AZ61镁合金激光焊接接头的组织与性能

王红英, 李志军

(深圳职业技术学院 工业中心, 深圳 518055)

摘 要: 采用CO2激光焊接系统对AZ61镁合金材料进行焊接, 研究两种不同焊接工艺条件下激光焊接接头的微观组织和化学成分的情况, 并对焊接接头进行显微硬度测试和接头拉伸实验。 结果表明: AZ61镁合金CO2激光焊接接头成形良好, 焊缝区域晶粒明显细化, 热影响区减小, 焊缝区域主要由细小的α-Mg相及(α+Al12Mg17)等共晶体组成; 焊缝的化学成分中铝含量明显高于母材, 而镁含量则低于母材; 合金成分铝的增加有利于焊缝区域晶粒细化和力学性能的提高。 焊接接头区域的显微硬度和抗拉强度都高于母材, 焊接接头具有良好的力学性能, 说明CO2激光焊接是焊接AZ61镁合金材料的有效方法。

关键词: AZ61镁合金; 激光焊接; 力学性能; 抗拉强度 中图分类号: TG403

文献标识码: A

Microstructure and properties of AZ61 magnesium alloy joints produced by laser welding method

WANG Hong-ying, LI Zhi-jun

(Industry Center, Shenzhen Polytechnic, Shenzhen 518055, China)

Abstract: The laser welding of AZ61 magnesium alloys was carried out using a CO2 laser welding experimental system. The microstructure and chemical composition of joints were investigated under two different process conditions. The microhardness measurement and tensile test were conducted for two typical joints. The results show that the joints with good appearance have been formed. A fine grained weld region is observed and no obvious heat effected zone is found. The weld zone mainly consists of small α-Mg phase, (α+Al12Mg17) and other eutectic phases. In the weld, the composition of aluminum increases while magnesium decreases compared with those of the base metal. The increase of aluminum benefits to refine the grain and improves the mechanical properties. The test results indicate that the microhardness and tensile strength of weld zone are higher than those of the base metal. Therefore, CO2 laser welding can provide an effective method to weld the AZ61 magnesium alloys.

Key words: AZ61 magnesium alloy; laser welding; mechanical properties; tensile strength

镁合金具有比质量轻、 比强度高、 回收性能好、 无污染和资源丰富等一系列优点, 在汽车、 摩托车、 兵器、 航空航天、 计算机电子工业等领域有着广阔的应用前景, 成为了节能、 保护环境的首选材料[1, 2]。 但要真正实现镁合金的在工业结构中的大量应用, 其焊接技术将是十分关键的因素。 因此对镁合金的焊接性能的研究将具有较大的工程意义和实际应用价值。

由于镁合金熔点低、 导热率高、 热膨胀系数大, 与氧、 氮的亲和力强, 使得镁合金的焊接较一般的钢材更加困难, 对焊接工艺的要求也更高。 目前有几种方法可以实现镁合金材料的焊接, 主要包括电弧焊[3-6]、 搅拌摩擦焊[7, 8]、 电子束焊接[9]和激光焊接[10-16]。 电弧焊方法早期主要用于镁合金铸造件的修补上, 但由于弧焊方法有较高的热输入, 使得焊接过程形成的热影响区很宽, 晶粒比较粗大, 形成的焊缝性能较差; 同时也会导致较大的焊接变形和高的残余应力, 还需进行焊后热处理。 真正要求比较高的场合激光焊接和电子束焊接方法都是比较好的选择, 一般来说, 电子束焊接方法被认为是一种焊接厚板材料的优选方法, 因为电子束方法可形成深/宽比很大的焊接接头。 而激光焊接方法焊接镁合金具有焊接速度快、 线能量低、 焊接变形小、 容易实现自动化生产等优点[10-17], 非常适合于镁合金各种结构件的焊接生产, 如汽车车体、 设备机壳等, 成为了焊接镁合金优选方法。

镁-铝-锌合金系列(AZ31, AZ61, AZ63, AZ80, AZ81, AZ91 和AZ92)是常用的镁合金材料, 从焊接性能方面来看, 在镁中加入小于10%的铝可改善镁合金的焊接性, 且细化晶粒。 但加入大于1%的锌则不利于镁合金的焊接, 容易导致热裂纹。 目前对镁合金激光焊接研究较多的是AZ31变形镁合金材料[11-14], 主要原因是AZ31的应用较多。 AZ61作为变形镁合金的一种, 近年来在各种结构件如手提电脑机壳、 自行车等方面应用越来越广泛, 但关于其激光焊接特性方面的研究还未见有报道。 针对AZ61镁合金结构件激光焊接的实际生产应用需要, 本文采用CO2激光焊接工艺实现了AZ61镁合金薄板的焊接, 研究了焊接接头的组织性能和化学成分, 并对焊接接头力学性能进行了深入地分析。

1 实验

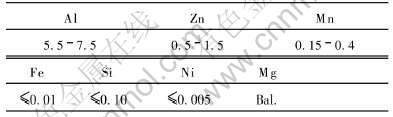

实验材料选择2.6mm 厚的AZ61镁合金板材, 材料的成分如表1所示。 板材首先被切成了80mm×245mm的试件, 焊接前样品用丙酮清洗以去除表面的油脂。 实验是在我们特制的CO2激光焊接实验系统上进行的, 此实验系统包括一个最大输出功率为2.0kW的CO2激光器、 具有特殊保护功能的焊枪、 特制的焊接夹具和机械自动行走机构等。 焊接过程中, 氩气从焊枪和焊接夹具两面同时加入, 用于保护焊接区域正反面的熔池; 焊接实验采用平板对接方式, 焊接过程不填充金属。

表1 AZ61镁合金的化学成分

Table 1 Chemical compositions of AZ61 Mg alloy(mass fraction, %)

实验工艺条件如表2所示, 在固定激光功率和保护气体流量等参数情况下, 研究了两种焊接速度对焊接接头性能的影响。 焊后利用UNIONS DZ3型高放大倍数金相显微镜分析了焊接接头的微观组织, 用X射线衍射仪(XRD)和X射线能谱分析仪(EDX)对焊接接头进行了相分析和化学成分分析。 利用HRS-150洛式硬度计测量了焊接区的显微硬度, 测试负载压力为98N; 在CMT-4304拉伸实验机上对焊接接头进行了拉伸实验。

表2 AZ61镁合金激光焊接实验的工艺参数

Table 2 Parameters of laser welding of AZ61 magnesium alloy

2 结果和讨论

2.1 焊缝形貌

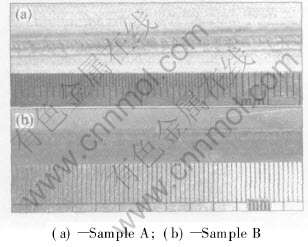

图1所示为实验获得的两个AZ61镁合金焊缝的表面形貌。 从图中可见, 激光焊接的焊缝表观连续均匀、 成形美观, 无气孔、 裂纹、 未熔合等表面缺陷存在。 图2所示为两个焊接接头的横断面形貌。 从中可见, 两条焊缝都完全熔透, 在不填充金属的情况, 焊缝都有一定的下塌量。 对比两个不同工艺条件下获得的焊缝形貌可见, 由于焊缝B采用

图1 AZ61镁合金激光焊接接头的表面形貌

Fig.1 Morphologies of two joints of AZ61 magnesium alloy produced by laser welding

图2 AZ61镁合金激光焊接接头断面形貌

Fig.2 Morphologies of cross section of two joints of AZ61 magnesium alloy

的焊接速度较慢, 单位长度的热输入较大, 使得焊缝B的正面和反面熔宽都较大。 而且相对焊缝A来说, 焊缝B的表面下塌量更大, 这也是因为焊缝B的热输入更大, 熔化的金属量更多的缘故。

2.2 接头的微观组织

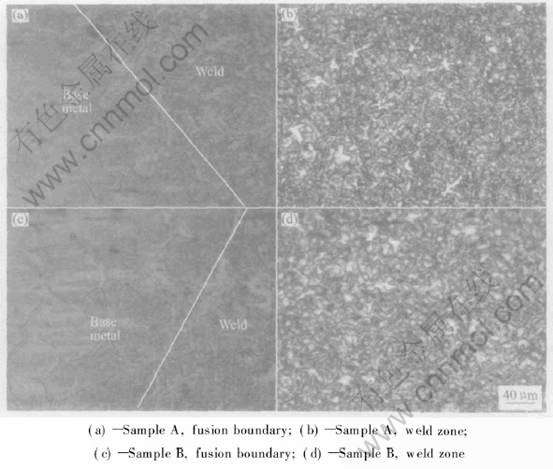

图3所示为试样A和B焊缝区域和熔合线附近区域的微观组织结构。 从图中可见, 母材金属区域为典型的变形镁合金的粗大等轴晶组织, 而焊缝熔合区为细小的柱状晶组织。 从图3(a), (c)可见, 两个接头区域的热影响区都不明显, 在熔合线附近没有发现明显的粗大晶粒组织形成。 当采用激光焊接方法时, 激光束能量非常集中, 焊后冷却速度又很快, 所以形成的热影响区很小; 同时快的冷却速度和结晶速度也是造成熔合区域晶粒细化的主要原因。 另外, 在AZ61镁合金中存在象铝这种细化晶粒的合金元素, 也使得熔合区域的晶粒细化。 对比两种焊接工艺条件所获得的焊缝组织结构可见, 焊缝B的晶粒稍大一些, 其原因可能是焊缝B单位长度的热输入更大, 焊缝熔融的截面积较大, 在焊后冷却时需带走的热量更多, 从而使冷却速度比焊缝A更慢。

2.3 相分析

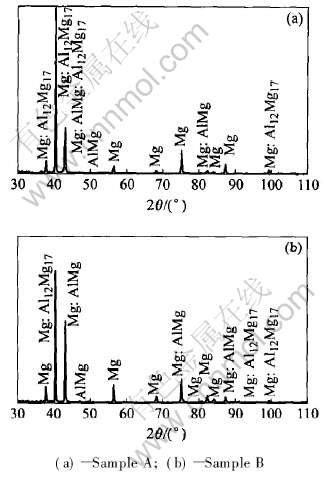

图4所示为两条焊接接头的X射线衍射谱。 从中可见, 两条焊缝中形成的相结构基本相同, 主要包括: α-Mg, (α-Mg+Al12Mg17), (α-Mg+AlMg)和(α-Mg+Al12Mg17+AlMg)等。 这是因为在焊缝冷却过程中, 有Al12Mg17和AlMg中间相析出, 并与α-Mg形成了共晶体。 结合图3可见, 由于激光焊接镁合金能量集中, 冷却速度非常快, 使得初生的α-Mg组织和共晶组织都明显细化, 从而获得了具有细小晶粒的接头组织。

图3 AZ61镁合金焊接接头的微观组织

Fig.3 Microstuctures of welds of AZ61 magnesium alloy

图4 两条焊接接头的X射线衍射谱

Fig.4 XRD patterns of two joints

2.4 化学成分分析

采用X射线能谱分析仪(EDX)对焊接接头进行了化学成分分析, 分析的结果如表3所示。 为了进行对比, 对未焊接的AZ61母材成分也进行了分析, 同时对两条焊缝表面分别在打磨前和打磨后的化学成分进行了分析。 从表中可见, 未经过打磨的焊缝表面氧含量都较高, 达到了10%以上, 说明尽管在焊接过程中一直有氩气保护, 但由于镁与氧的亲合力很强, 焊缝表面仍然有一定的氧化。 另外焊缝表面没有检测到有锌元素存在, 这可能是因为锌的沸点较低(906℃), 在表面的锌蒸发较快, 使得焊缝表面的锌含量很低。 此外未经过打磨的焊缝表面镁的含量比母材明显降低, 这主要是因为镁的沸点(1107℃)明显低于铝(2467℃), 在焊接过程中镁大量蒸发造成的。 而焊缝表面经过打磨掉一薄层后, 化学成分则明显不同。 此时, 氧含量明显减少, 只有2%左右, 而Al的含量增大, 并且已经检测到Zn的存在。 说明下层的焊缝金属氧化已明显减少, 由于Mg的大量蒸发使得Al的相对含量增大。 此外由于镁的含量较大, 蒸发很多, 镁的蒸汽压大,这样也抑制了锌的进一步蒸发, 结果在焊缝的下层锌的含量已变化不大。

表3 AZ61镁合金焊接接头化学成分

Table 3 Chemical compositions of joints of AZ61 magnesium alloys (mass fraction, %)

2.5 显微硬度

图5所示为2个焊缝区域显微硬度沿熔合区、 热影响区和母材的分布情况。 对两个试样来说, 焊缝区域的显微硬度都高于母材金属, 在熔合线附近的硬度还要稍高一些。 这说明焊缝区域的强度要好于母材, 这主要是因为焊缝区域的合金元素含量高于母材, 而且焊缝区域的晶粒明显细化, 从而起到了强化作用。

2.6 拉伸实验结果

焊接接头的抗拉强度采用了拉伸实验来测量。

图5 2个焊接接头的显微硬度测试结果

Fig.5 Microhardness profiles of two joints

结果发现, 试样A是在3.16kN的拉力情况下, 在母材金属区域被拉断的, 计算出的抗拉强度约为265MPa (实际约为AZ61镁合金的母材抗拉强度)。 而试样B在3.18kN的拉力情况下在母材金属区域被拉断, 计算出的抗拉强度也差不多为265MPa。 这表明两个试样都是在母材区域拉断, 焊接接头的抗拉强度都高于母材的抗拉强度。 由此可见, 采用激光焊接方法焊接AZ61镁合金获得的焊接接头具有很好的力学性能。 这也应当归结为焊缝区域的合金成分增加, 同时晶粒明显细化; 而且从相分析结果发现有金属间化合物析出, 从而起到了合金强化、 晶界强化和沉淀强化的作用, 使焊缝区域的强度提高。

3 结论

1) 在两种焊接速度情况下, CO2激光焊接2.6mm厚的AZ61镁合金薄板都获得了较好的接头形貌, 焊缝成形美观、 无表面缺陷存在, 焊缝完全熔透。

2) 焊缝熔合区域为细小的柱状晶组织, 无明显的粗晶结构的热影响区形成。 焊缝由细小的α-Mg相、 (α-Mg+Al12Mg17)和(α-Mg+AlMg)等共晶相组成。

3) 焊缝的表面发生了一定的氧化, 氧的含量较高, 锌和镁的含量明显降低; 而在打磨掉表面薄层后, 氧的含量已很少, 锌的含量维持在母材的水平, 铝的含量明显提高, 镁的含量降低, 说明焊缝中合金元素的相对含量较母材提高。

4) 焊缝区域的显微硬度和抗拉强度都明显高于母材, 说明AZ61镁合金激光焊接接头具有很好的力学性能。

5) 焊缝区域的晶粒细化、 合金元素的含量提高是接头性能提高的主要原因。

REFERENCES

[1]Avedesian M, Baker H. Magnesium and Magnesium Alloys[M]. Materials Park, Ohio: ASM International, 1999.

[2]中国机械工程学会焊接学会. 焊接手册(第二卷)[M]. 北京, 机械工业出版社, 1992.

The Welding Society of Chinese Mechanical Technology Society. Welding Manuals (Volume 2)[M]. Beijing: China Machine Press, 1992.

[3]Zhang Y M, Zhang S B. Welding aluminum alloy 6061 with opposing dual-torch GTAW process[J]. Welding Research Supplement, 1999, 6: 202-206.

[4]Marya M, Edwards G R, Liu S. An investigation on the effects of gases in GTA welding of a wrought AZ80 magnesium alloy[J]. Welding Journal, 2004, 83(7): 203-212.

[5]徐锦锋, 翟秋亚. AZ91B镁合金TIG焊接头组织与性能[J]. 特种铸造及有色合金, 2004, 4: 23-25.

XU Jing-feng, ZHAI Qiu-ya. Microstructure and properties of TIG welding joint for AZ91B Mg alloy[J]. Special Casting and Nonferrous alloy, 2004, 4: 23-25.

[6]郑荣, 林然. AZ31B镁合金薄板TIG焊接[J]. 焊接, 2003, 4: 43-44.

ZHENG Rong, LIN Ran. TIG welding of AZ31B Mg alloy sheets[J]. Welding, 2003, 4: 43-44.

[7]Lee W B, Yeon Y M, Jung S B. Joint properties of friction stir welded AZ31B-H24 magnesium alloy[J]. Materials Science and Technology, 2003, 19(6): 785-790.

[8]张华, 林三宝, 吴林, 等. 镁合金AZ31搅拌摩擦焊接头的微观组织[J]. 中国有色金属学报, 2003, 13(6): 1510-1513.

ZHANG Hua, LIN San-bao, WU Lin, et al. Microstructure of friction stir welds in AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Meatls, 2003, 13(6): 1510-1513.

[9]Wu S H, Huang J C, Wang Y N. Evolution of Microstructure and texture in Mg-Al-Zn alloys during electron-beam and gas tungsten arc welding[J]. Metall Mater Trans, 2004, 35(8): 2455-2459.

[10]Weisheit A, Galum R, Mobdike B L. CO2 laser beam welding of magnesium-based alloys[J]. Welding Journal, 1998, 77(4): 149-154.

[11]ZHU Jin-hong, LI Lin, LIU Zhu. CO2 and diode laser welding of AZ31 magnesium alloy[J]. Applied Surface Science, 2005, 247: 300-306.

[12]LIU Li-ming, WANG Ji-feng, SONG Gang. Hybrid laser-TIG welding, laser beam welding and gas tungsten arc welding of AZ31B magnesium alloy[J]. Mater Sci Eng A, 2004, A381: 129-133.

[13]LIU Li-ming, SONG Gang, WANG Ji-feng, et al. Microstructure and mechanical properties of wrought magnesium alloy AZ31B welded by laser-TIG hybrid[J]. Trans Nonferrous Met Soc China, 2004, 14 (3): 550-555.

[14]LIU Li-ming, MIAO Yu-gang, SONG Gang, et al. Effect of heat input on microstructure and properties of welded joint in magnesium alloy AZ31B[J]. Trans Nonferrous Met Soc China, 2004, 14(1): 88-92.

[15]宋刚, 刘黎明, 王继峰, 等. 变形镁合金AZ31B 的激光焊接工艺研究[J]. 应用激光, 2003, 23(6): 327-329.

SONG Gang, LIU Li-ming, WANG Ji-feng, et al. Study of YAG laser welding process on wrought magnesium[J]. 2003, 23(6): 327-329.

[16]Zhao H, Debroy T. Pore formation during laser beam welding of die-cast magnesium alloy AM60B—mechanism and remedy[J]. Welding Research Supplement, 2001, 8: 204-210.

[17]Dhahri M, Masse J E, Mathieu J F, et al. Laser welding of AZ91 and WE43 magnesium alloys for automotive and aerospace industries[J]. Advanced Engineering Materials, 2001, 3(7): 504-507.

(编辑何学锋)

收稿日期: 2005-11-09; 修订日期: 2006-02-24

通讯作者: 王红英, 电话: 0755-26731625; E-mail: wanghy@oa.szpt.net