文章编号:1004-0609(2012)07-2133-08

基于CFD的充填管道固-液两相流输送模拟及试验

吴 迪1, 2,蔡嗣经1, 2,杨 威1, 2,王文潇3,王 章3

(1. 北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京 100083;

2. 北京科技大学 土木与环境工程学院,北京 100083;

3. 马钢集团矿业有限公司,马鞍山 243000)

摘 要:为解决和睦山铁矿充填料浆的管道自流输送问题,采用固-液两相流理论和计算流体动力学(CFD)方法,建立充填料浆在管道中自流输送的两相流控制方程;利用Gambit构造实际管道的三维网格模型,在Fluent的3D解算器中进行数值模拟。通过分析管道输送的阻力损失和弯管部分的受力情况,获得料浆输送的最佳浓度和流量。料浆坍落度试验、自然沉降试验以及现场工业输送试验验证了数值模拟结果的可靠性。研究结果为该矿即将投入使用的永久充填系统运行参数的选取提供了重要的依据。

关键词:自流输送;固-液两相流;计算流体动力学;数值模拟;阻力损失

中图分类号:TD853.34 文献标志码:A

Simulation and experiment of backfilling pipeline transportation of solid-liquid two-phase flow based on CFD

WU Di1, 2, CAI Si-jing1, 2, YANG Wei1, 2, WANG Wen-xiao3, WANG Zhang3

(1. State Key Laboratory of High-efficient Mining and Safety of Metal Mines, Ministry of Education,

University of Science and Technology Beijing, Beijing 100083, China;

2. School of Civil and Environmental Engineering, University of Science and Technology Beijing, Beijing 100083, China;

3. Magang Group Mining Co., Ltd., Ma’anshan 243000, China)

Abstract: In order to solve the gravity transportation problems of backfilling slurry by pipelines in Hemushan Iron Mine, solid-liquid two-phase flow theory and computational fluid dynamics (CFD) method were used. Two-phase flow control equations of backfilling slurry in the pipeline through the gravity transportation were established. The three-dimensional (3D) mesh model of real pipeline was established using soft Gambit and the numerical simulation was conducted in the 3D solver of Fluent. Through analyzing resistance loss of the pipeline and force condition of the elbow, optimal transportation concentration and volume flow of the backfilling slurry were acquired. The slump test and natural settlement test of backfilling slurry and in-situ industrial transportation test verify the reliability of the numerical simulation results. The research results provide important basis for the parameter selection of the permanent backfilling system in the mine.

Key words: gravity transportation; solid-liquid two-phase flow; computational fluid dynamics; numerical simulation; resistance loss

充填采矿法能够有效保护矿区地表及周边生态环境、降低矿石损失贫化、减少尾矿的排放以及控制采场的地压,因而近些年来被越来越多的地下矿山所采用。和睦山铁矿也不例外,其后观音山矿段原设计采矿方法为空场法,而根据矿体的开采技术条件,存在矿石损失率大和采场地压显现突出等问题。因此,和睦山铁矿拟在后观音山矿段改用充填采矿法,基于节约成本的考虑,设计采用胶结尾砂充填料浆管道自流输送的方式进行井下充填。因此,对充填料浆管道自流输送问题的研究对于指导此矿山的充填采矿实践具有重要的意义。

充填料浆的管道输送是一种典型的固-液两相流动[1-3]。料浆作为一种水和固体颗粒相混合的非牛顿流体[4],在管道中的流动规律与料浆浓度和流速等因素有很大关系。传统的两相流体力学研究方法主要依赖于经验分析和实验研究,但受到设备和成本等多方面条件的限制[5]。随着计算机技术的发展,在经典流体动力学与数值计算方法的基础上,形成了计算流体动力学(CFD)。CFD通过计算机数值计算和图像显示方法,在时间和空间上定量地描述流场的数值解,以获得理想的研究结果。Fluent作为目前国际上应用最广的CFD数值模拟软件,在固-液两相流动方面应用广泛[6-9]。WANG等[10]报道了使用Fluent软件对深井煤矿自流输送充填系统中料浆的流动速度的研究,但是并未涉及对管道系统的受力分析。许毓海等[11]只是在理论上确定了自流输送参数,缺乏相应的数值模拟及试验数据支持。虽然自流输送方式省去了泵送设备而控制了成本,但也使得充填料浆的浓度比较低,并造成了一系列问题,例如排水费用的增加[12]等。而国外的充填矿山较多采用泵送充填料,对自流输送系统的研究报道也较少。

基于上述分析,本文作者在固-液两相流理论的基础上,采用Fluent数值模拟软件研究充填料浆浓度及流量对其管道输送的影响,着重对管道系统的阻力损失及弯管受力情况进行分析,并与室内试验和现场工业试验的结果进行对比验证,同时还考虑料浆的脱水,最终得到全尾砂充填料浆管道自流输送的最佳运行参数。

1 数学模型

矿山充填管道浆体输送工艺及其力学结构的复杂性决定当前尚无法求得管道输送问题的精确解。为便于建模和分析计算,将充填料浆固-液两相流的管道输送模式视为均质满管流,假设固体颗粒不发生相 变[13],并将充填料浆的流动作为不可压缩定常流处 理[14],模拟过程中不考虑热交换和地下采矿作用等因素对管道输送的影响。

1.1 模型选择

描述流体运动主要有拉格朗日法和欧拉法,其中欧拉法应用较为广泛,它能从整个流场的角度分析流速和压强的变化规律,因此本文选用欧拉法。在Fluent中,共有3种欧拉-欧拉多相流模型:流体体积模型、欧拉模型和混合物模型,其中混合物模型可用于两相流或多相流。对于泥浆流和水力运输,采用混合物模型或欧拉模型,本研究根据问题的需要选用混合物模型[15-16]。

1.2 控制方程

1) 连续方程

(1)

(1)

式中: 表示第k相的体积分数;

表示第k相的体积分数; 表示第k相的密度(kg/m3);

表示第k相的密度(kg/m3); 表示第k相的平均速度(m/s)。

表示第k相的平均速度(m/s)。

2) 动量方程

(2)

(2)

式中:p表示压力(Pa);τk表示分子动力(N/m2); 表示紊动应力(N/m2);Mk表示单位体积相间动量传递(N/m3);(Fint)k表示内在力(N/m3);g为重力加速度(m/s2);SD为动量源项(N/m3)。

表示紊动应力(N/m2);Mk表示单位体积相间动量传递(N/m3);(Fint)k表示内在力(N/m3);g为重力加速度(m/s2);SD为动量源项(N/m3)。

3) 能量方程

(3)

(3)

式中:hk表示第k相的显焓;keff表示有效热传导率;SE为能量源项(N/m3)。

1.3 流场算法

计算区域和控制方程的离散采用有限体积法,并选取一阶迎风格式进行离散;流场数值计算采用分离解法中的压力耦合方程组的半隐式方法(SIMPLE算法)[17]。

1.4 边界条件

设定竖直管道模型的入口边界条件为速度入口(VELOCITY_INLET),水平管道的出口边界条件为出口流动(OUTFLOW)。对于充填料浆的自流输送,设定竖直方向(Y轴)的重力加速度为-9.81 m/s2。

2 几何模型

充填钻孔自地表施工至-120 m水平,钻孔内套直径为120 mm的钢管,高度为100 m;-120 m中段水平充填管道使用内径为120 mm的PF钢丝编织复合管,长度为200 m,充填倍线[18]为3。-120 m中段以下充填倍线进一步降低,可满足充填料浆自流输送的要求。

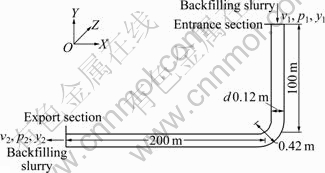

本研究采用Fluent的前处理软件Gambit进行几何建模,管道的几何模型与实际尺寸及布置方式保持一致,如图2所示。管道竖直高度为100 m,水平长度为200 m,管道内径为0.12 m。弯管呈90°,弯径比为3,即曲率半径为0.36 m。

图1 充填管道的几何模型

Fig.1 Geometry model of backfilling pipeline

图1中,v1和v2分别表示垂直管道入口断面处和水平管道出口断面处充填料浆的平均流速;p1和p2分别表示充填料浆在垂直管道入口断面处和水平管道出口断面处的表面压力;y1和y2分别表示垂直管道入口断面处和水平管道出口断面处的海拔高度。

根据图1所示参数,有伯努利方程[19]:

(4)

(4)

式中:hf为管道的阻力损失。

3 数值模拟分析

根据和睦山铁矿的开采技术条件,考虑到来源及成本等因素,采用混合矿全尾砂作为试验的充填材料,经试验室测定其密度为2 900 kg/m3。将几何模型导入到Fluent的3D求解器中进行分析。根据问题的需要,模拟采用Realizable k-ε湍流模型。

3.1 料浆浓度的影响

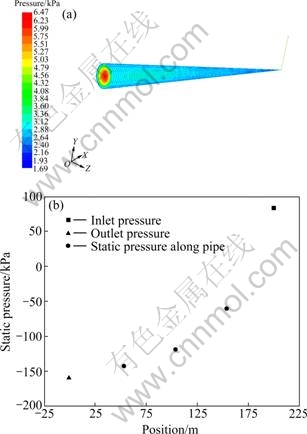

和睦山铁矿临时充填系统的料浆制备输送能力为60~80 m3/h。为了与实际情况相吻合,可以保持充填料浆的输送流量不变(不妨取为80 m3/h),通过改变料浆的浓度进行数值模拟分析。由于篇幅有限,在此仅展示充填料浆浓度为60%、流量为80 m3/h的管道压强分析结果,如图2所示。

图2 充填管道压强分析

Fig.2 Pressure analysis results of backfilling pipeline: (a) Outlet dynamic pressure; (b) Inlet and outlet static pressures

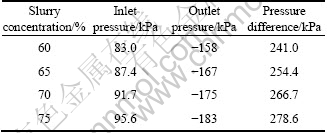

分别选取60%、65%、70%和75%的充填料浆输送管道进行数值模拟,管道入口和出口压强的分析结果如表1所列。

在已设定的边界条件下,保持流量不变,垂直管道和水平管道直径相等,则v1=v2,因此,根据式(4),阻力损失(hf)为

(5)

(5)

由式(5)和表1数据可知,当料浆浓度为60%时管道的阻力损失最小。随着料浆浓度的增大,管道的入口和出口压强差将增大,阻力损失也随之增大。

表1 料浆流量为80 m3/h时不同充填料浆浓度管道的入口和出口压强

Table 1 Inlet and outlet pressures of pipeline at slurry flow of 80 m3/h and different slurry concentrations

3.2 料浆料量的影响

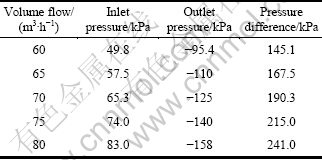

根据临时充填系统的料浆制备输送能力为60~80 m3/h,保持充填料浆的浓度为60%不变,分别选取料浆流量为60、65、70、75和80 m3/h进行数值模拟分析,得到5种不同料浆流量下输送管道的入口和出口压强,结果如表2所列。

表2 料浆浓度为60%时不同料浆流量下管道入口和出口压强

Table 2 Inlet and outlet pressures of pipeline at slurry concentration of 60% and different slurry flows

同理,由式(5)和表2数据可知,当充填料浆的体积流量为60 m3/h时,管道输送的阻力损失值最小。

3.3 弯管受力分析

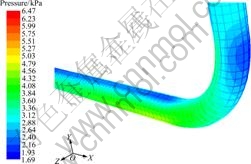

以充填料浆浓度为60%、流量为80 m3/h的管道为例,进行受力分析。弯管部分的压强分布如图3 所示。

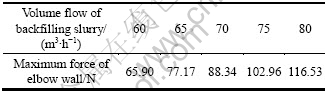

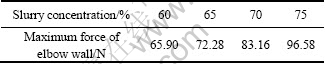

根据受力分析结果,得出不同料浆流量条件下的弯管壁面处的最大作用力,如表3所列。

依据表3,当充填料浆的体积流量为60 m3/h时,弯管壁面的受力最小,因此,也最不易磨损。此结果与流量分析得出的结果一致。

保持料浆体积流量为60 m3/h不变,分析料浆浓度对弯管受力的影响,结果见表4。

图3 弯管壁面压强分布

Fig. 3 Pressure distribution of elbow wall

表3 料浆浓度为60%时不同料浆流量条件下的弯管壁面处的最大作用力

Table 3 Maximum force of elbow wall at slurry concentration of 60% and different slurry flows

表4 料浆流量为60 m3/h时料浆浓度对管道壁面受力的影响

Table 4 Effect of slurry concentration on force of elbow wall at slurry flow of 60 m3/h

根据表4可知,当充填料浆的浓度为60%时,弯管壁面的受力最小,与浓度分析得出的结果互相印证。

4 实验验证

为验证数值模拟结果的可靠性,于实验室进行了充填料浆的坍落度试验和沉降试验,并在现场进行了充填料浆的输送工业试验。

4.1 坍落度试验

测定坍落度主要是为了了解充填料浆的流动性,并辅以直观经验评定其粘聚性和保水性。全尾砂坍落度试验结果见表5和图4。

表5 充填料浆的坍落度

Table 5 Slump of backfilling slurry

由于混合矿全尾砂颗粒较细,随着不断稀释,当料浆浓度为55%时,料浆表观浓度很低,无法测定坍落度;当充填料浆浓度为80%时,由于料浆呈现出干硬性,也无法测定其坍落度。

当坍落度小于6.8 cm,即充填料浆浓度超过75%时,难以实现自流输送;而当料浆浓度为60%,即坍落度为23.5 cm时,其流动性能明显改善。因此,在满足重力自流输送的条件下,充填料浆的最佳输送浓度为60%。坍落度试验的测定结果验证了数值模拟的正确性。

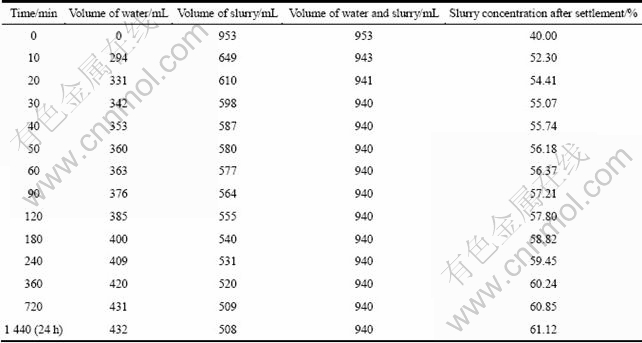

4.2 沉降试验

尾砂的沉降性能对充填体的物理性质具有较大影响,它决定着充填体的沉降特性。充填料浆一般在最初阶段常常处于饱和状态,在脱水的过程中,由于毛细压力和固体颗粒自重的作用,充填料浆体积减小,此过程就是充填料浆的自然沉降过程。起始浓度为40%的全尾砂浆沉降试验结果见表6。

由表6可以看出,经过24 h的沉降,充填料浆的浓度达到61.12%。数值模拟得出料浆的最佳输送浓度为60%,与沉降后的料浆浓度比较可知,料浆经过管道输送到井下形成的充填体通过自然沉降的脱水量较少,表明此输送浓度具有较高的工业可行性。

4.3 工业输送试验

为了对实验室试验结果和计算机数值模拟结果进行对比验证,在和睦山铁矿建立了临时充填系统(见图5),以进行充填料浆的输送工业试验。临时充填系统设立了较完善的自控系统,能够用来调节全尾砂放砂流量、水泥用量及水量,同时对料浆输送参数进行检测。充填料经两段连续搅拌均匀后制备成浓度适中、流动性良好的充填料浆,而后进入测量管。测量管上安装电磁流量计和γ射线浓度计,分别用来检测充填料浆的流量和浓度。

图4 试样坍落度测试照片

Fig. 4 Photos of samples at different slumps measurement: (a) 6.8 cm; (b) 16 cm; (c) 20.7 cm; (d) 25.5 cm

表6 起始浓度为40%的料浆的沉降试验结果

Table 6 Results of settlement test of backfilling slurry at initial slurry concentration of 40%

图5 临时充填系统照片

Fig. 5 Photos of temporary filling system: (a) Mixing plant; (b) Filling borehole; (c) Underground elbow

该矿利用临时充填系统对19号矿房采空区进行充填。现场工业试验及监测结果表明,当充填料浆浓度超过60%时,容易发生堵管现象;当料浆流量超过60 m3/h时,弯管拐弯处承受的压力过大,出现了跑浆现象。在对19号矿方采空区进行充填的过程中,始 终控制料浆的浓度为60%、流量为60 m3/h,保证了 良好的输送效果,且形成的充填体脱水也较少。工业试验的结果进一步验证了数值模拟的合理性。

5 结论

1) 在充填料浆流量一定的条件下,管道自流输送的阻力损失随着料浆浓度的增大而增大。当料浆浓度超过一定值时,容易引起充填管道的堵塞。

2) 在充填料浆浓度一定的条件下,管道自流输送的阻力损失和弯管壁面的受力随着料浆流量的增大而增大。当料浆流量过大时,会超过充填管道的输送能力而引起管道堵塞,同时弯管拐弯部分也会有跑浆甚至爆管的可能。

3) 通过数值模拟、室内试验和工业试验,得出了充填料浆管道自流输送的最佳浓度为60%、最佳流量为60 m3/h。因此,使用Fluent软件对充填料浆管道 固-液两相自流输送进行模拟研究是可行的。

4) 充填料浆沉降试验结果表明60%的料浆输送浓度是可行的,并且能满足井下充填体脱水的要求,但充填体的强度有待进一步研究。

REFERENCES

[1] 刘永兵, 陈纪忠, 阳永荣. 管道内液固浆液输送的数值模拟[J]. 浙江大学学报: 工学版, 2006, 40(5): 858-862.

LIU Yong-bing, CHEN Ji-zhong, YANG Yong-rong. Numerical simulation of liquid-solid two-phase flow in slurry pipeline transportation [J]. Journal of Zhejiang University: Engineering Science, 2006, 40(5): 858-862.

[2] 徐自力, 屠 珊, 杜秀杰. 弯曲圆管中矿浆湍流场的三维数值模拟及分析[J]. 西安交通大学学报, 2000, 34(5): 46-48.

XU Zi-li, TU Shan, DU Xiu-jie. Analysis of three-dimensional turbulent flow of mineral slurry in curved pipe [J]. Journal of Xi’an Jiaotong University, 2000, 34(5): 46-48.

[3] DAVID H, SEBASTIAN A, PETER R. Pipe lining abrasion testing for paste backfill operations [J]. International Journal of Multiphase Flow, 2009, 22: 1088-1090.

[4] DAVID A M, ALASTAIR D S. The effects of a highly viscous liquid phase on vertically upward two-phase flow in a pipe [J]. International Journal of Multiphase Flow, 2003, 29: 1523-1538.

[5] 张 政, 谢灼利. 流体-固体两相流的数值模拟[J]. 化工学报, 2001, 52(1): 1-6.

ZHANG Zheng, XIE Zhuo-li. Numerical simulation of fluid-solid two-phase flows [J]. Journal of Chemical Industry and Engineering (China), 2001, 52(1): 1-6.

[6] 王春林, 马庆勇, 李婷婷, 彭 娜. 搅拌浆液池固-液两相流搅拌的数值模拟[J]. 排灌机械, 2007, 25(6): 38-40.

WANG Chun-lin, MA Qing-yong, LI Ting-ting, PENG Na. Numerical simulation of solid-liquid two-phase flow in slurry pond [J]. Drainage and Irrigation Machinery, 2007, 25(6): 38- 40.

[7] 曾 鸣, 徐志强, 皇甫京华, 刘炯天, 张荣曾. 射流浮选柱的两相流数值模拟[J]. 煤炭学报, 2008, 33(7): 795-798.

ZENG Ming, XU Zhi-qiang, HUANGFU Jing-hua, LIU Jiong-tian, ZHANG Rong-zeng. Two-phase flow numerical simulation of jet flotation column [J]. Journal of China Coal Society, 2008, 33(7): 795-798.

[8] 高贵军, 寇子明, 董宪姝. 选煤厂浓缩池沉降规律的多相流仿真[J]. 煤炭学报, 2010, 35(S): 210-212.

GAO Gui-jun, KOU Zi-ming, DONG Xian-shu. Multiphase flow simulation of thickener settlement law in coal preparation plant [J]. Journal of China Coal Society, 2010, 35(S): 210-212.

[9] 李 昳, 何伟强, 朱祖超, 张玉良, 崔宝玲. 脱硫泵固液两相流动的数值模拟与磨损特性[J]. 排灌机械, 2009, 27(2): 125-128.

LI Yi, HE Wei-qiang, ZHU Zu-chao, ZHANG Yu-liang, CUI Bao-ling. Numerical simulation of solid-liquid two-phase flow and abrasion characteristics in desulfurization pump [J]. Drainage and Irrigation Machinery, 2009, 27(2): 125-128.

[10] WANG X M, ZHAO J W, XUE J H, YU G F. Features of pipe transportation of paste-like backfilling in deep mine [J]. Journal of Central South University of Technology, 2011, 18(5): 1413-1417.

[11] 许毓海, 许新启. 高浓度(膏体)充填流变特性及自流输送参数的合理确定[J]. 矿冶, 2004, 13(3): 16-19.

XU Yu-hai, XU Xin-qi. Rheologic behavior of high-density backfilling and reasonable determination of the parameters for its gravity-flow transport [J]. Mining and Metallurgy, 2004, 13(3): 16-19.

[12] 何哲祥, 徐从武. 武山铜矿北矿带充填存在的问题与对策[J]. 铜业工程, 2002, 3: 1-3.

HE Zhe-xiang, XU Cong-wu. Filling problems and relevant solutions for north zone of Wushan Copper Mine [J]. Copper Engineering, 2002, 3: 1-3.

[13] 王晓玲, 曹月波, 张明星, 杨丽丽. 辐流式沉淀池固液两相流三维数值模拟[J]. 工程力学, 2009, 26(6): 243-248.

WANG Xiao-ling, CAO Yue-bo, ZHANG Ming-xing, YANG Li-li. Three-dimensional simulation of solid-liquid two-phase flow in a circular secondary clarifier [J]. Engineering Mechanics, 2009, 26(6): 243-248.

[14] 王新民, 丁德强, 吴亚斌, 张钦礼, 卢央泽. 膏体充填管道输送数值模拟与分析[J]. 中国矿业, 2006, 15(7): 58-59.

WANG Xin-min, DING De-qiang, WU Ya-bin, ZHANG Qin-li, LU Yang-ze. Numerical simulation and analysis of paste backfilling with piping transport [J]. China Mining Magazine, 2006, 15(7): 58-59.

[15] 赵斌娟, 袁寿其, 刘厚林, 黄忠富, 谈明高. 基于Mixture多相流模型计算双流道泵全流道内固液两相湍流[J]. 农业工程学报, 2008, 24(1): 8-10.

ZHAO Bin-juan, YUAN Shou-qi, LIU Hou-lin, HUANG Zhong-fu, TAN Ming-gao. Simulation of solid-liquid two-phase turbulent flow in double-channel pump based on mixture model [J]. Transactions of the CSAE, 2008, 24(1): 8-10.

[16] 刘建瑞, 徐永刚, 王董梅, 苏起钦. 离心泵叶轮固液两相流动及泵外特性数值分析[J]. 农业机械学报, 2010, 41(3): 86-88.

LIU Jian-rui, XU Yong-gang, WANG Dong-mei, SU Qi-qin. Numerical simulation of solid-liquid two-phase turbulent flow in impeller channel and pump characteristics analysis [J]. Transactions of the CSAM, 2010, 41(3): 86-88.

[17] 朱红钧, 林元华, 谢龙汉. FLUENT流体分析及仿真实用教程[M]. 北京: 人民邮电出版社, 2010: 13-35.

ZHU Hong-jun, LIN Yuan-hua, XIE Long-han. FLUENT fluid analysis and simulation practical tutorial [M]. Beijing: People’s Posts and Telecom Press, 2010: 13-35.

[18] 邓代强, 高永涛, 杨耀亮, 吴顺川. 基于流体力学理论的全尾砂浆管道输送流变性能[J]. 北京科技大学学报, 2009, 31(11): 1381-1382.

DENG Dai-qiang, GAO Yong-tao, YANG Yao-liang, WU Shun-chuan. Rheological properties of full tailings slurry in pipeline transportation based on the hydromechanics theory [J]. Journal of University of Science and Technology Beijing, 2009, 31(11): 1381-1382.

[19] 孙恒虎, 黄玉诚, 杨宝贵. 当代胶结充填技术[M]. 北京: 冶金工业出版社, 2002: 113-114.

SUN Heng-hu, HUANG Yu-cheng, YANG Bao-gui. Contemporary cemented backfilling technology [M]. Beijing: Metallurgical Industry Press, 2002: 113-114.

(编辑 陈卫萍)

基金项目:国家“十一五”科技支撑计划资助项目(2007BAK23B05)

收稿日期:2011-06-26;修订日期:2012-01-13

通信作者:蔡嗣经,教授,博士;电话:010-62334370;E-mail: sjcai@ustb.edu.cn