文章编号:1004-0609(2008)06-0980-05

基于M-K模型的铝锂合金热态下成形极限预测

马高山,万 敏,吴向东

(北京航空航天大学 机械工程及自动化学院,北京 100083)

摘 要:基于板材的基础性能参数,以M-K理论为基础,在不同温度下对5A90铝锂合金的成形极限图进行理论计算。确定了理论预测成形极限图时所需的初始厚度不均度(f)在不同温度下的值,其值在室温下为0.95,在较高温度下为0.995。预测了材料参数应变强化指数(n)、应变速率敏感性指数(m)对5A90铝锂合金的成形极限曲线的影响规律。结果表明,成形极限曲线随m值和n值的增大而上升。同时,对7种变形温度下铝锂合金的成形极限图进行了预测,并在25~300 ℃温度范围内对其进行成形极限实验,通过对实验曲线与理论预测曲线的对比分析,验证了理论预测的可行性和准确性。

关键词:铝锂合金;成形极限图;理论预测;M-K模型

中图分类号:TG 386; V 26 文献标识码:

ATheoretical prediction of FLDs for Al-Li alloy at elevated temperature based on M-K model

MA Gao-shan, WAN Min, WU Xiang-dong

(School of Mechanical Engineering and Automation, Beihang University, Beijing 100083, China)

Abstract: The forming limit diagrams (FLDs) of 5A90 Al-Li alloy were determined analytically based on the Marciniak-Kuczynski concept of localized necking using the constitutive equation. The initial thickness imperfection parameter, f, at various temperatures was determined, which is an important parameter in predicting FLDs. The f-values are 0.95 at room temperature and 0.995 at elevated temperatures. The effects of the strain-hardening exponent (n-value), and strain-rate exponent (m-value) on the FLDs were predicted, and it is shown that the forming limit strain increases with increasing n-value and m-value. Furthermore, the FLDs of Al-Li alloy were predicted at seven temperatures, and the FLDs tests of 5A90 Al-Li alloy in the forming temperature range of 25-300 ℃ were carried out. The predicted results of the FLDs are in qualitative agreement with the experimental observations.

Key words: aluminum-lithium alloy; forming limit diagram; theoretical prediction; M-K model

铝锂合金作为一种新型的铝合金材料,由于具有优良的综合性能而在航空航天领域得到了广泛的应 用[1]。实验表明,在铝中加入1%的锂,其密度可降低3%,弹性模量提高6%[2],而且,铝锂合金具有高的比强度和比刚度、高弹性模量等特点,用其代替常规的高强度铝合金可使结构质量减轻10%~20%,刚度提高15%~20%[3]。因此,将其用作结构材料潜在经济效益极大,被认为是21世纪飞行器的主要结构材料。然而,铝锂合金在室温下的塑性较差,难以采用传统的冷成形工艺生产复杂零部件,给其应用带来一定的困难。研究表明,对于较难成形的轻质合金材料,如镁合金、铝锂合金,其塑性随成形温度的升高有明显的改善[4-6]。因此,研究铝锂合金在热态下的成形极限,对于进行铝锂合金热成形的数值模拟等具有重要的意[7-9]。

成形极限图(Forming limit diagrams,FLDs)作为判断和评定板材成形性的最为综合和直观的方法之一,在工业上得到广泛的应用,是评价板料成形性能优劣和解决板材冲压问题的一个非常有效的工具[10]。成形极限曲线位置的高低反映了材料在各种应力状态下局部极限变形能力的大小,其位置越高则材料的成形性能越好。通常,确定成形极限图的方法有两种,理论计算和实验确定。理论计算成形极限图是采用不同的屈服准则和塑性本构关系、基于不同拉伸失稳准则作为颈缩与破裂的条件进行解析的[11]。拉伸失稳准则是建立成形极限图的理论基础。HILL[12]提出的集中性失稳理论和SWIFT[13]提出的分散性失稳理论为塑性变形拉伸失稳理论奠定了基础。SWIFT分散性失稳条件是在简单加载的前提下,只适用于双向等拉应力状态;而在Hill集中性失稳理论中,由于在双向拉伸条件下不存在零应变线而不可能发生集中失稳,所以,HILL失稳理论也具有一定的局限性。对此,MARCINIAK和KUCZYNSKI[14]于1967年从材料损伤角度提出一种凹槽假说,即著名的M-K理论[14],该理论是目前应用最为广泛的损伤失稳理论。本文作者在研究了5A90铝锂合金板材在一定温度下的变形规律和建立其本构关系模型的前提下[6],以M-K理论为基础,对5A90铝锂合金在不同变形温度下的成形极限图进行理论预测,同时与不同温度下的成形极限试验数据进行对比分析,以验证理论预测的正确性和准确性,从而建立5A90铝锂合金成形极限图的预测模型。

1 成形极限图的理论预测

1.1 FLD理论预测的实现

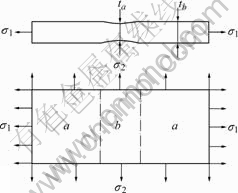

M-K理论以凹槽假设为基础核心,进行了厚度不均假设。根据此假设可知,板材的集中性失稳是由板材表面初始存在的缺陷引起的。其理论数学模型示意图如图1所示,其中,a区为均匀变形部分,b区为不均匀变形区,即凹槽部分。

M-K理论的要点主要包括如下几个方面[14]:

1) 板料受到双向受拉的平面应力状态,且变形前后板料的体积保持不变:

2) 认为槽外a区的变形为简单加载,a区内主应力成比例增加:

应变也成比例,且在加载过程中比值不变:

3) 槽内次应变的增量dε2b与槽外次应变的增量dε2a相等:

4) 板料在变形的每一瞬间,都必须满足力的平衡条件:

式中ta和tb分别为板料a区和b区的厚度。

图1 M-K理论的数学模型示意图

Fig.1 Schematic diagram of model of M-K theory

塑性变形时,凹槽内外应力状态是不同的。如果a区按固定路线加载,应力状态不变,则b区的加载路线将沿着不同层次的屈服表面挠曲变化,改变应力强度与应力状态以满足静力平衡条件和几何协调条件,并最终达到平面应变状态。在平面应变状态下, dε2b = 0,凹槽加深,dε1b>dε1a ,最终板材在凹槽处发生破裂。在各应变值的计算过程中,还引入3个过程参数d、ρ和β,以便于进行迭代计算。其中,d为等效应力和主应力的比值,即d=σi /σ1;ρ为次应变dε2与主应变dε1的应变比,即ρ = dε2/dε1 = ;β为等效应变dεi与主应变dε1 的应变比,即β = dε/dε1 =

;β为等效应变dεi与主应变dε1 的应变比,即β = dε/dε1 = 。

。

由相关铝锂合金的研究可知,5A90铝锂合金板材在较高温度下变形时,其各向异性特征明显减弱,可以近似为各向同性[6]。因此,为简化计算,可将铝锂合金板材在加热状态下视为各向同性材料,在对铝锂合金的成形极限图进行理论计算时不考虑各向异性,而采用基于各向同性假设的Mises屈服准则。

5A90铝锂合金在一定温度下的本构关系模型可写成如下形式[6]:

式中 K、n和m均为与温度有关的材料常数,分别为强度系数、应变强化指数和应变速率敏感性指数;T为绝对温度。通过采用式(6)所示的本构关系模型,以M-K凹槽理论为基础,结合简单加载、Mises屈服准则、材料体积不变原理以及增量理论,并采用数字迭代算法,通过编程计算可得到板材破裂时的极限应变值[15],由此可得到铝锂合金在各变形温度下的成形极限理论曲线,从而实现对成形极限的理论预测。

1.2 初始厚度不均度的确定

由M-K理论可知,假设板料中存在一凹槽,即板料在最初存在一个厚度不均度,将其设为f = tb0/ta0,其中ta0和tb0 分别为板料a区和b区的初始厚度。实际上,M-K理论中假设的凹槽也可以看作是板料中存在的缺陷。变形温度的不同对这一缺陷的敏感程度也不同,一般来说,升高变形温度有利于弥补材料中的缺陷对材料成形造成的不利影响,使材料向有利的方向变形。许多成形极限的预测研究中,初始厚度不均度都是通过假设得到的,且认为不同变形温度下的初始厚度不均度是相同的[16]。事实上,不同温度下的初始厚度不均度应存在着一定的差别,因此,确定合理的、不同变形温度下的初始厚度不均度,对成功预测成形极限曲线有着重要的意义。

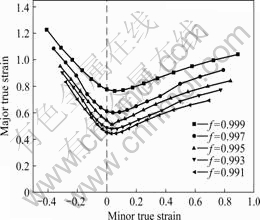

图2所示为5A90铝锂合金在300 ℃下变形时初始厚度不均度对成形极限图的影响预测。总的来说,初始厚度不均度 f 值越大,成形极限曲线越高,这说明板料中的缺陷越不明显,越有利于成形。由图可知,成形极限曲线随初始厚度不均度 f 值的减小而下降,但其下降的趋势在逐渐减弱,并最终趋向一个固定的值。因此,当初始厚度不均度为一个较小的值时,可以使用与之差别不大的某一值来代替,且其值对成形极限图预测的影响并不大。

图2 300 ℃下初始厚度不均度对成形极限图的影响

Fig.2 Effects of initial thickness imperfection parameter f on FLDs at 300 ℃

5A90铝锂合金在室温变形时初始厚度不均度对成形极限图影响规律的预测如图3所示。由图可知,不同的初始厚度不均度值下,室温时的成形极限曲线与300 ℃时的成形极限曲线有着相同的趋势,两者不同的是其初始厚度不均度的值有所差异。这是因为不同的变形温度下材料对缺陷的敏感程度不相同,因此,室温下的初始厚度不均度不同于高温下的值,其值应比高温下的略低。

图3 室温下初始厚度不均度对成形极限图的影响

Fig.3 Effects of initial thickness imperfection parameter f on FLDs at room temperature

基于室温下变形对材料缺陷的敏感性,以及上述对初始厚度不均度的分析,参照图3和4中的各成形极限曲线,在对室温下的成形极限曲线进行理论预测时,可取其初始厚度不均度 f 值为0.95,而在其他较高温度下其值可采用0.995。

2 材料参数对FLDs的影响预测

由铝锂合金的相关研究可知,5A90铝锂合金在一定温度下的应变硬化指数(n)和应变速率敏感性指数(m)的大小范围均在0.01~0.3之间[6],故在理论计算n值和m值对成形极限曲线影响规律的预测研究时可采用此取值范围。

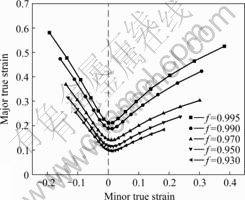

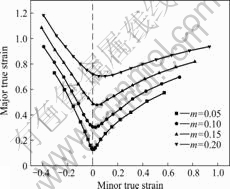

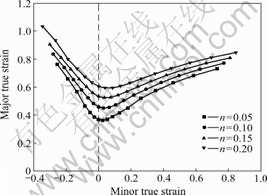

如图4所示为在应变硬化指数(n)相同的条件下,应变速率敏感性指数(m)对成形极限图影响规律的预测。在此成形极限图的理论计算中,取n=0.01,m值的取值范围为0.05~0.2。由图中曲线比较可知,在较低的应变强化条件下,应变速率敏感性指数m值对成形极限曲线的影响非常显著,随着m值的增大,其成形极限曲线显著升高。这说明材料的m值越大,材料在变形中越不易达到极限应变,对成形也越有利。

图4 n = 0.01时m值对成形极限图的影响规律

Fig.4 Effect of m-value on FLDs for given n-value (n=0.01)

为考察应变硬化指数对成形极限曲线的影响规律,进行了在m = 0.1,n值的取值范围为0.05~0.2时的成形极限图的理论计算。如图5所示显示了在应变速率敏感性指数m值相同的条件下,应变硬化指数n值对成形极限图影响规律的预测。由图可知,成形极限曲线随n值的增大而上升,并且对平面应变区域的影响更为显著。相关研究表明,m值和n值对铝锂合金的成形极限影响规律的预测是正确的[6]。

图5 m=0.1时n值对成形极限图的影响规律

Fig.5 Effect of n-value on FLD for given m-value (m=0.1)

3 不同温度下FLDs的理论预测及实验验证

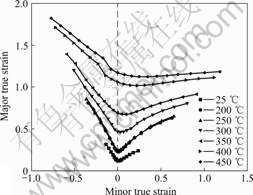

在确定了初始厚度不均度和预测了材料常数对成形极限图的影响规律的基础上,可实现对不同变形温度下的成形极限曲线进行理论预测,7种不同温度下5A90铝锂合金的成形极限理论预测曲线如图6所示。由图可知,5A90铝锂合金的成形极限曲线随温度的升高呈上升趋势。将变形温度从室温提升到200 ℃的过程中,成形极限曲线有较大提升;然而,200和250 ℃时两者的成形极限曲线相差较小,这是由于变形温度由200 ℃上升到250 ℃时,材料的n值下降而m值上升,两参数值综合作用所致;继续提升变形温度,则成形极限曲线继续大幅提升;450 ℃时的成形极限曲线相对400 ℃提升较小,两成形极限曲线较为接近。

图6 7种温度下的理论预测成形极限曲线

Fig.6 Theoretic FLDs for 5A90 Al-Li alloy at seven temperatures

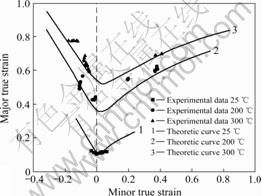

为验证理论预测的可行性与正确性,进行了5A90铝锂合金在25~300 ℃温度范围内的成形极限实验。实验采用半球形刚性凸模胀形实验,凸模外径为d 100 mm。实验设备采用北京航空航天大学研制的热环境通用板材成形性能实验机BCS-50AR。实验用材为5A90铝锂合金板材,板料厚度为1.5 mm,将板材沿轧制方向制成所需成形极限试样[17],试样长度为176 mm,宽度范围为20~176 mm,宽度间隔20 mm。

图7所示为3种变形温度下的5A90铝锂合金成形极限曲线实验数据与理论预测曲线的对比示意图。通过比较理论预测曲线与实验数据可知,虽然在较高变形温度下的理论预测曲线稍显偏低,但总的来说,成形极限的理论预测与实验结果比较接近,两者的吻合度较好。

图7 3种温度下的理论预测曲线与实验数据对比

Fig.7 Theoretic FLDs for 5A90 Al-Li alloy and experimental data at three temperatures

通过上述分析可知,本研究基于材料基础性能参数和M-K理论进行不同温度下的成形极限图的预测是可行和准确的,为不同变形温度下的成形极限图的建立提供了一种简便实用的方法,从而可以减少甚至避免繁琐的成形极限实验,具有重要的实际意义。

4 结论

1) 以M-K理论为基础,对5A90铝锂合金的在不同变形温度下的成形极限图进行理论计算,并通过成形极限实验对理论预测结果进行验证,结果表明5A90铝锂合金成形极限图的理论预测是准确的。

2) 确定理论预测不同温度下的成形极限图时所需的初始厚度不均度的值,预测材料常数对成形极限图的影响规律,为其他金属板材在不同温度下的成形极限图的理论预测提供参考。

REFERENCES

[1] MENG L, ZHENG X L. Overview of the effects of impurities and rare earth elements in Al-Li alloys[J]. Mater Sci Eng A, 1997, 237: 109-118.

[2] RIOJA R J. Fabrication methods to manufacture isotropic Al-Li alloys and products for space and aerospace applications[J]. Mater Sci Eng A, 1998, 257: 100-107.

[3] XUN YU-wei, ZHUN Yi-yuan, MAO Wen-feng, CUI Jian-zhong. Superplastic forming technology of aircraft structures for Al-Li alloy and high-strength Al alloy[J]. Journal Materials Processing Technology, 1997, 72: 183-187.

[4] TAKUDA H, ENAMI T, KUBOTA K, HATTA N. The formability of a thin sheet of Mg-8.5Li-1Zn alloy[J]. Journal of Materials Processing Technology, 2000, 101: 281-286.

[5] TAKUDA H, MORISHITA T, KINOSHITA T, SHIRAKAWA N. Modelling of formula for flow stress of a magnesium alloy AZ31 sheet at elevated temperatures[J]. Journal of Materials Processing Technology, 2005, 164/165: 1258-1262.

[6] 马高山, 万 敏, 吴向东. 5A90铝锂合金热态下本构关系研究[J]. 塑性工程学报, 2007, 14(3): 68-71.

MA Gao-shan, WAN Min, WU Xiang-dong. Research on the constitutive relationship of 5A90 aluminum-lithium alloy at hot forming temperature[J]. Journal of Plasticity Engineering, 2007, 14(3): 68-71.

[7] ABEDRABBO N, POURBOGHRAT F, CARSLEY J. Forming of aluminum alloys at elevated temperatures-Part 2: Numerical modeling and experimental verification[J]. International Journal of Plasticity, 2006, 22: 342-373.

[8] ABEDRABBO N, POURBOGHRAT F, CARSLEY J. Forming of AA5182-O and AA5754-O at elevated temperatures using coupled thermo-mechanical finite element models[J]. International Journal of Plasticity, 2007, 23: 841-875.

[9] NARAYANASAMYA R, SATHIYA N C. Experimental analysis and evaluation of forming limit diagram for interstitial free steels[J]. Materials & Design, 2007, 28(5): 1490-1512.

[10] MOSHKSAR M.M, MANSORZADEH S. Determination of the forming limit diagram for Al 3105 sheet[J]. Journal of Materials Processing Technology, 2003, 141: 138-142.

[11] 韩 非, 万 敏, 吴向东. 板料成形极限理论与实验研究进展[J]. 塑性工程学报, 2006, 13(5): 80-86.

HAN Fei, WAN Min, WU Xiang-dong. Theoretical and experimental investigation progress on the forming limit of sheet metal forming[J]. Journal of Plasticity Engineering, 2006, 13(5): 80-86.

[12] HIL L R. On discontinuous plastic states with special reference to localized necking in thin sheets[J]. J Mech Phys Solids, 1952, 1: 19-31.

[13] SWIFT H W. Plastic instability under plane stress[J]. J Mech Phys Solids, 1952, 1: 1-18.

[14] MARCINIAK Z, KUCZYNSKI K. Limit strain in the processes of stretch-forming sheet metal[J]. International Journal of Mechanical Sciences, 1967, 9: 609-620.

[15] GRAF A, HOSFORD W F. Calculations of forming limit diagrams[J]. Metallurgical Transactions A, 1990, 21: 87-93.

[16] NAKA T, NAKAYAMA Y, UEMORI T, HIRO R, YOSHIDA F. Effects of temperature on yield locus for 5083 aluminum alloy sheet[J]. Journal of Materials Processing Technology, 2003, 140: 494-499.

[17] 万 敏, 胡运斌, 谢 英, 张 平, 许成喜, 袁 胜. 飞机蒙皮铝合金板材成形极限及应用[J]. 中国有色金属学报, 2002, 12(Special 1): 180-183.

WAN Min, WU Xiang-dong, XIE Ying, ZHANG Ping, XU Cheng-xi, YUAN Sheng. Forming limit of aircraft skin aluminum alloy sheets and its applications[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(Special 1): 180-183.

基金项目:国家自然科学基金资助项目(50475004)

收稿日期:2007-09-25;修订日期:2008-01-02

通讯作者:马高山;电话:010-82338788;E-mail: mgs_adam@163.com

(编辑 何学锋)