显的贯通裂隙,从而在顶板上形成诱导可控崩落,防止顶板大面积的突然垮落,改善地下开采安全生产环境;最终资源的回收率由70%左右提高到84.6%,贫化率由25%~40%降低到15%以下,实现了资源的高效回收。

关键词:连续采矿;顶板诱导崩落;预裂爆破;崩顶爆破;地压灾害

中图分类号:TD856.11 文献标识码:A 文章编号:1672-7207(2008)03-0429-07

Technology of blast-induced caving roof and its application in

No.92 orebody of Dachang Tongkeng Mine

ZHANG Shi-chao, ZHOU Ke-ping, HU Jian-hua, SU Jia-hong, GU De-sheng

(School of Resources and Safety Engineering, Central South University, Changsha 410083, China)

Abstract: In order to solve the problems such as lower whole reclamation rate of resources and difficulties in controlling of anaphasic ground pressure and so on that occurred in mining large-sized poor ore deposit by traditional methods, the comprehensive technology of continual mining—induced caving roof was studied, and induced caving roof technology was the key for disposing abandoned stope and controlling anaphasic ground pressure. Based on the geological engineering condition of Dachang Tongkeng Mine’s No.92 orebody, an industrial trial of the comprehensive technology was taken. By theoretical analysis and engineering analogy ways, the rational parameters, operation project and security control arrangement of blasting induced caving roof were ascertained, and the practical application of blasting induced caving roof was also analyzed. The trial results show that with the disposal of induced caving roof by presplitting blasting and induced caving roof blasting, about 17.8 m in thickness of rock cushion is successfully formed in the inferior abandoned stope, which can bring down the harm of dashing blast of an explosion caused by roof collapse; apparent run-through flaws arise between presplitting blasting holes, and controllable caving is formed in the roof, abrupt collapse of large area roof is prevented, the productional safe surroundings of underground mining is improved; eventually, the resources’ reclamation rate is improved from about 70% to 84.6%, and the dilution rate is abated from 25%-40% to below 15%, so efficiently withdrawing is actualized.

Key words: continual mining; blast-induced caving roof; presplitting blasting; caving blasting; ground pressure disaster

地下大型矿体传统的开采过程中存在资源整体回收率低、后期地压控制难等问题,为解决这些采矿技术难题,研究采用连续采矿-顶板诱导崩落综合技术,即将厚大的矿体划分为阶段(盘区),再将阶段(盘区)划分为矿段;以矿段为回采单元,矿段间不留间柱;采切、回采分别在相邻矿段平行进行,矿段采用从一端向另一端连续推进、从上至下进行回采的连续回采工艺[1-4];顶板诱导崩落技术则遵循:取一定的回采步距宽,从一端向另一端先回采3个回采步距宽的矿块后即处理2个回采步距宽的采空区顶板,之后则回采1个回采步距宽的矿块便及时处理前1个回采步距宽度的采空区顶板,最后一个回采步距回采完毕则对该回采步距及前一回采步距宽矿块同时进行处理。

1 顶板诱导崩落技术整体方案

1.1 工程概况

连续采矿-顶板诱导崩落综合技术选用了广西大厂铜坑矿92号矿体的T112—T115单元作为工业试验矿块。该试验单元矿体垂直标高在420~530 m之间,平均厚度为65 m,整体东高西低,南高北低,单元水平面积为110 m×80 m。试验确定回采步距宽度为16 m。

试验单元顶板岩石非常坚硬,普氏系数为11~13。顶板内节理、裂隙不太发育,属中等稳固,可崩性差。

1.2 技术整体方案

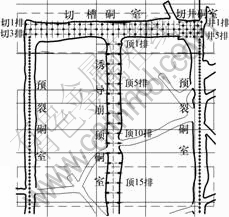

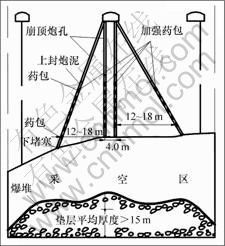

顶板诱导崩落技术质量的高低是综合技术能否成功实施的关键。人们对诱导崩落方法及工程实践进行了多年研究,并对有切缝、钻孔、强制爆破、注液软化等一些诱导崩落技术措施进行了探讨。这些技术措施对节理裂隙较发育或软弱的岩体有一定的效果,但对中等稳固以上的岩体,效果不明显,且成本太高[5-7]。为有效实现中等稳固以上顶板的诱导崩落,在方案对比分析的基础上,确定了从一端拉槽、削帮(削边壁),两侧预裂、中间部分强制崩顶诱导的方案,具体的工程布置及诱导崩落实施方法为:先在一端以VCR法或爆破成井技术进行拉槽,然后,从切槽硐室以切割天井为自由面以排炮进行爆破,在顶板与相邻矿柱间创造自由面,并破坏顶板的完整性(为初始崩落创造条件)。在两侧预裂硐室布置单排预裂孔,在中间诱导崩顶硐室以布置排炮由一端向另一端爆破,以对顶板进行诱导崩顶,破坏顶板稳定性,达到诱导拱顶被切割部分顶板崩落的目的。具体的诱导工程布置见图1。

图1 顶板诱导崩落处理工程示意图

Fig.1 Sketch map of project engineering of induced caving roof

在研究采用的综合技术中,顶板诱导崩落是建立在下方连续采矿技术基础上的工程技术,下方连续回采形成的采空区给顶板的诱导崩落提出了操作安全、工程效果稳定可靠以及技术实施经济可行等方面的要求[4-5]。任何技术差错造成的“崩”而不“落”,不仅更易出现不确定的顶板较大规模垮落,形成新的安全生产隐患,还将给下一步顶板诱导崩落的实施设置障碍。因此,对顶板的诱导崩落必须采用科学、合理的方法确定其技术参数和操作方法。

2 顶板诱导崩落技术参数的确定

2.1 安全顶板厚度

安全顶板的厚度关系到顶板内炮孔施工和爆破作业的安全。理论分析和数值模拟结果研究表明,对于铜坑矿92号矿体,在开采技术参数条件下,中等稳固以上顶板安全厚度取12~15 m[8-9]。

2.2 空区缓冲垫层厚度

为了有效地降低顶板冒落带来的冲击气浪危害,需要在空区下方形成一定厚度的缓冲垫层。缓冲垫层厚度可利用B.P.伊缅尼托夫提出的缓冲层厚度计算经验公式[10]:

对平均厚度为50~70 m高的采空区,经计算得缓冲层厚度宜为15~20 m。

对铜坑矿92号矿体试验单元而言,采空区平均高度为65 m,要形成理论要求厚度的岩石缓冲垫层,根据对崩顶炮孔爆破控制的初始崩落范围和矿岩松散系数为1.60、崩落岩石堆放形状等多因素的考虑,经反复验算,确定崩顶炮孔需爆破的长度约为20 m。

2.3 炸药的选用

对切割天井、切割槽、中间诱导崩顶炮孔的爆破所采用的炸药没有特别的要求,一般采用矿山平时生产用的乳化铵油炸药或2号岩石炸药即可。

预裂孔的爆破采用上述同样类型的炸药,但药卷需采用自制药卷。药卷的直径需根据炮孔直径和线装药密度等因素确定。对直径为165 mm的炮孔,确定采用直径为90 mm的药卷比较合适。

2.4 炮孔孔径的确定

炮孔孔径的确定应在综合考虑充分利用顶板内已有工程和顶板内作业安全等方面的因素确定诱导崩落处理顶板工程布置水平后,根据该水平至采空区的顶板厚度、矿内现有钻孔设备条件和特点以及尽量减少炮孔工程量等方面的情况来确定[11]。对中等稳固以上的顶板,根据矿山钻孔设备性能特点,确定处理顶板的切割槽炮孔、预裂孔和中间诱导崩顶炮孔均采用孔径为165 mm的炮孔。

2.5 爆破诱导崩落炮孔孔网参数

2.5.1 预裂孔间距

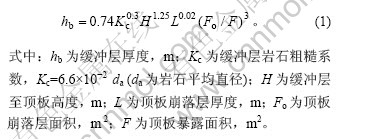

为减少预裂爆破对下方矿段的破坏和控制顶板崩落空间范围,预裂孔在水平位置上与下方空区的矿段边界靠空区一侧5 m处布置(见图2)。

图2 预裂孔布置示意图

Fig.2 Sketch map of presplitting holes

预裂孔直线单排布置,应用经验类比确定预裂孔间距[12]:

当预裂孔孔径d 预>60 mm时,则孔距a顶取值:

对于硬岩,d 预前面倍数取小值;对于软岩,取大值。

炮孔孔径取165 mm时,经计算,预裂孔孔距为1.32~1.98 m,对中等稳固以上顶板,取1.4 m。

2.5.2 强制崩顶爆破参数

中间诱导崩顶炮孔为扇形排炮。

排距L崩取值:

对于硬岩,d崩前面倍数取小值;对于软岩,取大值[13]。

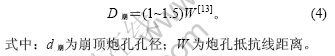

崩顶炮孔孔距D崩取值:

采用直径为165 mm炮孔时,排距取值为3.80~ 4.95 m,对顶板硬岩情况取4.0 m比较合适。

崩顶排炮中间两孔孔距取4.0 m。因顶板诱导崩落对块度没有太大要求,为体现诱导效果,排炮两边斜孔孔底距取12~18 m,孔口距0.465 m。对于边孔倾斜角,顶板高侧为60?,顶板低侧为70?~72?。

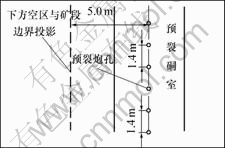

中间诱导崩顶炮孔布置示意图如图3所示。

图3 诱导崩顶炮孔布置示意图

Fig.3 Sketch map of induced caving blasting holes

2.5.3 其他炮孔孔网参数

其他炮孔孔网参数依据地下开采矿山对中等稳固以上矿岩的生产经验设计。

a. 切割天井炮。切割天井主要为下一步切割拉槽提供爆破自由面,考虑到切割天井爆破夹制作用大和采用矿用炸药等因素,类比同类矿山工程经验,综合确定切割天井炮孔采用梅花形布孔,孔网参数为2.1 m×2.1 m,排距为1.5 m,孔距为3 m。炮孔布置示意图如图4所示。

图4 切割天井炮孔布置示意图

Fig.4 Sketch map of cutting raise holes

b. 切割槽炮孔。考虑节省工程和安全需要,中等稳固以上顶板的切割槽设置的宽度设计为5 m。

切割槽排距L切槽取值:

对于硬岩,d切槽前面倍数取小值;对于软岩,取大值[13]。

切割槽炮孔孔距D切槽取值:

采用直径为165 mm炮孔时,切割槽排距为23×0.165 mm=3.8 m,考虑切割槽爆破夹制作用大,取3 m比较合适,采用梅花形布置,实际排距为2.25 m。

孔距根据切割槽凿岩巷道宽取4 m,采用梅花形的布孔方式。

炮孔具体布置示意图如图5所示。

图5 切割槽炮孔布置示意图

Fig.5 Sketch map of cutting chamfer holes

2.6 预裂孔线装药密度的确定

地下大直径预裂爆破的线装药密度ql可按下式计算[10, 12]:

对顶板为硬岩的情况,经计算,确定合理的线装药密度为2.0 kg/m。

3 技术实施

3.1 顶板诱导崩落装药结构和起爆方法

对中等稳固以上顶板的诱导崩落,既需考虑提高下方生产的资源回收率,滞后下方开采工作面一定的距离再进行处理,又需诱导崩落可靠性好,在下方形成一定厚度的缓冲垫层,尽量降低顶板出现大面积垮落的可能性,还需尽量体现诱导的理念,节省崩落成本。这些除诱导崩落工程布置外,还必须通过顶板诱导崩落爆破的具体操作来实现。

对切割井、切割槽的爆破按照矿山常规的爆破方法进行操作,诱导崩落爆破的关键在于对中间诱导崩顶孔和两侧预裂孔的装药和起爆。

3.1.1 诱导崩顶爆破

爆破采用矿山现用乳化铵油炸药,炸药密度为1.15×103 kg/m3,单个药卷长度为0.6~0.8 m,质量为12.5 kg。

以切割槽为自由面,对崩顶炮孔实行多排微差爆破。采用空气间隔装药,空气间隔取2.0 m。炮孔下部和上部均填充炮泥。根据缓冲垫层初始厚度对崩落岩石量的要求,经反复验算后确定较合理的中间诱导崩顶孔处理的深度为20 m左右。

在实际操作中间诱导崩顶孔的爆破时,因排炮斜孔孔距布置较大,为避免在顶板诱导处理过程中悬顶现象的发生,考虑布置在诱导崩顶孔的最顶端药包,采用加强药包或取2~3 m孔段采取连续装药的方式(见图3),其目的是通过爆破加强的作用在较顶端炮孔间产生贯通裂隙,诱导下部岩石冒落。

3.1.2 预裂爆破

炸药用乳化铵油自制药卷,药卷直径为90 mm,长度为0.8 m,单个药卷质量为5.85 kg。

采用空气间隔装药,空气间隔取2.0 m,线装药密度为2.09 kg/m,用将药卷间隔绑在铁丝或粗绳索上的办法下放炸药,铁丝或粗绳索每隔一定距离打结以防止药卷滑落。从预裂与中间诱导崩落的结合效果和预裂药量节省两方面综合考虑,预裂孔的装药深度控制在25 m比较合适。预裂孔装药结构示意图如图6所示。

1—封堵塞;2—下填充炮泥(与下封堵塞长共计2.0 m);

3—炸药;4—空气间隔取2.5 m;5—导爆索;6—上填充炮泥(长度2.0 m);7—炮孔

图6 预裂孔装药结构示意图

Fig.6 Sketch map of packing framework of presplitting holes

为保证预裂孔间的贯通效果,在预裂孔最顶端的药包采用加强药包或采取2~3 m连续装药的方法。

两侧预裂炮孔的爆破采用两侧同等范围内的预裂孔同时起爆的方式,1次爆完相应要求范围内的预 裂孔。

两侧预裂孔与中间诱导崩顶孔中间的处理关系为:预裂孔处理先于诱导崩顶孔处理[9, 14]。但从作业安全的角度考虑,实际操作时采取两者同时爆破但雷管不同段的方法,通过爆破微差来实现先处理预裂孔后处理诱导崩顶孔的目的。

3.2 安全技术措施

在顶板诱导崩落的爆破作业过程中采取了以下安全技术措施:

a. 在诱导崩落顶板过程中,预埋地压观测仪器(应力计和位移计)组成观测网络以随时加强顶板稳定性监测,在确认安全的情况下进入作业地段作业。已实施顶板崩落或预裂爆破区域,设置警示安全标志,严禁人员、设备进入或接近崩落区,以防诱导崩落层突然坍落。同时,对顶板大规模地压活动和大量冒顶实行预测预报。

b. 下方单元四周与空区直接相通的入口实行封闭,以防顶板大量冒落时产生的空气冲击波对人员造成危害。

c. 多作业面同时实施爆破作业时,一般采用一次点火,在距离较远而实行多点点火时,则由专人控制好点火时间和各点间的通讯联络信号。

d. 切割槽部分形成后,在顶板处理水平,为防止爆破冲击波可能对爆破作业人员造成的危害,在诱导崩落处理顶板水平爆破作业人员作业时,均退避到附近的监测硐室。

e. 处理诱导崩顶炮孔时,当经监测判定前面炮孔处理区域不安全时,则采取后面排炮炮孔加大装药的方式进行爆破,以确保爆破作业人员的安全。

4 工程效果

4.1 爆破直观效果

诱导崩顶爆破为加强抛掷爆破,单个药包爆破所形成的漏斗为加强抛掷爆破漏斗,爆破漏斗张开角 θ>90?。顶板岩石爆破后,岩石块基本在爆破漏斗夹角范围内进行抛掷。若忽略空气阻力等的影响,可认为抛体质心基本上沿弹道轨道运行,其基本方程 为[15]:

可见,抛掷距离s主要与抛速、抛角等因素有关,爆落岩石有不同的抛速、抛角,落点也不尽相同。在多药包爆破共同作用下,崩落岩石的第一落点并不一定是其最终位置点,最终形成的爆堆在空区宽度方向呈现中间略高、两端稍低和在长度方向呈现一端向另外一端缓缓降低的形状,爆堆边缘部分则按岩石自然安息角堆放;爆堆的平均厚度根据崩落控制范围岩石的体积和岩石松散系数以及爆堆堆放范围等的初步验算,为17.8 m左右。

通过对两端预裂孔的预裂爆破,在预裂孔之间形成了明显的贯通裂隙(见图7),这为顶板岩石下一步可控自然冒落创造了条件。

(a) a号预裂孔;(b) b号预裂孔;(c) c号预裂孔

图7 预裂爆破后少量预裂钻孔平面展开图

Fig.7 Flat deployed figure of few presplitting holes after presplitting blasting

4.2 爆破后续整体效果

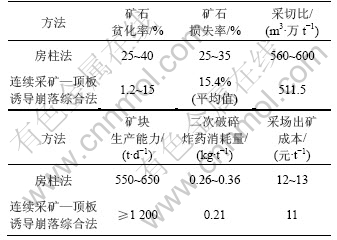

通过对顶板分几个步骤的爆破诱导崩落处理,在下方整个生产过程中没有发生大面积顶板突然垮落的地压灾害现象,生产安全得到有效保障;在顶板处理后的一段时期内,顶板陆续出现了一些小的冒落,但随着时间的推移,顶板趋向稳定;由于顶板的诱导崩落处理区域滞后回采工作面1个回采步距,有效地避免了资源的回收出现大的贫化和损失,相比原房柱法开采,取得了更理想的采矿经济技术指标(见表1)。

表1 采矿方法技术经济指标对比

Table 1 Comparison of mining methods on technical and economic indicators

5 结 论

a. 通过顶板诱导崩落的实施,提前释放了顶板大面积失稳带来的危险,并在下方形成了一定厚度的岩石垫层,使下方连续采矿生产安全得到有效保障。并且顶板诱导崩落技术与连续采矿技术的综合实施最终有效地提高了大型矿体开采的回收率,使其由原来的70%左右提高到84.6%。

b. 顶板的处理体现了诱导的思想,工程量较省,成本较低,在先期拉槽、强制崩落形成崩落条件后,后期通过预裂孔和诱导崩顶孔的处理,可以达到轻微扰动破坏平衡拱从而使顶板冒落的目的。

c. 顶板通过诱导崩落处理后,在预裂孔间形成的贯通裂隙有利于下一步地压的发展,顶板岩石不断自然冒落填充空区,岩石冒落呈拱向上发展,随着时间的推移,经历一个平衡—屈服—平衡的多轮循环,直至归于平衡。这样,不会给后面矿山的地压管理带来大的安全隐患。

d. 该综合技术着重采矿、出矿、空区处理、地压监测等多个环节的有效协调,因此,与以往常规采用的房柱法之类的方法相比技术要求要高,但并没有过多改变矿山原有的生产作业手段,也不需要重新购置其他设备,不需要对施工人员进行较长时间培训,因此,该技术也较容易为矿山生产所接受并推广应用。

参考文献:

[1] 古德生. 地下金属矿采矿科学技术的发展趋势[J]. 黄金, 2004, 25(1): 18-22.

GU De-sheng. The science & technology development of underground mental mining[J]. Golden, 2004, 25(1): 18-22.

[2] 吴爱祥, 韩 斌, 古德生, 等. 我国地下金属矿山连续开采技术研究的发展[J]. 有色矿山, 2002, 31(1): 1-5.

WU Ai-xiang, HAN Bin, GU De-sheng, et al. The development of research on continual mining at underground mental mines in China[J]. Nonferrous Mines, 2002, 31(1): 1-5.

[3] 吴爱祥, 古德生, 余佑林. 我国地下金属矿山连续开采技术的研究[J]. 金属矿山, 1998(2): 49-52.

WU Ai-xiang, GU De-sheng, YU You-lin. Study on continual mining technology in underground metal mine in our country[J]. Metal Mines, 1998(2): 49-52.

[4] 古德生, 许伦武, 罗典平. 地下金属矿山采矿连续工艺[J]. 中国矿业, 1992, 1(2): 49-52.

GU De-sheng, XU Lun-wu, LUO Dian-ping. The continual mining technology in underground metal mine[J]. China Mining Magazine, 1992, 1(2): 49-52.

[5] 邓 建, 李夕兵, 古德生. 无间柱连续采矿法矿段回采的地压规律与控制技术[J]. 中国有色金属学报, 2001, 11(4): 666-670.

DENG Jian, LI Xi-bing, GU De-sheng. Ground pressure and control techniques in non-pillar continuous mining method[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 666-670.

[6] 李俊平. 缓倾斜采空场处理新方法及采场地压控制研究[D]. 北京: 北京理工大学机电工程学院, 2002.

LI Jun-ping. The research on new methods of slowly declining abandoned stope’s disposal and control with stope’s ground press[D]. Beijing: School of Mechanical and Electronic Engineering, Beijing Institute of Technology, 2002.

[7] 李俊平, 钱新明, 郑兆强. 采空场处理的研究进展[J]. 中国钼业, 2002, 26(3): 11-15.

LI Jun-ping, QIAN Xin-ming, ZHENG Zhao-qiang. The research development of abandoned stope disposal[J]. China Moly, 2002, 26(3): 11-15.

[8] 周科平, 苏家红, 古德生, 等. 复杂充填体下矿体开采安全顶板厚度非线性预测方法[J]. 中南大学学报: 自然科学版, 2005, 36(6): 1094-1099.

ZHOU Ke-ping, SU Jia-hong, GU De-sheng, et al. The nonlinear forecasting method of the least security coping thickness when mining under complex filling body[J]. Journal of Central South University: Natural Science, 2005, 36(6): 1094-1099.

[9] HU Jian-hua, ZHOU Ke-ping, LI Xi-bing, et al. Numerical analysis of application for induction caving roof[J]. Journal of Central South University of Technology, 2005, 12(Suppl.1): 146-149.

[10] 刘殿中. 工程爆破实用手册[M]. 北京: 冶金工业出版社, 1999.

LIU Dian-zhong. Practical manual of engineering blasting[M]. Beijing: Metallurgical Industry Press, 1999.

[11] 阳天海, 龙 源, 顾文彬, 等. 光面、预裂爆破参数选择与质量措施研究[J]. 爆破, 2000, 17(1): 10-15.

YANG Tian-hai, LONG Yuan, GU Wen-bin, et al. Study on parameters selection and quality measures in smooth and presplitting blasting[J]. Blasting, 2000, 17(1): 10-15.

[12] 张富民. 采矿设计手册: 第2卷[M]. 北京: 中国建筑工业出版社, 1987.

ZHANG Fu-min. Mining design manual: Vol.2[M]. Beijing: China Architecture Building Press, 1987.

[13] 徐小荷, 廖国华, 马 光, 等. 采矿手册: 第2卷[M]. 北京: 冶金工业出版社, 1990.

XU Xiao-he, LIAO Guo-hua, MA Guang, et al. Mining manual: Vol.2[M]. Beijing: Metallurgical Industry Press, 1990.

[14] 古德生, 邓 健, 李夕兵. 无间柱连续采矿的岩石力学优化[J]. 中南工业大学学报: 自然科学版, 1999, 30(5): 441-444.

GU De-sheng, DENG Jian, LI Xi-bing. Rock mechanics optimization of non-pillar continuous mining[J]. Journal of Central South University of Technology: Natural Science, 1999, 30(5): 441-444.

[15] 赵福兴. 控制爆破工程学[M]. 西安: 西安交通大学出版社, 1987.

ZHAO Fu-xing. Controlled blasting engineer[M]. Xi’an: Xi’an Jiaotong University Press, 1987.

收稿日期:2007-10-30;修回日期:2008-01-25

基金项目:国家科技支撑计划项目(2006BAB021304-1-1);“十五”国家科技攻关资助项目(2003BA612A-10-1)

通信作者:张世超(1972-),男,湖南沅江人,博士研究生,从事采矿工艺、爆破、矿业研究与开发;电话:0731-7928426;E-mail: zsc0925@126.com